finetech FINEPLACER lambda User manual

FINEPLACER®lambda

Sub-Micron Bonding System

Operator’s Manual

Finetech GmbH & Co. KG

Boxberger Str. 14

12681 Berlin

Service +49 (0) 30 93 66 81-350

Fax +49 (0) 30 93 66 81-144

service@finetech.de

All specifications and characteristics are subject to change without notice.

FINEPLACER®lambda

Rev-Nr. 1.1

2

Content Page Content Page

1 HINTS FOR USING THIS MANUAL 4

2 GENERAL INFORMATION ON

FINEPLACER® SYSTEMS AND THIS

MANUAL 4

2.1 APPLICATION OF THE

FINEPLACER® LAMBDA 4

2.2 OPERATING PRINCIPLE,METHOD OF

WORKING AND SYSTEM FEATURES 6

2.3 METHOD OF WORKING,POSITIONING

AND PLACEMENT 7

2.4 PURPOSE OF THE EQUIPMENT;

WARNING AGAINST MISUSE;

WARRANTY CONDITIONS 7

2.5 GENERAL SAFETY INSTRUCTIONS:

MASS/WEIGHT 8

2.6 SAFETY REGARDING ELECTRICAL

MAINS POWER 9

2.7 ELECTROSTATIC DISCHARGE,

ELECTROMAGNETIC COMPATIBILITY 10

2.8 HEAT AND FIRE HAZARDS,RISK OF

BURNS 10

2.9 CONDITIONS OF WORK AREA;OTHER

POSSIBLE HAZARDS 11

3 THE FINEPLACER® SYSTEM 13

3.1 INTRODUCTION 13

3.2 MAJOR ASSEMBLIES OF THE BASIC

EQUIPMENT 13

3.2.2 SUPPORT ARM (71), HOLDING THE

FOLLOWING PARTS: 16

3.2.3 PIVOT ARM (27) 16

3.2.4 PLACER CONTROL BOX 17

3.3 SHORT DESCRIPTION OF BASIC

FUNCTIONS AND DIRECTIONS FOR

INSTALLATION 18

3.3.1 MAINS CONNECTION 18

3.3.2 DISPLAYS AND OPERATING ELEMENTS18

3.3.3 GENERATION AND CONNECTION OF

VACUUM AND COMPRESSED AIR 19

3.3.4 PLACER SUPPORT 19

3.3.5 CAMERA CONTROL AND POWER

SUPPLY FOR OPTIONS 19

3.3.6 RS-232 INTERFACE 20

3.3.7 FINETECH MODULE INTERFACE 21

3.4 OPERATING INSTRUCTIONS FOR THE

PLACER CONTROL BOX 21

3.4.1 SWITCHING ON 21

3.4.2 CONTROLLING THE BRIGHTNESS 22

3.4.3 UNDERSTANDING THE VACUUM

CONTROL 22

3.4.4 VACUUM CONTROL SAFETY SYSTEM 23

3.5 PARTS,CONTROLS AND INDICATORS 23

4 INSTRUCTIONS FOR SET-UP27

4.1 INITIAL SET-UP OF THE

FINEPLACER® 27

4.1.1 PREPARATION OF THE BASIC

COMPONENTS AND SUBASSEMBLIES 27

4.1.2 PREPARATION OF THE POSITIONING

TABLE'S HEIGHT ADJUSTABLE

TRACKS 27

4.1.3 PROVIDING SUITABLE PLACEMENT

HEADS FOR THE PIVOT ARM 28

4.1.4 INTERCONNECTION OF THE LAMBDA 28

4.1.5 PRELIMINARY SETTINGS AND

CHECKOUT 29

4.2 ADJUSTING THE PLACEMENT

ACCURACY OF THE LAMBDA29

4.2.1 REQUIRED TOOLS: 30

4.2.2 DISTINGUISHING BETWEEN LAMBDA

A6, A7 AND A7+ 30

4.2.3 ADJUSTING THE PLACEMENT

ACCURACY 30

4.3 ADJUSTING THE PLACEMENT ARM'S

COPLANARITY 35

5 OPERATING INSTRUCTIONS 38

5.1 ADJUSTABLE LOCK POSITION FOR THE

MANUAL OPTICS SHIFTING 38

5.2 LOADING THE COMPONENT FOR

PLACEMENT 39

5.3 ALIGNMENT 39

5.4 PLACEMENT 39

FINEPLACER®lambda

Rev-Nr. 1.1

4

1Hints for Using this Manual

