4.1 Routing Cordsets .......................................................................................................................................................................... 47

4.2 Initial Electrical Connections ......................................................................................................................................................... 47

4.3 Electrical Connections to the Guarded Machine ............................................................................................................................48

4.3.1 Connecting the OSSD Outputs ..............................................................................................................................................48

4.3.2 Connecting the FSD Interfacing ............................................................................................................................................ 49

4.3.3 Machine Primary Control Elements and External Device Monitoring .................................................................................... 50

4.3.4 Warning (Auxiliary) Output .................................................................................................................................................... 50

4.3.5 Alarm Output (All Models Except SX5-B) .............................................................................................................................. 51

4.3.6 Preparing for System Operation ............................................................................................................................................ 51

4.4 Wiring Diagrams .............................................................................................................................................................................51

4.4.1 Machine Interface Connections for the Stand-alone Models ..................................................................................................51

4.4.2 Machine Interface Connections for the Master Models (8-pin) ..............................................................................................55

4.4.3 Machine Interface Connections for the Master (12-pin) ........................................................................................................ 56

4.4.4 Machine Interface Connections for the Master (17-pin and 17+8-pin) .................................................................................. 60

4.4.5 Remote Scanner Connections (8-pin) ................................................................................................................................... 62

4.5 Power Supply and PC Connections ..............................................................................................................................................63

5 Initial Checkout ........................................................................................................................................................... 64

5.1 Apply Initial Power and Configure the SX Scanner System ...........................................................................................................64

5.2 Verify the Optical Field (Initial Verification) ................................................................................................................................... 64

5.3 Perform a Trip Test ....................................................................................................................................................................... 65

6 Configuration Instructions .........................................................................................................................................67

6.1 System Configuration Settings ......................................................................................................................................................67

6.1.1 Response Time and Scan Cycle Setting ............................................................................................................................... 67

6.1.2 Automatic or Manual Start/Restart ........................................................................................................................................ 67

6.2 Muting Functions ............................................................................................................................................................................68

6.2.1 Mute Devices .........................................................................................................................................................................68

6.2.2 Mute Device Requirements .................................................................................................................................................... 68

6.2.3 Examples of Muting Sensors and Switches ........................................................................................................................... 69

6.2.4 Mute Enable (ME) ..................................................................................................................................................................69

6.2.5 Mute Lamp Output .................................................................................................................................................................70

6.2.6 Mute Time Limit (Backdoor Timer) ........................................................................................................................................ 70

6.2.7 Mute-Dependent Override ..................................................................................................................................................... 70

6.2.8 Muting Function T (X) (Bidirectional) or L (Unidirectional) Selection .....................................................................................72

6.3 Encoder Functions ........................................................................................................................................................................ 74

6.4 Install the Configuration Software ................................................................................................................................................. 76

6.5 Software Interface .........................................................................................................................................................................77

6.5.1 Main Menu .............................................................................................................................................................................77

6.5.2 Toolbar .................................................................................................................................................................................. 78

6.5.3 Status Bar ..............................................................................................................................................................................78

6.5.4 Task Selection ....................................................................................................................................................................... 79

6.6 Using the Software .........................................................................................................................................................................79

6.6.1 Output Configuration .............................................................................................................................................................. 81

6.6.2 Zone Set Configuration ...........................................................................................................................................................82

6.6.3 Input Configuration ................................................................................................................................................................. 86

6.6.4 Detection Configuration ......................................................................................................................................................... 88

