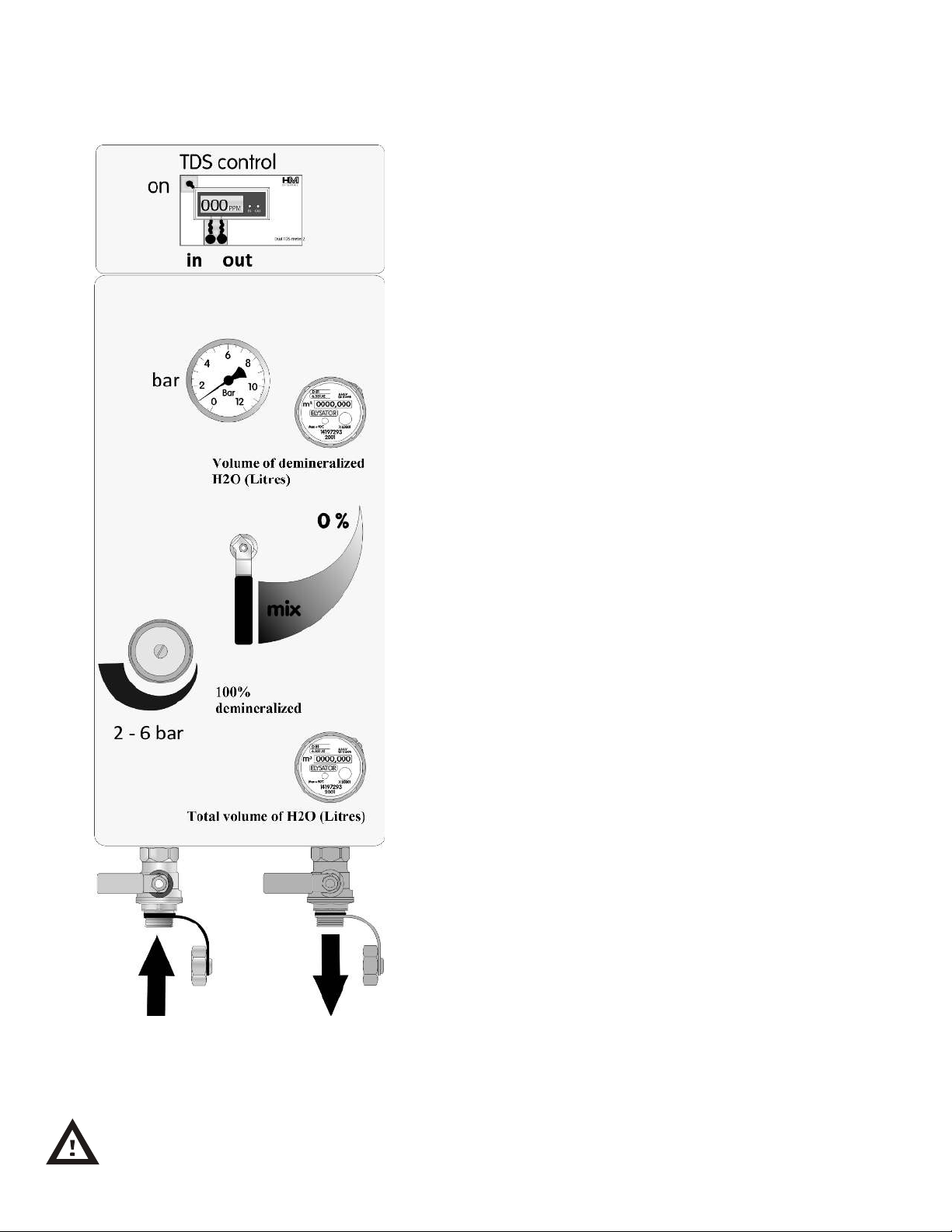

Trouble shooting the TDS meter

Malfunction

Solution

The display goes off after approx.

20 seconds.

This is not a malfunction; it automatically switches off to conserve the

batteries. Press the "POWER" button again.

The inlet value (IN) shows -000-

The sensor in the inlet has no measuring values or is defective. Use the flush

valve to check whether the whole unit is full of water. If this is the case and

the malfunction persists, then the measuring device and sensor must be

replaced.

