www.barco.com

Integration in the Barco SpinMaster system

All Barco and Loepfe sensor systems and sensors can be integrated in Barco’s SPiNMaSter plant wide monitoring system.

With SPiNMaSter, the whole production process can be monitored starting from opening lines to draw frames, flyers, ring frames, OE

machines, winders and twisters. The SPiNMaSter system also allows the connection of production machines equipped with other (non-

Barco) yarn quality detection or clearer systems.

A total solution to fight contamination in spinning mills

YarnMaster

The YarNMaSter 900 eliminates yarn defects as well as foreign fibers and reports

the events on-line according to international standards, being: thick and thin

places, IPI values, splices, yarn count deviations, imperfections, foreign fibers.

Polypropylene

The polypropylene sensor is added to the BarcOPrOFile®sensor in such a way that

the yarn barely touches the PP sensing head. The sensing head detects colored,

white and colorless polypropylene contamination in the yarn.

In opening lines - Cotton Sorter

The cOttON SOrter RX-CS is a real time system for detection and removal of

contaminants in raw cotton. All unwanted material that differs from the cotton

throughput will be detected by ultra-fast CCD cameras and removed by a special

pneumatic ejection unit.

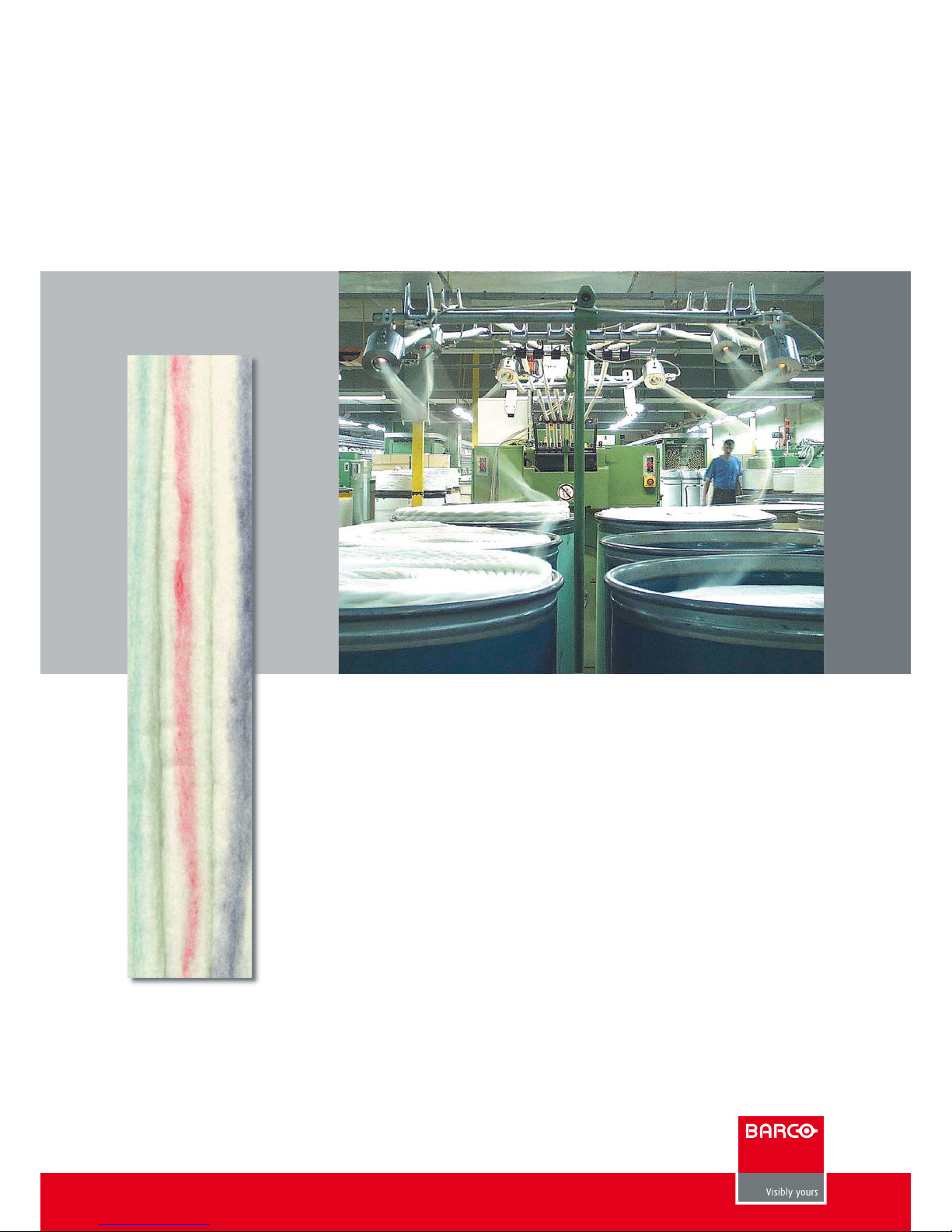

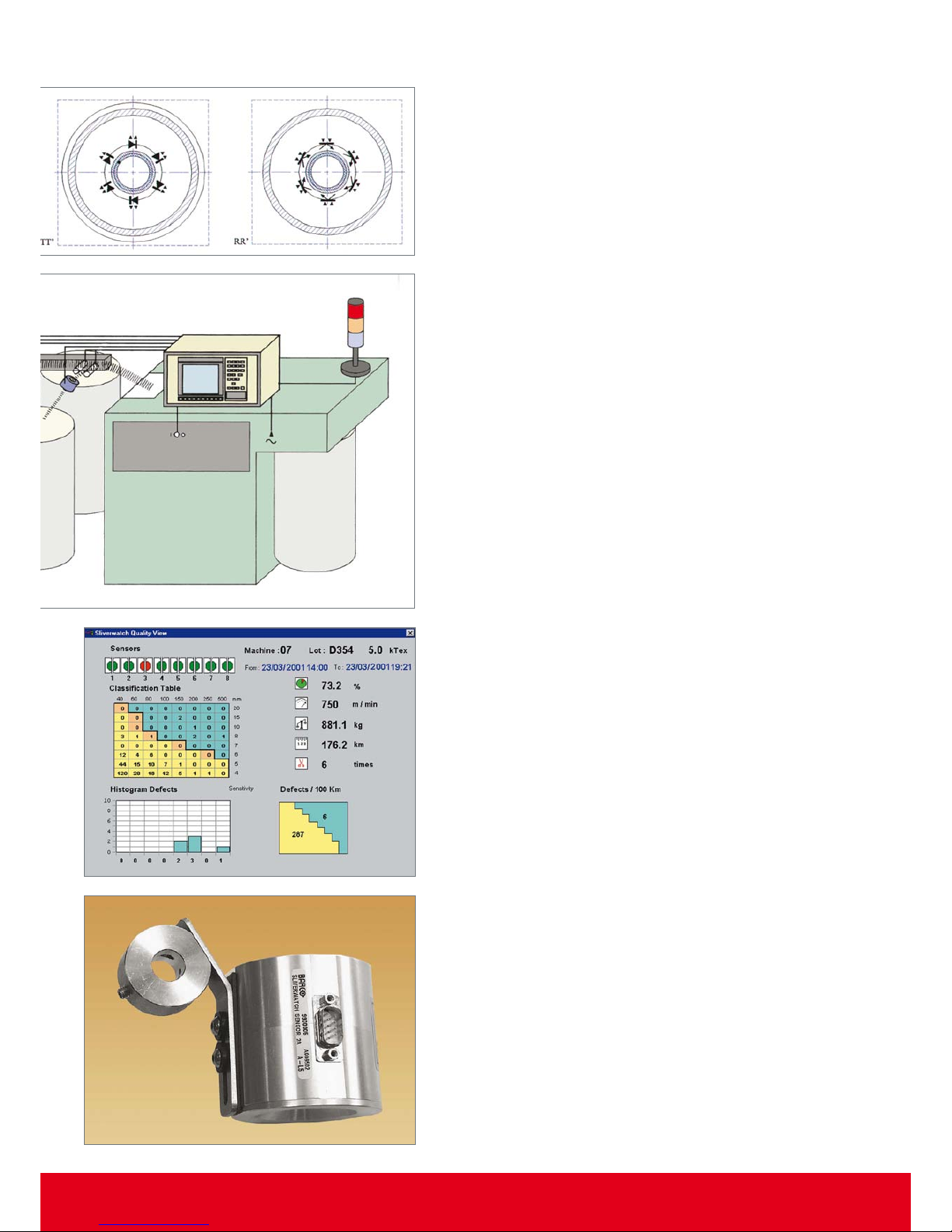

