PROJECT PEN KITS

Continues over...

WHAT’S REQUIRED

For more info and

videos scan here

Preparing a wooden or acrylic/polyester

blank for a pen mandrel.

1. Cut a blank to the length of each tube

plus approximately 2.5mm to allow for

trimming and squaring off the ends.

2. Mark the centre on the end of the blank.

3. Using the recommended drill bit, drill a

hole lengthwise through the blank.

4. Apply epoxy glue, Polyurethane glue or

gap filling cyanoacrylate (super glue) to

the tubes.

5. Insert the tube into the blank with a

twisting motion to spread the glue

evenly inside the hole.

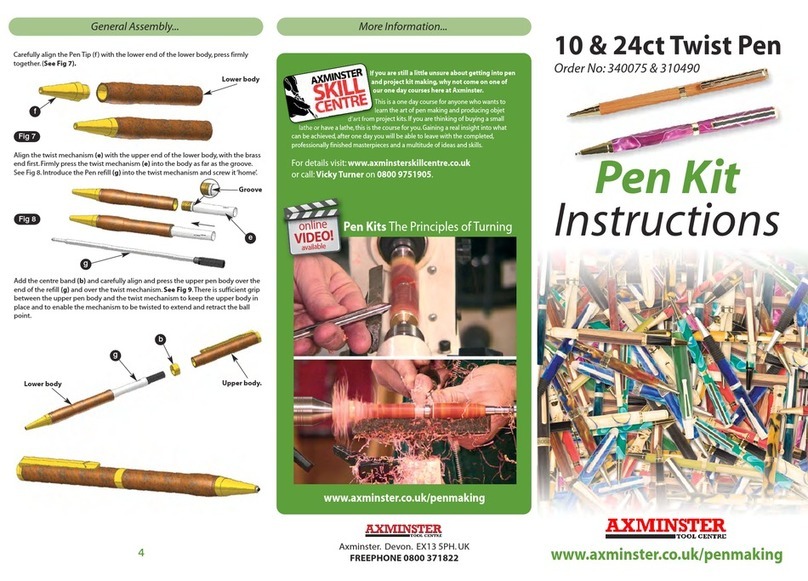

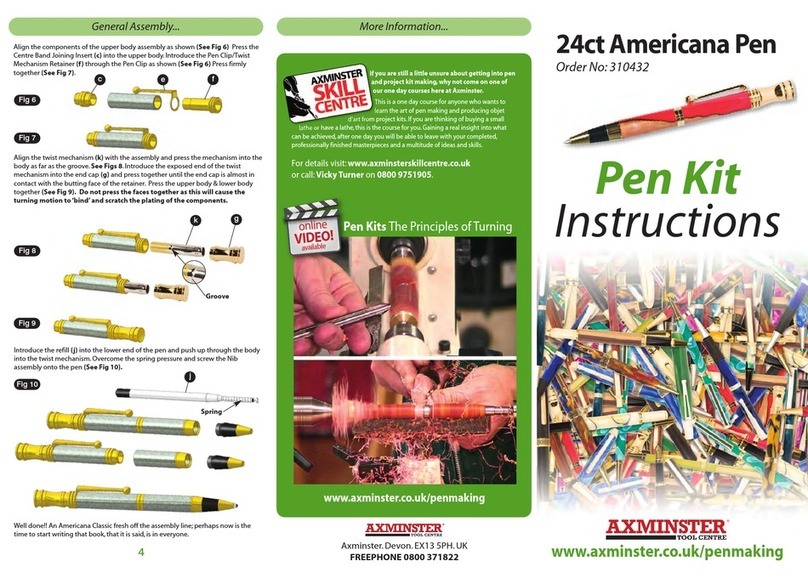

1. Assemble the bushes and blanks on

the pen mandrel as shown in the

diagram, with the Centre Band Bush’s

smaller diameter sitting against the

Upper Pen Blank (53mm long tube). (If

using a wooden blank, check the grain

alignment).

NOTE. The Centre Band Bush includes a

Dummy Centre Band.

2. Secure the bushings and blanks onto

the mandrel.

3. Slide the tailstock with a live centre into

place against the mandrel and lock in

position. This is for support; only slight

pressure is required.

Bushing Set:

310381

Drill Bit Size:

7 mm

Minimum Blank Size:

16 mm x 16 mm x 120 mm

6. Centre the tube lengthwise inside the

blank.

7. Allow the adhesive to cure.

8. When cured, square the ends of the

blank. Using a barrel trimmer with a

guide matching the inner diameter

of the tube or a universal pen blank

squaring jig with a disc sander.

9. Take the excess material down flush

with the ends of the brass tube. (do

not trim beyond the length of the tube

since this may interfere with operation

of the mechanism and assembly).

Tips/Hints

•If using a wooden blank, draw a short

pencil line lengthwise across the centre

of the blank. This will help maintain grain

alignment when mounting the blanks

onto a mandrel.

•Excessive pressure may cause the drill

bit to wander and/or split the blank. Slow

the feed rate and back the drill bit out

repeatedly for chip removal.

•Roughen the brass tube slightly with

abrasive for better adhesion.

•Certain acrylic blanks are more

transparent than others, especially

lighter colors or blanks with light colored

swirls. To avoid the risk of the brass tube

showing through the pen blank, paint

the tubes white or black before gluing

them in.

•The barrel trimmer guide also cleans any

adhesive that may have gotten inside of

the tube.

4. Using sharp tools, turn the blanks

down to become the Upper Pen Barrel

(53mm long tube) and Lower Pen

Barrel (60mm long tube) with profiles

of your choice.

5. Turn the bottom end of the Upper Pen

Barrel to match the outer diameter of

Dummy Centre Band.

6. Remove the Dummy Centre Band and

turn a 5.6mm (7/32”) long shoulder

on the bottom end of the Upper Pen

Barrel, the same diameter as the bush.

ENSURE that the corner is SHARP.

7. Turn the blanks very slightly oversize,

then sand and polish the ends down to

the same diameter as the bushings.

8. Using successively finer abrasives

gradually sand and polish both Pen

Barrels.

9. Finish both Pen Barrels with your

preferred choice of polish.

Tips/Hints

•Don’t be afraid to sharpen frequently

especially when turning acrylics.

Artisan European Twist Pen - 10kt Gold

Code: 310404

PREPARING THE BLANKS, HINTS & TIPS

TURNING THE BLANK, HINTS & TIPS