Please read the safety instructions first before operating the FINEPLACER®

•Have a look at the pictures before reading the operating instructions to

familiarize yourself with the FINEPLACER®. Start with the basic machine and

do the same with each module belonging to your special system configuration.

•Read the operating instructions.

•Read the maintenance instructions.

•Learn more about the most important points for avoiding problems.

•In case of defects, and before dismantling anything, contact your dealer or the

manufacturer.

•Perform the same procedure for all other optional module-concerned parts

attached after part A.

2General Information on FINEPLACER®Systems

and this Manual

This manual will be updated regularly, however, it is possible that it does not cover all

the details of your equipment accurately, subject to errors and technical changes,

especially those made on a customer's request. For optional modules, see also

specific manual sections.

Assured properties must be agreed upon by contract expressly and in writing.

The trade name 'FINEPLACER®' is now registered with Systems 2000 GmbH within

the United States of America.

2.1 Application of the FINEPLACER®lambda

The lambda is designed to position fine pitch devices e. g. Flip Chips and Flip Chip

assemblies, optoelectronic components, micro electro mechanic systems (MEMS),

micro optoelectronic mechanic systems (MOEMS), sensors, micro optics, TAB, bare

chips and other high-count surface mounted devices (SMD). The FINEPLACER®

System is based on a unique placement principle integrated into five machine models

according to the type and sizes of the various components and substrate dimensions.

Using the highly accurate Vision Alignment System (VAS), the FINEPLACER®lambda

is designed to accurately place the component on the first attempt. As its accuracy is

1 µm, it is possible to position new technology components with very fine pitch

uniformly and accurately.

FINEPLACER®lambda

Rev-Nr. 1.1

5

Optional accessories include special optics for positioning large fine pitch devices on

their substrates and high magnification systems for observing chip bonding. All state

of the art bonding technologies can be performed, such as thermocompression,

ultrasonic/thermosonic bonding, ACF bonding, UV cure and bonding of C4 chips. Due

to the modular system, the necessary configuration may easily be optimized,

corresponding to your individual requirements. As every FINEPLACER®, the lambda

allows cost effective and safe manual component placement and bonding at one

work station and in the same operation.

