Barford SM312 User manual

MODEL SM312

Model SM312

OPERATOR MANUAL + PARTS LIST

MODEL SM312

2

Contents

1 Introducon............................................................

2 Warranty.................................................................

3 EU Declaraon........................................................

4 Safety Recommendaons......................................

5 Decals For Machine Operang…………………………...

6 Know Your Machine...............................................

7 The Power Unit and Controls……………………………..

8 Transporng Conveyor .........................................

9 Operang the Diesel Powered Conveyor............

10 Maintenance.......................................................

11 Technical Specicaons.....................................

12 Technical drawings…………………………………………...

13 Hydraulic Schemac………………………………...........

14 Electrical Schemacs………………………………………..

Spare Parts List..................................................

Notes……………………………………………………………..

3

4-6

7

8-12

13

14-15

16-19

20

21-23

24-28

29

30

31

32-36

37-50

51

Page:

3

MODEL SM312

Thank you for purchasing an Barford conveyor.

This manual is as important as your conveyor and should be read thoroughly before

operang your machine.

Safety is always at the forefront at Barford Equipment Ltd. It is recommended that all

safety informaon should be read and followed.

MANUFACTURER:

Barford Equipment Ltd

72-74 Omagh Road

Dromore

Co.Tyrone

N.Ireland

BT78 2AJ

Tel: + 44 (0) 2882 897401

Serial Number: ______________________

Product / Model: ______________________

1) INTRODUCTION

MODEL SM312

4

Barford Conveyors carries a one year warranty on labour and on all non-consumable

parts.

All Barford Conveyors are carefully examined and tested before leaving the premises.

Every Barford machine must be registered for warranty. Please complete the Warranty

Registraon Cercate on the next page. One copy should be kept by you the customer

and a copy returned to Barford Equipment Ltd at the above address . Before warranty

can be honoured a Warranty Cercate must be held on le at BARFORD EQUIPMENT

LTD.

NOTE: If servicing or repairing any parts that is non factory supplied will invalidate

the warranty. It is the sole responsibility of the operator to read, understand and

comply with all instrucons as stated in this manual.

2) WARRANTY

5

MODEL SM312

Your Warranty starts from the day that warranty registraon has taken place

Date:______________________ Serial Number:_________________________

SAFETY

Has the Manual been read and understood?

Have you carried out a risk assessment for the proposed

working area?

Do you have a proper working Radio Remote (oponal extra)?

Is the machine set up on a level surface?

Any extra opons are in place?

All guards are ed and secure?

Are you happy with the rst test of the machine?

If not, why?

HYDRAULICS AND THE CONVEYOR

Check oil level and for water in the diesel tank?

Comments________________________________________________

Check oil level in hydraulic tank?

Comments________________________________________________

Are the control valves operang?

Any leaks in the hydraulic system?

Are all persons who will be operang the machine fully trained

and informed of the workings of the machine?

Is the control panel and emergency stops in good working order?

Is the belt tracking?

Checked tension of discharge belt?

Copy to be retained and hard copy to be returned to above address.

Please Note: no warranty registration received means no warranty on machine

Barford Equipment Ltd

72-74 Omagh Road

Dromore Co.Tyrone

N.Ireland BT78 3AJ

T: + 44 (0) 2882 897401

Registraon Cercate

YES NO

YES NO

YES NO

YES NO

YES NO

YES NO

YES NO

YES NO

YES NO

YES NO

YES NO

YES NO

YES NO

YES NO

YES NO

MODEL SM312

6

Copy to be retained & hard copy to be returned to Barford oce.

Please note: No warranty registraon received, means no warranty on the machine!

Customer Name:

BARFORD Dealer/Distributer:

Customer Contact Name:

Contact:

Customer Contact:

Phone Number:

Customer Full Address:

Applicaon:

Engine Registered:

Instrucon Manual Received:

Notes or Comments:

I the undersigned conrm that I have received the Barford product and that the operators

fully understand the operaons of the machine. I was present when all checks were

marked and I hereby sign below to agreeing to the condions of the Barford warranty:

Signatures:

YES NO

YES NO

7

MODEL SM312

We the undersigned:

Barford Equipment Ltd

72-74 Omagh Road

Dromore

Co.Tyrone

N.Ireland

BT78 3AJ

Declare under our sole responsibility that the following apparatus:

BARFORD

Model:_________________________

Serial Number:___________________

Is in conformity with the following relevant EC legislaon:

Machinery Direcve 2006/42/EC

Based on the following harmonised standards: EN12100-2:1998, EN ISO 12100:2010, BS

EN ISO 4413:2010 and therefore complies with the following essenal requirements of

the Machinery Safety Direcve EHSR1.1, EHSR1.2, EHSR1.3, EHSR1.4, EHSR1.5, EHSR1.7.

