INTRODUCTION

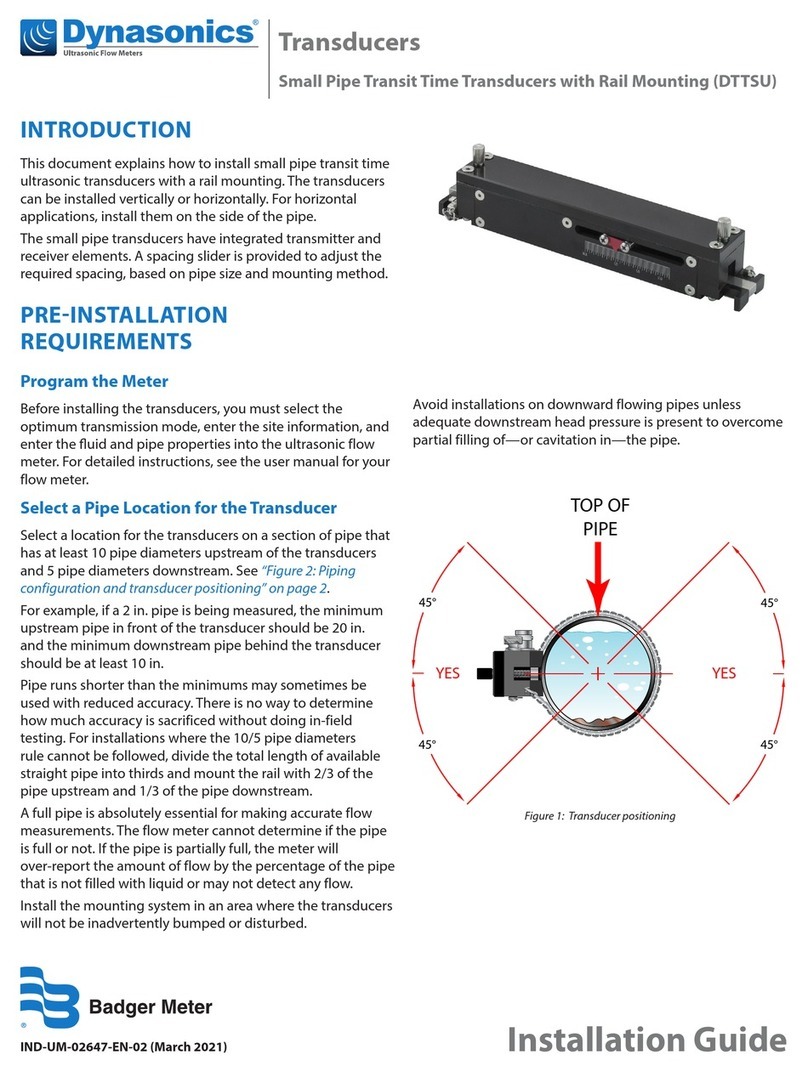

This document explains how to install small pipe transit time

ultrasonic integral transducers and transducers with remote

mounting. The transducers can be installed vertically

or horizontally.

The transducers have integrated transmitter and receiver

elements that eliminate the requirement for spacing

measurement and alignment.

PREINSTALLATION

REQUIREMENTS

Program the Meter

Before the flow meter will be operational, you must select the

optimum transmission mode, enter the site information, and

enter the uid and pipe properties into the ultrasonic flow

meter. For detailed instructions, see the user manual for your

flow meter.

Select a Pipe Location for the Transducers

Select a location for the transducers on a section of pipe that

has at least 10 pipe diameters upstream of the transducers

and 5 pipe diameters downstream. See “Figure 2: Piping

configuration and transducer positioning” on page2.

For example, if a 2 in. pipe is being measured, the minimum

upstream pipe in front of the transducer should be 20 in.

and the minimum downstream pipe behind the transducer

should be at least 10 in.

Pipe runs shorter than the minimums may sometimes be

used with reduced accuracy. There is no way to determine

how much accuracy is sacrificed without doing

in-field testing.

For installations where the 10/5 pipe diameters rule cannot

be followed, divide the total length of available straight pipe

into thirds and mount the rail with 2/3 of the pipe upstream

and 1/3 of the pipe downstream.

