1About this Document 1

1.1 Objective and Target Audience of this User Manual.................................................. 1

1.2 Symbols and Typographic Conventions...................................................................... 1

1.3 Figures ........................................................................................................................ 2

1.4 Other Applicable Documents ..................................................................................... 2

1.5 Downloading Manuals................................................................................................ 3

2Safety 5

2.1 Intended Use .............................................................................................................. 5

2.2 General Safety Instructions ........................................................................................ 5

2.2.1 Organizational Measures............................................................................... 6

2.2.2 Safety Measures During Installation.............................................................. 6

2.2.3 Safety Measures when Starting and Operating............................................. 7

2.2.4 Safety Measures During Maintenance .......................................................... 7

3Product Description 9

3.1 System Overview........................................................................................................ 9

3.2 Model Overview ....................................................................................................... 10

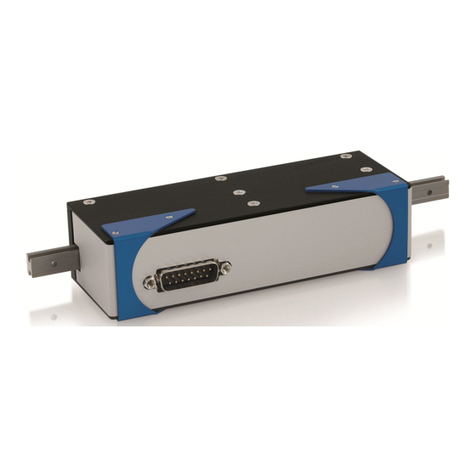

3.3 Product View ............................................................................................................ 11

3.4 Product Labeling....................................................................................................... 11

3.5 Scope of Delivery...................................................................................................... 12

3.6 Suitable Controllers .................................................................................................. 12

3.7 Accessories ............................................................................................................... 12

3.8 Technical Features.................................................................................................... 13

3.8.1 Limit Switches .............................................................................................. 13

3.8.2 Reference Switch......................................................................................... 13

4Unpacking 15

5Installation 17

5.1 General Notes on Installing ...................................................................................... 17

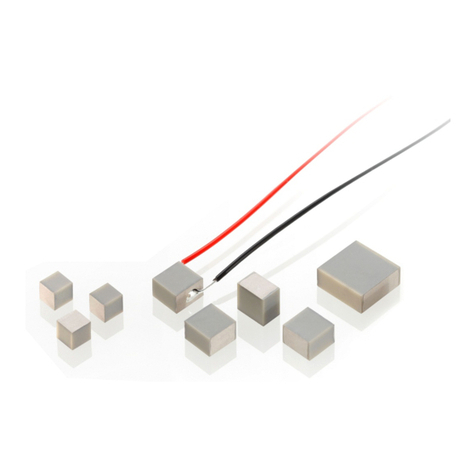

5.2 Changing the Tip....................................................................................................... 18

5.3 Providing a Suitable Mechanical Mounting and Installation Environment.............. 20

5.4 Installing the M-228 / M-229 in a Mechanical Mounting ........................................ 21

5.5 Connecting the M-228 / M-229 to the Controller.................................................... 23

6Startup 25

6.1 General Notes on Startup......................................................................................... 25

Contents