4

13

1

89

67

5

4

11

13

20 10

2

15 30

23

15

25 31

24

21

13 14 18

32

26

29

22

12

3

28 27 16

19

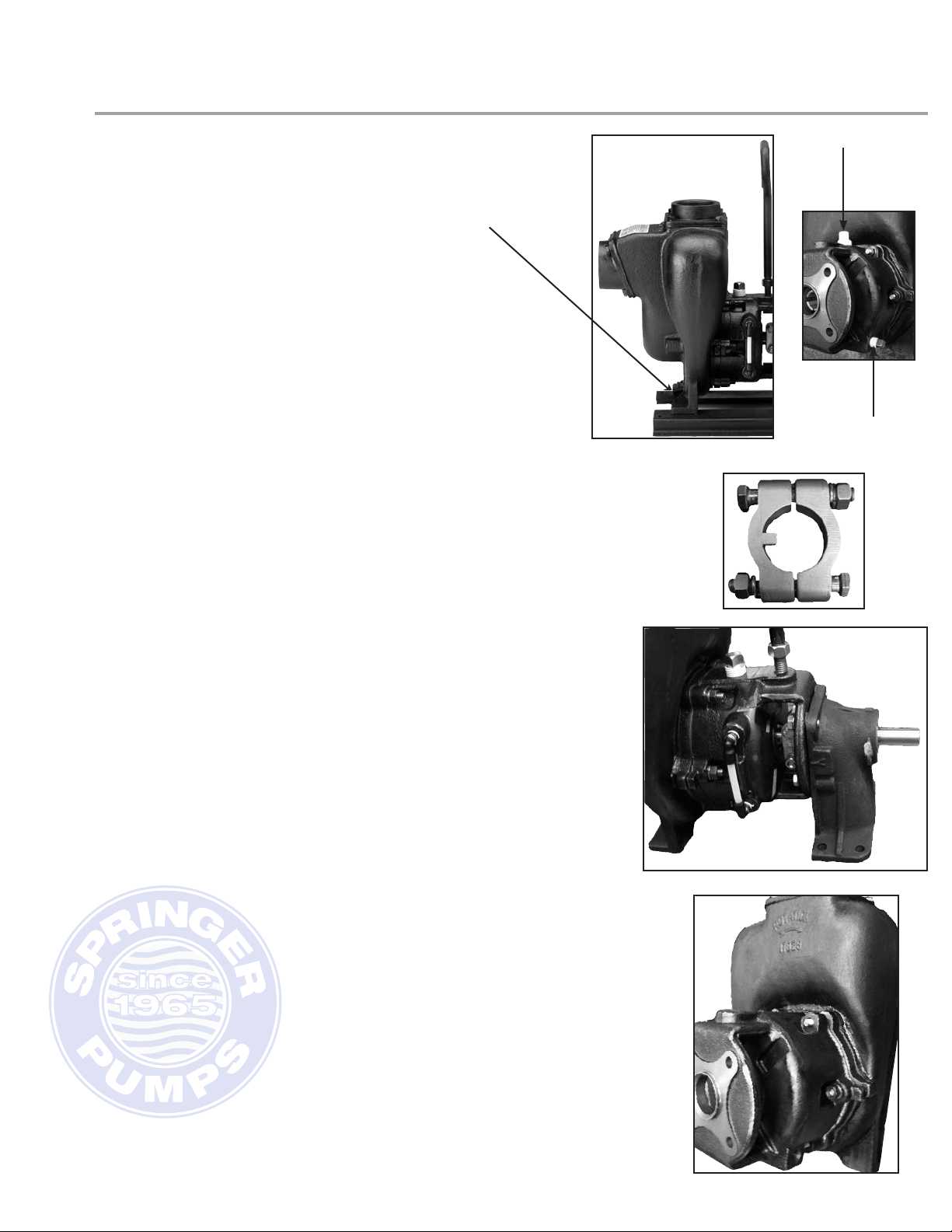

ITEM PART NO DESCRIPTION QTY

⁄ 6

⁄

⁄

⁄

⁄

⁄

6

89

12

3

4

56

14

15

16

17

7

10 11 12 13 26

18 28 19 24 25 29 27 21 22 20

23

8

ITEM PART NO DESCRIPTION QTY

⁄

⁄

⁄

ITEM PART NO DESCRIPTION QTY

1

ITEM PART NO DESCRIPTION QTY

Tel: 866-777-6060

Fax: 866-777-6383

Website: www.springerpumps.com

Int'l: +001 267 404 2910