150 Banjo Drive ℡765-362-7367 INT’L℻765-362-0744

15

11

8

17

5

23

28

27

6

12

18

1

94

2

10 18 12

13

7

18

22

3

21

20

26

25

24

14

16

19

19

18

16

18

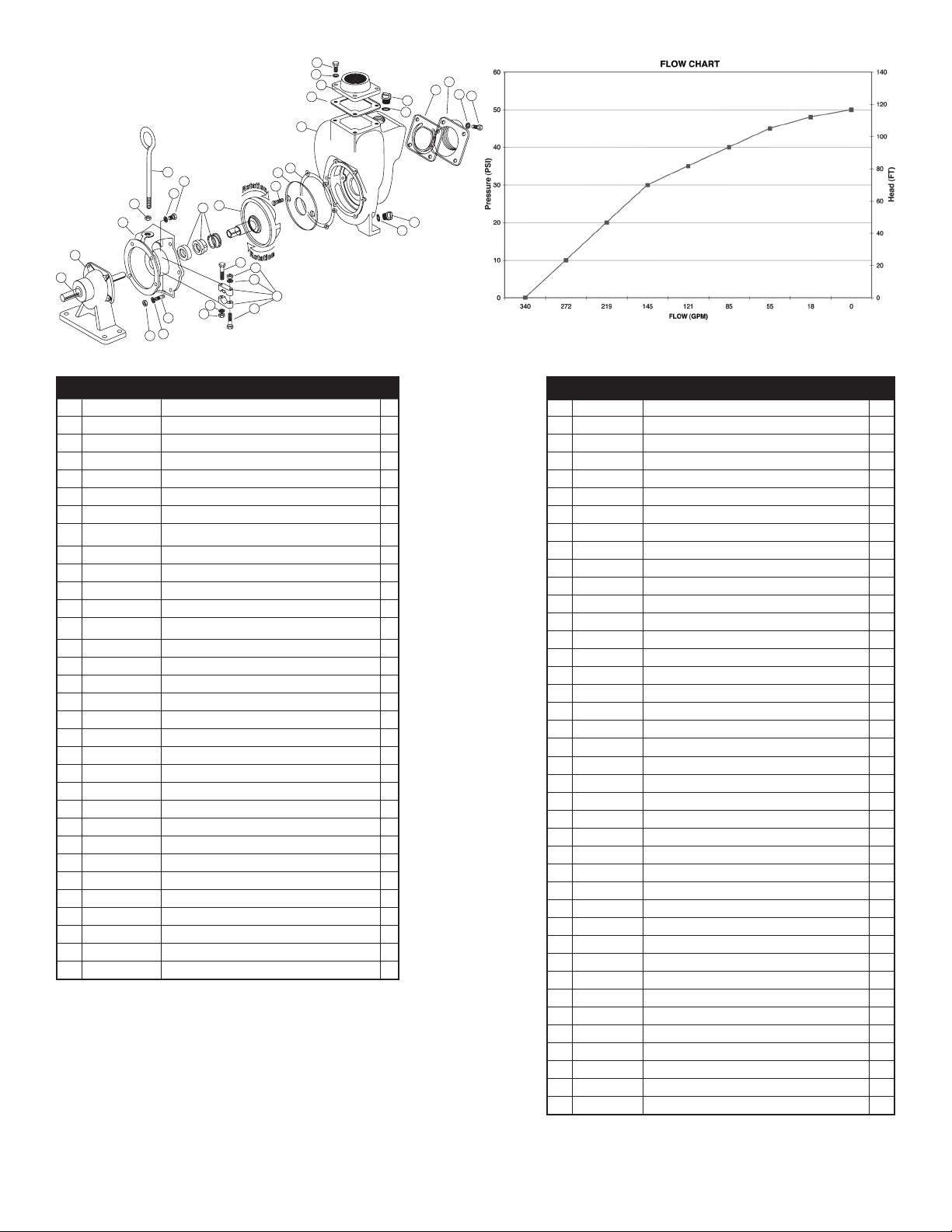

REPLACEMENT PARTS 3" SS PUMPS

ITEM PART NO DESCRIPTION QTY

1 18008SS NPT Outlet Flange 1

2 18012SS NPT Inlet Flange 1

3 18026SS Adapter for Gas Engine 1

3 18048SS SS C-Flange Adapter 1

4 13777SS ¾" Stainless Steel Plug 1

5 18023SS 1" SS Impeller & Drive Shaft for Gas Engine 1

5 18023-1.125SS 1

1⁄8" SS Impeller & Drive Shaft for Electric

Motor 1

6 12777SS ½" Stainless Steel Plug 1

7 18034 5⁄8"SS Jam Nut 1

8 18004SS SS Wear Plate 1

9 18044 FKM (viton type) Outlet Gasket 1

10 18042 FKM (viton type)Gasket Check Valve

Assembly 1

11 18021 Adapter Gasket 1

12 18010SS 3⁄8" - 16 x 11⁄8" SS Cap Screw HXHD 8

13 18033 Handle 1

14 18129 Clamp Assembly 1

15 18001SS SS Pump Housing 1

16 18030 3⁄8" -24 x 2¼" SS Bolt 2

17 18106SS Wear Plate Flat Head Screw 2

18 V20018 3⁄8" Lock Washer 8

19 18032 3⁄8" x 24 SS Hex Nut 2

20 18504 1" Shaft 1

21 18500 Bearing Pedestal 1

22 18027 3⁄8" -16 x 1½"HHCS 1

23 18025SS FKM (viton type) Seal Assembly 1

24 V20019 3⁄8" 16 SS Hex Nut 6

25 V20018 3⁄8" SS Lock Washer 6

26 18218 3⁄8" -16 x 24 x 21⁄8" SS Stud 6

27 13778V O-Ring FKM (viton type) 1

28 UV15163V O-Ring FKM (viton type) 1

N/S 18100SS Repair Kit(Consist of items 5, 8,11,17 & 23) 1

