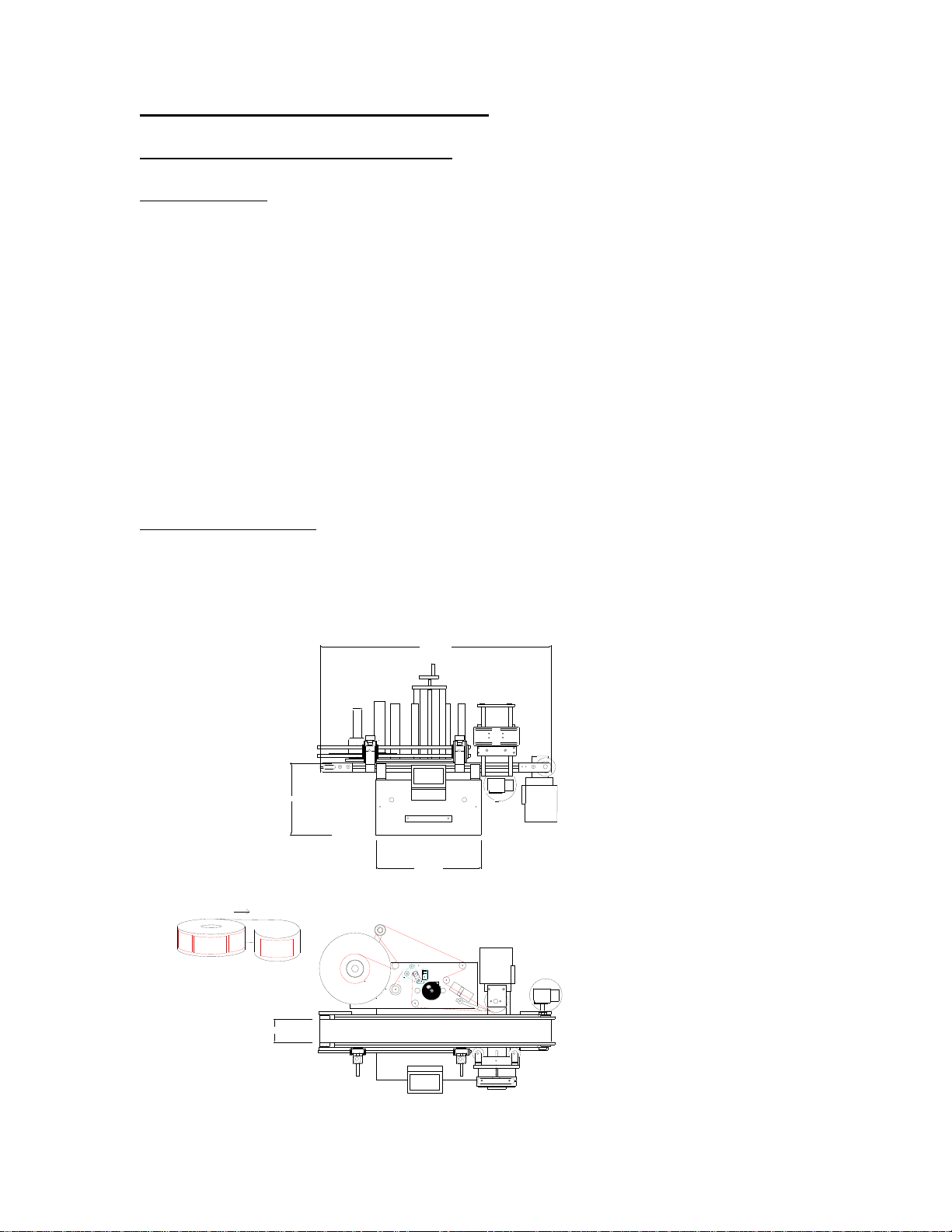

Guide Rollers –The guide rollers direct the path of the label movement around the label

head, it is very important that the correct path is threaded around the guide rollers to gain

the correct operation of the labeller. Label rings are fitted to the guide rollers to aid in the

tracking of the label head to give the operator a path to thread the label back at the correct

height. The label rings can be adjusted by sliding the up or down the roller.

