12/22

2

TITAN MODELS 124 & 305 MANUAL

Wire Mesh Conveyors

Table of Contents

Page 2 ......................................................................................... Table of Contents

Warranty

Page 3 ....................................................................................Safety/Safety Decals

Page 4 .................................................................................................. Introduction

I. Receiving

II. Installation

Support Assembly

Page 5 .......................................................................................... Frame Assembly

Page 6 ...................................................................................Component Checklist

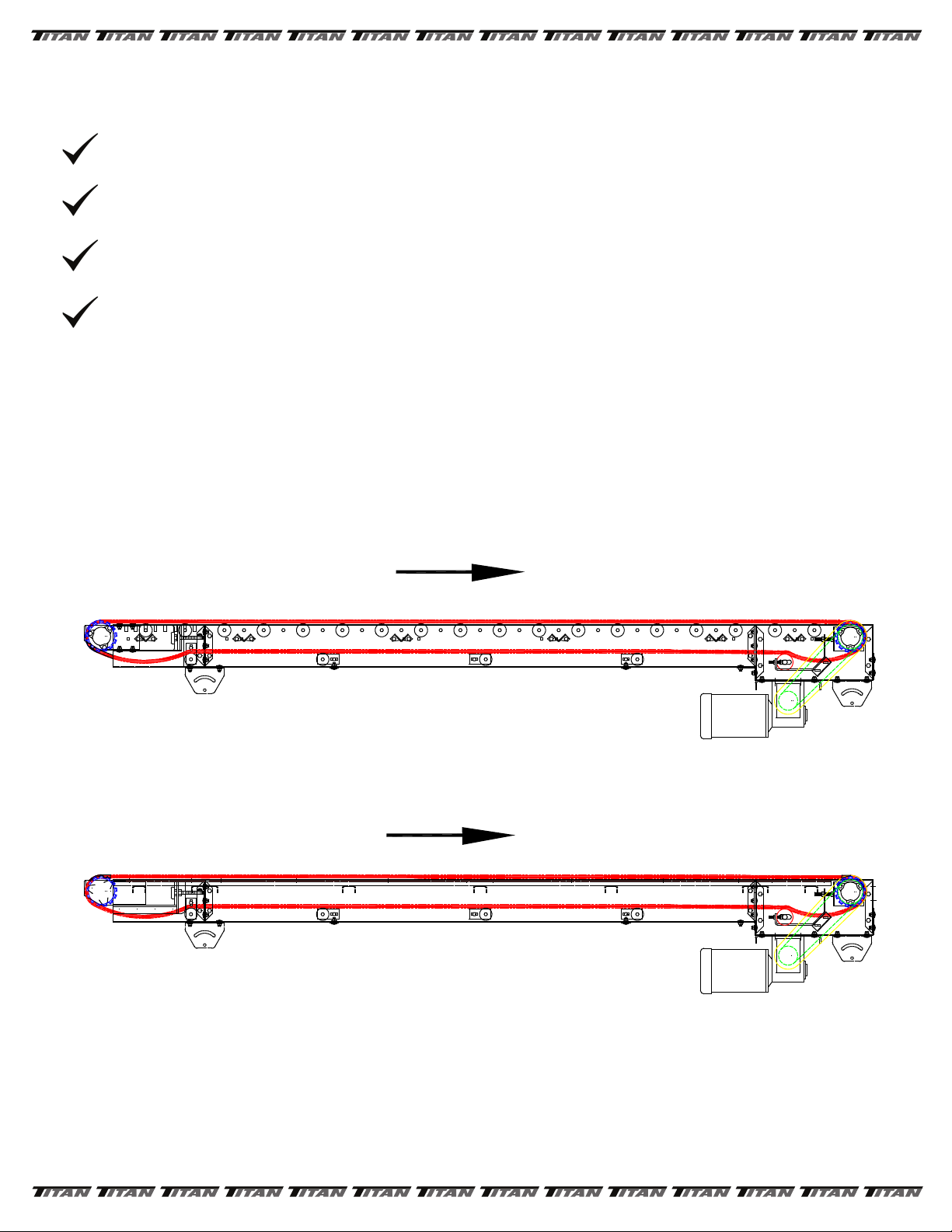

Belt Installation

Belt Threading Chart

Page 7 ........................................................................................ Sprocket Location

Flat Wire Belt Assembly

Page 8 ........................................................................................... III. Maintenance

