Charger 6 / Charger 12 rel. 1.3c -E- english, page 3 of 22

table of contents

0. table of contents..............................................................................................................................3

1. Technical Description ....................................................................................................................4

1.1 Intended use....................................................................................................................................4

1.2 construction ....................................................................................................................................4

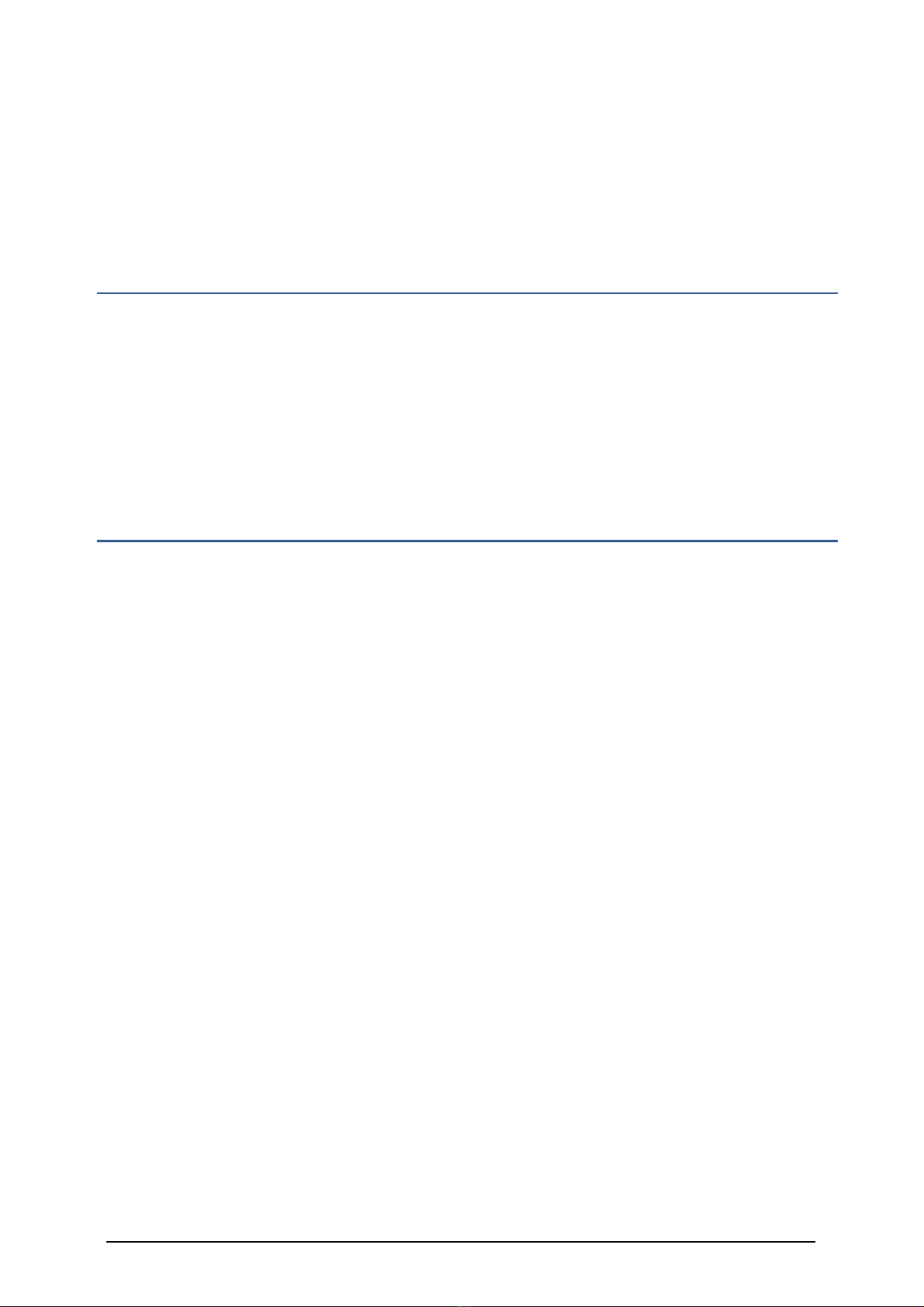

1.2.1 Battery charger CHARGER 6 ...................................................................................................6

