Avid Technology CNC Rotary Axis Use and care manual

Avid CNC Rotary Axis

Table Top Installation & Calibration Instructions

Version 2019Q4.2

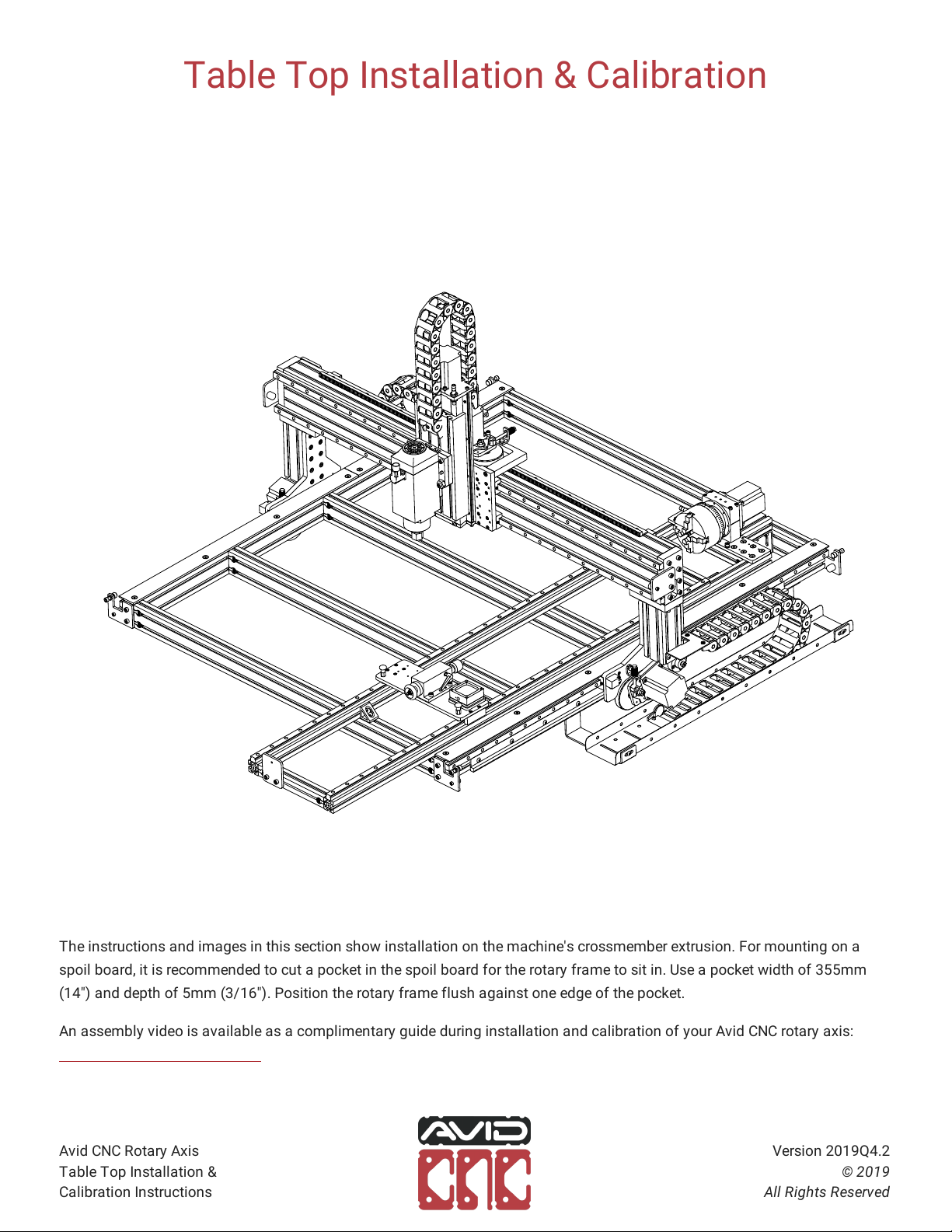

Table Top Installation & Calibration

The instructions and images in this section show installation on the machine's crossmember extrusion. For mounting on a

spoil board, it is recommended to cut a pocket in the spoil board for the rotary frame to sit in. Use a pocket width of 355mm

(14") and depth of 5mm (3/16"). Position the rotary frame flush against one edge of the pocket.

