6

The main vibration frequencies produced by the generator

are as follows:-

4 pole 1500 rpm 25 Hz

4 pole 1800 rpm 30 Hz

However, vibrations induced by the engine are complex and

contain frequencies of 1.5, 3, 5 or more times the

fundamental frequency of vibration. These induced vibrations

can result in generator vibration levels higher than those

derived from the generator itself. It is the responsibility of the

generating set designer to ensure that the alignment and

stiffness of the bedplate and mountings are such that the

vibration limits of B.S. 5000 Part 3 are not exceeded.

In standby applications where the running time is limited and

reduced life expectancy is accepted, higher levels than

specified in BS5000 can be tolerated, up to a maximum of

18mm/sec.

Two bearing generators require a substantial bedplate with

engine/generator mounting pads to ensure a good base for

accurate alignment. Close coupling of engine to generator

can increase the overall rigidity of the set. For the purposes

of establishing set design the bending moment at the engine

flywheel housing to generator adaptor interface should not

exceed 275 kgm (2000 ft lbs) . A flexible coupling, designed

to suit the specific engine/generator combination, is

recommended to minimise torsional effects.

Alignment of single bearing generators is critical and

vibration can occur due to the flexing of the flanges between

the engine and generator. As far as the generator is

concerned the maximum bending moment at this

point must not exceed 275 kgm

(2000 ft lbs).

Single bearing generators require a substantial bedplate with

engine/generator mounting pads to ensure a good base for

accurate alignment.

The maximum bending moment of the engine flange must be

checked with the engine manufacturer.

Torsional vibrations occur in all engine-driven shaft systems

and may be of a magnitude to cause damage at certain

critical speeds. It is therefore necessary to consider the

torsional vibration effect on the generator shaft and

couplings.

It is the responsibility of the generator set manufacturer to

ensure compatibility, and for this purpose drawings showing

the shaft dimensions and rotor inertias are available for

customers to forward to the engine supplier. In the case of

single bearing generators coupling details are included.

Important ! Torsional incompatibility and/or

excessive vibration levels can cause

damage or failure of generator and/or

engine components.

The standard build terminal box arrangement is for cable

entry into the right hand side of the terminal box when

viewed from generator N. D. E.

Cable entry from the left hand side is possible if specified at

time of order.

The terminal box is constructed with a removable panel for

easy adaptation to suit specific glanding requirements.

Within the terminal box there are insulated terminals for line

and neutral connections and provision for earthing.

The neutral is NOT connected to the frame.

Caution! No earth connections are made on

the generator and reference to site

regulations for earthing must be

made. Incorrect earthing or

protection arrangements can result

in personal injury or death.

The main stator winding has six leads brought out to

terminals in the terminal box. The three leads brought to the

neutral terminal have been arranged to allow for the

provision of differential protection with the option of clamps

and mounting plates for specific current transformers

supplied by Newage International.

If it becomes necessary for customers to use current

transformers not of Newage supply, these should be fitted

by competent technicians with particular care being taken to

ensure the cables are positioned centrally within the current

transformer opening.

The generator AVR incorporates protection circuits which

operate on overload or fault conditions.

If a detected abnormal condition still exists after 8 seconds

the AVR de-excites the generator causing a collapse in

output voltage. This de-excitation may be as a result of an

electronic solid state protection circuit, or the AVR tripping

the excitation circuit breaker, if fitted, which would be

located adjacent to the AVR.

To reset the AVR trip circuits it is necessary to stop the

engine - generator. The AVR solid state trip circuits will

automatically reset after the generator has been stationary

for 3 seconds. The excitation trip circuit breaker needs to be

manually reset if fitted.

The system designer should ensure that these AVR

functions are compatible with the overall system protection.

Fault current curves (decrement curves), together with

generator reactance data, are available on request to assist

the system designer to select circuit breakers, calculate fault

currents and ensure discrimination within the load network.