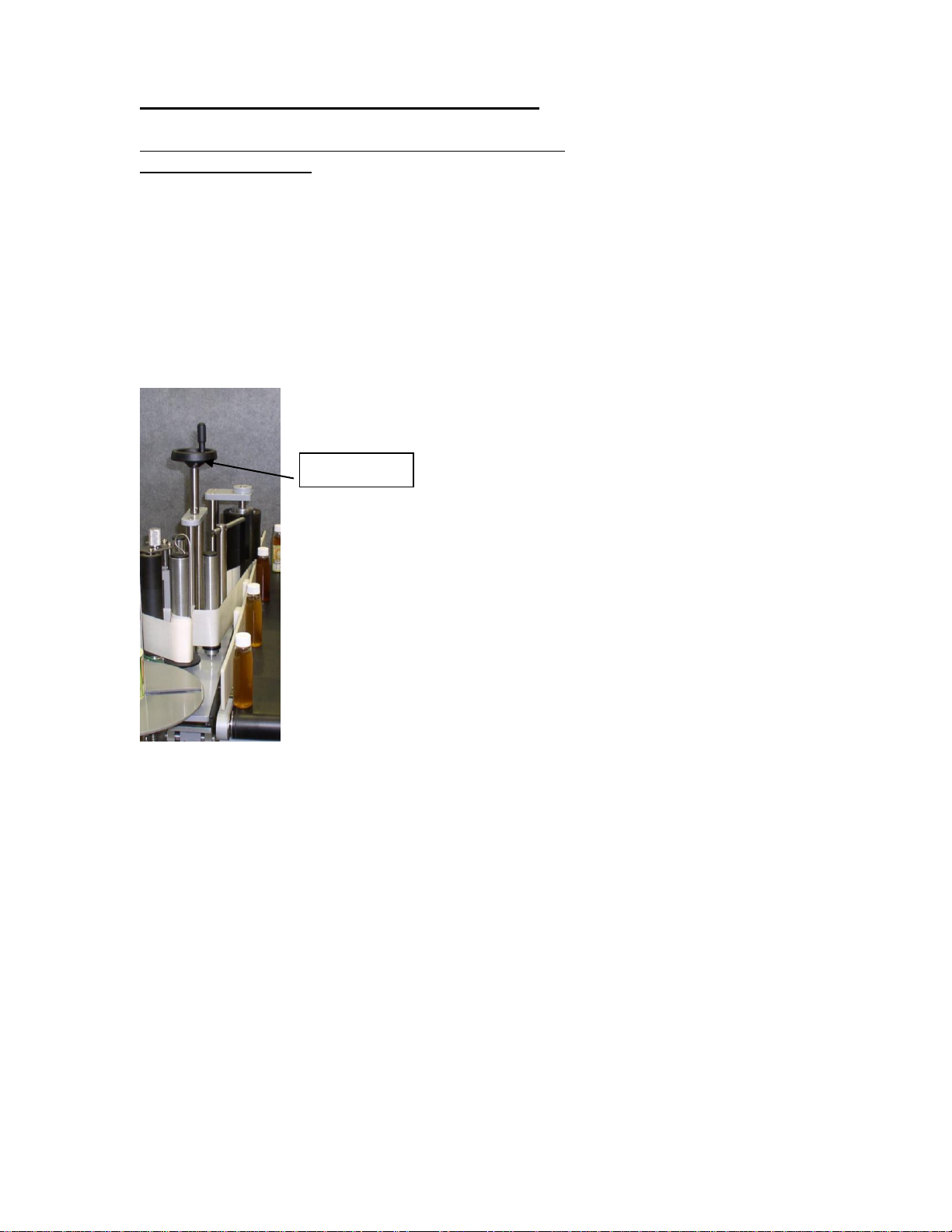

Label Gap Sensor –The Label Gap Sensor’s purpose is to end a labelling cycle. The

Label Gap Sensor is a fork sensor that has a beam of light that shines from an emitter to a

collector across the sensor. This beam of light is adjustable to control the sensitivity. The

sensitivity must be set to allow the sensor to only trigger when the label backing paper is

in the sensors eye. The sensor must not trigger on any part of the label. When the sensor

is triggered it sends a signal to the PLC (Programmable Logic Controller) to say stop

ejecting the label.

Refer to supplier instruction manual for set up explanation.

