2.2 Use

To reduce the risk of explosion, DO NOT use in paint spray booths or within 10ft of

spraying operations, as per the requirement of UL 499.

This unit must be operated in a well-ventilated area.

Isolate mains supply before removing any covers.

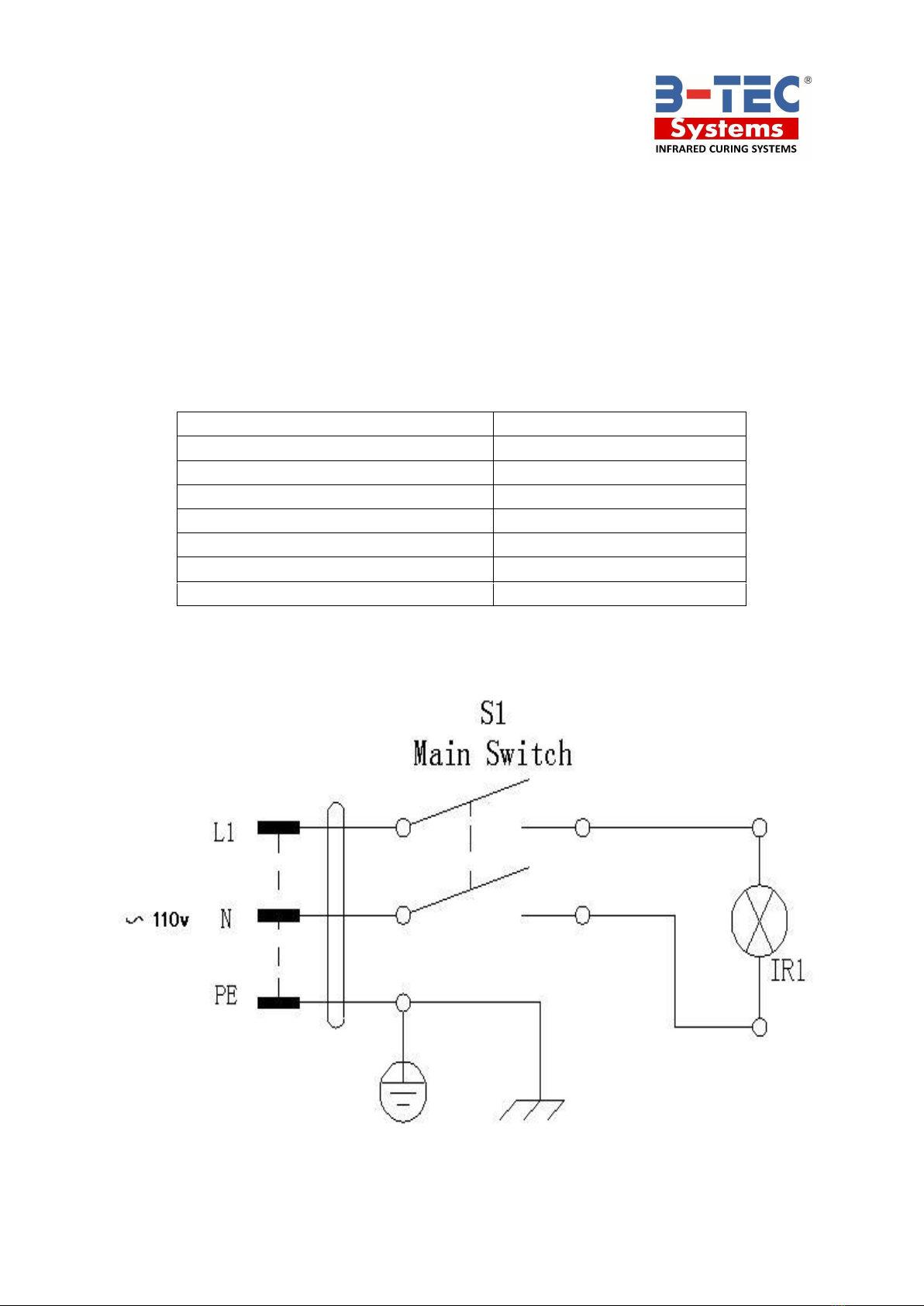

The machine should be well grounded for safety. The grounding device should be

connected to the proper output port under correct direction. Unauthorized alteration or

change of output port is strictly prohibited. Use of any outlet converter is also disallowed.

If you are ever uncertain, please find a professional electrician to check whether the

grounding is correct. Please make sure the machine is well grounded to avoid electric

shock.