A full pipe is absolutely essential for making accurate flow

measurements. The flow meter cannot determine if the pipe

is full or not. If the pipe is partially full, the meter will

over-report the amount of flow by the percentage of the pipe

that is not filled with liquid or may not detect any flow.

Install the mounting system in an area where the transducers

will not be inadvertently bumped or disturbed.

Avoid installations on downward flowing pipes unless

adequate downstream head pressure is present to overcome

partial filling of—or cavitation in—the pipe.

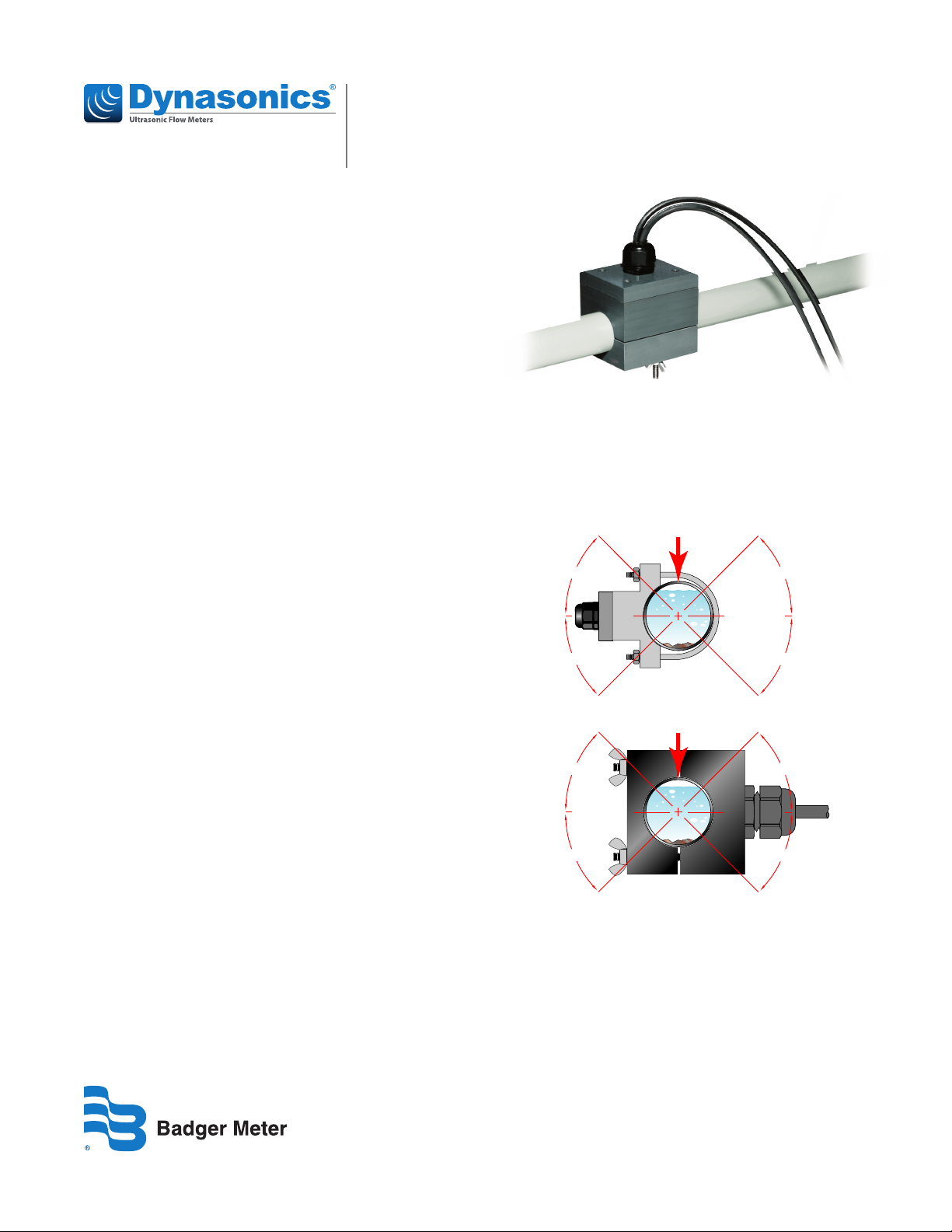

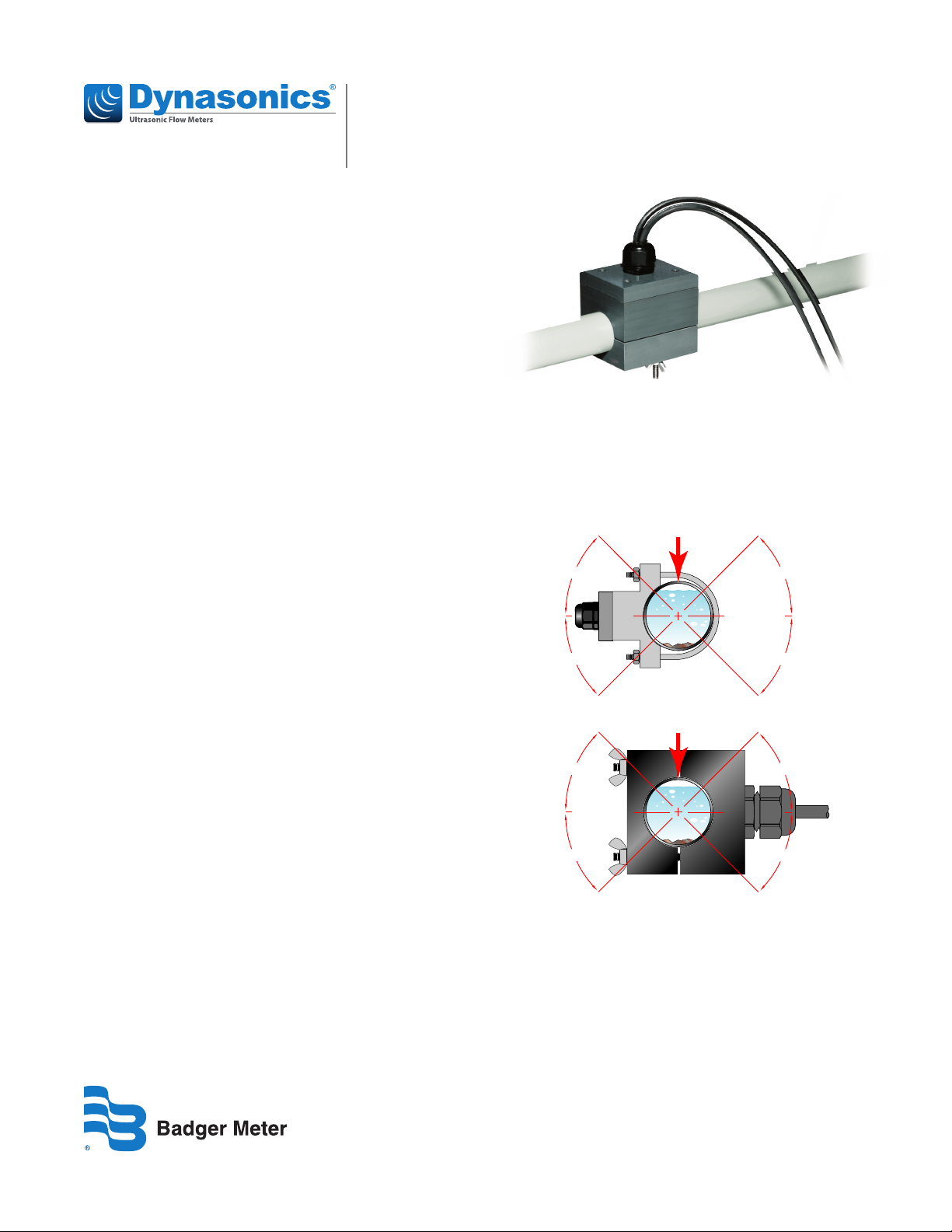

YES

45°

45°

YES

45°

45°

Top of

Pipe

45°

45°

YES

YES

45°

45°

Top of

Pipe

U-Bolt

Figure 1: Transducer positioning

Transducers

Small Pipe, Fixed Size Transit Time Ultrasonic Transducers

IND-UM-02649-EN-05 (March 2021) Installation Guide