Axess Sepro User Manual

V2.0 |->

DD0000116802

i

13.2.06

CONTENTS

I - SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

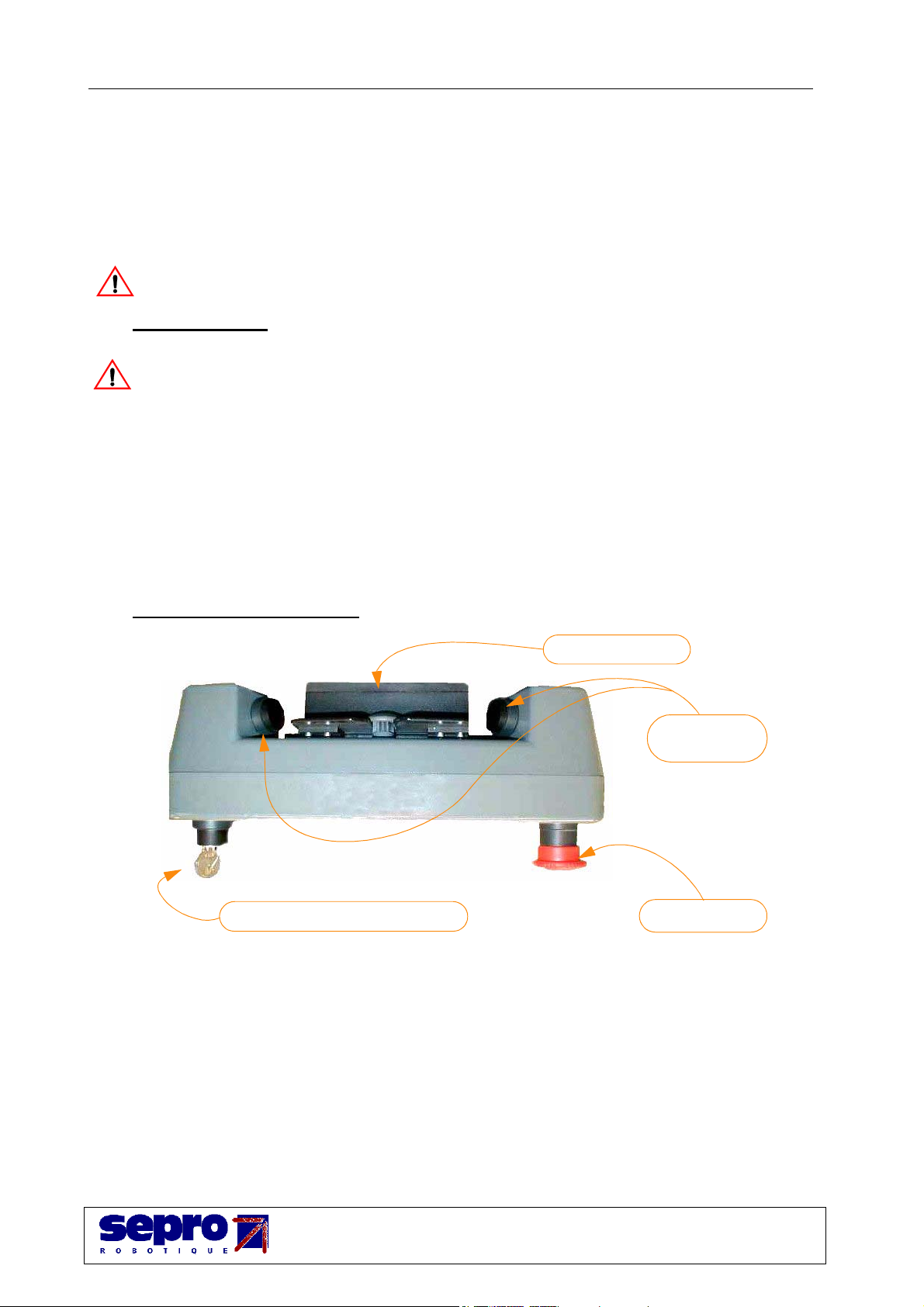

I - 1. Emergency stops . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

I - 2. The pendant’s safety devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

I - 2. 1. The safeguard override key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

I - 2. 2. Working with the pendant out of its holder . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

