AZEK Timbertech Impression Rail Express User manual

TimberTech.com.au

Installation Guide

Aluminium Posts ...........................4

Level Balustrades..........................8

Stair Balustrades ......................... 10

Gate Kits....................................... 13

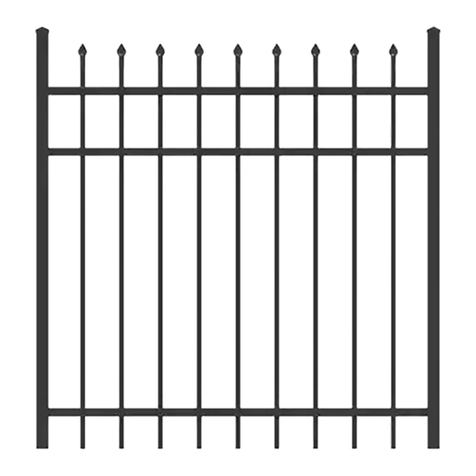

Aluminium Balustrade

Impression Rail™

Express

Page 2

Installing Impression Rail™Express

Aluminium Balustrade System

Important Information

• Please read all instructions completely before starting any part of the installation. Always make sure to visit www.TimberTech.com.au to

ensure you are viewing the most current installation instructions, care and cleaning, technical information and more.

• Impression Rail Express should be installed using the same good building principles used to install wood, composite, or metal balustrade

and in accordance with the local building codes and the installation guidelines included below.

• The AZEK Co. LLC accepts no liability or responsibility for the improper installation of this product.

• Impression Rail

Express

may not be suitable for every application and it is the sole responsibility of the installer to be sure that Impression

Rail is t for the intended use. Since all installations are unique, it is also the installer’s responsibility to determine specic requirements in

regards to each balustrade application.

• The AZEK Co. LLC recommends that all applications be reviewed by a licensed architect, engineer or local building ofcial before

installation. If you have any questions or need further assistance, please call TimberTech Customer Service at 1-800-726-300, or visit our

website at www.TimberTech.com.au.

• Impression Rail Express is tested as a whole system and should be used that way. It is not intended to be used in conjunction with other

balustrade systems or fasteners.

• The following Installation Guidelines are applicable for installation of Impression Rail Express only.

• IMPORTANT: Make sure the DRIVE TOOL/DRILL is congured or set to use the SCREW setting when driving and/or tightening all

FASTENERS.

• SAFETY: Always wear goggles when handling, cutting, drilling and fastening materials.

• Failure to install this product in accordance with applicable building codes and Impression Rail Express’s written Balustrade Install Guide

may lead to personal injury, affect balustrade system performance and void the product warranty.

• The buildup or generation of static electricity is a naturally occurring phenomenon in many plastic based products such as carpeting,

upholstery, and clothing, and can occur on alternative decking under certain environmental conditions. This static electricity can discharge

once contact is made with hardware, balustrade, or other conductors of electricity.

NOTE: IF INSTALLING POST LIGHTING,

WIRING MUST BE INSTALLED PRIOR TO

SECURING POSTS TO DECK/STAIR SURFACE

AND INSTALLING HAND RAIL SNAPS.

It is the responsibility of the installer to

meet all local code requirements and obtain

all required building permits. The installer

should determine and implement appropriate

installation techniques for each installation

situation. AZEK Co. LLC or its reseller shall

not be held responsible for improper or

unsafe installations.

Page 3

Installing Impression Rail™Express

Aluminium Balustrade System

Important Note:

Actual Level Balustrade Lengths Are As Follows:

• 1830mm Balustrades = 1765mm

• 2440mm Balustrades = 2320mm

• 75mm x 75mm posts are required to reach

1830mm & 2440mm lengths

Visit www.timbertech.com.au/installation to view

installation videos.

Consult your local building codes for guard and handrail

requirements.

