Also Available from Banks Power

Add even more power, control,

and efficiency to your Ford F-150

(Not all products available for all years/engines)

Monster®

Exhaust

AutoMind®

Programmer

Ram-Air®

Cold Air Intake

iDash®

1.8, 4.3 or 5.0"

Banks Monster Exhaust System

Constructed from heavy-duty stainless steel,

Banks' large bore, mandrel-bent Monster

exhaust connects to your truck's factory

intermediate pipe, cutting backpressure

and increasing flow. Gives you increased

power, greater longevity and maximum fuel

efficiency. The polished-stainless straight-

through muffler outflows stock by a mile and

delivers a commanding, yet civil, exhaust

note. Huge 6x5 inch tip comes in polished

chrome-over stainless or high-temp black.

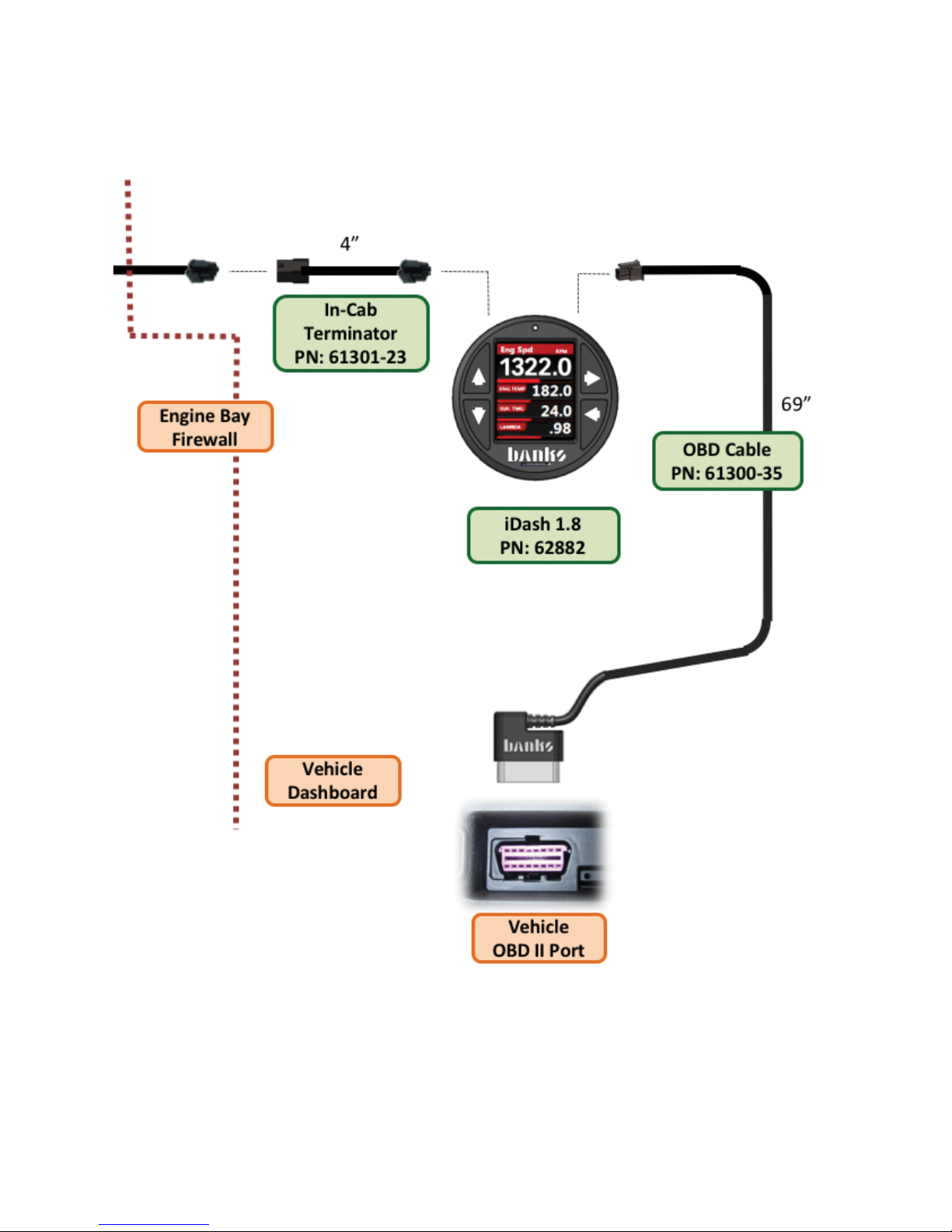

Banks iDash digital gauges

Monitor and control what’s happening

under the hood with a Banks man-machine

interface. Read and clear trouble codes, set

performance and fuel economy parameters,

customize the display, and so much more.

Available in three sizes to fit your specific

application. The 1.8" size fits perfectly in a

pilar mount, and the 4.3" and 5.0" give you a

large, easy-to-navigate touchscreen. Add the

AutoMind Flash Programming Module

to give your engine even more horsepower!

Banks AutoMind Programmer

The AutoMind comes ready to run with

pre-loaded power right out of the box. Its

calibrations were developed with power and

increased MPG in mind. Displays a host of

critical engine functions and provides service

technician diagnostic capabilities with its

ability to scan and clear vehicle trouble codes.

Banks Ram-Air Intake System

Opens up your truck’s breathing with a

flowbench-developed and dyno-proven intake

system that is less restrictive than stock.

Ram-Air's lifetime filter has a huge outlet

with deep filter pleats that maximize flow

and a complete air filter housing that draws

in cooler, denser air to the engine for greater

power and fuel economy.

Banks Stinger System

The Stinger combines intake, exhaust, and

programming into one package, giving you

greater performance at a better price! Intake,

exhaust, and tuning—all designed to optimize

airflow, air density, continuous power & MPG.