HYDRAULIC OIL RECYCLERS

3

SERVICING

A. When To Replace

The DAHL unit will shut off when the restriction of the filters

causes the pump to produce a predetermined suction. The

water-absorbing cartridge should be changed at this point.

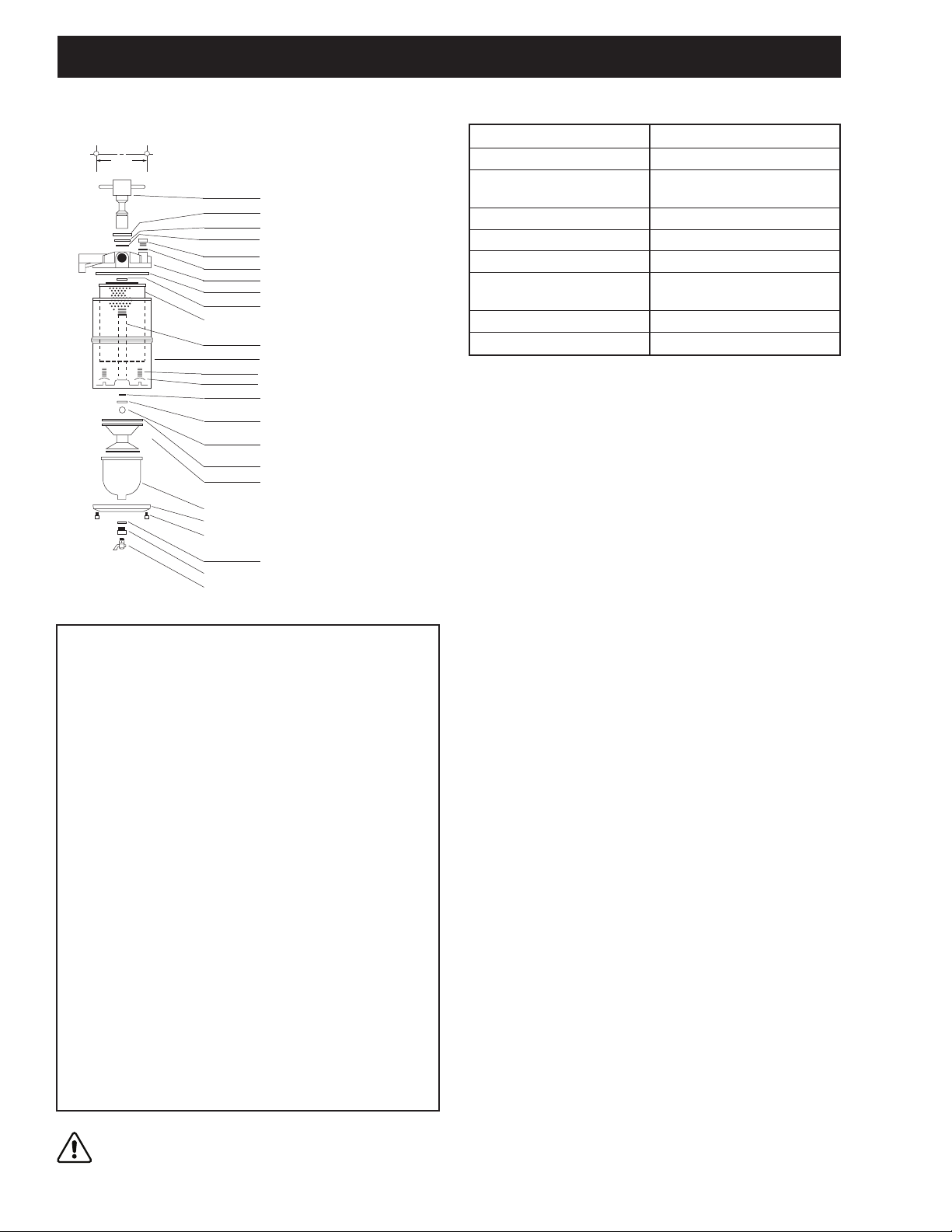

B. How To Replace Water-Absorbing Cartridge

1. Turn on the override switch and check the vacuum reading.

Note the vacuum rating. Turn the unit off.

NOTE: If the hydraulic oil tank is above the DAHL unit, close the

shut-off valves or disconnect the DAHL unit to prevent oil

from flowing out of the DAHL body when disassembling.

2. Drain the body by opening the draincock. It may be necessary to

open the primer plug slightly to allow air to flow into the body.

Drain only enough oil to allow easier handling of the filter body.

3. Close the draincock and primer plug.

4. Loosen the T-Bolt handle to release the filter body from the lid.

(It is not necessary to completely remove the T-Bolt from the

wAteR-AbsoRbing cARtRiDge ReplAcement _____________________________

A. When To Replace

The synthetic element is a secondary filter and should not

become plugged as quickly as the water-absorbing cartridge.

The actual life will be dependent upon the filtering conditions.

