TMI Products Save-T SCREEN-PRO User manual

SCREEN-PRO™

IN-JAMB MOUNTING METHOD

INSTALLATION INSTRUCTIONS

All Season Roll-Up Doors

Spring Loaded

Carefully examine the crate(s) for damage before opening. If the carton is damaged, immediately notify shipping

company. Open the carton(s) and remove all protective packaging. Retain the shipping carton(s) until the unit(s) is

installed and properly operating. TMI, LLC is not responsible for delayed or late claims.

READ THIS FIRST

Group of Companies

Serial No: ________________ Model #: _______________ Date Purchased: ___________

Read and Save These Instructions

To Reduce the Risk of Injury, Observe the Following:

Warning

• Use this unit only in the manner intended by the manufacturer. If you have any questions, contact the manufacturer.

• Installation work must be done by a qualied person(s) in accordance with all applicable codes and standards.

• When cutting or drilling into wall or ceiling, do not damage electrical wiring and other hidden utilities.

Please read the “READ THIS FIRST” note on the front cover of this manual before proceeding.

TYPES OF DOORS

2

There are a variety of doors used at both industrial

and commercial facilities. Each has its specific

opening/closing mechanism. This Screen-Pro unit

has been shipped with hardware to accommodate

an In-Jamb Mounting Method. It should be mounted

inside a plain doorway opening using the door

jambs to attach the Guide Tracks.

PLAIN

DOORWAY

OPENING

OVERHEAD

DOOR ROLL-UP

DOOR

4

Screen Material with

Modular Panels

(Attached to Roller Drum)

Pull

Straps

Lock

Strap

Guide

Tracks

Top Spreader

Angle

Brush Seal

Bar Brush Seal

Screen Roller Drum

Mounting

Angles

Drum

Mounting Plate

(Spring)

Drum

Mounting Bracket

(Bearing)

Rollover

Straps

SCREEN-PRO COMPONENTS

–IMPORTANT –

This Screen-Pro model has been designed

to fit inside a doorway opening that has an

8'' jamb width or larger.

It is recommended that two people

install the door together.

The following tools will be needed

for installation:

•Carpenter’s Level (Min. 4’ Length)

•Carpenter’s Square

•Hammer Drill

•Masonry Drill Bit (For 3/8” Diameter Anchors)

•3/8” Diameter and Various Wall Anchors

•Assorted Shim Stock

•Socket and Wrench Set

•Hand Tools

•Four Bar Clamps (36” Long)

•Two Ladders

•Forklift (Supplied by Dealer or Customer)

REQUIRED TOOLS

STEP 1

STEP 2

Lay the basic components in front of the doorway opening.

Using work horses will make the assembly process easier although it is

not essential. Place the Guide Tracks with the Guide Flare facing up.

Brush

Seal

Brush Seal

Bar

Slide the Brush Seal into the edge

groove of the Brush Seal Bar.

Left Guide

Track

Mounting

Angle

1'' from

edge

1'' from

edge

Guide

Flare

Guide

Flare

Mounting

Angle

Right Guide

Track

STEP 3

Drill 4 mounting holes on one

side of each Mounting Angle.

The holes should be placed

approximately 1'' from each

edge and equally spaced

between those holes.

NOTE:

There is a left and a right

Guide Track.

3

STEP 4

Place each Mounting Angle on the

outer edge of each Guide Track.

The bottom of the Mounting Angle

should be flush with the bottom of

the Guide Track (See illustration).

Then mark each hole.

Then drill 4 mounting holes on the opposite

side of each Mounting Angle. The holes should

be placed approximately 2'' from each edge and

equally spaced between those holes.

2'' from

edge

2'' from

edge

Mounting

Angle

Mounting

Angle

Guide

Track

Guide

Track

4

STEP 5

STEP 6

STEP 7

Remove the Mounting Angles and drill

the holes in the Guide Tracks.

Replace the Angles and secure them

using self-tapping sheet metal screws.

IMPORTANT

The Guide Track Flare Plate ships flat and must be

bent out 11/2” before any assembling takes place.

Guide Track

Top Spreader

Angle

Angle

facing

down

Spreader

Mounting

Bracket

2'' Brush

Seal Bar

Brush Bristles

should face down

Self-Tapping

Sheet Metal

Screws

Attach the Top Spreader Angle to the top of

the Guide Track using the Spreader Mounting

Bracket. Make sure the back of the Spreader

Angle is facing down and toward the wall.Use

2 bolts and flange nuts on each side to

secure al the components..

With the brush bristles facing down, center the 2'' Brush Seal Bar

on top of the Spreader Angle and mark the pre-drilled holes on the

Spreader Bracket. Remove the brush and drill the holes.

Reposition the Brush and use the supplied Self-Tapping Sheet

Metal Screws to attach the Brush Bars to the Spreader Bracket

Sheet

Metal

Screws

5

STEP 8

STEP 9

Attach a Drum Mounting Plate to

the top of each Track Guide using

5/16'' x 1-1/4'' bolts with flange

nuts. The square cradle (spring

side) goes on the left and the

round cradle (bearing side) is on

the right.