Important Note: Suggested Tools:

•Appropriate fasteners

for mounting posts to

deck

•Miter saw with carbide-

tipped non-ferrous

blade

•Cordless drill

• Tape measure

Prior to construction, check with your local regulatory

agency for special code requirements in your area.

Common balustrade height is 1100mm. Post spans will vary

depending on job site conditions. Never span more than 2440mm

on-center between balustrade posts. Spans longer than 3660mm

in length will require reduced post spans. For all other applications,

consult a design professional or an AZEK balustrade representative

for more information. Read instructions completely to get an

understanding of how the product goes together and how each piece

affects the other.

•Level

• Power cords, drop

sheets and safety

glasses

•5mm Drill bit

•150mm #2 Square drive

bit

• Installation jig (optional)

Page 4

Installing Aluminium Posts

Determine All Posts Needed and Prepare (end,

center or corner)

Important Note:

75mm x 75mm posts are required to reach 1830mm and

2440mm lengths. 50mm x 50mm posts must be set in-line to

balustrade. Do not install post caps and vinyl post base

covers until balustrade assembly is completed.

Install Lower Deck Rail Clips – Two Options:

Option A - When No Installation Jig Is Available

•Measure 73mm from top of casting shoulder and place a pencil

mark for location of the top edge of the Balustrade clip. (Dia. #1)

•Center clip on post and secure with (2) - #8x20mm self-drilling

screws. Clips are included in the Balustrade Kits.

Option B - Using Installation Jig (Sold separately.

Accessory

pack includes Installation Jig and Touch-up paint.)

• Place Installation Jig (w/arrow facing base plate) on top of base

plate upper edge. (Dia. #2)

•Place clip in hole and fasten with (2) - #8x20mm self-drilling

screws. Clips are included in the Balustrade Kits.

1

Dia. #1

Dia. #4

2

Cap

Square Post

Post Base Plate

Vinyl Cover

*Do not install

until balustrade

assembly is

completed.

Deck Edge

Joist

Stringer

45mm x 140mm

Blocking

45mm x 140mm

Cross Block

Rest

Installation Jig

on Base Plate

– Arrow Down

Place Clip in

hole, hold clip

rmly while

installing (2)

Self-Drilling

Screws.

Dia. #2

Shims

below

base

45mm x 140mm

Blocking

4X 10mm x 150mm

construction lag screws (sold

separately)

*Verify local code

requirements for post

attachment hardware.

Dia. #3B

(SIDE VIEW)

Dia. #3A

(TOP VIEW)

How to Secure 75mm x 75mm Posts

to Deck

• Install proper post blocking (Dia. #3A & 3B).

Use proper attachment screws or anchors

shown in diagram. (Hardware for post

attachment are not provided with the posts.)

•With 5mm drill bit, pre-drill through deck

boards and into blocking.

(Dia. #3C)

•Drill a 15mm hole in center of four deck

screw holes for lighting wires (optional).

• Level and plumb post using shims.

•Secure posts to deck frame with suggested

screws.

(Dia. #3B)

*Verify local code requirements for post

attachment hardware.

•Install post caps (after Balustrades are

installed). (Dia. #4)

Pre-drill 5mm holes for post

attachment fasteners (sold

separately).

15mm hole for lighting

wires (optional)

Dia. #3C

(TOP VIEW)

Page 5

Installing Aluminium Posts

Install Stair End Posts

(if applicable)

• Temporarily install end stair

post so balustrade centerline

aligns with top stair posts

installed in Step 1 (if applicable).

Recommended post installation

locations are shown. (Dia. #5)

Conrm with local code ofcials

before installing stair balustrade

sections or stair balustrade posts

to ensure compliance with local

code requirements.

Install End Posts

(if applicable)

Install posts at all end locations with

maximum gap between post and wall

to be less than a 100mm opening

(Dia. #6)

Install 90-degree Corner

Posts

Position post on same 75mm

centerline (typical) and temporarily

fasten using a single fastener through

base plate mounting hole. (Dia. #7)

3

4

5

Dia. #5

Dia. #6

DECK

EDGE

TOP VIEW

LOCATE

90° CORNER

POST

DECK

EDGE

Dia. #7

Important Note:

75mm x 75mm posts are required at all

transitions. 50mm x 50mm posts may

not be used to start/end a run or to

form a corner.