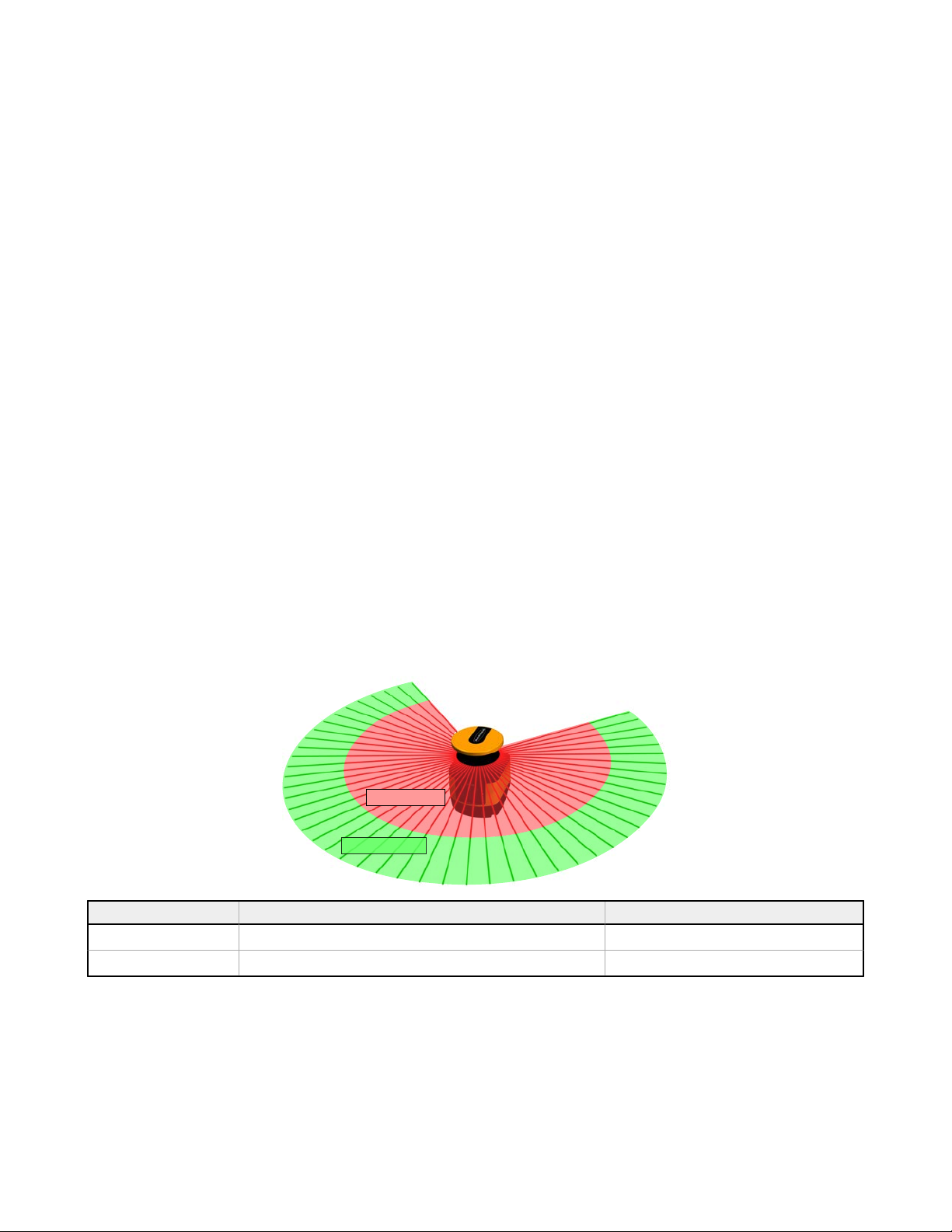

6.6.5 Create or Edit Safety and Warning Zones .............................................................................................................................89

6.6.6 Special Editing and Display Functions .................................................................................................................................. 90

6.6.7 Use Live Monitoring to Assign Safety and Warning Zones ................................................................................................... 91

6.6.8 Protect a Vertical Area (Reference Points) .............................................................................................................................91

6.6.9 Select and Visualize Areas on the Graph ..............................................................................................................................92

6.6.10 Connect a Scanner to a PC (Discover the Scanner) ........................................................................................................... 93

6.6.11 Validate and Accept the Configuration ................................................................................................................................. 94

6.6.12 Load a Saved Configuration to a Scanner ...........................................................................................................................94

6.6.13 Monitor the Scanner ............................................................................................................................................................. 95

6.6.14 Save a Configuration File .................................................................................................................................................... 96

6.6.15 Edit an Existing Configuration ............................................................................................................................................. 96

6.6.16 Wink Function ......................................................................................................................................................................96

6.7 Print the Safety System Report .....................................................................................................................................................97

6.8 Change the Password ...................................................................................................................................................................97

6.9 Reset the Password ......................................................................................................................................................................97

6.10 Configure a Static IP Address .....................................................................................................................................................98

6.11 Perform a Factory Reset .............................................................................................................................................................98

7 Operating Instructions ............................................................................................................................................... 99

7.1 Status Indicators ........................................................................................................................................................................... 99

7.2 Display Menu ................................................................................................................................................................................ 99

7.3 Resetting the System ....................................................................................................................................................................99

7.3.1 Reset Signal Function ......................................................................................................................................................... 100

8 Checkout Procedures ...............................................................................................................................................101

8.1 Periodic Checkout Requirements ................................................................................................................................................101

8.2 Schedule of Checkouts ............................................................................................................................................................... 101

SX Safety Laser Scanner