2 - 65

Thread tension unit

Main unit

Disassembly

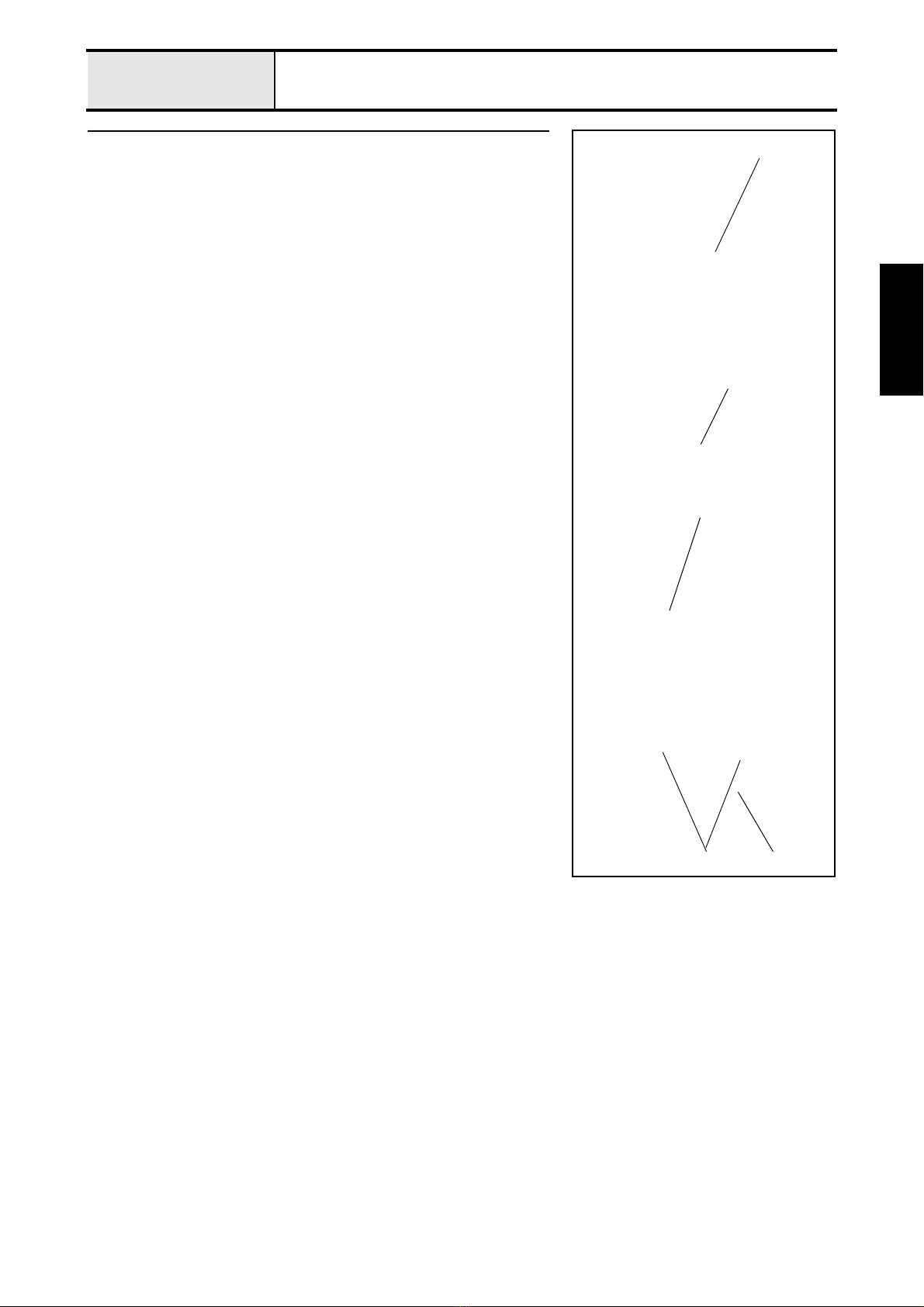

1 Loosen the tension nut removal

1. Loosen the tension nut 1, and then remove the washer 2, spring ,

tension disc presser 3, tension disc felt 4, rotary disc assembly 5, and

second tension disc felt 4. (6 locations)

NOTE

• The thread tension washer 6is inserted between the washer

2and the spring only for thread tension A.