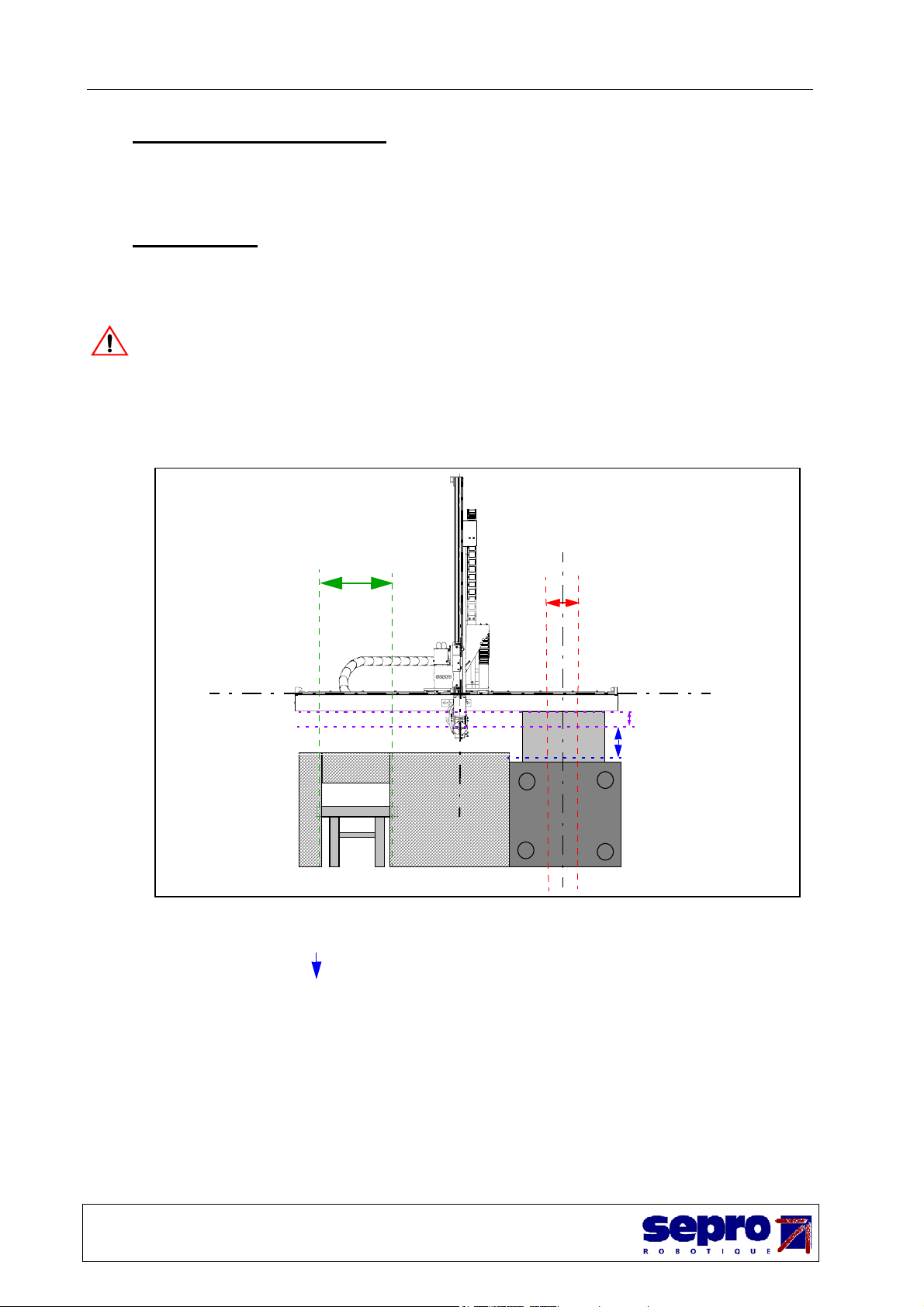

I - 3. Peripheral units and safeguards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