We the undersigned, undertake to transmit, in response to a reasoned request by

naonal authories, relevant informaon on the machinery by the following method of

transmission:

Parcel

Name and posion of person binding the manufacturer or authorised representave:

Signature:________________________

Name:

Funcon:

Locaon: Same as above address

Date of issue:______________________

3) EU DECLARATION OF CONFORMITY

MODEL SM312

8

The Barford Conveyor is designed with Safety in mind.

Barford Equipment Ltd: reserve the right not to take responsibility for any injury or

damage if the manual is not read and followed.

Ensure all operators are familiar with the machine, its funcons and capabilies

Inadequate knowledge of the machines operaon can lead to death or serious injury;

before commencing any maintenance work ensure that all energy sources i.e. Diesel

Engine or Electric Power pack are locked out using the isolators provided and signs are in

place indicang that maintenance work is being carried out.

Ensure the machine cannot be started while others carry out work on the machine by

locking out all energy sources.

All moving parts are covered by guards and shields to prevent accident or injury. If in the

event of repair work or servicing to be carried out, these covers may be removed.

Removed guards and shields should be replaced immediately aer maintenance work is

nished. Operang the machine is not permied with missing guards.

Ensure machine is operated and driven on a level and stable surface.

OPERATING CONVEYOR SAFELY:

• Read the operator’s manual carefully taking note of all the safety informaon.

• DO NOT aempt to adjust the conveyor belt while they are running.

• If excessive machine vibraon occurs, stop the engine and remedy the problem.

CHEMICAL SAFETY:

• Always follow instrucons on chemical container. Protecve clothing should be

worn when using chemicals (gloves and goggles). Use the appropriate tools when

opening a chemical container. Always use a well venlated area.

• DO NOT smoke, eat or drink while handling chemicals. Dispose of all waste in line

with local and naonal regulaons.

HIGH PRESSURE FLUIDS:

• Check all hoses and lines regularly. Replace when needed.

• Check all connecons and ghten when needed.

• Always relieve pressure if uid escapes before disconnecng hydraulic hose or lines.

• DO NOT use your bare hands or parts of the body to check for leaks.

• Always seek medical help if an accident occurs.

4) SAFETY RECOMMENDATIONS

9

MODEL SM312

OPERATING PERSONNEL:

• Only authorized, competent or trained personnel should operate the Barford

conveyor.

• Only authorized, competent or trained personnel should carry out maintenance

work on the Barford conveyor.

• All instrucons should be followed.

PLANT MANAGEMENT IS RESPONSIBLE FOR:

• The working area around the machine and the machine itself.

• Any persons in the area of the equipment.

• Any persons operang the equipment.

• Safety of any persons carrying out machine maintenance on site.

• Risk assessment and Health & Safety regulaons are adhered to (local and naonal).

• Ensuring that all doors and guards are closed and installed correctly.

• Ensuring that all maintenance issues, electrical or mechanical, are xed before

machine is operated.

ON SITE ENVIRONMENT:

• Risk assessment should be carried out before, during and aer operaon of the

machine.

• Ensure appropriate measures are taken for site personnel training in Health & Safety

awareness.

• All hazardous materials must be handled in accordance with the manual

instrucons.

APPROPRIATE CLOTHING:

• All persons operang the machine should wear appropriate clothing e.g. Hard hat,

ear protecon, dust masks and protecve footwear.

• Any loose clothing should be tucked in and kept away from rotang parts.

4) SAFETY RECOMMENDATIONS CONTINUED

MODEL SM312

10

WORKING WITH ELECTRICS:

• It is recommended that any persons working with the electrical operaons on the

conveyor must work to the standards of EN50110 or similar.

• Before starng machine ensure that all electrical cables and connectors are in good

working order. Also de-energised parts are checked for presence of power and

ground or short circuit them in addion to insulang elements and adjacent live

parts.

