Manual 7960-780

Page 2 of 2

• Input the total number of units that will use this

feature.

• Set the Lead Unit cooling setpoint.

• Set the Lead Unit heating setpoint.

• Set the Lag 1 Unit cooling setpoint.

• Set the Lag1 Unit heating setpoint.

• Set the Lag2 Unit cooling setpoint.

• Set the Lag2 Unit heating setpoint.

• Set the Lag3 Unit cooling setpoint.

• Set the Lag3 Unit heating setpoint.

Enable Lead/Lag

Use this option to turn on the lead/lag feature. Press

ENTER button to enable LEAD/LAG. Press UP or DOWN

button to change NO to YES. Press ENTER button.

Default setting is “NO”.

Unit #

Use this option to identify the unit that the ECU Series

controller will be connected to. For easy identification

in the future, it is suggested that each wall mount be

identified with a unit number. This unit number will

correspond with the controller unit number programmed

into this setting. Default setting is “1”.

Example: Four units are being set up with lead/lag

operation. Each of the four units are identified 1 thru

4, and each controller is set up with the corresponding

unit number 1 thru 4.

Press DOWN button to scroll to Unit #. Press ENTER

button. Press UP or DOWN button to select unit #.

Press ENTER button to save unit #.

# of Units

Use this option to identify how many total units will be

used in lead/lag operation. Default setting is “4”.

Press DOWN button to scroll to # of Units. Press

ENTER button. Press UP or DOWN button to select #

of units. Press ENTER button to save # of units. This

number must be the same on all the units that are used

in lead/lag operation.

Unit Temperature Setpoints for Cooling and Heating

Cooling and heating setpoints are adjustable for the

lead unit and up to three lag units. During normal lead/

lag operation, every 24 hours lead operation will rotate

to the next unit in the unit # order. Lag unit(s) will

also follow the same unit # rotation. It is important

that each ECU Series controller has the same value

for all heating and cooling setpoints to ensure that as

each unit is selected as Lead, Lag1, Lag2 or Lag3,

it operates at the same temperature settings. Default

setpoints are as follows:

• Lead Unit cooling setpoint is 72°

• Lead Unit heating setpoint is 70°

• Lag1 Unit cooling setpoint is 74°

• Lag1 Unit heating setpoint is 68°

• Lag2 Unit cooling setpoint is 76°

• Lag2 Unit heating setpoint is 66°

• Lag3 Unit cooling setpoint is 78°

• Lag3 Unit heating setpoint is 64°

Press DOWN button to scroll to LEAD COOL SETPT.

Press ENTER button. Press UP or DOWN button to

adjust. Press ENTER button to save.

Repeat above steps for each of the units’ lead and lag

setpoints as needed.

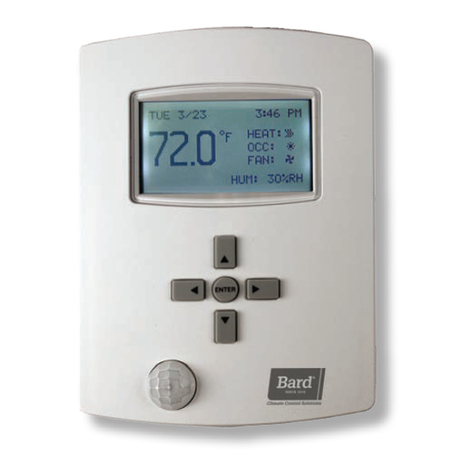

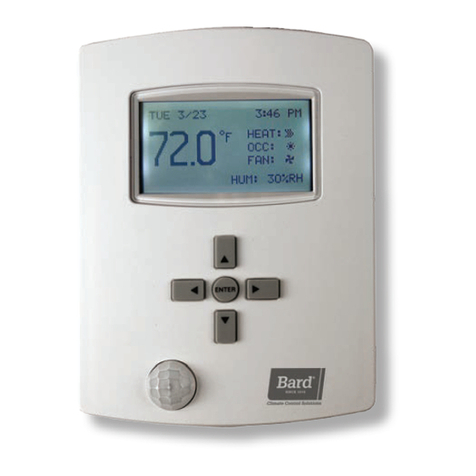

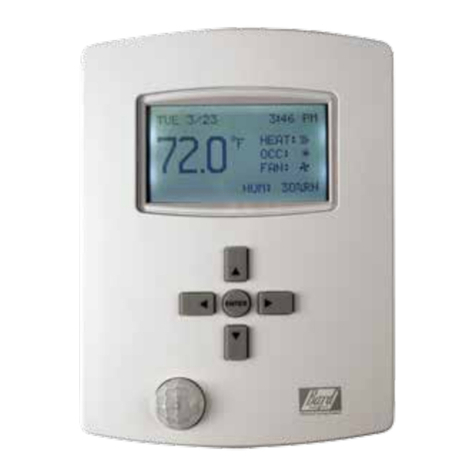

The Home screen will show the unit lead/lag status

continually. This is located on the top line of the

display between the date and time. The screen will

display one of the following status indicators: LEAD,

LAG 1, LAG 2, LAG 3. THe lead/lag status determines

the setpoint that will be used that day. Status will

rotate based on day of the year.