Manual 2100-359

Page 5

CONDENSATE DRAIN

A plastic drain hose extends from the drain pan at the top

of the unit down to the unit base. There are openings in

the unit base for the drain hose to pass through. In the

event the drain hose is connected to a drain system of

some type, it must be an open or vented type system to

assure proper drainage.

A 1/4 inch clearance to combustible material for the first

three feet of duct attached to the outlet air frame is

required. See Wall Mounting Instructions and Figures 3

and 3A for further details.

Ducts through the walls must be insulated and all joints

taped or sealed to prevent air or moisture entering the

wallcavity.

Some installations may not require any return air duct. A

metallic return air grille is required with installations not

requiring a return air duct. The spacing between louvers

on the grille shall not be larger than 5/8 inch.

NOTE: If no return air duct is used, applicable

installation codes may limit this cabinet to

installation only in a single story structure.

Any grille that meets with 5/8 inch louver criteria may be

used. It is recommended that Bard Return Air Grille Kit

RG2 through RG5 or RFG2 through RFG5 be installed

when no return duct is used. Contact distributor or

factory for ordering information. If using a return air

filter grille, filters must be of sufficient size to allow a

maximum velocity of 400 fpm.

Design the duct work according to methods given by the

Air Conditioning Contractors of America (ACCA).

When duct runs through unheated spaces, it should be

insulated with a minimum of one inch of insulation. Use

insulation with a vapor barrier on the outside of the

insulation. Flexible joints should be used to connect the

duct work to the equipment in order to keep the noise

transmission to a minimum.

These instructions and any instructions packaged with

any separate equipment, required to make up the entire

air conditioning system should be carefully read before

beginning the installation. Note particularly any tags and/

or labels attached to the equipment.

Size of unit for a proposed installation should be based

on heat loss calculation made according to methods of

Air Conditioning Contractors of America (ACCA). The

air duct should be installed in accordance with the

Standards of the National Fire Protection Association for

the Installation of Air Conditioning and Ventilating

Systems of Other Than Residence Type, NFPA No. 90A,

and Residence Type Warm Air Heating and Air

Conditioning Systems, NFPA No. 90B. Where local

regulations are at a variance with instructions, installer

should adhere to local codes.

DUCT WORK

All duct work, supply and return, must be properly sized

for the design air flow requirement of the equipment. Air

Conditioning Contractors of America (ACCA) is an

excellent guide to proper sizing. All duct work or

portions thereof not in the conditioned space should be

properly insulated in order to both conserve energy and

prevent condensation or moisture damage.

While these instructions are intended as a general

recommended guide, they do not supersede any national

and/or local codes in any way. Authorities having

jurisdiction should be consulted before the installation is

made. See Page 1 for information on codes and

standards.

SHIPPING DAMAGE

Upon receipt of equipment, the carton should be checked

for external signs of shipping damage. If damage is

found, the receiving party must contact the last carrier

immediately, preferably in writing, requesting inspection

by the carrier’s agent.

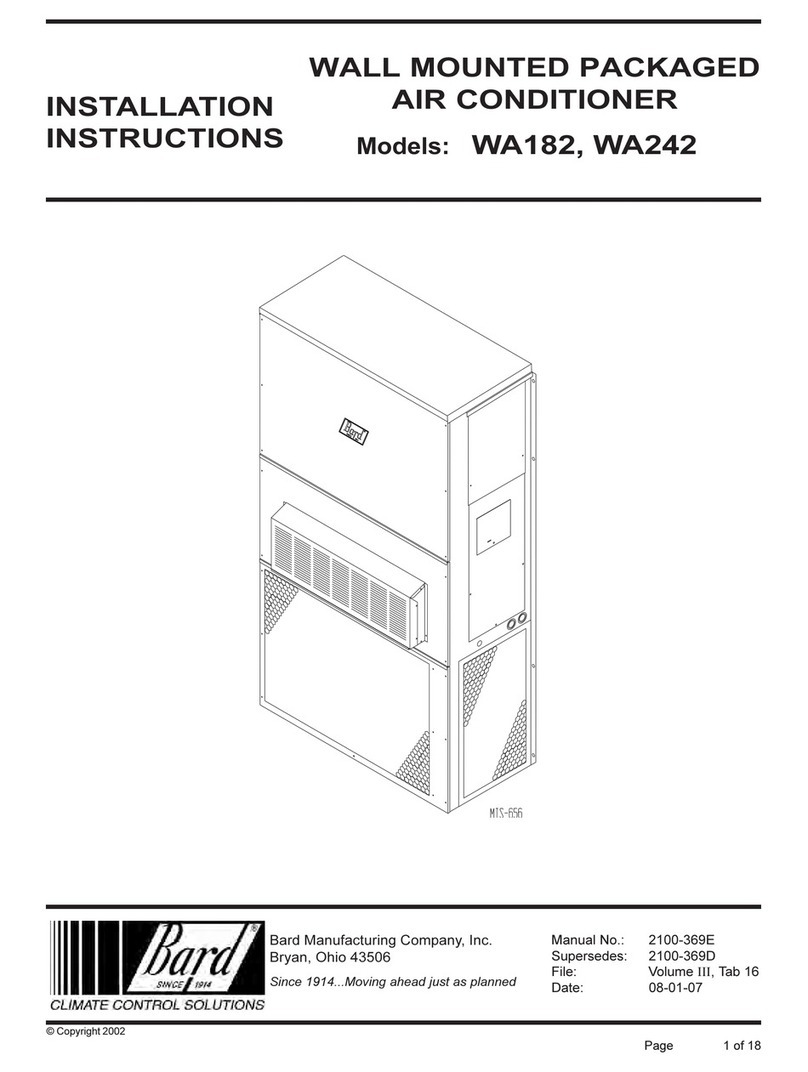

GENERAL

The equipment covered in this manual is to be installed

by trained, experienced service and installation

technicians.

The refrigerant system is completely assembled and

charged. All internal wiring is complete.

The unit is designed for use with or without duct work.

Flanges are provided for attaching the supply and return

ducts.

These instructions explain the recommended method to

install the air cooled self-contained unit and the electrical

wiring connections to the unit.