2

AB-6601

Safety Instructions

Please read instructions carefully and use the product

as specied in this manual.

Be sure to keep this manual near by for ready reference.

Usage Restrictions

This product is targeted for general air conditioning.

Do not use this product in a situation where human

life may be affected.

If this product is used in a clean room or a place

where reliability or control accuracy is particularly

required, please contact our sales representative.

Azbil Corporation will not bear any responsibility for

the results produced by the operators.

zCautions for connecting to system

•If this product breaks down, it does not have function

to avoid or notify the abnormal conditions to other

equipment.

Please take countermeasures independently from this

product.

•If the enclosed liquid leaks, the contacts are welded, etc.,

the output might be stuck to ON.

To use this product for controlling a heating device

such as hot water heater, be sure to implement safety

measures, e.g., preventing dry-heating.

zProhibitions for installing this product

Do not install the product in the following environments.

Doing so might cause malfunction of the device or device

failure in a short period of usage.

•Where special chemicals or corrosive gas (such as

ammonia, sulfur, chlorine, ethylenic compound, acids,

etc.) exist.

•Where water droplets or excessive damp air exists.

•Where condensation is made on the product.

•Where exposed to direct sunlight or high temperature.

•Where exposed to direct wind or rain.

•Where vibrations or shocks are applied.

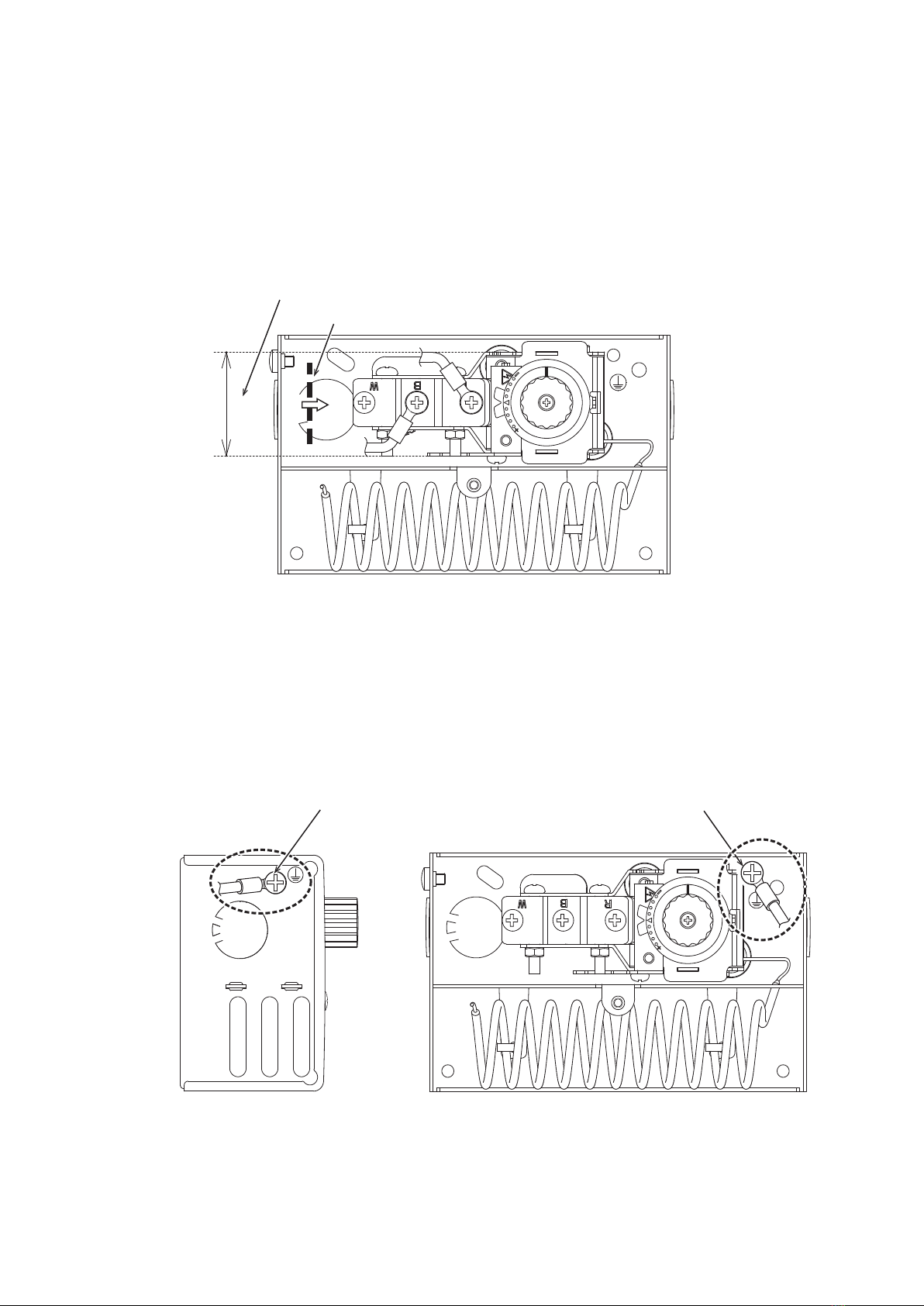

zCautions for installing this product

•Install this product in a location where representative

temperature of the measuring object can be measured.

•Do not install the product in locations such as the

following.Temperature may not be correctly measured.

•Where exposed to warm or cold wind directly.

•Where air stagnates or there is a draft.

• Where the product cannot be securely mounted.

• Where unauthorized persons can have easy access.

•Secure space around the product for maintenance.

Warnings and Cautions

WARNING

Alerts users that improper

handling may cause death or

serious injury.

CAUTION

Alerts users that improper

handling may cause minor injury

or material loss.

Signs

Alerts users possible hazardous conditions

caused by erroneous operation or erroneous

use. The symbol inside indicates the

specic type of danger.(For example, the sign

on the left warns of the risk of electric shock.)

Notifies users that specific actions are

prohibited to prevent possible danger. The

symbol inside graphically indicates the

prohibited action.(For example, the sign on

the left noties that disassembly is prohibited.)

Instructs users to carry out a specific

obligatory action to prevent possible danger.

The symbol inside graphically indicates

the actual action to be carried out. (For

example, the sign on the left indicates general

instructions.)

WARNING

If this product is connected to a system, be

sure to implement safety measures.

Failure to do might cause re.

Be sure to ground the product with ground

resistance of less than 100 Ω.

Improper grounding might cause electric

shock or malfunction.

Before wiring or servicing, be sure to turn off

the power to this product.

Failure to do might cause electric shock or

device failure.

Before attaching or detaching the terminal

cover for wiring, be sure to turn off the power

to the product and all the connected devices.

After the wiring work, attach the terminal

cover at the original position.

Failure to do so might cause electric shock.

If seal connectors or conduits cannot be used,

use grommets.

Failure to do so might cause electric shock

due to touching the terminals.