3B

DECK

SURFACE

STAIR DOWN

75mm TOP

STAIR POST

TEMPORARILY INSTALL

75mm BOTTOM STAIR

END POST ALIGNED

WITH TOP STAIR END

POST (REFER TO STAIR

INSTRUCTIONS)

75mm

TYPICAL

75mm

CENTERLINE

TYPICAL LOCATE END

POST

LESS THAN 100mm

OPENING

BUILDING WALL

75mm

CENTERLINE

TYPICAL

75mm

CENTERLINE

TYPICAL

Page 6

Install 45° Corner Posts

(Post to be installed at 22.5°

to accommodate a 45°

angle.)

Position post on same 75mm

centerline (typical) and temporarily

fasten to deck surface. Use one 22.5°

Balustrade Attach Kit (purchased

separately) to install 45° corner posts.

(Dia. #8)

Determine Center Post Locations

Loosely lay center post over deck edge and

adjust as required to determine nal center post

mounting locations. (Dia. #9 & #10)

6

7

Dia. #8

Dia. #9

Dia. #10

PLAN VIEW

CLOSE UP

VIEW

CENTER LINE

Installing Aluminium Posts

Dia. #8

POST DISSECTS

DECK ANGLE

TYPICAL

DECK

EDGE

75mm

CENTERLINE

TYPICAL

TOP VIEW

LOCATE 45°

ANGLEDPOST

75MM

CENTERLINE

TYPICAL

Page 7

STAIR CROSSOVER

BRACKET

POST BASE PLATE

VINYL COVER

POST

EXTRUSION

CLIP

Dia. #12B

Dia. #12D

Install Crossover Brackets on 50mm x 50mm Posts

•With 150mm #2 square drive bit, fasten straight crossover bracket (included) into post

with

(2) - #8x40mm Self-Drilling Screws. (Dia. #12A & #12B)

NOTE: Self-Drilling Screws must be installed in screw chases in-line with

balustrades.

•With 150mm #2 square drive bit, fasten H-channel to straight and stair crossover

brackets with (4) - #8x20mm Self-Drilling Screws. (Dia. #12C & #12D) Repeat for lower

8

9

Installing Aluminium Posts

Dia. #11

DECK EDGE

Secure 50mm x 50mm Posts to Deck (center only)

•For continuous hand rail systems, install 50mm x 50mm posts

centered between 75mm x 75mm end and corner posts.

NOTE: 50mm x 50mm Posts must be installed with center

screw chases in-line with balustrade (Dia. #11).

•Follow instructions in step 2 (Dia. #3A to Dia. #4).

Important Note:

75mm x 75mm posts are required at all transitions. 50mm x

50mm posts may not be used to start/end a run or to form a

corner.

STRAIGHT CROSSOVER

BRACKET

POST BASE PLATE VINYL COVER

*DO NOT INSTALL UNTIL

BALUSTRADE ASSEMBLY IS

COMPLETED.

POST

EXTRUSION

CLIP

Dia. #12A

Dia. #12C

LEVEL BALUSTRADES

STAIR BALUSTRADES

75mm CENTERLINE TYPICAL

Page 8

Dia. #1

Dia. #2

Dia. #2

Secure Level Balustrades to Posts

Slide bottom channel of pre-cut balustrade on

to lower clip. (Dia. #2) Tip: to avoid scratching

the posts, slide balustrade in from the side, then

downward onto the brackets.

• Insert clips into top channel of balustrade on

each end.

•Using (4) - #8x20mm self-drilling screws, attach

the upper two clips to the post.

•Using (8) - #8x20mm self-drilling screws,

secure the upper and lower clips to the

balustrade.