Fig. 8

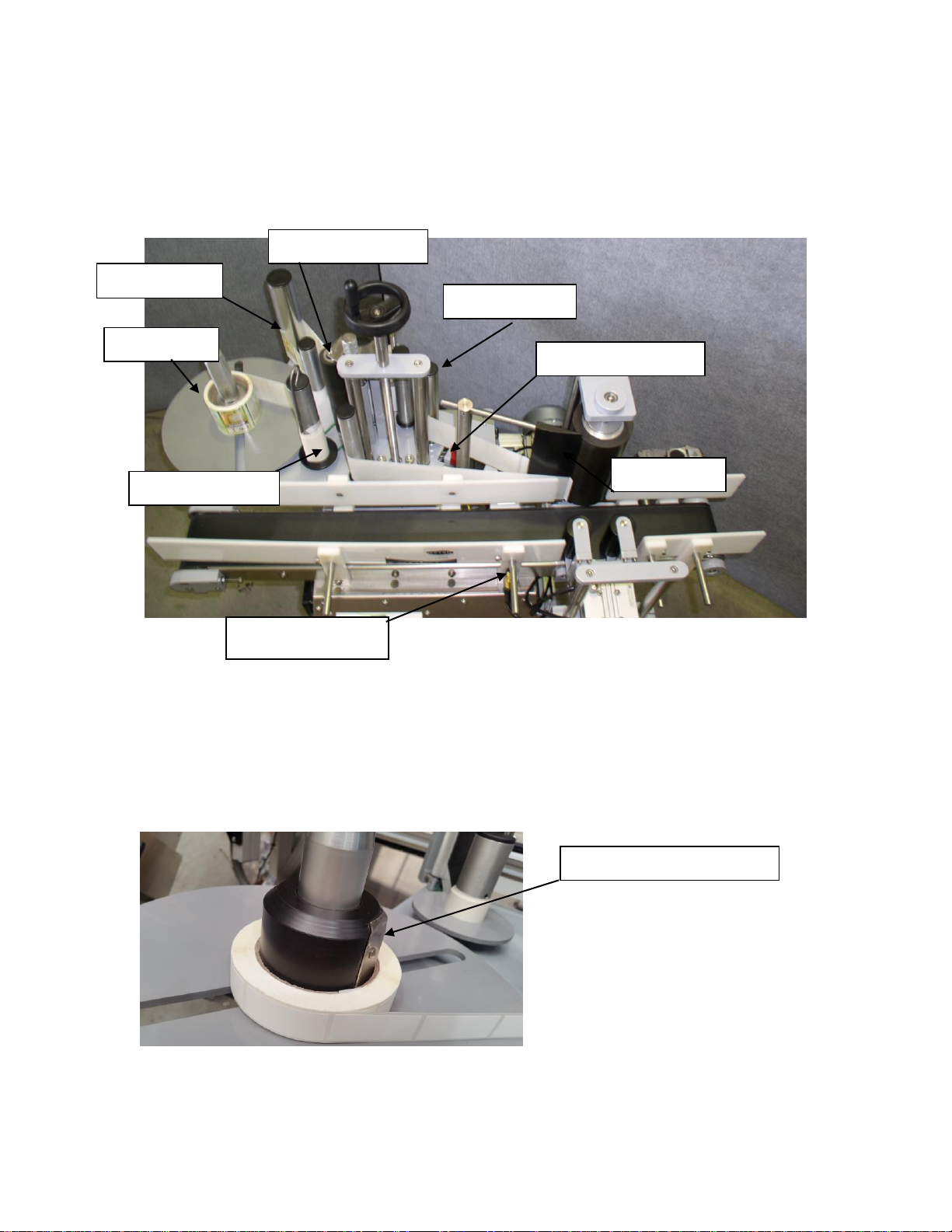

Label tension brush –The Label Tension Brush Assembly applies pressure to the label

surface to create some drag on the label to increase label web tension.

