Pre-installation Questions and Answers

About curing of the paint

Your stove or fireplace has been painted with the highest quality silicone stove

paint. This paint dries quickly in 15-20 minutes when first applied at the factory.

However, due to the high temperature silicone components, the paint will cure

when heat is applied to the appliance as it is first used. The following

information applies to the curing process to get the paint fully hard and durable.

Fire the appliance four successive times for 10 minutes each firing and a 5

minute cool down between each. Be aware during log and firebox paint curing

that a white deposit may be developing on the inside of the glass doors. It is

important to remove this white deposit from the glass doors using a fireplace

glass cleaner.

Babies, small children, pregnant women and pets should leave the

area during the cure phase.

Ventilate well, open doors and windows.

Do not touch during curing.

Why does my fireplace or stove give off odor?

It is normal for your fireplace to give off some odor at first. This is due to the curing of the paint, adhesives, silicones and any

undetected oil from the manufacturing process as well as the finishing materials used with the installations (e.g. marble, tile and the

adhesives used to adhere this product to the walls can react with heat and cause odors).

It is recommended that you burn your gas fireplace or stove for a minimum of four hours at a time with the fan off (if a fan is present)

after the curing of the paint has been completed. These odors can last upward to 40 hours of burn time; keep burning at a minimum

of four hours per use until odors dissipate.

Noise coming from the fireplace?

Noise is caused by the expansion and contraction of metal as the appliance heats up and cools down. This is normal and is similar

to the sounds produced by a furnace or heating duct. This noise does not affect the operation or longevity of your fireplace.

Note to the Installer:

Be sure appliance is working properly and its operation (including remote control operation, if included) is fully explained to and

understood by the customer.

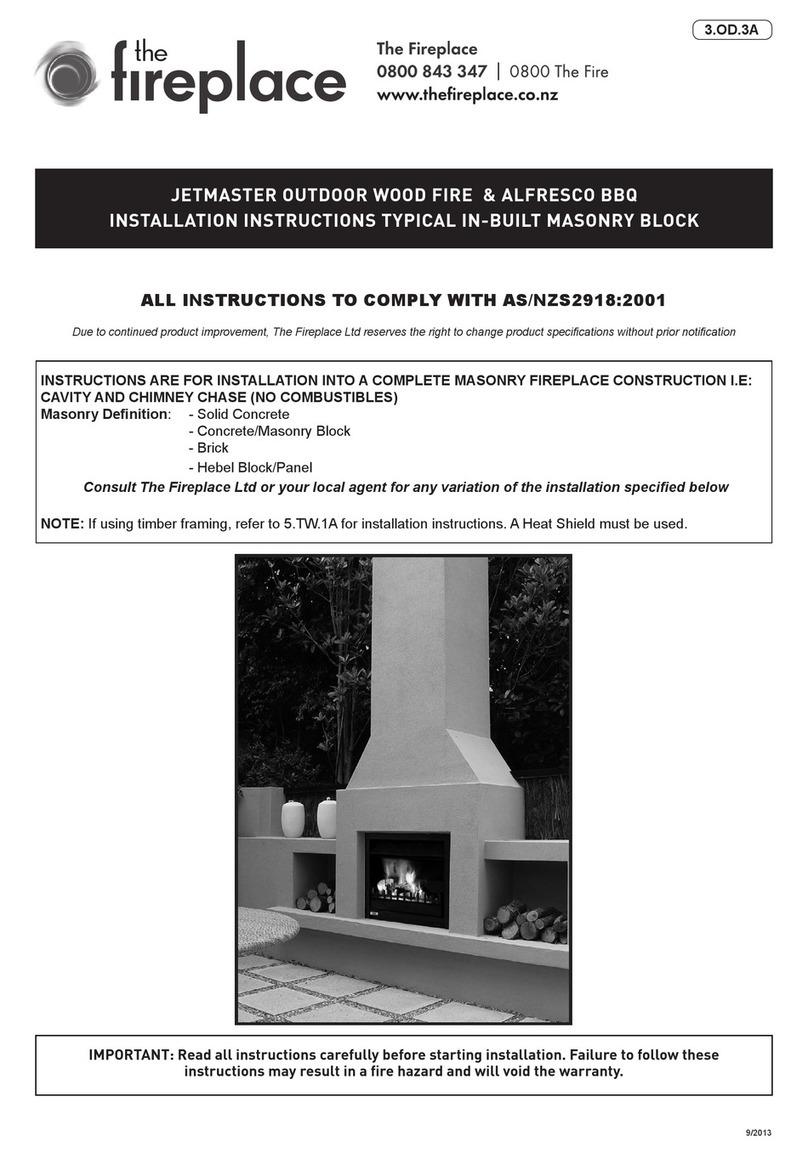

Important Information About Outdoor Fireplaces

Before you build in this appliance:

Do not insulate around the appliance. Heat

buildup could lead to component failure.

