-2- BE1127 Barrel Vise

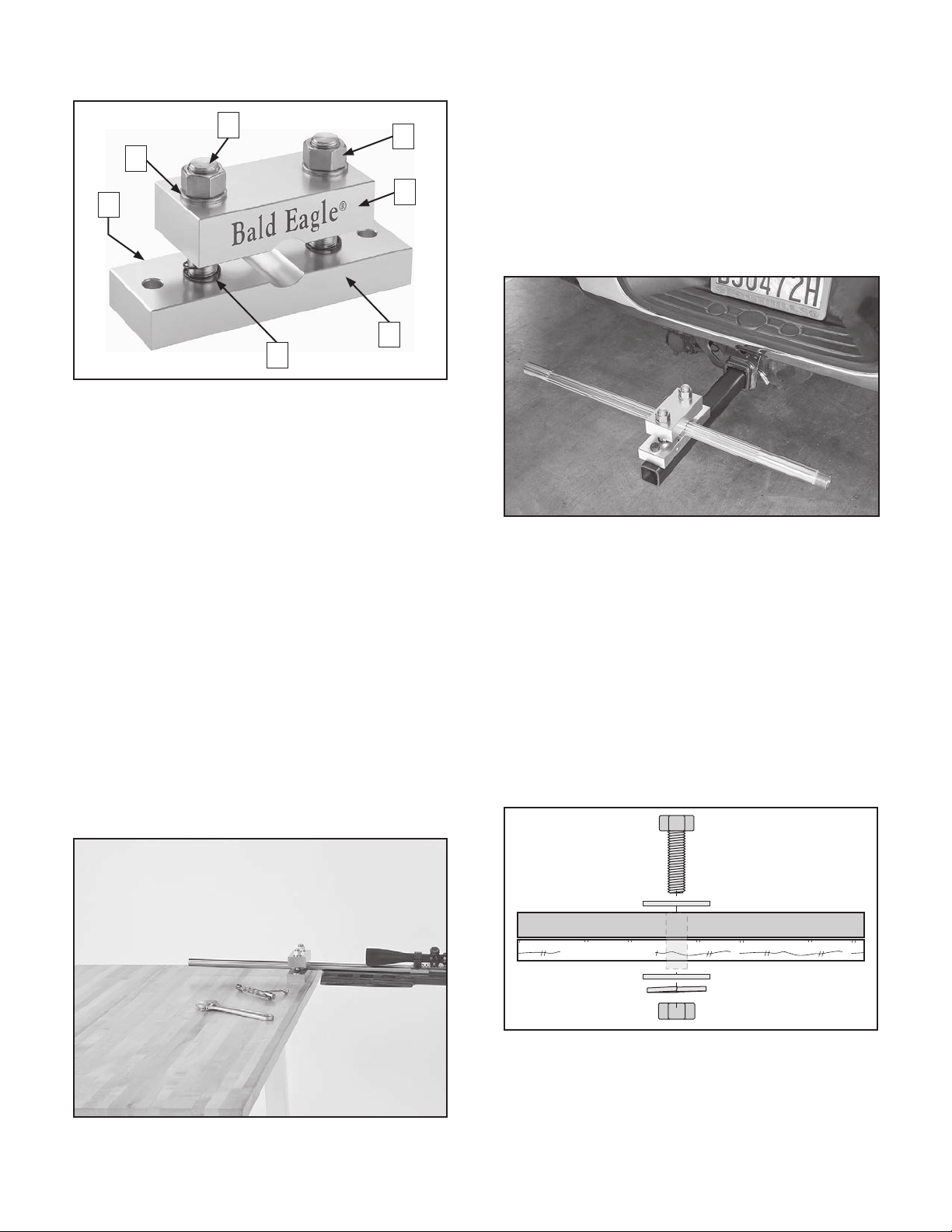

Mount the vise flush with or slightly overhang-

ing the surface edge, as shown in Figures 2–3.

Ensure there is enough clearance to slide the bar-

rel in as close to the action as possible and still do

any service work on the barrel. Additionally, main-

tain enough clearance to rotate an action wrench

and stock when assembling/disassembling the

barrel from the firearm. Mount the vise using one

of the two fastener configurations below.

