Barco - OV-808, OV-815– R599874 – installation manual – revision 01– November 2007 iv

4.7 Project specific kit.........................................................................................................................................12

5 Installation .......................................................................................................................................... 13

5.1 OverView.......................................................................................................................................................13

5.2 Installation of the pedestal..........................................................................................................................14

5.3 The components of the display module...................................................................................................... 22

5.4 Completion of the pedestal ......................................................................................................................... 23

5.5 Connecting the pedestals.............................................................................................................................24

5.6 Fixation to the floor......................................................................................................................................27

5.7 Installation of the display module...............................................................................................................28

5.8 Connecting the display modules of the first row........................................................................................30

5.9 Installation of the following rows ...............................................................................................................31

5.10 Installation of the engine support profile .................................................................................................33

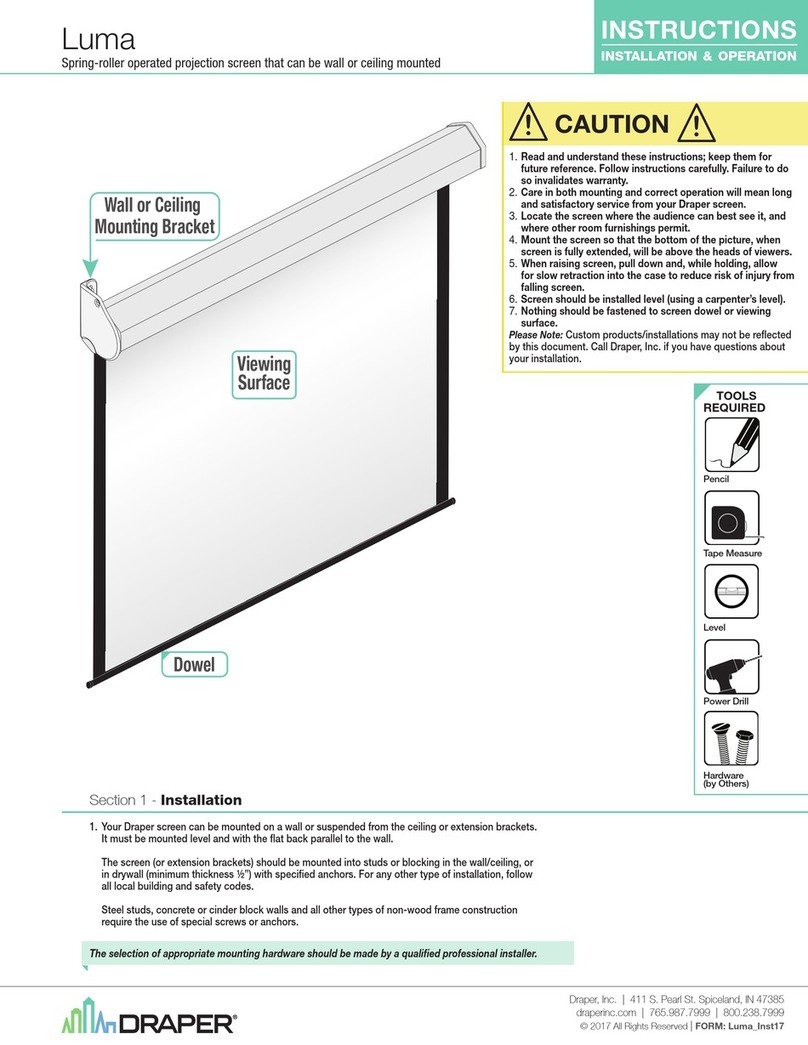

5.11 Installation of the Screen...........................................................................................................................34

5.12 Installation of the standard trim................................................................................................................41

5.13 Installation of the design trim ................................................................................................................... 45

5.14 Installation of the cabling interface ..........................................................................................................47

5.15 Installation of the side covers (curved setup) ..........................................................................................49

5.16 Installation of the Mirror............................................................................................................................50

5.17 Installation of the cable hub......................................................................................................................53

5.18 Precabling...................................................................................................................................................56

5.19 Installation of the top cover ......................................................................................................................57

5.20 Installation of the illumination unit...........................................................................................................58

5.21 Installation of the projection unit..............................................................................................................60

5.22 Finalizing the cabling .................................................................................................................................61

5.23 Grounding ...................................................................................................................................................63

5.24 Covers ......................................................................................................................................................... 64

5.25 Setting up the network..............................................................................................................................65

6 O tical adjustment.............................................................................................................................. 66

6.1 Preparation ...................................................................................................................................................66

6.2 The projection lens for XGA systems...........................................................................................................67

6.3 The projection lens for SXGA systems .........................................................................................................68

6.4 Strictly prohibited devices............................................................................................................................ 69

6.5 Adjustment devices......................................................................................................................................70

6.6 First steps...................................................................................................................................................... 71