• Use recommended current rating original fuses. If the operator suspects that there is a

problem, switch off the machine immediately.

• Before starting the machine, the isolator that carries the high voltage must be earth

bonded by a qualified electrician.

• Always risk assess the area where the machine will be in operation for overhead

cables and other dangerous obstacles. If contact is made with a live wire, de-energise

and alert all persons about approaching and touching the machine immediately.

• When cleaning the conveyor DO NOT hose down any electrical enclosures or the

electrical motor.

4) SAFETY RECOMMENDATIONS CONTINUED

11

MODEL SM312

DECALS FOR MACHINE SAFETY:

Operators should be familiar with all equipment and be trained in their safe use. Before

operation the operator must:

• Have read and understood the operators manual and all safety signs in the manual and on

the machine.

• Have received specific and adequate training in the operation to be carried out.

• Know the location and function of all controls on the machine.

• Know the location of all Emergency Stops and other safety equipment.

• Be aware of all moving parts of the machine.

Listed below are all the safety signs used throughout this manual and on the machine.

Operators must be familiar with these signs and be aware of their meaning. These signs are

used in this manual to warn of some of the potential hazards, which may exist while

operating this machine.

DECALS FOR MACHINE SAFETY:

4) SAFETY RECOMMENDATIONS CONTINUED

WARNING: Finger Crush

Hazard.

Be careful around machines pinch

points.

WARNING: Electric Shock

Hazard.

Beware of overhead cables when

selling up or moving the machine.

WARNING: Entanglement In

The Conveyor Hazard.

Make sure all guards are in place, shut

off the engine and remove the key

before performing maintenance or

repair work.

WARNING!

Read the instruction

manual before

proceeding.

WARNING: Possibility Of

Crushing By Overhead

Conveyor.

Stay a safe distance from the conveyor

while it is being raised or lowered

WARNING: Falling Objects

Hazard.

Stay a safe distance from area.

MODEL SM312

12

Emergency Stop Button.

Noise level.

Hydraulic oil

tank.

Diesel tank.

Mandatory:

Use eye protection.

Mandatory:

Use hearing protection.

Mandatory:

Wear a hard hat.

Mandatory:

Wear respirator.

4) SAFETY RECOMMENDATIONS CONTINUED

WARNING:

Rotating

Blade

Hazard.

Do Not Operate

With Guard

Removed or

opened.

Lockout/Tagout

Before Servicing.

WARNING:

High Pressure

Fluids Hazard.

Read the

instruction manual

before proceeding.

WARNING:

Crush Hazard.

Nip point.

NOTE: Actual decals on your machine may dier slightly from

above as new versions are released.

DECALS FOR MACHINE SAFETY

Hot surface:

Do not touch machine exhaust guard

when machine is running.

13

MODEL SM312

5) DECALS FOR MACHINE OPERATING

1. AWAY FROM OPERATOR.

(BLANK)

0. NEUTRAL POSSITION.

2. TOWARDS OPERATOR.

(CONVEYOR RUN)

3. FLOW CONTROL VALVE.

1. AWAY FROM OPERATOR.

(BLANK)

0. NEUTRAL POSSITION.

2. TOWARDS OPERATOR.

(SCREENBOX RUN)

3. FLOW CONTROL VALVE.

MODEL SM312

14

Please take note of all the dierent components of the machine

6) KNOW YOUR MACHINE

D: Jack Legs

F

HG

C

E

D

BA

Number: Description

ABeacon

BConveyor

CChassis

DControl panel

EPower unit

FSupport rest

Number: Description

GMaterial

Loading point

HTop screening

deck

IScreen box

spring

JBottom

screening deck

KToe Hitch

J

K

I

15

MODEL SM312

Emergency stop buon locaons:

6) KNOW YOUR MACHINE CONTINUED

There are two emergency stops on this machine. They are located

at the back of the conveyor, one at each side. In the event of an

emergency push this button. To release the button turn clockwise.

MODEL SM312

16

The power unit is aached at the chassis and provides the power output. This contains

the control panel, Hydraulic pump, engine throle, engine, oil cooler, conveyor belt

control valve bank and also the screen box control valve bank. The hydraulic and diesel

tanks are placed at either side of the power unit.