FINEPLACER®lambda

Rev-Nr. 1.1

6

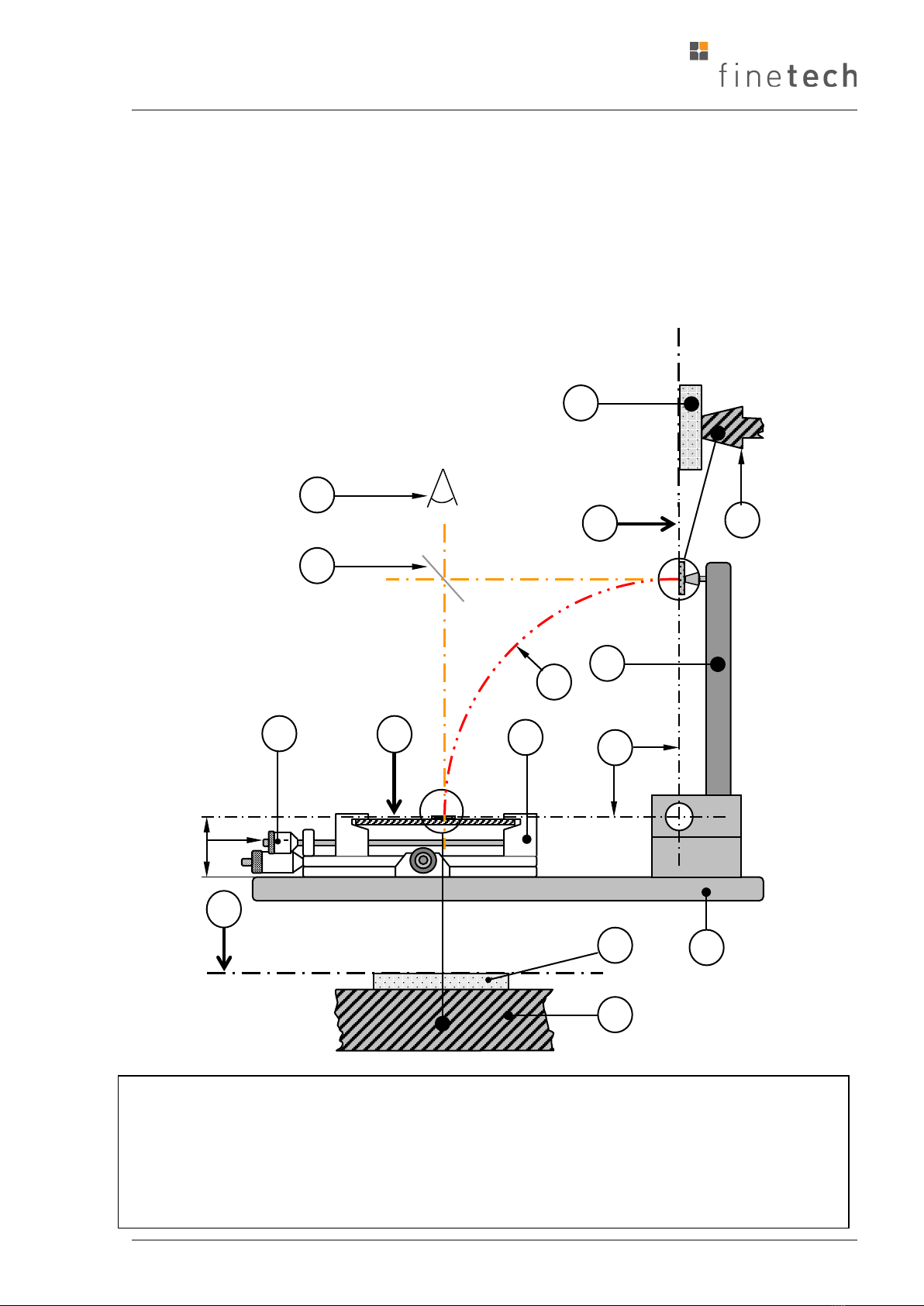

2.2 Operating Principle, Method of Working and System

Features

The patented advanced Vision Alignment System of the lambda is based on the

principle of imaging two orthogonal images simultaneously into one common image

plane, using a stationary beam splitter (30) and a single beam deflection (see fig. 1):