I - 4. The work zones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

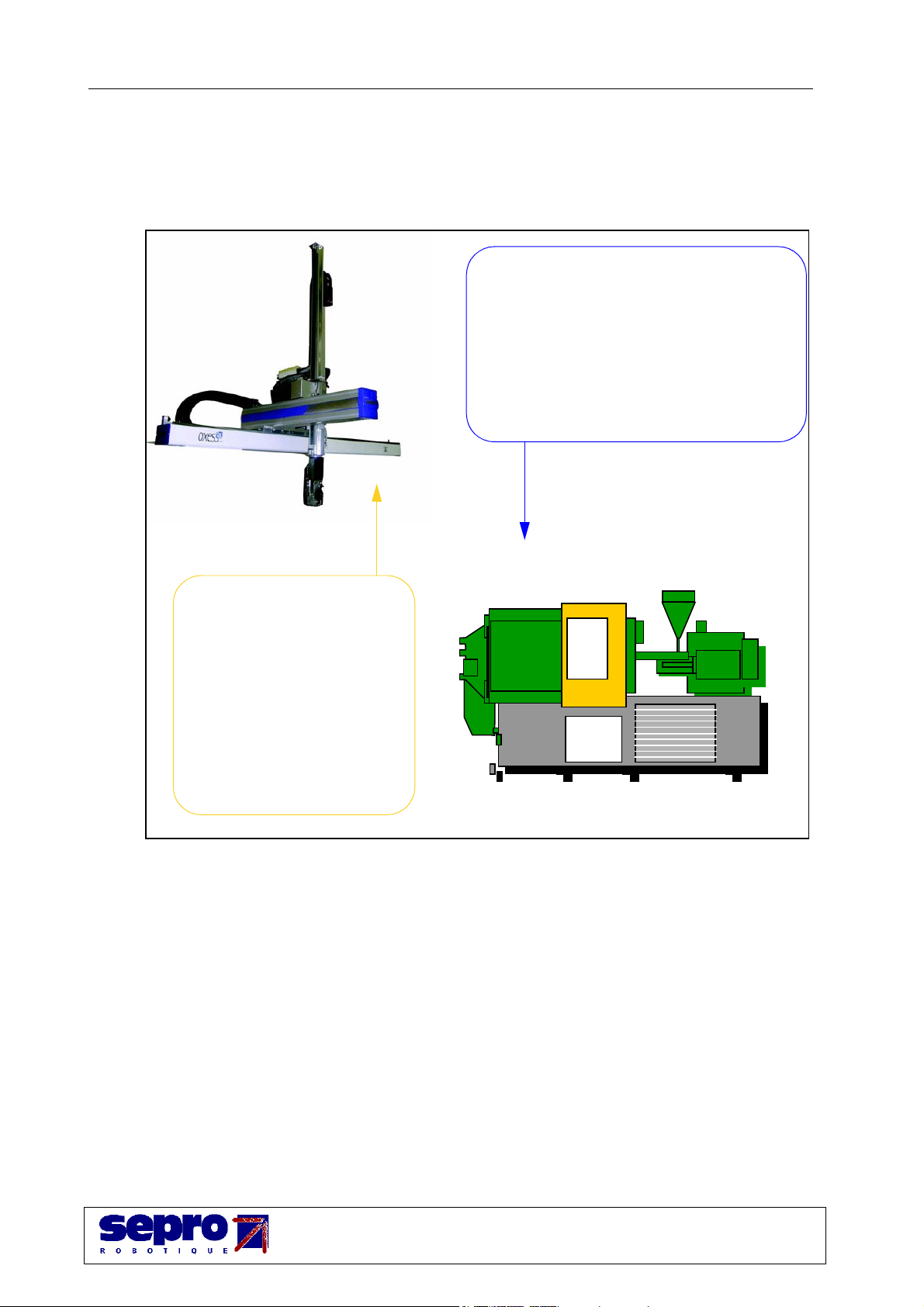

II - ROBOT / IMM DIALOGUE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

III - QUICK REFERENCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

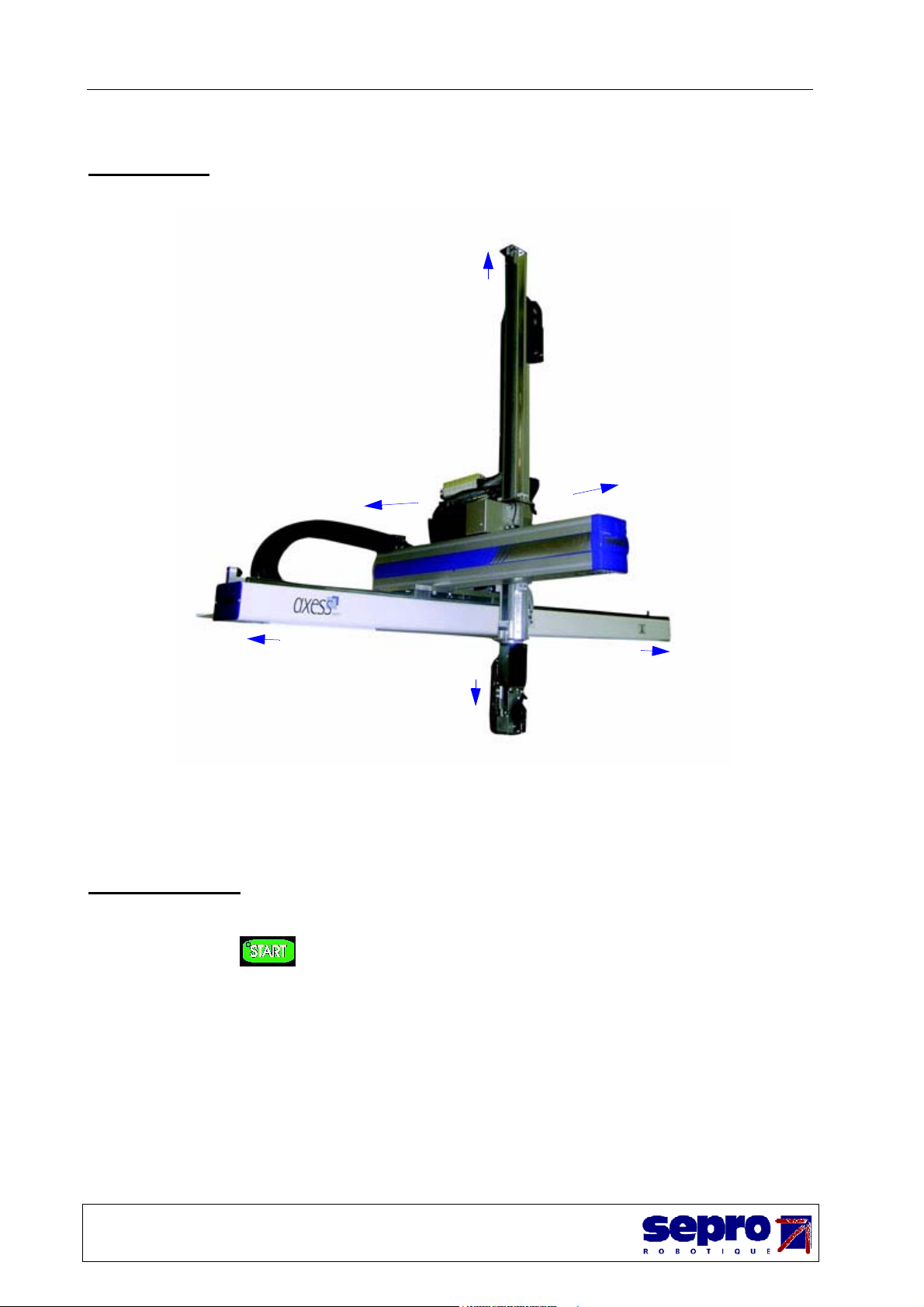

III - 1. The axes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

III - 2. Powering up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

III - 3. Navigating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

III - 3. 1. The modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

III - 3. 2. The function keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

III - 3. 3. Returning to the previous screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

III - 3. 4. Locking the numeric pad .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

III - 3. 5. Entering a numeric value. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

III - 3. 6. Entering text . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

III - 3. 7. Help key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

IV - MANUAL MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

IV - 1. Manually controlling a numeric movement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

IV - 1. 1. Moving an axis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

IV - 1. 2. Changing the movement speed - Kv . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

IV - 1. 3. Changing the movement mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

IV - 2. Manually controlling a pneumatic movement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

IV - 2. 1. Part grip and release . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

IV - 2. 2. Rotations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

IV - 3. Enabling a manual movement of the IMM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

IV - 4. Manually controlling an output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

IV - 5. Controlling the belt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

IV - 6. Teaching the points in manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

V - MOLD CHANGE - TEST MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

V - 1. Home page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

V - 2. Selecting a program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

V - 2. 1. Selecting a program on the pendant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

V - 3. Creating a program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

V - 3. 1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

V - 3. 2. Creating a program from an EPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

V - 4. Teaching the points in cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

V - 4. 1. Principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

V - 4. 2. Stacking sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

V - 5. Testing the program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18