• Tip: Use a 150mm drill bit for easier installation

of top attachment clip to post.

Cut Level Balustrades

Clamp or hold balustrade against post,

adjust for equal end spacing. (Dia. #1)

• Determine the desired center of the

balustrade; either a baluster hole or

between two baluster holes. (Dia. #2)

• Measuring from the determined

center, cut both ends of the

balustrades.

• Mark the hand and base rails

•Cut balustrade 2mm less than

opening size.

•Clean cut areas and apply touch-up

paint on exposed ends. Touch-up

paint sold separately.

2

1

Installing Level Balustrades

Centerline

Even number of balusters

Install Self-drilling Screws,

2x #8 x 20mm Outside,

2x #8 x 20mm Inside

Temporarily clamp balustrade against posts,

mark for cutting.

Cut balustrade 2mm less than opening size

Post

Assembly

Assembled

Balustrade

Balustrade

Clip

Install

balustrade

on lower clip

Slide hand rail clip

into channel & slide

against post

Balustrade

Clip

Page 9

#8 x 20mm Self-

Drilling Screws

Dia. #3

Install Base Rail supports

For openings greater than 1220mm, install

base rail support under center of base rail. (Dia.

#3)

•Slide base rail support under base rail and

mark.

• Install two deck screws into deck surface at

location of base rail support, install base rail

support over screws.

•Using (1) - #8x20mm self-drilling screw,

secure the base rail support to base rail, from

the outside of the balustrade so the screw will

not be visible from the deck surface. (Dia. #4)

3

Dia. #4

Dia. #5 Dia. #6

Cut and Install Hand and Base Rail Snaps

• Measure between posts at the hand and base

rails. (Dia.#5)

•For Continuous Level Balustrade, measure

opening from 75x75mm post to 75x75mm post.

•Cut hand & base snap covers 2mm less than

opening.

•Clean cut areas and apply touch-up paint on all

exposed metal.

•Snap each balustrade snap over the

corresponding balustrade channel until properly

seated. (Dia. #6)

TIP: Roll the Hand Rail Snap in place to avoid

scratching the posts and put weight down to get

to the “second” snap.

NOTE:

Do not install hand snaps yet if lighting

wires will be run through hand rails.

4

Important Note:

The hand rail snap covers should snap rmly onto the aluminium balustrade channels. Do not use a hammer. The

hand rails will snap by applying pressure from one end to the other. If you’re having issues snapping on the covers,

check the clips to ensure that they are bottomed out into the aluminium balustrade channels. Base rail supports

must be installed BEFORE installing Hand Rail Snaps.

Installing Level Balustrades

Locate

Base rail

support

Base

Rail

Support

Install Base Rail

Support over 2x

deck screws

Measure

Balustrade

Assembly

Board Deck

Page 10

Dia. #1A

Dia. #2

1Fit Stair Balustrades

• Position stair balustrade alongside 75mm

top stair post and temporarily installed 75mm

bottom post. (Dia. 1A)

• Determine the desired center of the

balustrade: either a baluster hole or between

two baluster holes. (Dia. 1C)

• Measuring from the determined center, cut

both ends of the balustrades.

• Position stair balustrade approximately

35mm above stair nosing. Tip: lay a 35mm

x 70mm Timber at on nose of stair

treads. This will allow enough room for

installation of bottom snap. Clamp stair

balustrade against top and bottom 75 mm x

75 mm posts. Using a sharp #2 pencil, mark

the stair channels at four (4) locations.

• If using a continuous hand rail, after

balustrade has been clamped to post, mark

cut lines on the H-channel and the 50 mm x

50 post using the bottom of the H-channel to

nd your angle for post cut. (Dia. 1B)

• Remove clamps and cut stair balustrade at

all four (4) locations. (Dia. 2) Take care to cut

stair channels at appropriate stair angle. Use

of Miter saw with a sharp non-ferrous blade

is recommended.

• Clean cut areas and apply touch-up

paint on all exposed ends.