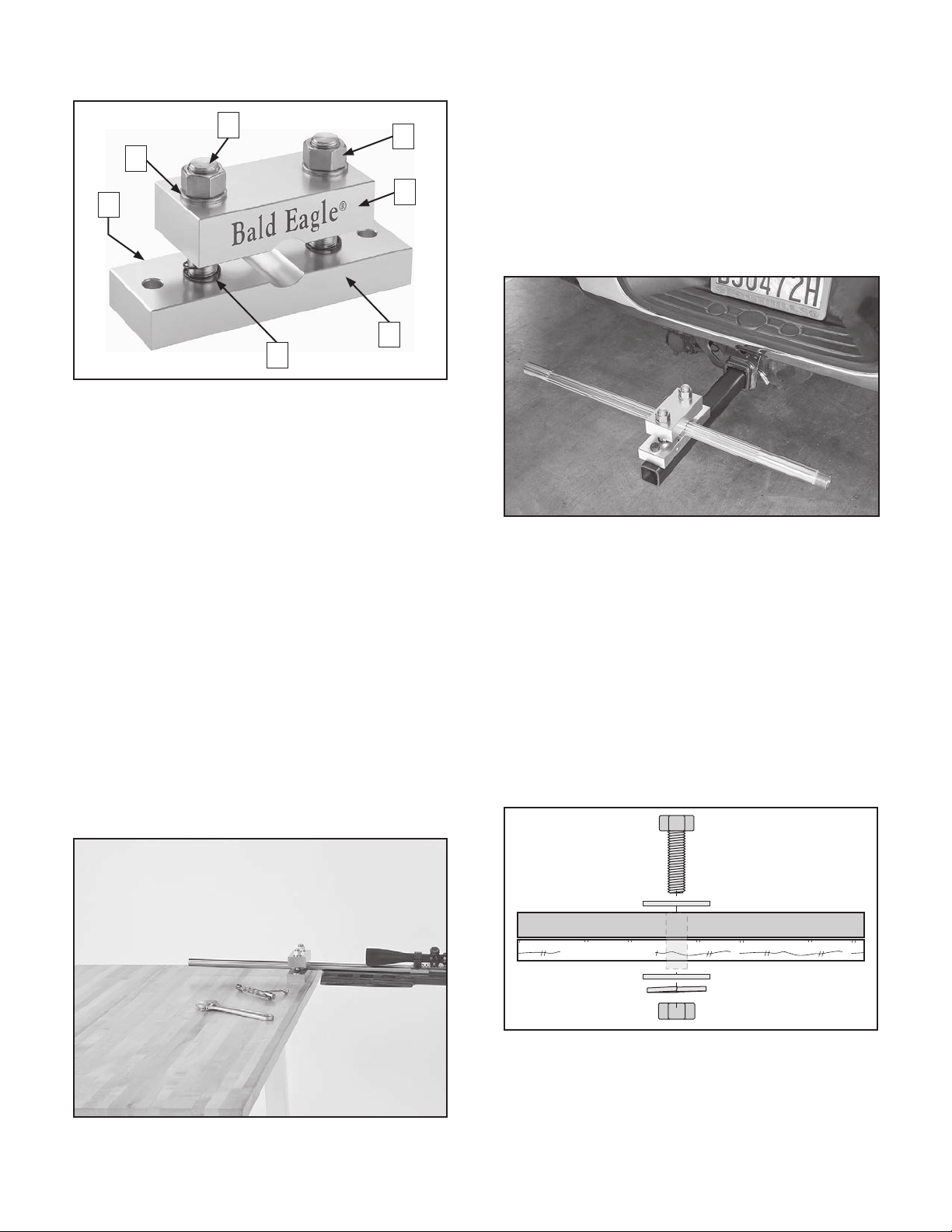

Figure 3. Mounting on a trailer hitch.

The base of this vise has mounting holes that

allow it to be fastened to a workbench or other

mounting surface. This prevents the vise from

moving during barrel removal and causing acci-

dental injury or damage to the firearm.