An assembly video is available as a complimentary guide during installation and calibration of your Avid CNC rotary axis:

https://youtu.be/dJZ4IF69yu0

Avid CNC Rotary Axis

Table Top Installation &

Calibration Instructions

Version 2019Q4.2

© 2019

All Rights Reserved

Parts and Tools Required

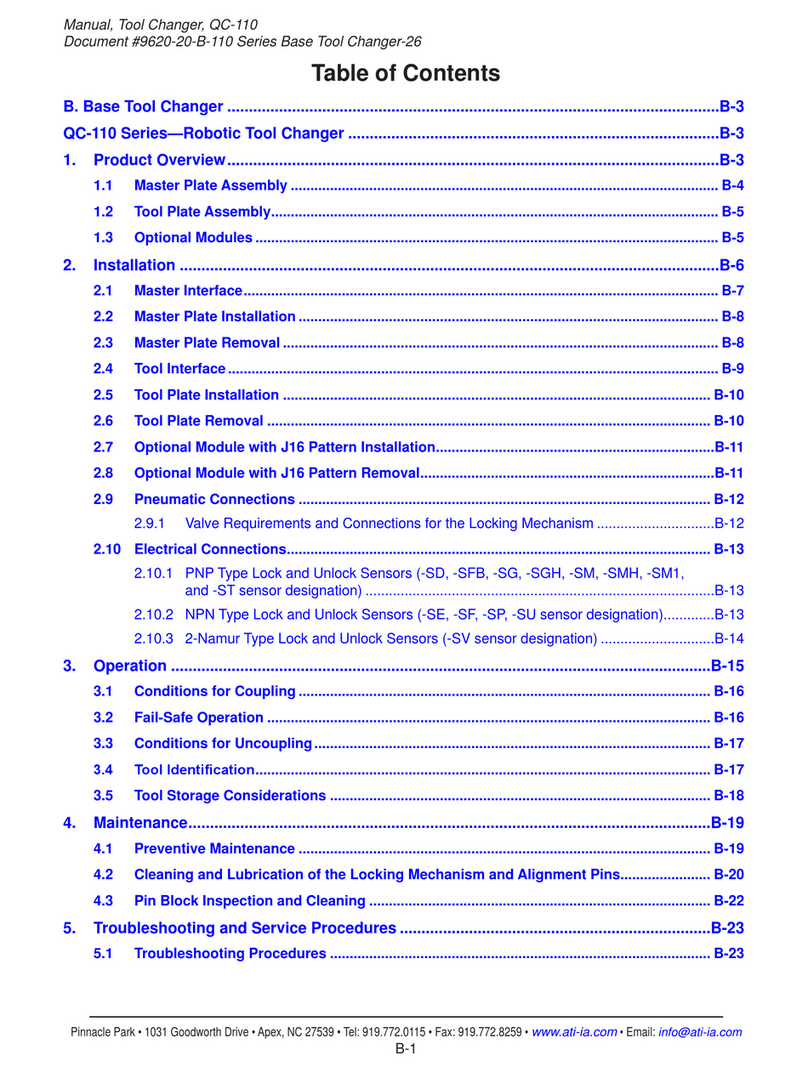

The following parts and tools will be used in Section 1.1 for installation on PRO CNC machines

QTY Part/Description Packaged In

1 CRP831-01, Bumper Plate CRP195-00-PRO-SHORT

4 40-4332 Mounting Bracket CRP195-00-PRO-SHORT

10 M8 Roll-in T-Nut CRP195-00-PRO-SHORT

2 M8 x 30mm Socket Head Cap Screw CRP195-00-PRO-SHORT

8 M8 x 16mm Button Head Cap Screw CRP195-00-PRO-SHORT

1 4080 Extrusion, 140mm (5-1/2") CRP195-00-PRO-SHORT

1 CRP190-19, Headstock Mounting Bracket CRP195-00-PRO-SHORT

2 M8 x 16mm Socket Head Cap Screw CRP195-00-PRO-SHORT

1 M12 Proximity Sensor Cable, 20' CRP190-00-BASE

1 NEMA 34 Motor Cable, 20' Rotary Electronics

1 CRP195-00-FAST: CRP195-00-PRO-SHORT

- (2) 40 Series Anchor Fastener

- (8) M8 Roll-in T-Nut

- (6) M8 x 16mm Socket Head Cap Screw

Remaining parts from this kit used in Section 1.3

Note: Rotary frames 1850mm (72") and longer will use parts packaged in CRP195-00-PRO-LONG. This kit includes an additional (4) 40-4332

mounting brackets with fasteners.