Important Notes:

• Actual Stair Balustrade Lengths: 1830mm

Balustrades = 1765mm and 2440mm Balustrades

= 2320mm. 75x75mm posts are required to reach

1830mm and 2440mm lengths.

• Stair balustrades are shipped at a 37 degree angle.

Balustrades are adjustable +/- 3 degrees.

• Maximum post spans on stair balustrade application

is 2440mm on center. Additional posts are required

on any stair application more than 2440mm in

length.

Installing Stair Balustrades

Dia. #1C

Centerline

Even number of balusters

Dia. #1B

Temporary clamp

balustrade against

posts and mark for

miter cuts.

Level post

Temporarily

installed Post

Tip: Lay a 35mm x

70mm Timber on

nose of stair treads

4x cut panel to t

Stair Balustrade

4x cut

balustrade

to t

4x cut

balustrade

to t

Page 11

Dia. #4

Dia. #5

Dia. #3

Dia. #6

2

3

Install Stair Clips On Posts

• After stair balustrade has been cut to proper

size and angle, place the balustrade on the

35mm x 70mm (or hold 35mm above stair

nosing) board, between the 75mm x 75mm

posts. Use a #2 sharp pencil to draw a line

across the top of the lower baluster channel

in two places (Dia. 3).

• Remove balustrade and bottom post. Attach

stair balustrade attach clips at marked

location as per (Dia. 4) and fasten with

#8x20mm self-drilling screws. Note the

direction of the angled stair balustrade attach

clips; they should be parallel to the angle of

the stairs.

• NOTE: Installation Jigs are not used for

stair balustrade installation.

Secure Stair Balustrade To 75mm x 75mm

Posts

• Once the stair balustrade attach clips have been

installed, re-attach the lower 75 mm x 75mm post to the

bottom step or landing. Place the stair balustrade onto

the lower stair balustrade attach clips (Dia. 5).

Tip: to avoid scratching the posts, slide stair balustrade

in from the side, then downward onto the brackets.

• When lower extrusion is fully seated on lower clips,

insert stair balustrade attach clips into upper extrusion.

Secure attach clips to post with 2-#8x20mm self-drilling

screws, then secure upper extrusion to stair balustrade

attach clip with 2-#8x20mm self-drilling screws. Repeat

this same procedure for bottom post, upper extrusion

(Dia. 6).

• When upper extrusion is secured to attach clips, return

to lower extrusion and secure lower extrusion to lower

stair clips with 2-#8x3/4″ 20mm self-drilling screws at

upper post and 2-#8x3/4″ 20mm self-drilling screws at

lower post.

PENCIL

MARK LINE

CLIP

TOP EDGE

Installing Stair Balustrades

INSTALL

2X #8 X

20mm SELF-

DRILLING

SCREWS

OUTSIDE

INSTALL

2X #8 X

20MM SELF-

DRILLING

SCREWS

4x #8 x 20mm

Self-drilling

Screws –

two inside and

two outside

BALUSTRADE

CLIP

Temporary

35mm x 70mm Timber

With #2 pencil place

mark on post at top of

lower stair extrusion

Balustrade

Clip

Page 12

Dia. #7

4Install Hand and Base Snap Covers

• Following the same angle as the secured stair

balustrade, clamp or hold hand/base rail snaps against

75mm x 75mm posts (Dia. 7). Using a sharp #2 pencil,

mark the hand/base rail snaps at all four (4) locations.

• Remove clamps and cut hand/base rail snaps at all four

(4) locations. Take care to cut snaps at appropriate stair

angle. Use of Miter saw with a sharp non-ferrous blade

is recommended. Cut 2mm less than opening size.

• Clean cut areas and apply touch-up paint on exposed

ends.

• Snap each balustrade snap over the corresponding

balustrade channel until properly seated (Dia. 8).