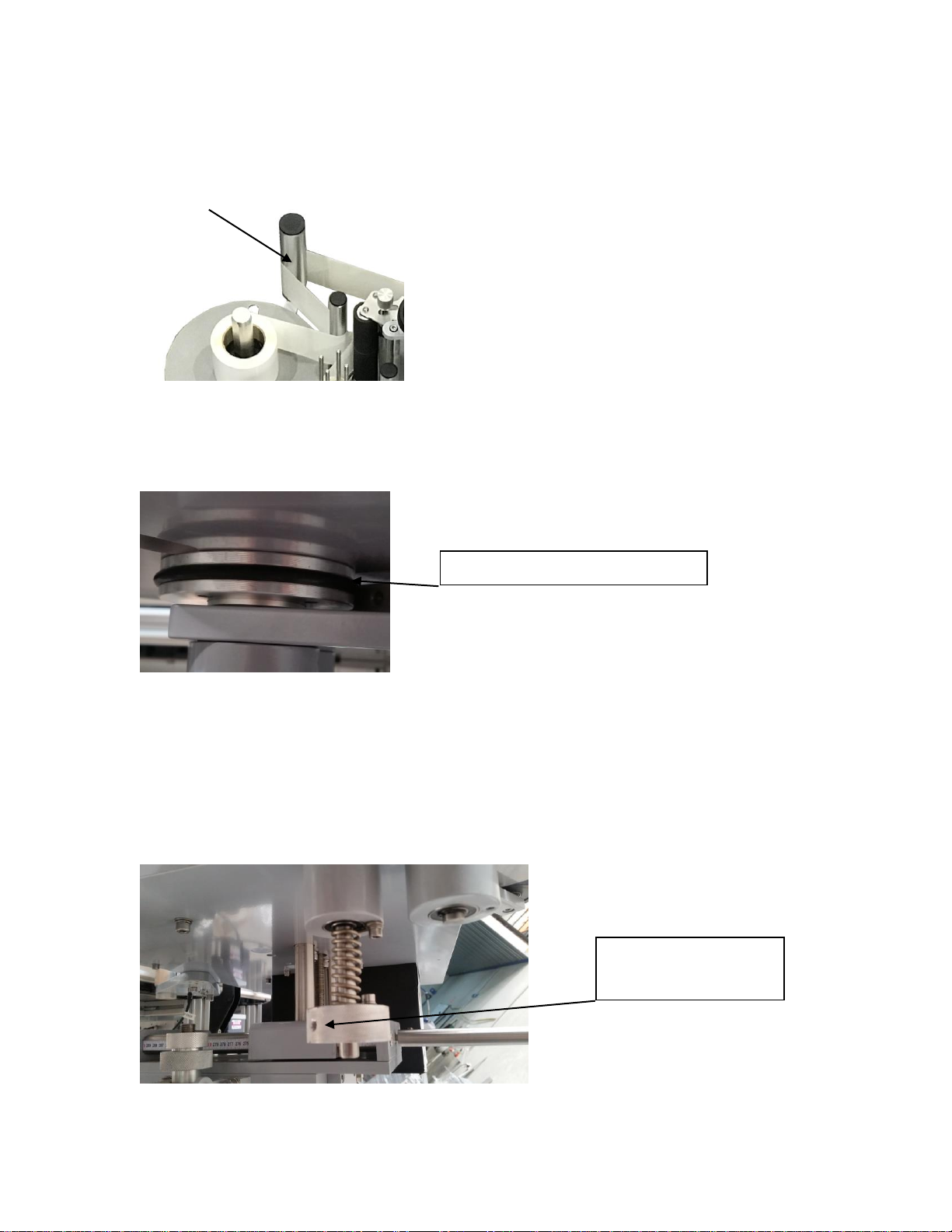

Peel Plate –The Peel Plate gives the labels a sharp edge to peel off the backing paper for

label application. The peel plate angle is adjustable. This is to get the label web tracking

correctly and it is important to achieve this before even applying a label to a product.

If the label web is tracking up, the peel plate must be tilted down to level out the label

web. If the label web is tracking down the peel plate must be tilted up. To adjust the peel

plate angle, follow the steps below.

•At the top of the mounting post for the peel plate bars there is a 6mm grubs crew.

There is also one at the bottom of the post. (DO NOT TOUCH THIS ONE)

•To change the angle of the peel plate, loosen the top grub screw.

•By sliding the peel plate bar left or right, the peel plate angle will change. Once

the desired position is obtained, re tighten the grub screw to hold the peel plate

bar into position.

If the label web is tracking correctly when just running labels out not onto a product and

there is a problem after application. The fault is not the label tracking. The likely causes

are passably the incorrect label ejection speed or that the product is not running square

and straight in the capture assembly.