Required Tools:

- 6mm Ball-End Allen Wrench

- 5mm Allen Wrench

- Tape Measure

Avid CNC Rotary Axis

Table Top Installation &

Calibration Instructions

Version 2019Q4.2

© 2019

All Rights Reserved

1.1.1 Installation Steps

1.1.1.1

Attach a bumper plate to the tailstock end of the rotary frame as indicated.

M8 Roll-in T-Nut

CRP831-01, Bumper Plate

M8 x 16mm Socket Head Cap Screw

65mm (2-1/2")

Avid CNC Rotary Axis

Table Top Installation &

Calibration Instructions

Version 2019Q4.2

© 2019

All Rights Reserved

1.1.1.4

Attach the headstock mounting bracket to the extrusion as indicated.

M8 Roll-in T-Nut

M8 x 16mm Socket Head Cap Screw

CRP190-19, Mounting Bracket

Assembly Note

Position the bracket flush with the end of the 4080 extrusion.

Avid CNC Rotary Axis

Table Top Installation &

Calibration Instructions

Version 2019Q4.2

© 2019

All Rights Reserved

1.1.1.10

Install an additional four brackets along the middle of the rotary frame, leaving the fasteners loose.

Rotary Length Option

This step is only applicable for rotary frame lengths 1850mm (72") and longer.

78

6

5

Assembly Note

These mid-support brackets will not be tightened until the Mid-Support Calibration section.