The outlet value (OUT) shows -

000-

Check the water meter to see whether the whole unit is full of water. If this is

the case, then this is not a malfunction, instead it is a correct measurement of

the demineralized water. If it can be assumed that the cartridge is exhausted

(due to the amount of treated water) and the display remains on -000-, then

the measuring device should be replaced along with the sensor.

The display remains empty, even

after pressing the

"POWER" button.

Change batteries. See Fig 6 below.

The display flutters, is difficult to

read or contains illegible

characters.

Change batteries. See Fig 6 below.

The display shows -ERR-

Measuring device malfunction. Reset by switching on and off quickly 2-3

times until the display is normal again. Otherwise, remove and reinsert the

batteries.

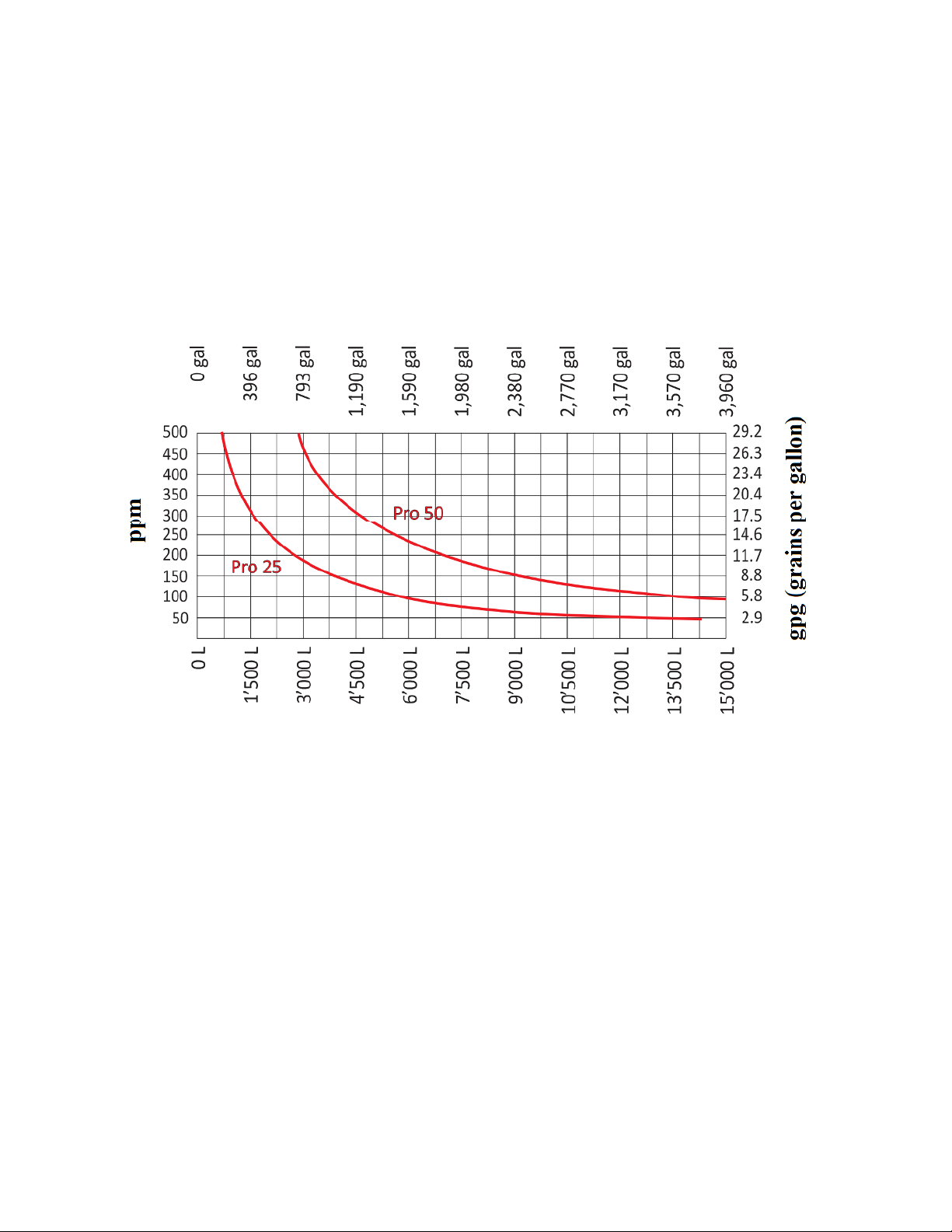

The resin seems to be used faster

(increased TDS) than the water

There probably is not a malfunction, instead the untreated water contains

dissolved solids (sulfate, nitrate, chloride) in addition to lime, which are

removed and thus reduce the capacity.