If the lamp / tube fails to work after starting, it may be caused by a loosened outlet plug.

In such a case, just switch off the machine and check that plug is secure in the socket in

the connection box.

Replace any chaffed or damaged cables / wires immediately to avoid the possibility of

electric shock.

Don’t misuse the electric cable. Do not drag the machine with the power cable or pull the

power plug. Keep the power cable away from hot, oily or sharp objects.

Should the power cable become damaged, ask the manufacturer, service provider or a

professional to replace it to reduce the risk of injury / damage.

2.3 Maintenance and Care

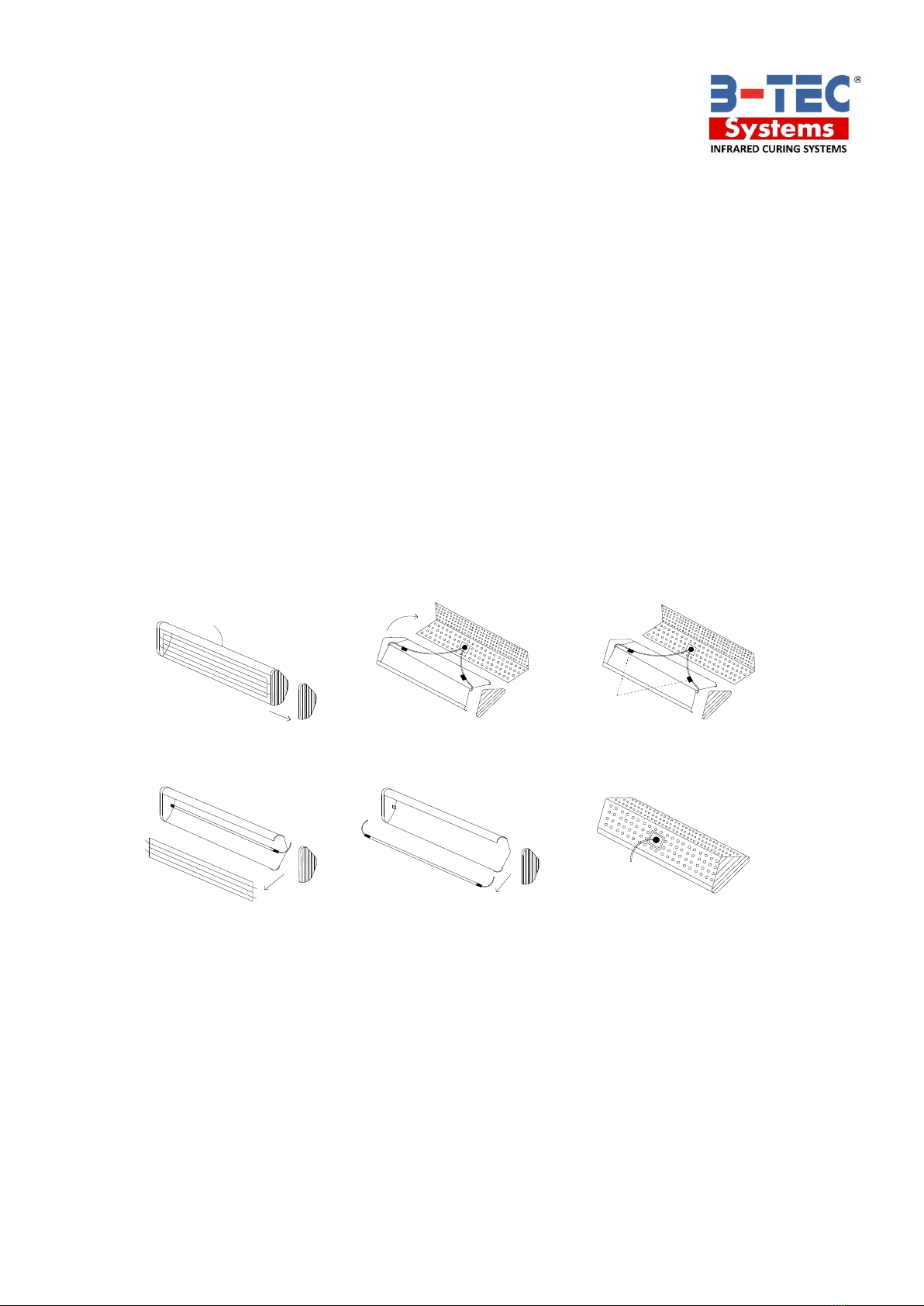

Regular cleaning of tubes and reflectors should be done by using a piece of soft cloth or

cotton with IPA, alcohol or mentholated spirits (Note: cleaning must only be conducted

after the machine is disconnected from the power supply and has cooled down if

necessary). Allow 15 minutes for the solvent to dissipate before switching the unit back

on.

