Dry-Mate Dry Disconnects 3

INSTALLATION

When installing the couplers, use a good quality thread sealant compatible with the liquid being used in the system. Screw the coupler

onto the thread hand tight; using a wrench, tighten the coupler onto the thread another 1/4 to 1/2 turn.

WARNING!

The Male should always be installed on the high-pressure side of the system. Failure to

installtheMaleonthehigh-pressuresidecantrappressurizeduidbetweentheballs,

causinguidtospraywhenthetwohalvesaredisconnected,whichmayresultin

signicantinjuryordeath!

NeveropenMaleorFemalecouplingswhendisconnected.High-pressureuidcanberetained

insidevalvecausinginjuryifopenedwhilenotconnectedtoamatingcoupler.Inspectallsafety

interlocks daily. If any of the safety features are not functioning or are damaged, unit must be

repaired before using in service. Inspect clamps and mating ribs for damage and wear. Bent or

damaged parts as well as excessive wear can adversely affect product performance. Inspect seals

and sealing area on faces of couplers for any signs of damage. All surfaces should be clean and

damage free prior to connection.

!

!

WARNING!

TheBanjoDM220andDM300SeriesshouldnotbeusedatpressuresabovetheMaximumPressureor

at temperatures above the Maximum Temperature or below the Minimum Temperature indicated. Use

outsideoftheseparameterscouldcausefailureofthettings,whichmayresultinsignicantinjuryor

death.

Although sold separately, the Male should only be used with the Female, and the Female should only

be used with the Male.

TheBanjoDM220andDM300Seriesshouldnotbeusedwithchemicalsorotheruidswithwhichitis

notcompatible.Beforeuse,conrmcompatibilityofthechemicalorotheruidbeingtransferredwith

thematerialsusedintheBanjoDM220andDM300Series.

!

!

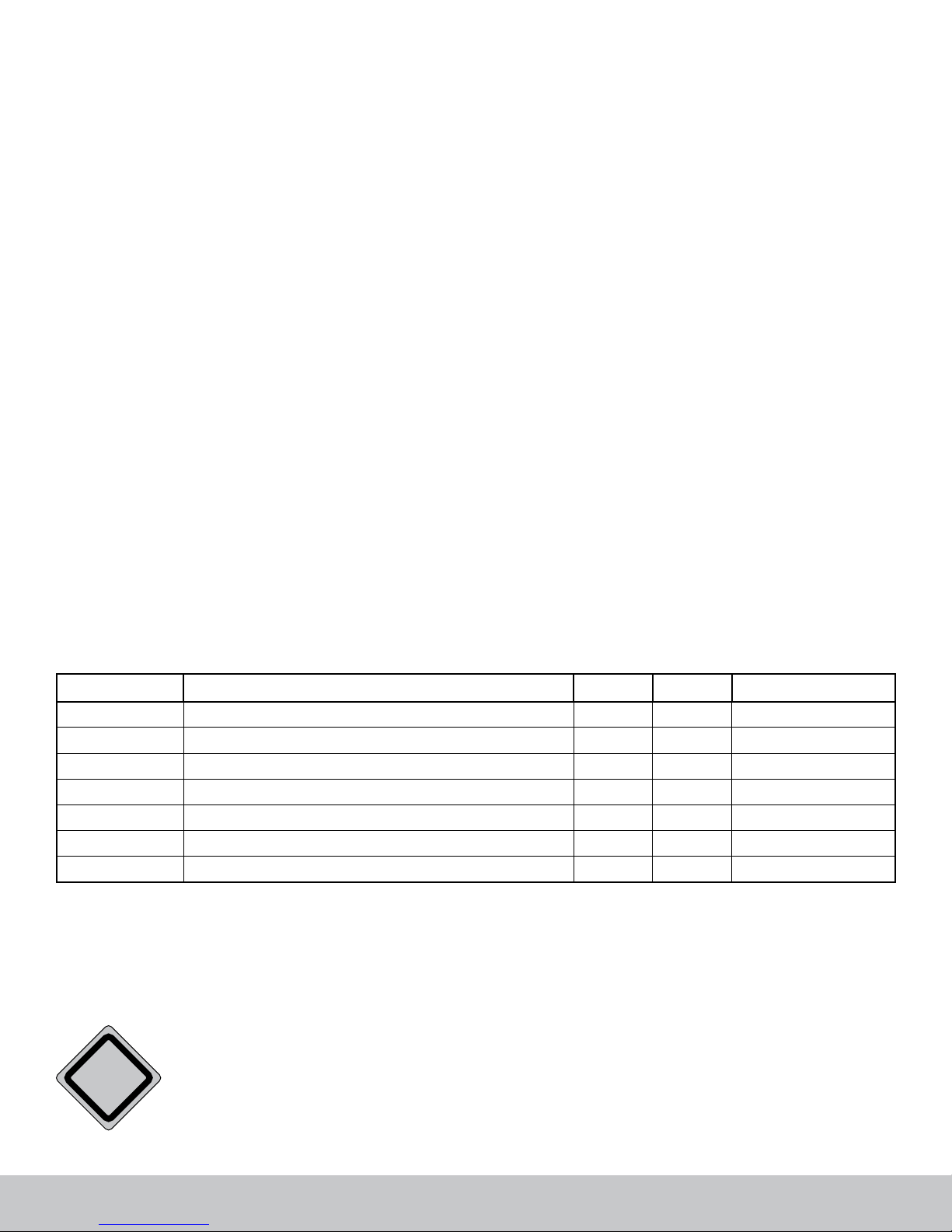

PART NO DESCRIPTION MAX PSI PIPE SIZE OPENING THRU BALL

DM300AFP 3" Full Port Male x 3" Female NPT Threads with FKM Seals 100 3" 3"

DM300ABFP 3" Full Port Male x 3" BSP Threads with FKM Seals 100 3" 3"

DM300ACF 3" Flanged Male with FKM Seals 100 3" 3"

DM300DFP 3" Full Port Female x 3" Female NPT Threads with FKM Seals 100 3" 3"

DM300DBFP 3" Full Port Female x 3" Female BSP Threads with FKM Seals 100 3" 3"

DM300DCF 3" Flanged Female with FKM Seals 100 3" 3"

Maximum Pressure 100 PSI @ 70° F Minimum Temperature -20°F @ 70 PSI Maximum Temperature 150° @ 75 PSI

*Female refers to DM300D variants. **Male refers to DM300A variants.