5

desktops, laptops, tablets and even phones with sufficiently large screens. Since AVLDrive is already

installed on the Little Weaver, installation is not needed.

If using the USB connection point between your loom and device, a USB driver may need to be

downloaded and installed from the AVL website: https://avllooms.com/apps/help-center under MANUALS

& DOWNLOADS > Downloads.

AVLDrive allows only WIF format weaving design files. WIF is the universal “weaving interface file” format

that was developed in the 1990s and is supported by nearly all weaving design software. For a small

membership fee, a large WIF library can be accessed at handweaving.net.

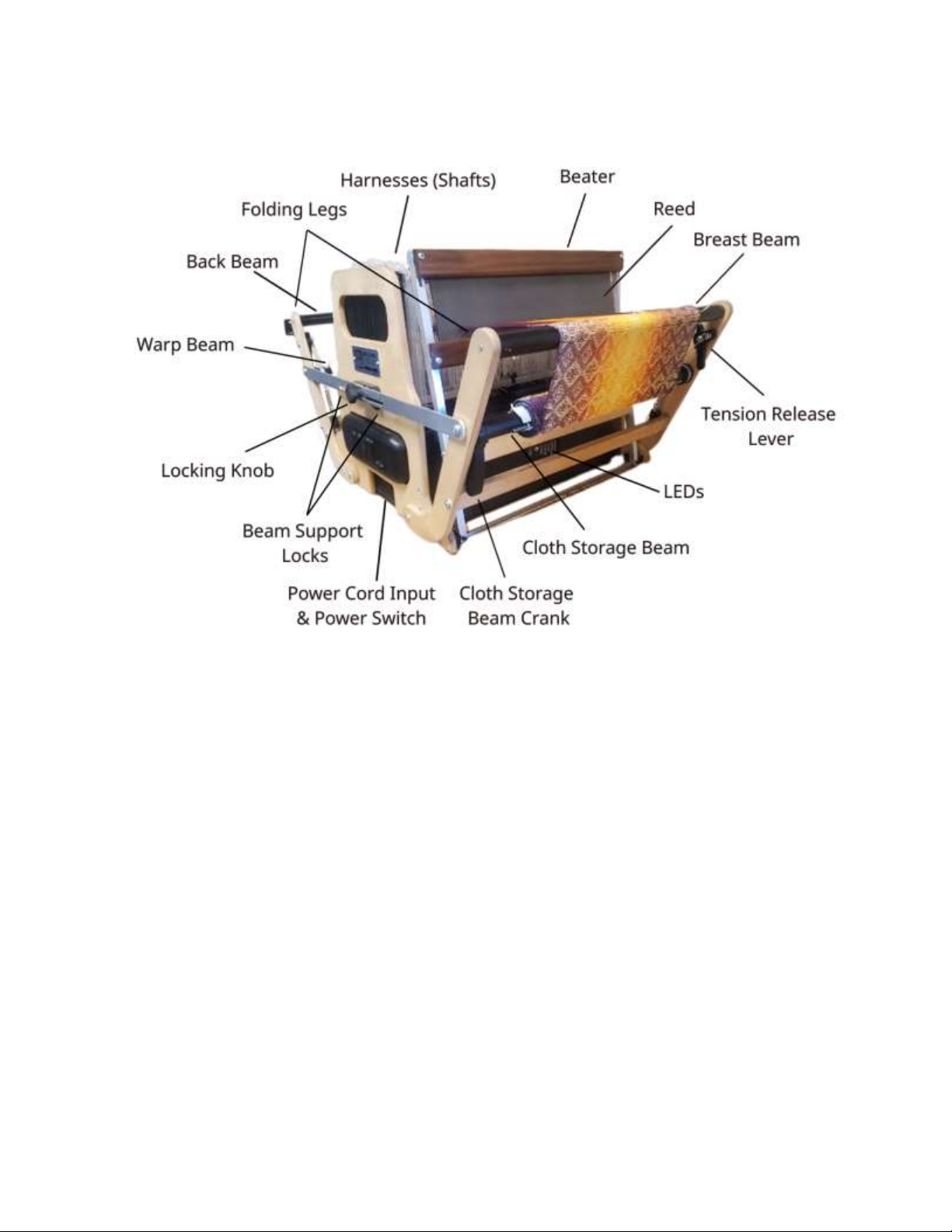

First Time Starting Up Your Loom

To run your loom, plug in the power cord and select the ‘On’position for the power switch. Little Weaver

requires approximately two minutes to boot up. Watch the Light Emitting Diodes (LEDs) on the front panel

under the beater. During the boot up sequence, all the LEDs will come on (except for the Error LED) for

approximately 45 seconds, turn off, and then Power & Network LEDs will power back on. Now, your Little

Weaver is ready.

There are two options for connecting to your Little Weaver for the first time: USB or wirelessly using Wi-Fi

direct or LAN.

USB

Connect the supplied USB cable between your Little Weaver and computing device, open a browser and

type 192.168.6.2 into the URL line for a device running the Mac OS, or 192.168.7.2 for every other device

(including Windows), and then hit enter. If a connection is made, the green COM LED will light and

AVLDrive will pop up on your screen. If an error message appears noting no connection made, install the

USB driver from the AVL webpage noted above in the Software section.

WiFi Direct and LAN

The Network LED color indicates to which WiFi type your Little Weaver is configured in AVLDrive. Green

indicates WiFi-direct is active and your Little Weaver is broadcasting its own WiFi SSID signal. Red indicates

that the WiFi-LAN is active and your Little Weaver is connected to your local WiFi router. When the

Network LED is flashing red, Little Weaver is attempting to connect to a router. If it fails to connect, Little

Weaver will automatically switch to WiFi-direct mode.

To connect via WiFi-direct, find Little Weaver’s WiFi signal on your computing device’s WiFi connection

menu. The id will typically be AVL_XXXXX where XXXXX is your Little Weaver’s serial number. Your Little

Weaver’s serial number can be found on the AVL plate on the side of the loom. Select it and type in the

passphrase CompuDobby5. Next, open your browser and enter the 192.168.16.2 in the URL line to open

AVLDrive. If a connection is made, the green COM LED will light and AVLDrive will pop up on your screen.

Using WiFi-LAN requires that Little Weaver be configured to connect to your local WiFi router. This

requires opening AVLDrive via USB or WiFi-direct, accessing the Network tab, enabling local router

connection, typing in your local WiFi router’s passphrase, and then selecting Restart network. If Little

Weaver logs onto your local WiFi router, the Network LED will light up red. Once Little Weaver is

connected, AVLDrive will provide instructions for restarting itself. And again, if a connection is made, the

green COM LED will light and AVLDrive will pop up on your screen.

Opening a Weaving File

In AVLDrive select the File tab. Your loom will come with a test file, which can be used to test the loom. Or,

use the File menu to access and download WIF files to the loom.