REPLACEMENT PARTS 3" CAST IRON PUMPS

ITEM PART NO DESCRIPTION QTY

1 18008 NPT Outlet Flange 1

1 M18008 3" Manifold Outlet Flange 1

2 18012 NPT Inlet Flange 1

2 M18012 3" Manifold Inlet Flange 1

3 18026 Adapter for Gas Engine & Bearing Pedestal 1

3 18048 C-Flange Adapter 1

3 18049 Hydraulic Motor Adapter 1

N/S 18055 Hydraulic Adapter Shaft 1

4 13777 ¾" Plug 1

5* 18023 1" Impeller & Drive Shaft for Gas Engine 1

5 18023-1.125 11⁄8" Impeller & Drive Shaft for Electric Motor 1

6 12777 ½" Plug 1

7 18034 5⁄8"SS Jam Nut 1

8 18004 Wear Plate 1

9 18009 EPDM Outlet Gasket 1

10 18013 Gasket Check Valve Assembly 1

11 18021 Adapter Gasket 1

12 18010SS 3⁄8" - 16 x 11⁄8" SS Cap Screw HXHD 8

13 18033 Handle 1

14 18029 Clamp Assembly (Old Style) 1

14 18129 Clamp Assembly (New Style) 1

15 18001 Pump Housing 1

16 18030 3⁄8" -24 x 2¼" Bolt 2

17 18106 Wear Plate Flat Head Screw 2

18 V20018 3⁄8" Lock Washer 8

19 18032 3⁄8" x 24 SS Hex Nut 2

20 18504 1" Shaft 1

21 18500 Bearing Pedestal 1

N/S 18502 Bearing SKF 66306-2RS1/C3 2

22 17704 Bolt 4

23* 18025 FKM (viton type) Seal Assembly 1

23 18025SD Severe Duty Seal 1

24 V20019 3⁄8" 16 SS Hex Nut 6

25 V20018 3⁄8" SS Lock Washer 6

26 18218 3⁄8" -16 x 24 x 21⁄8" SS Stud 6

27 13778 O-Ring 1

28 UV15163 O-Ring 1

N/S 18035 Z-Rail Mounting Bracket (Pair) 1

N/S 18100 Repair Kit (Consist of items 5*, 8,11,17, 23*) 1