7) THE POWER UNIT AND CONTROLS

N

L

M

Number: Description

LControl

Valves

MEngine

NHydraulic

tank

OBattery box

PBattery pow-

er isolator

switch

QDiesel tank

REngine fan

04

R

O

PQ

17

MODEL SM312

Standard Conveyor Control Panel

7) THE POWER UNIT AND CONTROLS CONTINUED

MODEL SM312

18

HYDRAULIC TANK FILL CAP, INDICATOR AND RETURN LINE FILTER:

The indicator is located at the side of the hydraulic tank, the return line lter and oil ll

cap is located on the top of the hydraulic tank.

SHUT DOWN OF DIESEL CONVEYOR:

• Observe all safety warnings. Make sure the conveyor is empty and clear of all ma-

terials.

• Empty the conveyor.

• Lower the engine revs using the hand throle.

• Stop the main conveyor unit.

• Stop the engine.

7) THE POWER UNIT AND CONTROLS CONTINUED

Hydraulic oil fill cap.

Return line filter.

Oil indicator

level

19

MODEL SM312

CONTROL VALVES AND HAND THROTTLE:

The control valves and speed adjustments are contained within the power unit.

The conveyor belt and the screen box have two separate control valves. To operate the

conveyor belt and the screen box pull lever towards the operator. To stop the conveyor

belt and screen box return levers to upright posion, this is the neutral posion.

To control the speed of the conveyor belt and screen box there are two ow control

thumb screws on top of each valve.

The engine throle lever is located under engine control panel. The engines rpm is

adjusted from here.

7) THE POWER UNIT AND CONTROLS CONTINUED

Flow control valves

Engine Throttle lever

MODEL SM312

20

Observe all safety warnings.

Before seng up for transit, ensure that the belt and screen box is clear of any material.

To set the conveyor up for transit the following steps must be followed:

1. Stop the engine.

2. Turn all control valves to neutral posions.

3. Ensure all door compartments are secured.

4. Check condion of tyres, ensure the rated air pressure is in both tyres.

5. This machine is transported by using the towing eye at the front of machine.

For shipping this machine will me xed to stac stools during transportaon.