Pay attention to all clearances to combustibles

and specifications stated in this manual.

Drainage- If this appliance is installed in a

location where it will be exposed to water and

moisture, drainage is an important

consideration.

Inadequate drainage will cause rust, which is not

covered by the warranty.

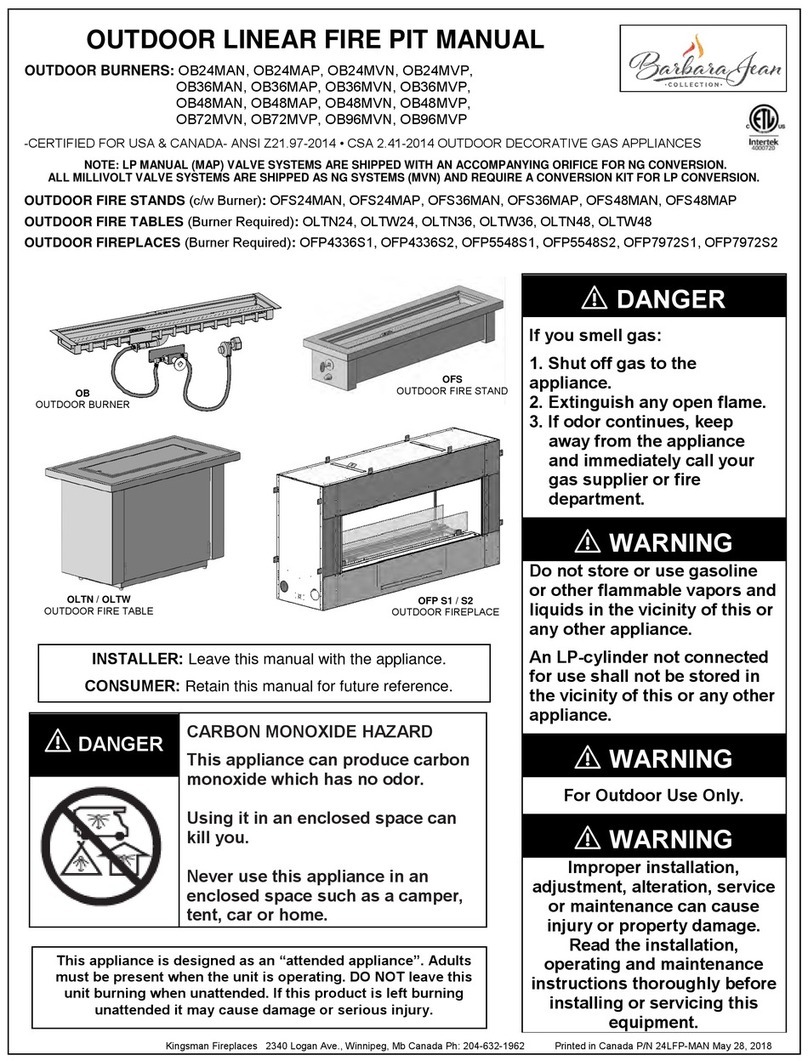

Information about outdoor fireplaces

Outdoor fire burning appliances may not function

properly at all times regardless of the

circumstances.

Wind can greatly affect flame performance. If used in windy conditions a wind guard is recommended.

Outdoor units require adequate ventilation in order to burn properly.

Restricted access to air is not only dangerous for persons near the appliance, but the appliance also will not function

correctly.

This appliance consumes air, burns fuel, and emits heat and exhaust gases.

Only approved media and accessories listed in this manual should be used with this appliance.

This appliance is not intended for use in temperatures below freezing.

The pilot burner (if equipped) should be OFF, and covered to protect it from the elements when not in use.

-Operating Instructions-

1. Be sure to read and understand all the

instructions in this manual before

operation of appliance.

2. Ensure all wiring is correct and properly

enclosed to prevent possible shock.

3. Check for gas leaks.

4. If brick or porcelain liners are used,

ensure they are installed.

5. Verify that the pilot can be seen when

lighting the appliance. If not, the log or

rock placement is incorrect.

6. If the unit is turned off, you must wait a

minimum of 60 seconds before re-

lighting it.