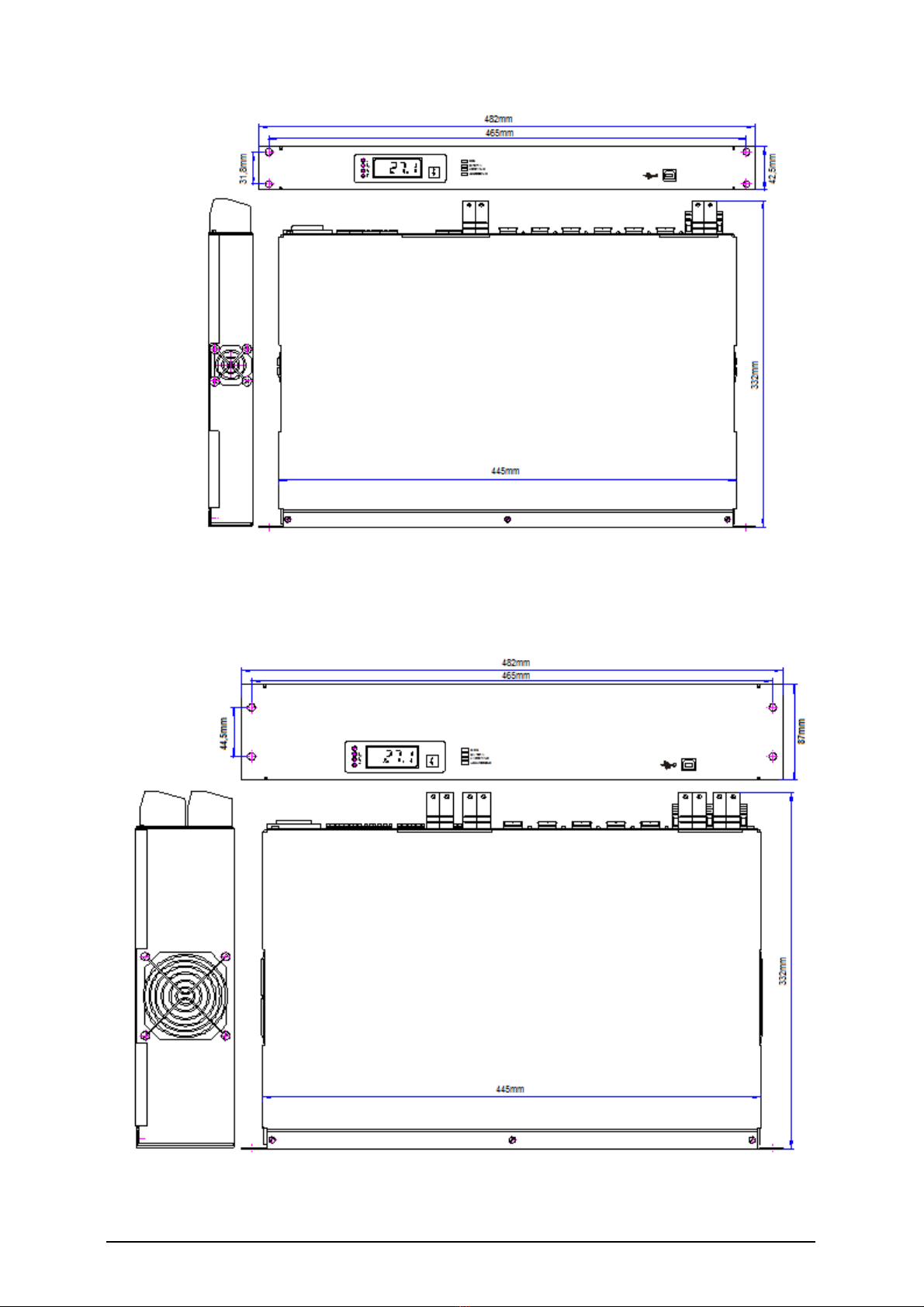

1.2.2 Battery charger CHARGER 12 ...................................................................................................7

1.3 Basic electrical parameters............................................................................................................9

1.4 Recommended working conditions...............................................................................................9

2 Operation principle...................................................................................................................... 10

3. Installation and connection .........................................................................................................13

3.1 Installation ....................................................................................................................................13

3.2 Connection ....................................................................................................................................13

4. Operation ......................................................................................................................................15

4.1 General information ....................................................................................................................15

4.2 Operation safety ...........................................................................................................................15

4.3 Digitale display ............................................................................................................................. 15

4.4 Digitale communication...............................................................................................................15

4.5 Operation state signaling.............................................................................................................16

4.6 Maintenance .................................................................................................................................17

5 Servicing........................................................................................................................................18

5.1 Circuit breakers ...........................................................................................................................18

5.2 Detecting faults and troubleshooting.......................................................................................... 19

6 Additional information ................................................................................................................ 19

6.1 Remarks of the manufacturer..................................................................................................... 19

6.2 List of indicated error codes........................................................................................................19

6.3 Handling packagings and used products ...................................................................................21