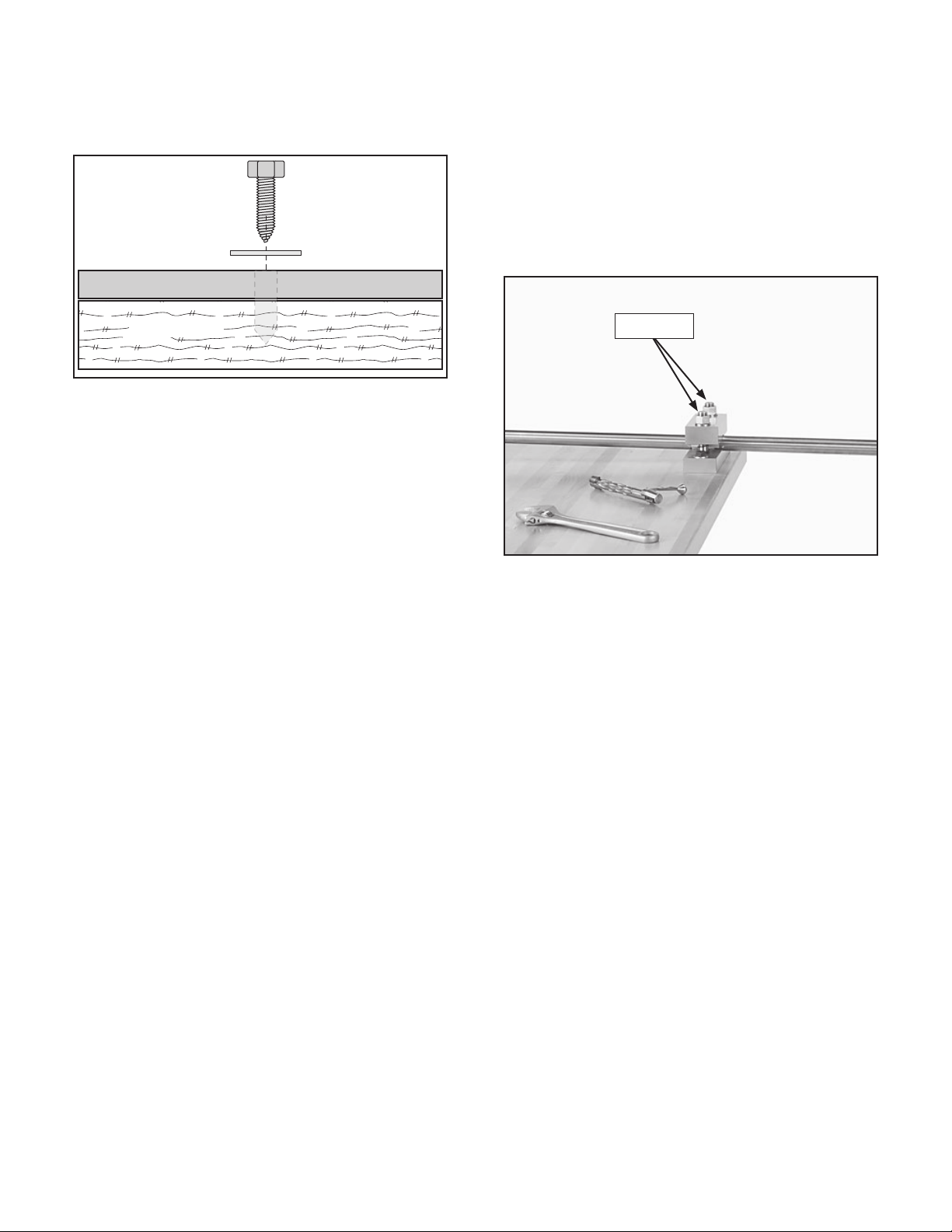

Vise Base

Workbench

Hex

Bolt

Flat Washer

Flat Washer

Lock Washer

Hex Nut

Figure 4. Example of a "Through Mount."

The strongest mounting option is a "Through

Mount" (see Figure 4) where holes are drilled all

the way through the workbench—and 7⁄16" hex

bolts, washers, and hex nuts are used to secure

the vise in place.

Mounting Vise

Select a mounting location that will not slide or tip,

such as a workbench or a trailer hitch (for mobile

applications). When using a smaller or lightweight

workbench, mount the vise considering the thread

direction of the barrel. Greater force is required

to remove barrels. For instance if the barrel is

right-threaded, mount the barrel on the right hand

side to prevent the workbench from tipping when

removing the barrel (see Figure 2).

Figure 2. Mounting on a workbench.