Otherwise there is a flow measurement malfunction (see below)

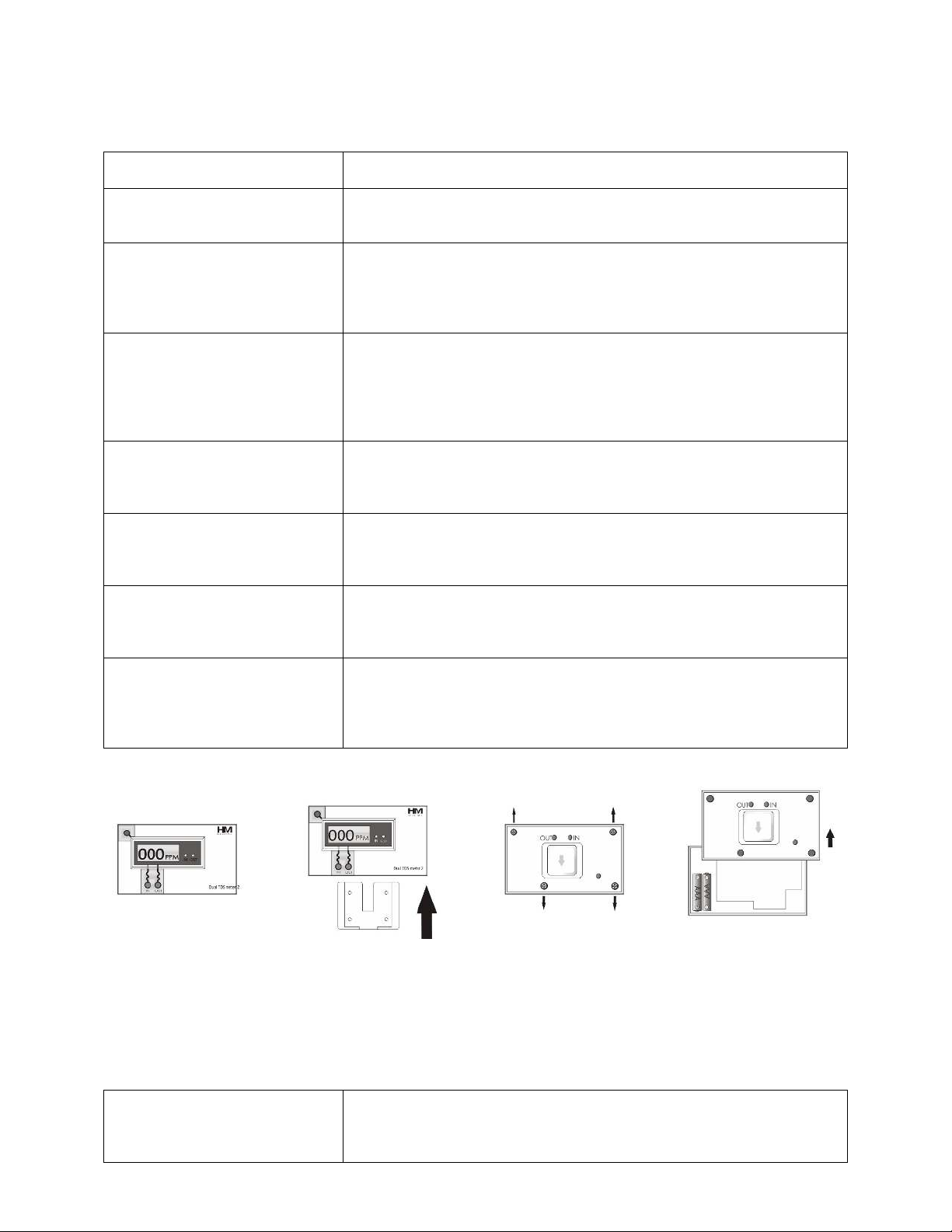

Changing the batteries

Figure 6: Changing the batteries

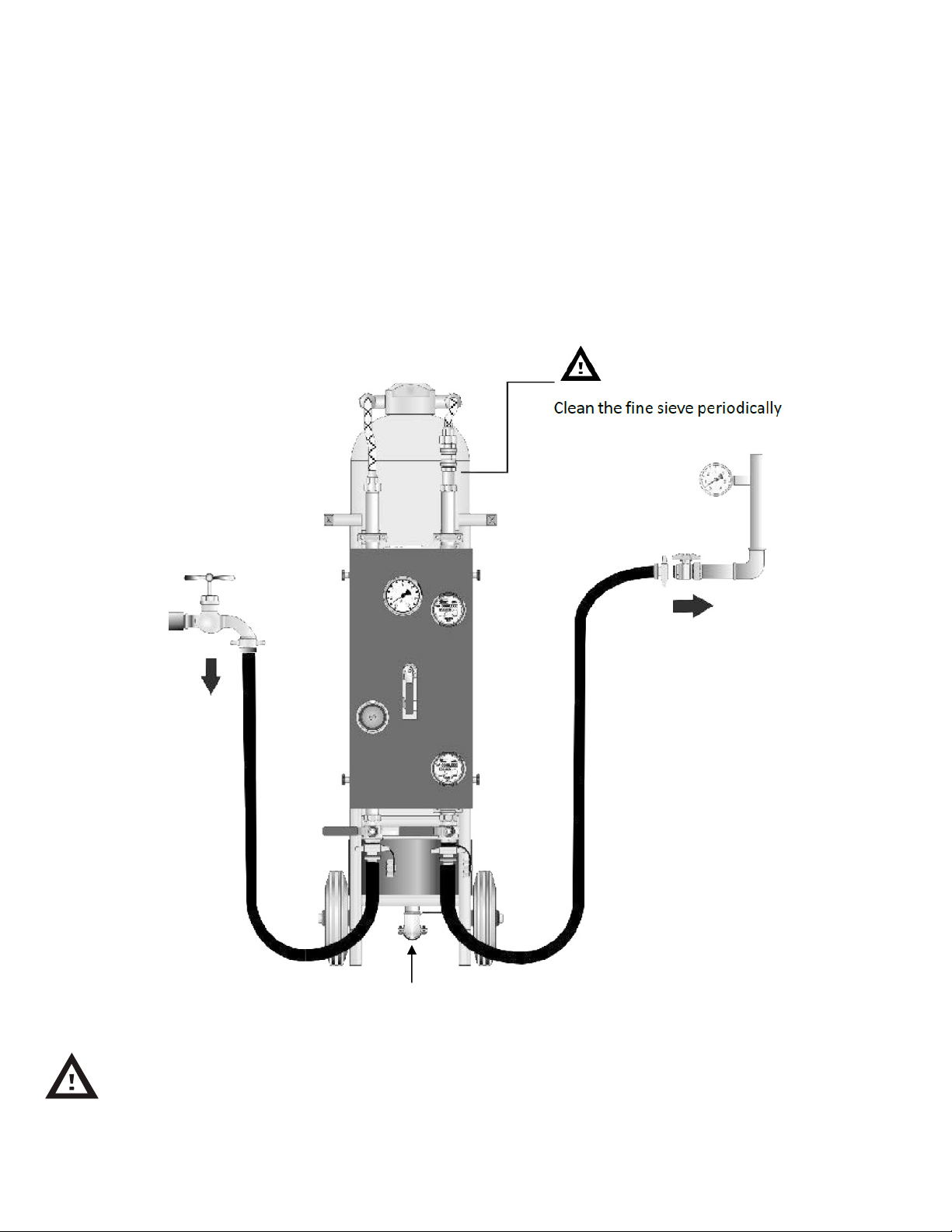

Flow rate measurement device malfunction

The water meters appear to be too

slow or to not run at all.

A fine sieve is installed in front of the outlet valve in order to prevent resin

from leaking into the system from the apparatus due to an operation failure. If

resin does leak out of the cartridge, it is caught in the fine sieve and interrupts

the function of the armatures. Solution: Rinse and clean armatures out.

First, loosen the

metal housing Pull the measuring device

upward out of the holder.

Loosen and remove

the four metal screws

on the back

Remove back side

and replace 2 AA

batteries.