Avid CNC Rotary Axis

Table Top Installation &

Calibration Instructions

Version 2019Q4.2

© 2019

All Rights Reserved

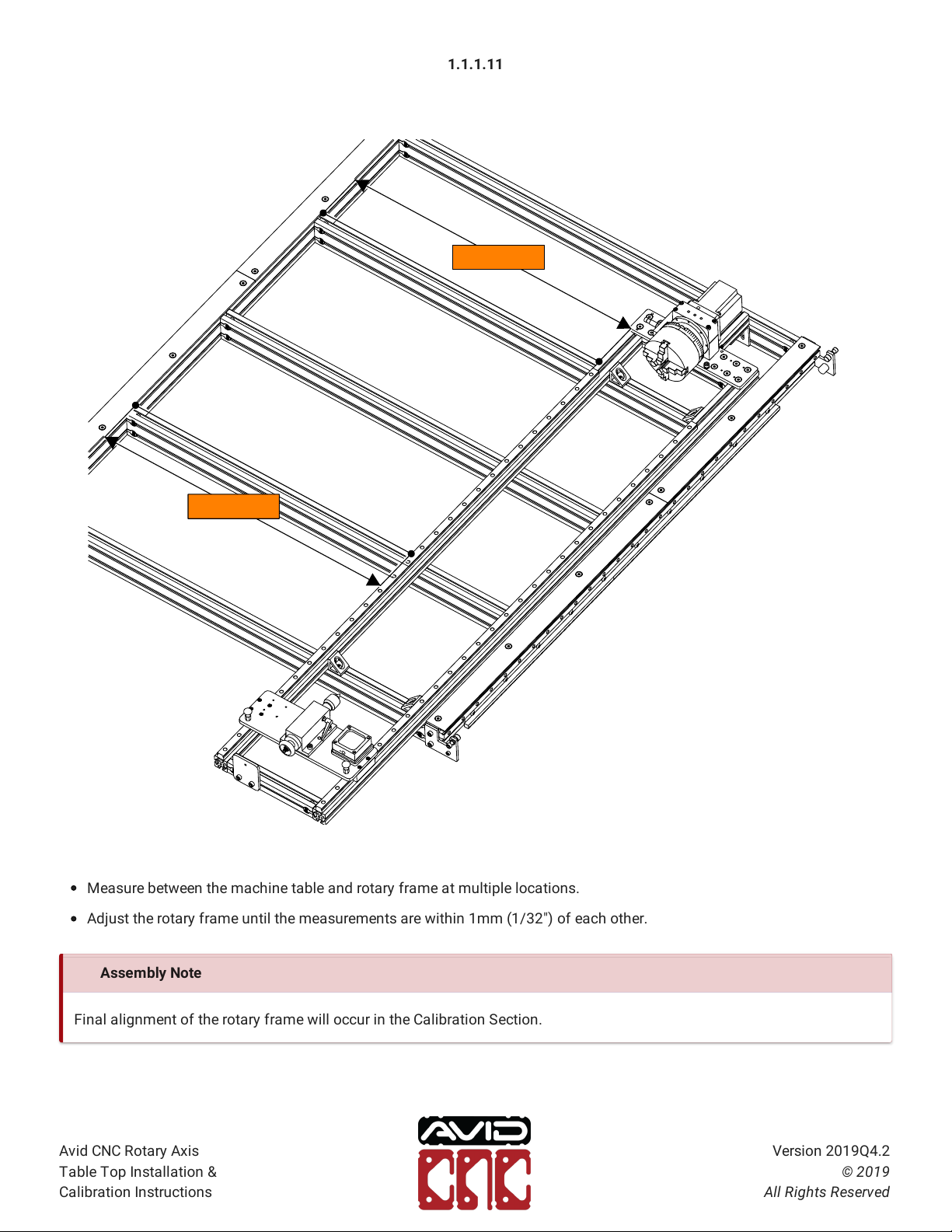

1.1.1.11

Measure between the machine table and rotary frame at multiple locations.

Adjust the rotary frame until the measurements are within 1mm (1/32") of each other.

MEASURE

MEASURE

Assembly Note

Final alignment of the rotary frame will occur in the Calibration Section.

Avid CNC Rotary Axis

Table Top Installation &

Calibration Instructions

Version 2019Q4.2

© 2019

All Rights Reserved

1.1.2 Motor & Sensor Connections

1.1.2.1

Attach the sensor and motor cable to the control box as indicated (Plug and Play Control Systems purchased prior to

October 2019 will use the "X+" sensor port).

Motor Cable

M12 Proximity Sensor Cable

"A" Sensor Port

"A" Motor Port

Assembly Note

For PRO machines purchased prior to 2019, an M12 splitter is required to connect the X+ and X- limit switches to the X- port

on the control box.

Avid CNC Rotary Axis

Table Top Installation &

Calibration Instructions

Version 2019Q4.2

© 2019

All Rights Reserved

Parts and Tools Required

The following parts and tools will be used in Section 1.2 for installation on Benchtop machines

QTY Part/Description Packaged In

1 CRP831-01, Bumper Plate CRP195-00-BTP

4 40-4332 Mounting Bracket CRP195-00-BTP

10 M8 Roll-in T-Nut CRP195-00-BTP

2 M8 x 30mm Socket Head Cap Screw CRP195-00-BTP

8 M8 x 16mm Button Head Cap Screw CRP195-00-BTP

1 4080 Extrusion, 122mm (4-3/4") CRP195-00-BTP

1 CRP190-19, Headstock Mounting Bracket CRP195-00-BTP

2 M8 x 16mm Socket Head Cap Screw CRP195-00-BTP

1 M12 Proximity Sensor Cable, 20' CRP190-00-BASE

1 NEMA 34 Motor Cable, 20' Rotary Electronics

1 CRP195-00-FAST: CRP195-00-BTP

- (2) 40 Series Anchor Fastener

- (8) M8 Roll-in T-Nut

- (6) M8 x 16mm Socket Head Cap Screw

Remaining parts from this kit used in Section 1.3

Note: Benchtop Standard installation parts will be packaged in CRP195-00-SHORT and does not include the 4080 extrusion, CRP190-19, or

CRP195-00-FAST.

Required Tools:

- 6mm Ball-End Allen Wrench

- 5mm Allen Wrench

- Tape Measure

Avid CNC Rotary Axis

Table Top Installation &

Calibration Instructions

Version 2019Q4.2

© 2019

All Rights Reserved

1.2.1 Installation Steps

1.2.1.1

Attach a bumper plate to the tailstock end of the rotary frame as indicated.

M8 Roll-in T-Nut

CRP831-01, Bumper Plate

M8 x 16mm Socket Head Cap Screw

65mm (2-1/2")

Avid CNC Rotary Axis

Table Top Installation &

Calibration Instructions

Version 2019Q4.2

© 2019

All Rights Reserved

Other manuals for CNC Rotary Axis

2

Table of contents

Other Avid Technology Industrial Equipment manuals