On draw frames - SliverWatch

This detection system is installed in the creel of draw frames handling the first step

drawing. The purpose is to stop the draw frame if a contaminated sliver is detected,

so that the operator can eliminate the contamination. This avoids that second step

drawing and spinning spreads the contamination over many meters of yarn.

On Open-End spinning frames - ABS

The ABS sensor is installed on the yarn withdrawal tube in the spin box. ABS can

be installed on OE machines regardless the presence of whatever type of yarn

clearer. With ABS the sensor simply comes as an add-on, replacing the original

yarn withdrawal tube with an “intelligent” one. This way, the original investment

in yarn clearing is safeguarded.

Barco n.v.

Th. Sevenslaan 106

8500 Kortrijk

BELGIUM

Tel (intl) 32 56 262611

Fax (intl) 32 56 262690

e-mail: sales.bv@barco.com

A00526 03 EN 23/8/2007 DPD

Barco Sedo GmbH

Neuwies 1

35794 Mengerskirchen

GERMANY

Tel (intl) 49 64 76310

Fax (intl) 49 64 763131

e-mail: sedo@barco.com

Barco Loepfe srl

Via El Alamein, 11/C

22100 Como

ITALY

Tel (intl) 39 31 3370457

Fax (intl) 39 31 305565

BarcoVision Ltd

Capricorn Park

Blakewater Road

BB1 5SQR Blackburn, Lancashire

UNITED KINGDOM

Tel (intl) 44 1254 662244

Fax (intl) 44 1254 267100

BarcoVision LLC

4420 Taggart Creek Road

Suite 101

28208 Charlotte, North Carolina

USA

Tel (intl) 1 704 3929371

Fax (intl) 1 704 3995588