Belt

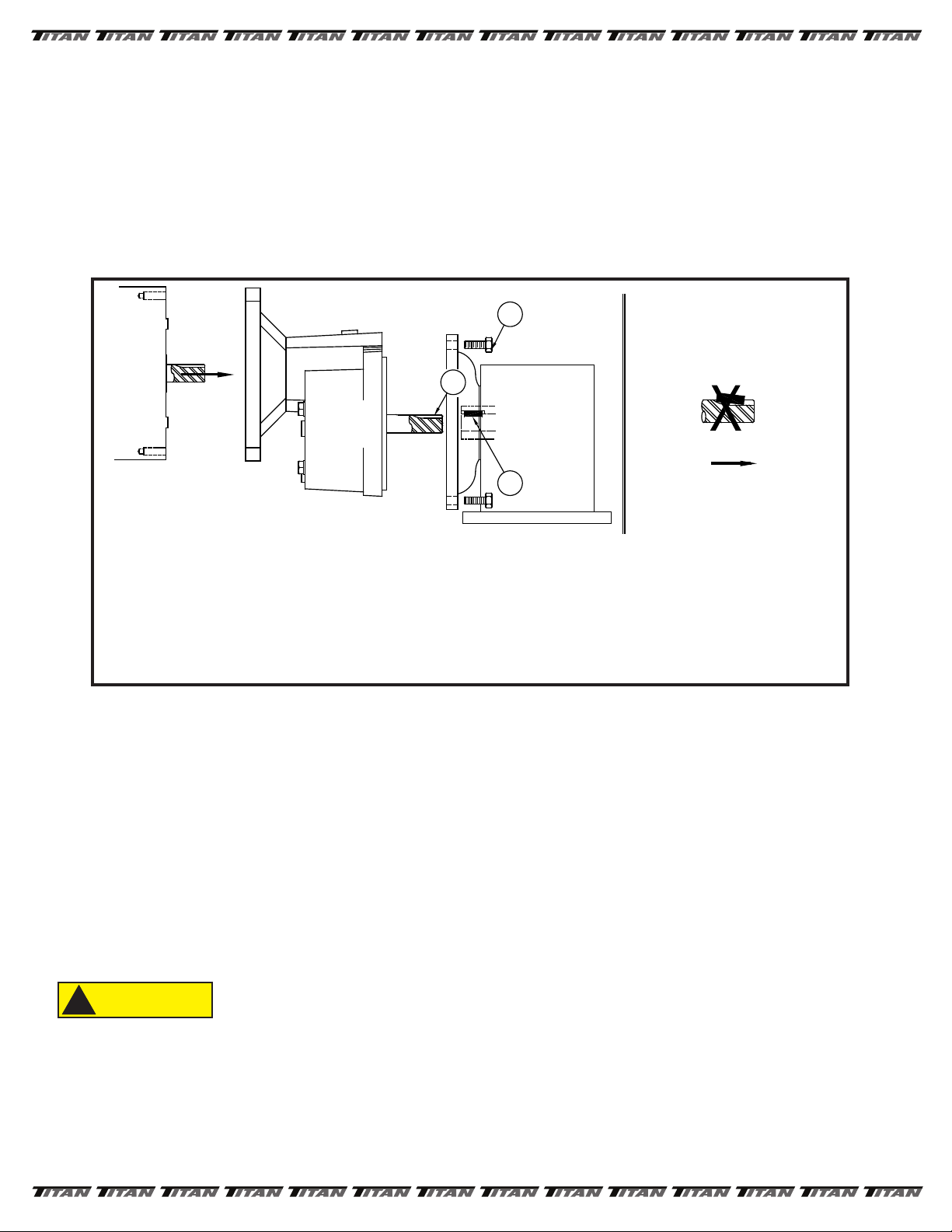

Motors

Page 9 ......................................................................................................Reducers

Page 11.....................................................................................................Bearings

V-Belt & Sheaves

Page 12 ..................................................................................... Chain & Sprockets

Page 13 .......................................Model 124 Roller Bed Deck Blow Apart Drawing

Page 14 .......................................Model 124 Wear Strip Deck Blow Apart Drawing

Page 15 ................................................................Model 305 Wire Mesh Conveyor

(A) Seller warrants that the material in and the workmanship on the equipment manufactured by TITAN will be free from defects at time of shipment. If

during the rst year from the date of shipment, the Buyer establishes to the seller’s satisfaction that any part or parts manufactured by TITAN were defec-

tive at the time of shipment, TITAN will, at its own expense, repair or replace (but not install) replacement parts. For a time purpose of this warranty, one

year will constitute 2080 hours of operation based on an 8 hour day. Sellers liability under this warranty is limited to replacement parts only and the seller

will make no allowance for corrective work done unless agreed to by the seller in writing. Charges for correction of defects by others will not be accept-

able, unless so authorized in writing, prior to the work being performed, by an ocer of the company. Damage caused by deterioration due to extraor-

dinary wear and tear (including, but not in limitation, use said equipment to handle products of a size, weight and shape or at speeds or methods which

dier from information originally provided), chemical action, wear caused by the presence of abrasive materials or by improper maintenance or lubrication

or improper storage prior to installation, shall not constitute defects. Failure to install equipment properly shall not constitute defects. Warranty does not

cover consumable items. Warranty does not cover belt tracking or adjustment at installation or periodic adjustment that may be required during normal

operation. Refer to the maintenance manual for belt tracking instructions.

(B) Seller has made no representation, warranties, or guarantees, expressed or implied, not expressly set forth on above paragraph. Seller shall not be

liable hereunder for any consequential damages included but not in limitation, damages which may arise from loss of anticipated prots or production or

from increased cost of operation or spoilage of material.

(C) The components used in manufacture of said equipment which were manufactured by others will carry such manufacturers’ customary warranty, which

seller will obtain for buyer upon request.

(D) No representative of TITAN has been conferred with any authority to waive, alter, vary or add to the terms of warranty state herein, without prior autho-

rization in writing executed by an ocer of the company.

(E) The foregoing is in lieu of any and all other warranties, expressed or implied, or those extending beyond the description of

the product.