A

1

6

2

3

4

5

4

S51

S51

S51

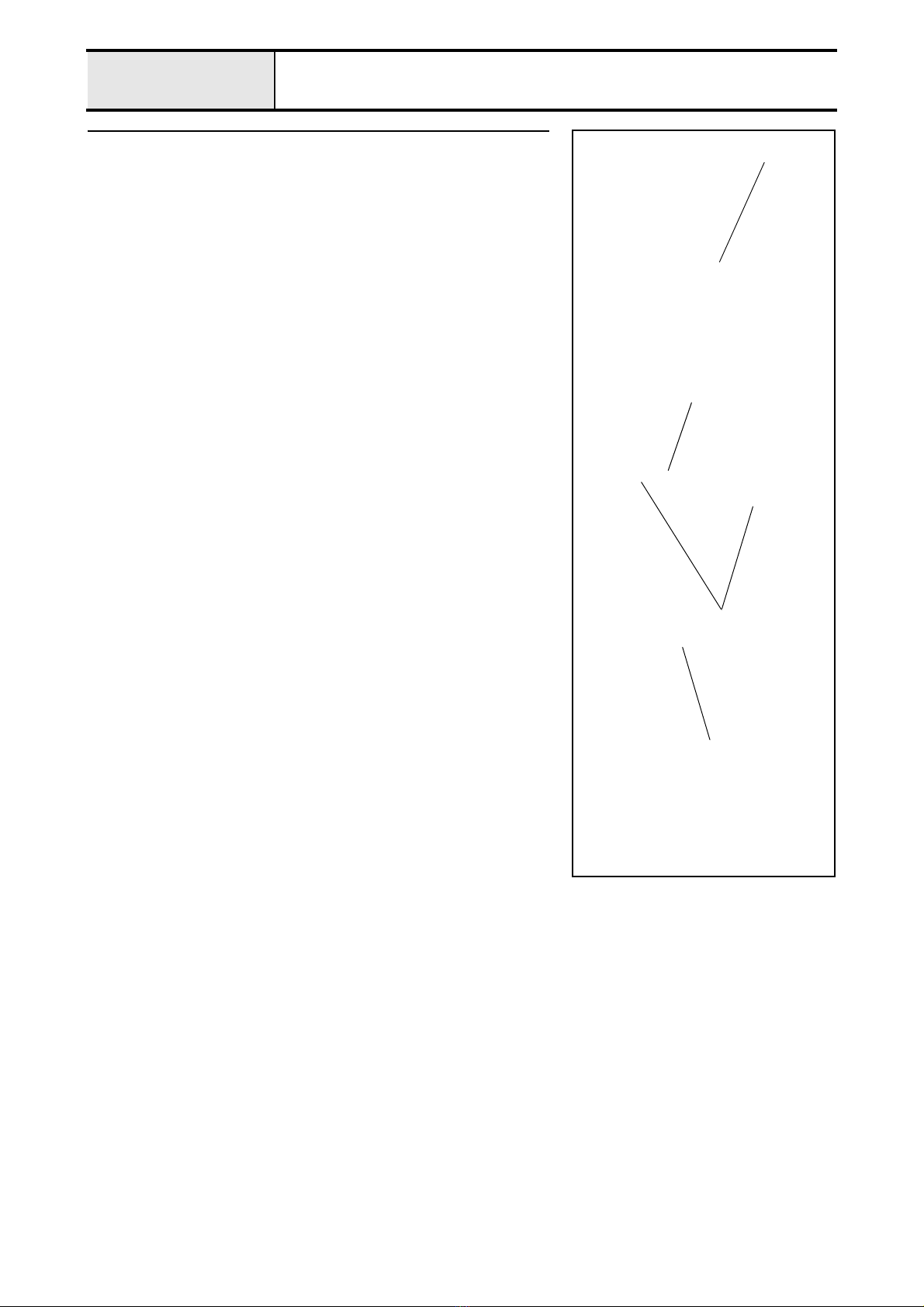

2 Tension base bracket removal

1. Remove the cord bush (KR51) 1from the tension base bracket, and then

remove the tension base lead wire assembly 2from the head PCB

assembly on the tension base.

2. Remove the screw 1, and then remove the head grounding wire.

3. Remove the 4 screws 2, and then remove the tension base bracket.

4. Remove the 2 screws 3, and then remove the bracket cover from the

tension base bracket.

1

21

2

3

2

2

Inspect to make sure that all parts are lint-free

and clean.