The device should be protected by a 15-Amp-fuse.

For replacement lamps / tubes, contact your distributor.

2.4 More Information

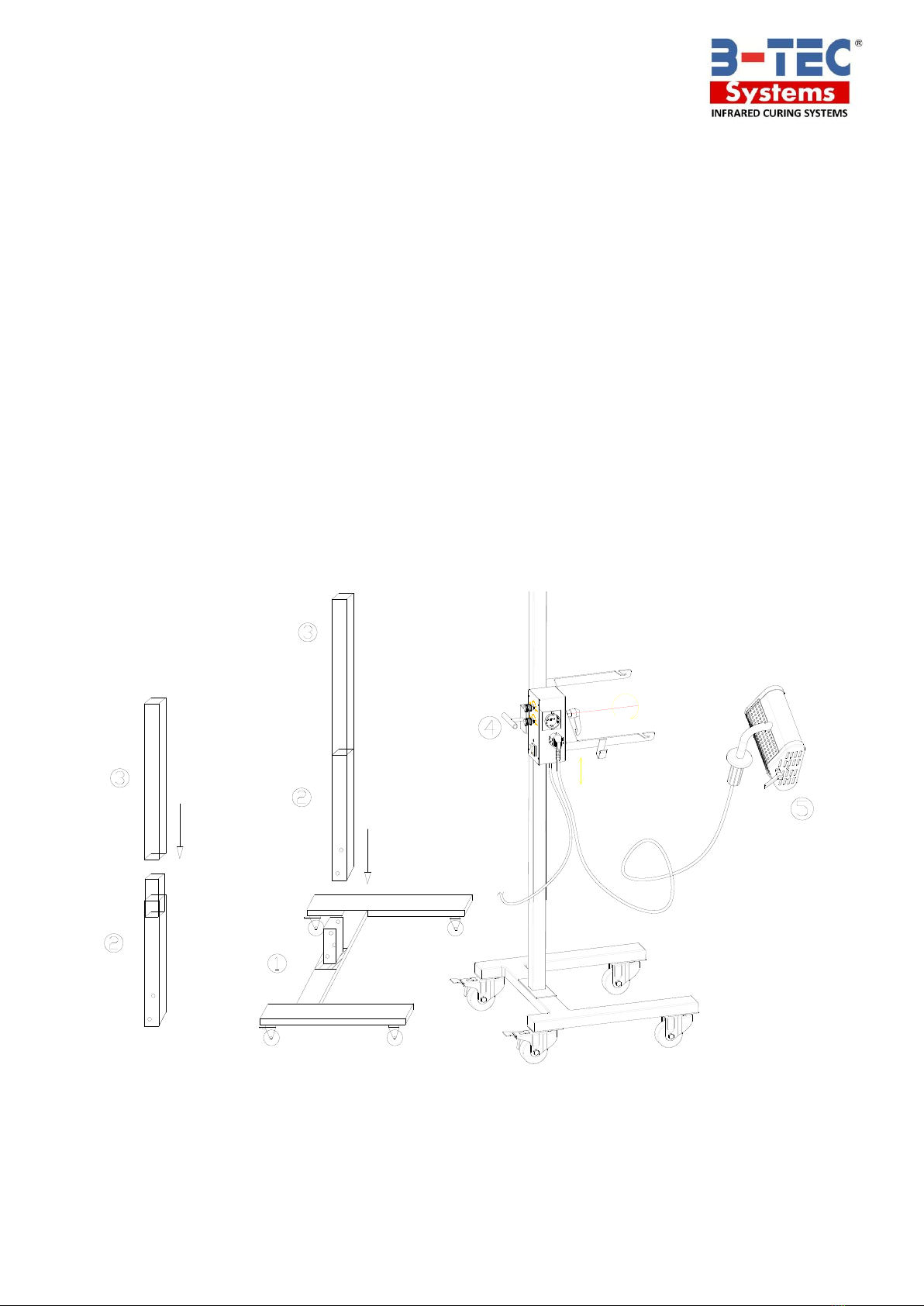

Always turn the unit off before moving, especially over rough surfaces.

Do not use the equipment in damp or wet locations.