8) TRANSPORTING CONVEYOR

Towing eye

Table of contents

Other Barford Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

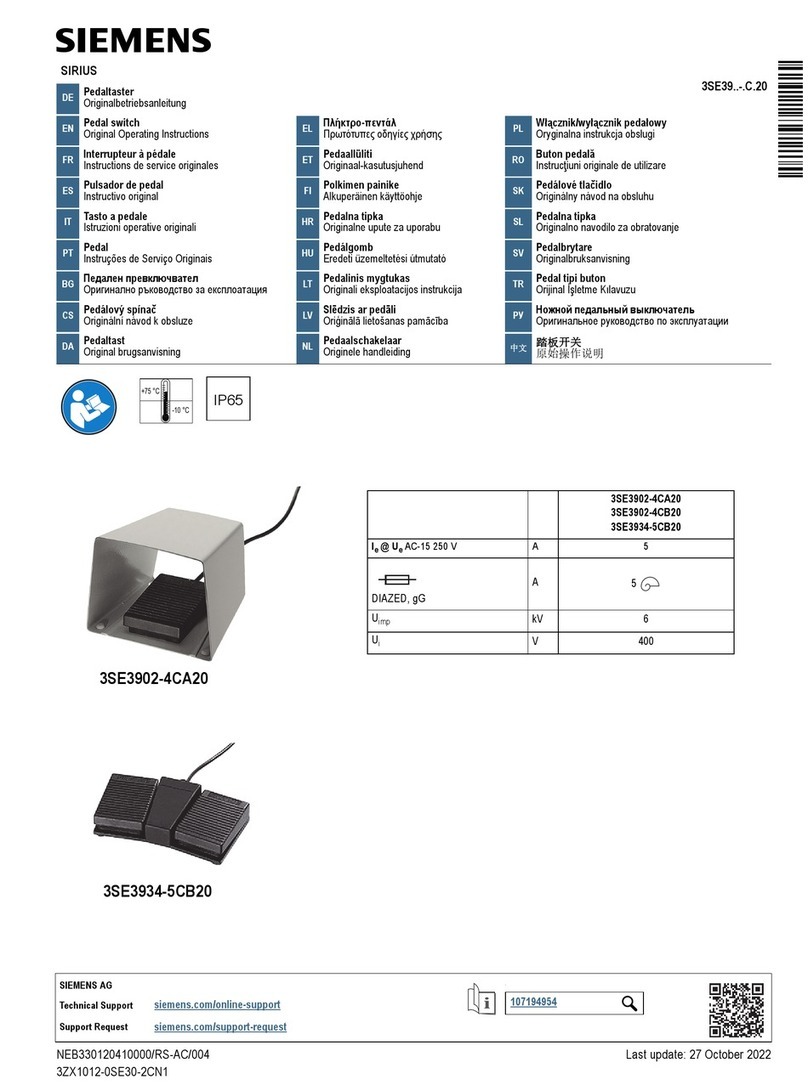

Siemens

Siemens SIRIUS 3SE39 C 20 Series Original operating instructions

finetech

finetech FINEPLACER lambda Operator's manual

steute

steute Ex 14 Mounting and wiring instructions

Emerson

Emerson Bettis M18 Installation, operation and maintenance manual

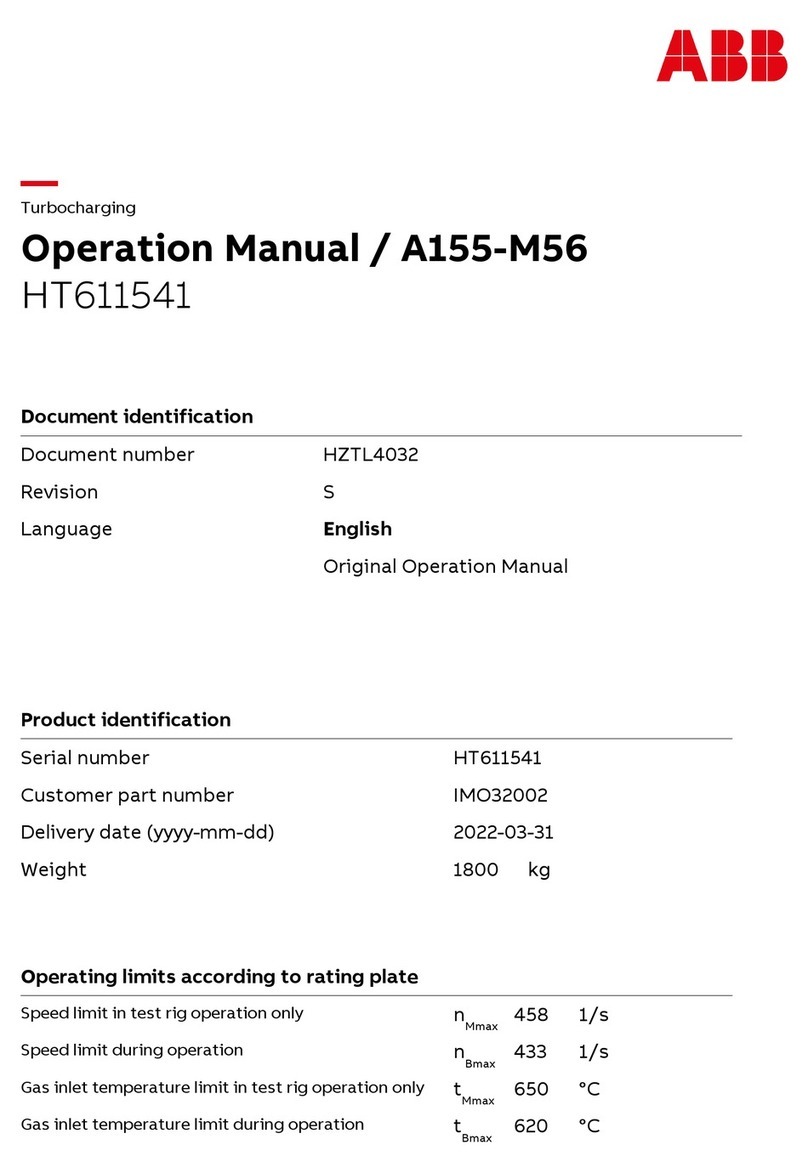

ABB

ABB HT611541 Operation manual

Airxcel

Airxcel Marvair VAIVA36 Maintenance and service manual