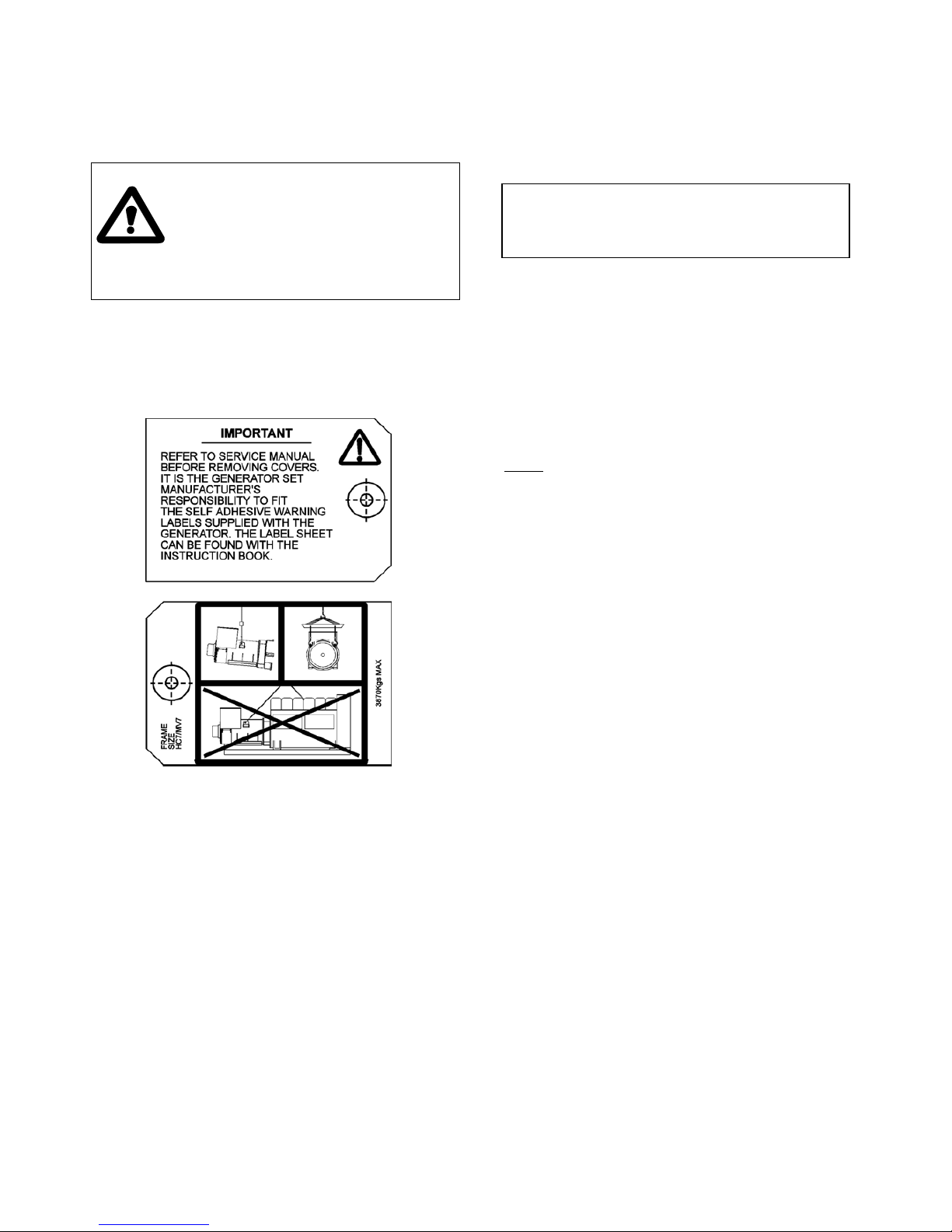

This instruction book must be read before incorporation of

the generator into a generating set. Maintenance must be

carried out with the generating set out of service and

precautions taken to avoid accidental starting of the

generator set.

Warning !

Incorrect installation, service or

replacement of parts can result in

severe personal injury or death,

and/orequipment damage. Service

personnel must be qualified to

perform electrical and mechanical

service.