IMPORTANT: Use the bottom

hole of each set of holes.

Bottom Hole

(Set 1)

Bottom Hole

(Set 2)

Drum Mounting Plate

(Spring Side)

Drum Mounting Plate

(Bearing Side)

Place the assembly into the doorway

opening. The bottom of each Guide

Track should be resting on the floor.

The front edge of the Drum Mounting

Plates should be flush with the front

edge of the door jamb tight against

the header. Make sure the assembly

is plumb. Mark the 4 mounting holes

on each of the jamb.

Remove the assembly and drill the holes. If the

jamb is wood, a lag screw with washer is all

that is needed. If the jamb is concrete or steel

& concrete, a wall anchor should be placed in

each hole.

Stand the assembled unit upright and lean it against a

wall. Place the Screen Roller Drum into each Drum

Mounting Plate.

The Spring Locking Clip (square shaft) should be to the

left and the Bushing/Bearing (round shaft) to the right.

STEP 10

Guide

Track

WARNING

The spring tension for the Roller Tube

is pre-set at the factory and is shipped

with the Lock Plate in place. DO NOT

remove the plate until the assembly

process is completed. Also DO NOT

remove the Roll Ties until the Roll

Tube is secured to both End Plates.

Bushing/Bearing

Screen on

Roller Drum

Spring

Locking Clip

Roll Ties

Front edge of

Drum Mounting Plate

flush with

front edge of

door jamb

tight against

the header

STEP 11 Spring

Loading

Clip

Bushing/Bearing

6

STEP 12

Cotter

Pin

Bottom Edge

of Screen

facing down

Once the shaft is in both cradles, place a Cotter Pin

through the square shaft and cradle to secure it (left side).

Square

Cradle

Round

Cradle

The Bottom Edge of the Screen facing down.

Then carefully cut the Roll Ties without

cutting the screen. Slip the bottom

edge of the screen into the Guide

Tracks. Place the leading edge in front

of the Rubber Gasket to create a seal.

With the Screen Roller Drum in place,

remove the Spring Locking Clip.

Bottom Edge

of Screen

Rubber

Gasket

Roll Ties

Spring Locking

Clip

STEP 13

Reposition the assembly in the

doorway opening and fasten it

securely against the jambs

with lag screws and washers.

After all adjustments are made the the Rear Spreader Plate

can be attached. It is fastened to the back (exterior) of the

Guide Tracks. Use 4 self-tapping screws.

Rear Vinyl Cover

1. Rear Vinyl Cover will attach behind

the screen barrel when standing inside the

building looking out.

2. Mount aluminum angle to header and

then attach vinyl flap using the hook/loop

provided.

3. If you ordered the Aluminum Rear Spreader

upgrade, then you will only need the 4 tek screws

to fasten the Aluminum Spreader to the back side

of the guide tracks.

Check the door movement. If the spring

needs more tension, follow the procedure

on page 8, entitled “ADDING TENSION

TO THE SPRING.”

STEP 14

Exterior of

Doorway

Opening

Rear Spreader Plate

Guide

Track

Guide

Track

Self-Tapping

Screws

Self-Tapping

Screws

Screen

Barrel

Screen

Door Jamb

Aluminum Angle

Vinyl Flap

(attach to angle

with hook and loop

(OUTSIDE

OF THE

BUILDING)

SIDE VIEW OF

SCREEN BARREL & DOOR OPENING

STEP 15

7

The final steps are attaching the Rollover Straps and Lock

Down Straps.

Lock Straps

Rollover Straps

Footman

Loops

Footman

Loop

Footman

Loops

Footman

Loops

Pull Straps

Slides

Slide

“D” Rings

Guide Tracks

STRAP PLACEMENT

NOTE: The “D” Rings, Pull Straps and Slide Handles are

attached at the factory. Also, one end of the Rollover Straps is

attached to the bottom of the screen.

Pull the screen down to

release the 2 Rollover Straps.

ASlide is attached to each

strap. Make sure the straps

are laying flat and not twisted.

Feed the strap through the Footman Loop

that has been pre-attached to the Guide

Track. Then take the strap back through

the slide as shown in the illustration to the

right. Adjust the strap so it is taut when the

door is in the open position.

The purpose for Lock Straps is to hold the

screen in the down position. so the bottom

bar is touching the floor.

Once the Rollover Straps are set, pull the screen to the down position. Take the short Lock Straps with the Snap

Hooks on one end and snap the hook into the “D” Ring. Take the other end of the strap and pull it at a diagonal

so the Strap Grommet is centered on the front of the Guide Track. Mark the hole. IMPORTANT: Place the

screen in the open position. Drill the Pilot Hole for the Tab Weld Nut (supplied). Next, place the screen in the

down position. Finally, with the Weld Nut on the inside of the Guide Track, secure the strap with the Bolt through

the Strap Rivet.

