Electrical connections

The units are delivered with a number of electrical components that need to be connected after rigging.For all

electrical components, please refer to the specific wiring diagrams in the submittal package.

Connecting pipework

All piping external to BAC cooling equipment must be supported separately.

In case the equipment is installed on vibration rails or springs, the piping must contain compensators to eliminate

vibrations carried through the external pipework.

The equipment outlet piping must be installed under the operating level of the equipment to prevent air suction and

pump cavitation.

Suction pipe sizing should be done according to good practice, which may for larger flows require larger pipe

diameters than the outlet connection. In such cases adapter pieces need to be installed.

Freeze protection

These products must be protected against damage and/or reduced effectiveness due to possible freeze-up by

mechanical and operational methods. Please contact your local BAC Balticare representative for recommended

protection alternatives.

Bleed Line Installation

On all open cooling towers, install a bleed line with valve between the system circulating pump discharge riser and

a convenient drain. Locate the bleed line in a portion of the riser piping that drains when the pump is off.

The bleed valve should always be open when the unit is in operation, unless the bleed rate is automatically

controlled by a water treatment system.

Safety Precautions

All electrical, mechanical and rotating machinery constitutes a potential hazard, particularly for those not familiar

with its design, construction and operation. Accordingly, adequate safeguards (including use of protective

enclosures where necessary) should be taken with this equipment both to safeguard the public (including minors)

from injury and to prevent damage to the equipment, its associated system and the premises.

If there is doubt about safe and proper rigging, installation, operation or maintenance procedures, contact the

equipment manufacturer or his representative for advice.

When working on operating equipment, be aware that some parts may have an elevated temperature. Any

operations on elevated level have to be executed with extra care to prevent accidents.

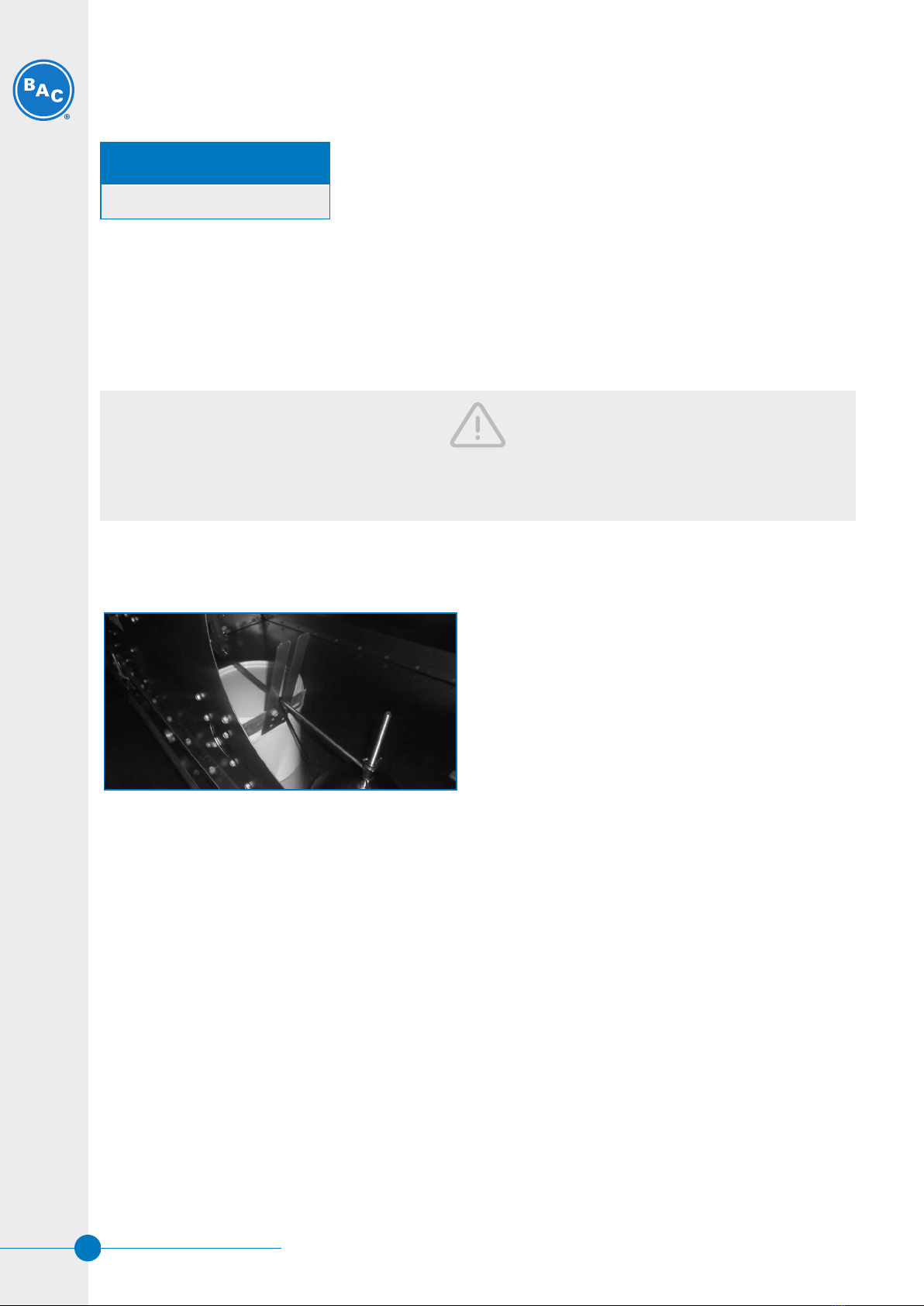

AUTHORIZED PERSONNEL

The operation, maintenance and repair of this equipment should be undertaken only by personnel authorized and

qualified to do so. All such personnel should be thoroughly familiar with the equipment, the associated systems

and controls and the procedures set forth in this and other relevant manuals. Proper care, personal protective

equipment, procedures and tools must be used in handling, lifting, installing, operating, maintaining and repairing

this equipment to prevent personal injury and/or property damage. Personnel must use personal protective

equipment where necessary (gloves, ear plugs, etc...)

W W W . B A L T I M O R E A I R C O I L . E U

8