TURBISWITCHGS5

Turbidity Limit Value Evaluation Unit

Evaluation Unit Measuring cells (in-line installation) Immersion Probes

SAFETY PRECAUTIONS

• Installation, initial start-up and maintenance may only be performed by trained personnel!

• The device may only be connected to supply power which complies with the specifications in the technical data and on the serial plate!

• The device must be disconnected from all sources of power during installation and maintenance work!

• The device may only be operated under the conditions specified in the operating instructions!

DESCRIPTION

The TURBISWITCHGS5 evaluation unit in conjunction with the associated transducers is an optical turbidity measurement for determining

the solid content in a liquid medium.

The turbidity signal is read out as an adjustable limit value via the evaluation unit.

The turbidity measurement is based on the optical absorption method, i.e. it reacts to light loss due to undissolved solids in the medium. Due to

clocked infrared light, the measurement is insensitive to external light.

If the measured turbidity value is exceeding or below the trigger point value, the output relay in the TURBISWITCHGS5 is actuated in

accordance with the settings.

Attention: Operation of the transducers of the TRUBOMAT series (TT-GS, TR-GS and CP1) at the evaluation unit

TURBISWITCHGS5 is not possible!

TECHNICAL DATA

Supply power 100...240VAC / 50...60Hz (TURBISWITCH GS5G) or

10...30VDC and 12...24VAC (TURBISWITCHGS5D)

Power consumption 1...5W

Ambient temperature -10...+45°C

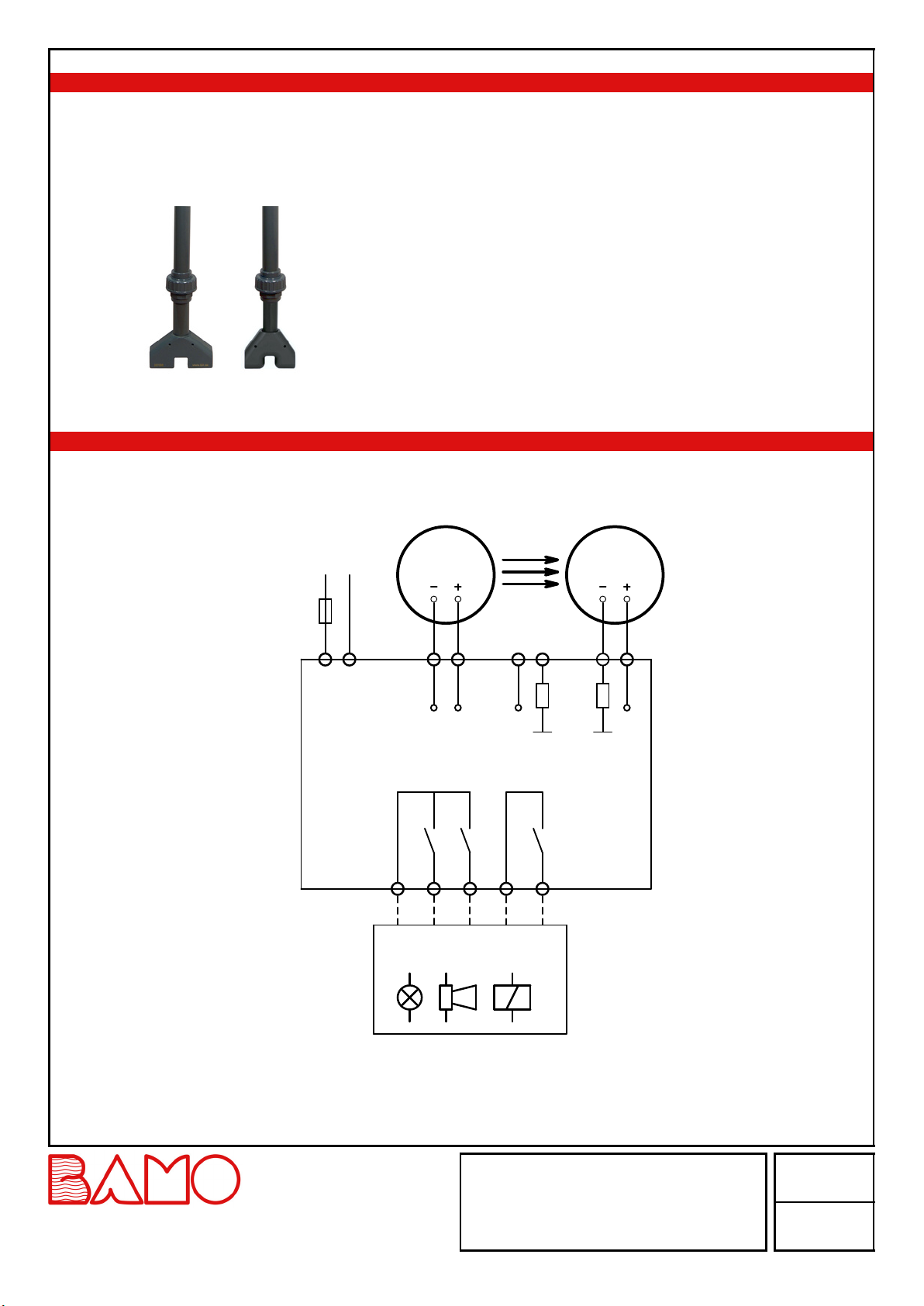

Output relays 2x potential free limit value contact (normally open)

(turbidity value is exceeding or below the trigger point value)

1 x potential free fault contact (normally open)

All contacts are open when supply power is switched off!

Output relay switching capacity 250VAC, 3A / 30VDC, 1A

Note: Contacts are not protected against overload! Use external protective device!

Housing dimensions 22.5x100x122mm

Top-hat rail dimensions 35x7.5mm (DINEN60715)

Protection IP40

Connector terminals Screw terminals, max. 1.5mm²

Limit value 0…100% within 3 measuring ranges (depending on the solid content)

LOW (5% steps); MEDIUM (2% steps); HIGH (1% steps)

Reset hysteresis Adjustable 1…25% of the selected limit value

Cable length Max. 100m between sensor and evaluation unit

Display 2½-place LED, 5x7 pixel matrix display

Settings Rotary/pushbutton selector on front panel

Switching delay Adjustable 0.1…9.9seconds

CE Mark: The device fulfills the legal requirements of applicable EU-guidelines.

TUR

19-08-2021 M-410.03-EN-AA 410-03/1

Turbidity Limit Value

Evaluation Unit

TURBISWITCHGS5

22, Rue de la Voie des Bans · Z.I. de la gare · 95100 ARGENTEUIL

Tel

Fax

+33 (0)1 30 25 83 20

+33 (0)1 34 10 16 05

Web

E-mail

www.bamo.eu

INTERNATIONAL