Lock

Strap

Snap

Hook

“D”

Ring Bolt Tab

Weld

Nut

Pilot Hole

Strap

Grommet

800-888-9750

TMI, LLC • 5350 Campbells Run Road • Pittsburgh, PA 15205-9738 • 412.787.9750

Copyright © 2011 TMI, LLC Catalog No. II-TMI-SP-RUD 01-11

NOTES

Second, wind up the screen so

it is completely on the Roller

Drum. Using a strap or cord,

secure the screen so it is

unable to unwind. Place the

Lock Plate into the Drum Hub.

Next, remove the Cotter Pin on

the left side and lift the Screen

Roller Drum out of the Drum

Bracket Cradles.

ADDING TENSION TO THE SPRING

Roller

Drum

Stabilize

Roller Drum

Spring

Locking Clip

Drum

Hob

Lock

Plate

Strap

or Cord

If after testing the door movement, the spring

needs more tension, the following procedure

should be taken. First, remove the assembly

from the doorway opening.

Cotter

Pin

Cradle

Cradle

Then, with the Roller

Drum totally stabilized,

lock a Vise Grip onto the

shaft. Keeping everything

in tension, remove the

Lock Plate. Turn the shaft

clockwise one complete

turn and replace the

Spring Locking Clip.

Finally, reattach the Screen Roller Drum to the Drum Mounting Plates (See Step 11, Page 7)

and continue the installation through Step 15.

Popular Projection Screen manuals by other brands

HAPRA

HAPRA Home Cinema CT operating instructions

ligra

ligra DesignPro TENSIONED Assembly & installation manual

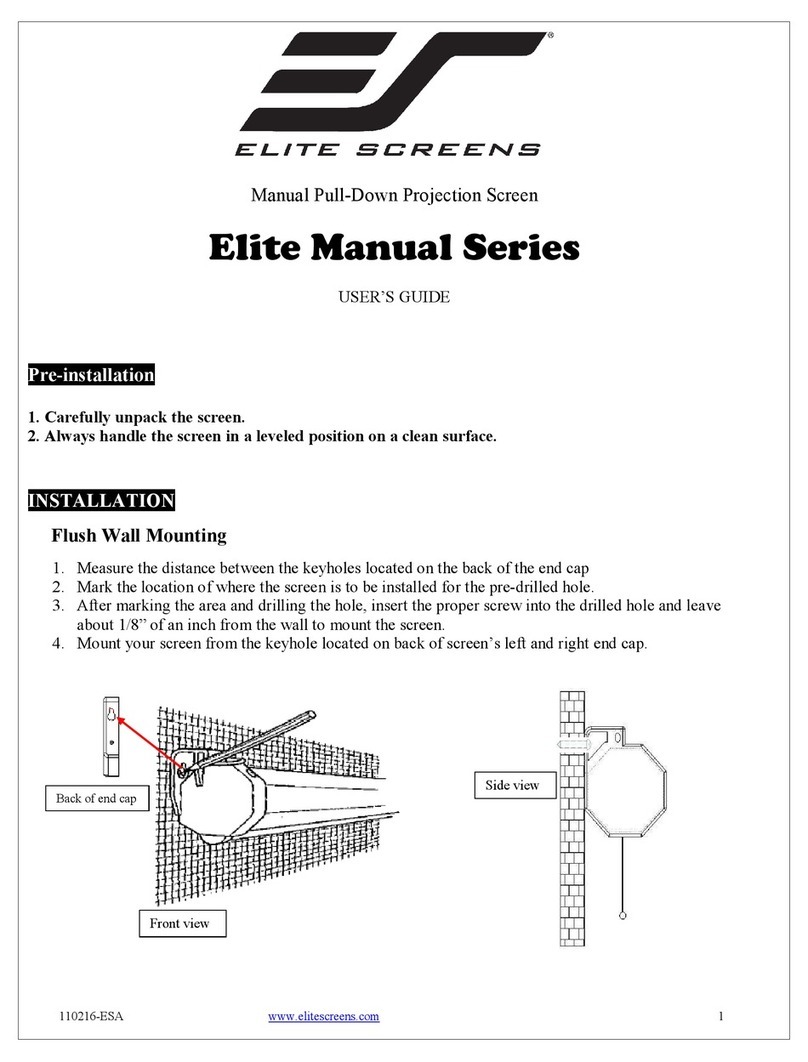

Elite Screens

Elite Screens TE100HC2 Specifications

INSANE impact

INSANE impact MAX 127 owner's manual

SkillKorp

SkillKorp GS10 manual

Da-Lite

Da-Lite TENSIONED DUAL MASKING ELECTROL Instruction book

Draper

Draper Onyx Assembly/mounting instructions

Stewart Audio

Stewart Audio Cima AC NT owner's manual

Classic Exhibits

Classic Exhibits SEGUE DESIGN Sunrise VK-1903 Setup instructions

FONESTAR

FONESTAR PPEL-FA Series quick start guide

Elite Screens

Elite Screens Elite ES-M120UWV2 user guide

Elite Screens

Elite Screens Home100IWH2-A features and benefits