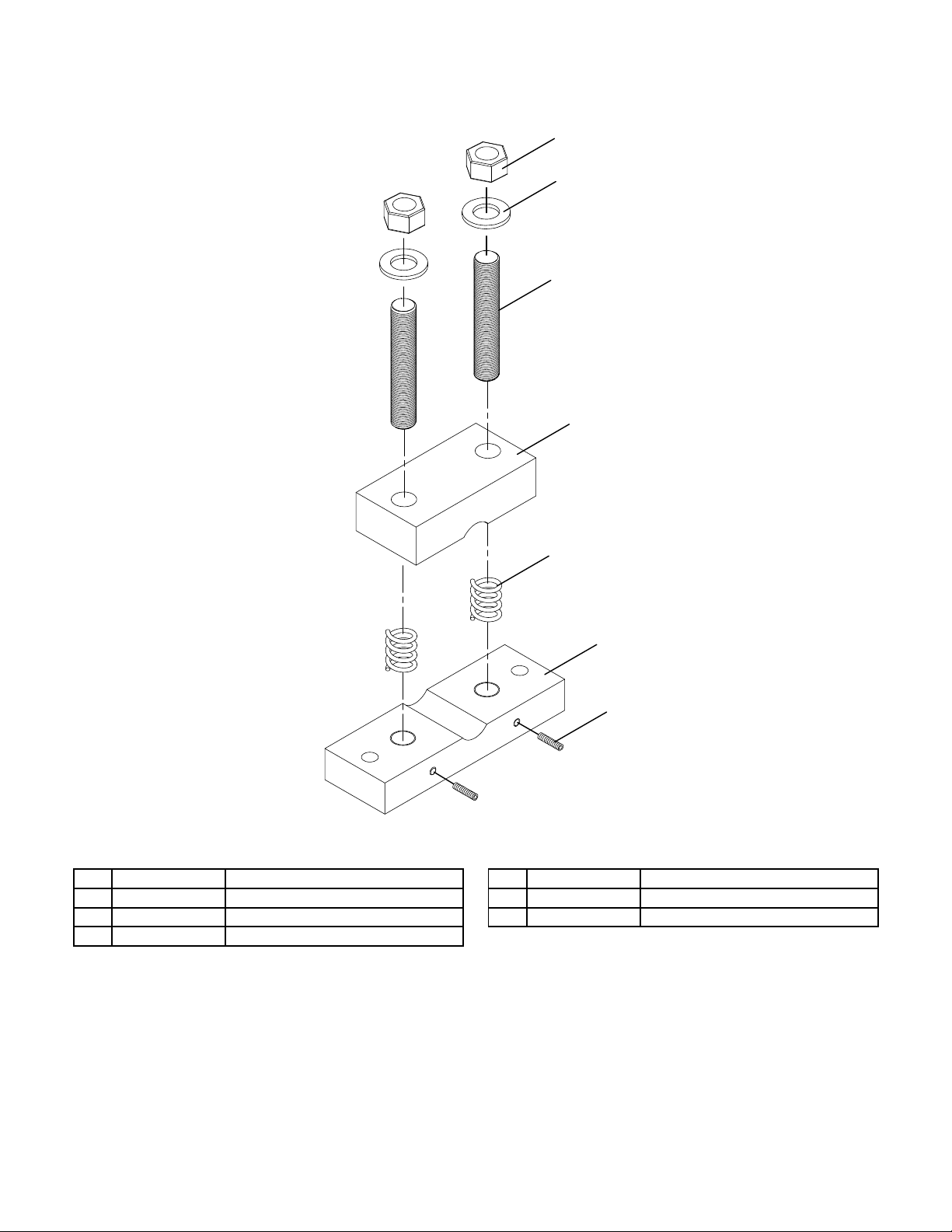

Description Qty

A. Set Screws 1⁄4-20 x 7⁄8................................ 2

B. Flat Washers 3⁄4.......................................... 2

C. Studs

3⁄4-16 x 4 ........................................... 2

D. Hex Nuts 3⁄4................................................ 2

E. Vise Body (Top) ......................................... 1

F. Vise Body (Bottom) .................................... 1

G. Compression Springs................................. 2

Figure 1. BE1127 Barrel Vise components.

B

C

F

A

G

D

E

Inventory