• Tip: Support balustrade with a block of wood when

installing hand rail snap.

l

Dia. #8

Installing Stair Balustrades

Temporarily clamp top

and bottom balustrade

snaps against posts and

mark for miter cuts. Cut

2mm less than opening

size

863mm to 965mm

from stair nosing to

top of baslustrade

Page 13

Remove all Items From Package

Gate Kit Includes:

Measure Opening Between Posts (Dia. #1)

Measure, Mark and Cut Picket Gate Balustrade

(without Gate End Posts)

Measurement must be exactly 115mm less than gate opening.

Deduct 115mm from opening measurement and cut both

balustrade ends, leaving equal picket spacing. (Dia. #2)

Insert Gate End Posts Into Balustrade Upper and

Lower Horizontal Channels. (Dia. #3)

1

2

3

4

Dia. #1

Dia. #2

Dia. #3

Suggested Tools:

• Cordless Drill

• Pencil

• Tape Measure

• Safety Glasses

• #2 Sq. Drive Bit

• 3.2mm Drill Bit

• Miter Saw w/ Non-

Ferrous Blade

• One (1) - Picket Balustrade

• Two (2) - Snap Covers

• Two (2) - Gate End Posts w/ Welded Rods

• Sixteen (16) - 3/4" Self-Drilling Screws

• Two (2) - Self-Closing Hinges

• One (1) - Locking Latch Kit w/ Key

• Four (4) - Gate Support Brackets

• Sixteen (16) - Color Matched Self-Drilling Screws

• Measure opening between posts. (Dia. #1)

Installing Gate Kits

Page 14

Dia. #4

Dia. #5

Dia. #6

Drill 16 - 3.2mm Holes (Dia. #4) and Install

20mm Self-Drilling Screws to Secure Gate

Ends to Balustrade

Measure Between Gate End Posts

Measure between Gate End Posts, deduct 2mm and cut hand &

base snap covers. Once cut, position snap covers over

hand &

base horizontal channels and press in place. (Dia. #5)

Install Support Bracket

To install Support Bracket, rst attach Support

Bracket to Post using 2x #8 x 20mm self-drilling

screws as shown, then press Support Bracket

against Horizontal Balustrade, drill 2x 3.2mm pilot

holes and secure using remaining 2x #8 x 20mm

self-drilling screws. Repeat for remaining brackets.

(Dia. #6)

Install Gate Hinges Per Instructions Provided In Hinge Package

Install Gate Latch As Per Instructions Provided In Latch Package.

5

6

7

8

9

Installing Gate Kits

4x Support

Bracket

Post

4x #8 x 20mm Color

Matched Self-Drilling

Screws per support

Horizontal Balustrade

2 HOLES PER BALUSTRADE

PER POST PER SIDE (16)

Page 15

Installing Impression Rail™Express

Aluminium Balustrade System

Important Note:

The diagrams and instructions in this brochure are for illustration purposes only and are not meant to replace a licensed

professional. Any construction or use of the product must be in accordance with all local zoning and/or building codes. The

consumer assumes all risks and liability associated with the construction or use of this product. The consumer or contractor

should take all necessary steps to ensure the safety of everyone involved in the project, including, but not limited to, wearing the

appropriate safety equipment. Except as contained in the written limited warranty, AZEK does not provide any other warranty,

either express or implied, and shall not be liable for any damages, including consequential damages.

Plan Drawings / Notes

AZEK Building Products

1330 W Fulton Market, Suite #350

Chicago, IL 60607

©2019 AZEK Building Products. All Rights Reserved. TimberTech.com.au

Table of contents

Other AZEK Fencing & Gate manuals

Popular Fencing & Gate manuals by other brands

RITE-HITE

RITE-HITE FLASHFOLD FLSFLD manual

Diversified Fall Protection

Diversified Fall Protection Swing Gate installation manual

WamBam

WamBam VF13007 Assembly instructions

PVC

PVC HF-SEMIP-DC install guide

Twoey Outside

Twoey Outside 2390 quick start guide

Orbinox

Orbinox RB Installation, operation and maintenance manual