B. How To Replace Synthetic Cartridge

1. Drain the body by opening the draincock. It may be necessary

to open the primer plug slightly to allow air to flow into the

body. Drain only enough oil to allow easier handling of the filter

body.

2. Close the draincock and primer plug.

3. Loosen the T-Bolt handle to release the filter body from the lid.

(It is not necessary to completely remove the T-Bolt from the

DAHL filter lids.) Support the filter body with your hand prior

to release.

synthetic cARtRiDge ReplAcement____________________________________

4. Remove the cartridge with a turning motion.

5. Inspect the ejector spring(s) at the bottom of the body. Also

check the centerpipe O-Ring and replace if hard or damaged.

6. Remove and replace the lid cover gasket. Be sure the lid groove

and body lip are clean. (Grease the lid cover gasket before

positioning.)

C. Reassembly

1. Lubricate the top and bottom cartridge gaskets. Install the

cartridge onto the centerpipe with a turning motion.

2. Fill the filter body with clean oil to within one inch of the

top.

3. Double check the lid cover gasket position in the lid groove.

4. Attach the body to the lid and hand tighten the T-Bolt handle.

5. Start unit and check for leaks.

DAHL filter lids.) Support the filter body with your hand prior

to release.

5. Remove the cartridge with a turning motion.

6. Inspect the ejector spring(s) at the bottom of the body. Also

check the centerpipe O-Ring and replace if hard or damaged.

7. Remove and replace the lid cover gasket. Be sure the lid groove

and body lip are clean. (Grease the lid cover gasket before

positioning.)

C. Reassembly

1. Lubricate the top and bottom cartridge gaskets. Install the

cartridge onto the centerpipe with a turning motion.

2. Fill the filter body with clean oil to within one inch of the

top.

3. Double check the lid cover gasket position in the lid groove.

4. Attach the body to the lid and hand tighten the T-Bolt handle.

5. Start unit and check for leaks.

Poor performance of the recycler or blender units is usually caused

by one or more of the following:

A. Air Leaks

1. Fittings. Insure the O-Rings on the fittings in the DAHL

filter ports are lubricated and not damaged, cracked or dirty.

NOTE: When using JIC 37° fittings, be sure only mating JIC

37° fittings are used. Misalignment will occur and air

leakage will result from an attempt to fasten a SAE 45°

fitting to a JIC 37° fitting. Check for fitting looseness,

seat dents, misalignment or unmatched threads. All

fittings must be wrench tight.

2. Bubbles In The Bowl. If bubbles appear at the depressurizer

cone, a leak is indicated between the tank and the inlet port.

NOTE: Old lines (rubber hose or metal tubing) may crack

when moved. Check areas around push-on fittings, pipe

adapters, hose clamps, etc. If air bubbles appear at the

draincock, check for particles stuck in the valve seat

or a partly open draincock. Also check for defective,

miscentered or unlubricated bowl gaskets. Check the

bowl plug O-Ring to make sure it is not cracked or

extruded out of place. The bowl plug should be hand

tightened only.

3. Gaskets. If the lid or bowl has been removed, make sure

the gasket grooves are clean. Inspect the gaskets for proper

seating in the grooves. Lubricate the gasket(s) with oil or

grease.

B. Clogging and Restriction

1.

Lines. Check for collapsed lines caused by sharp bends or

excessive turns. Check the tank and/or filter shut-off valve(s).

2. Filter Elements. Early clogging can occur from badly

contaminated fuel or oil (micro-organism growth, rust,

sludge, dirt, etc). Always carry a spare DAHL element.

Asphaltinic materials (fuel oxidation products), which are

normally harmless to the injection system, can eventually

plug original equipment filters remaining in the fuel system.

If problems persist after the DAHL element has been

replaced, also replace the other fuel filter elements.

3. Filter Inlet. Severely contaminated fluids may cause inlet

plugging. In this event, close the tank supply shut-off valve

(if equipped) and disconnect the inlet line. Remove the bowl

and clean the inlet. Should the depressurizer cone also be

plugged, disassemble and clean out.

4. Bleed Back. If fuel in the DAHL filter bleeds back to

the fuel tank, an air leak or reverse flow valve problem is

indicated. Inspect lines and fittings first as indicated above.

If the reverse flow valve is clogged, use air or clean fluid to

flush out.

C. Motorized Pump Malfunction

Danger! Electric Shock Hazard. Only qualified

personnel should test or repair defective components.

1. Check the power source and on-off toggle switch for

operation.

2. On water-activated automatic shut-off models, drain the

water or select the override position on the switch.

D. Water Sensor Light Malfunction

NOTE: This is a 12 Volt DC low voltage system. There is no

danger of electrocution from the probes at the clear bowl

even though the current is switched on.

1. With the unit on, test the light by temporarily attaching a test

wire across the two probes at the clear bowl.

2. If the water level is above the probes and the light still does

not work, refer to PROBE CLEANING section.

TROUBLESHOOTING

!