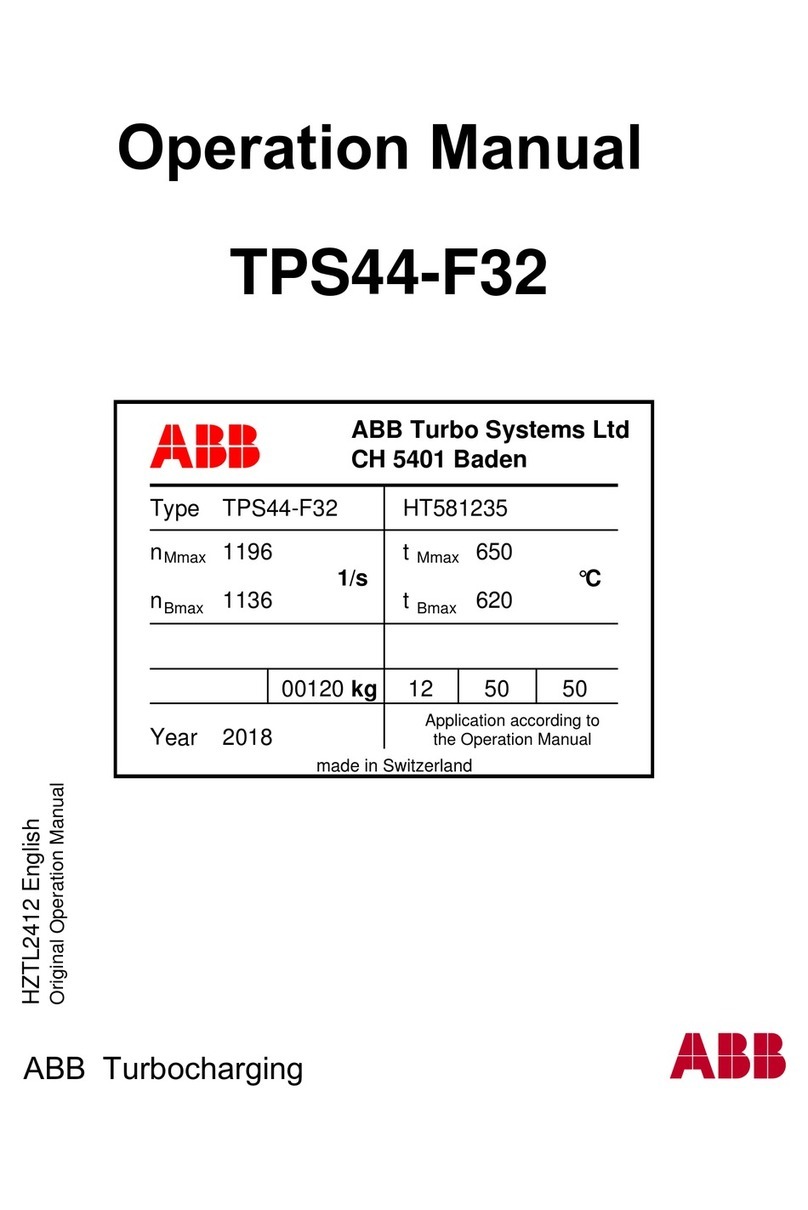

Fig. 1: Operating principle of A6/A7 (sketch of the lateral view, right hand side)

A Observation point (camera) B Working level

C Bottom glass scale or substrate D Surface of the heating

E UAP Upper Arm Position F Top glass scale or component

H Working level and UAP must form angle of 90°

A

F

H

30

C

B

51a

E

B

70

D

27

29

G

20

FINEPLACER®lambda

Rev-Nr. 1.1

7

The configuration shown in fig. 1 allows orthogonal view of the objects

component (F) and substrate (C), so both are seen to be observed "vertically from

above" (A). The overlay image allows a comparison of all connectors on each

component lead with each substrate pad at a glance.

2.3 Method of Working, Positioning and Placement

To adjust the positioning table (29) manually, observe the dual image overlay

through the video system. Coarse align using the air cushion, fine align by means of

the micrometer screws. Angular deviations are eliminated by turning the positioning

table around an electromagnet mounted in the optical axis.

Shift the video optics to the right-hand end position and place the component held in

the positioning head (F) on the substrate (C) by simply swinging down the pivot

arm (27) following the curve (G). To release the component, switch off the

placement head's vacuum by pressing the vacuum foot switch.

FOR AN ACCURATE PLACING IT IS AN ESSENTIAL PRECONDITION,

•THAT THE TABLE HEIGHT HAS BEEN BROUGHT INTO THE WORKING LEVEL(B) WITH THE HELP

OF THE MICROMETER SCREW (51A)AND THAT THE UPPER ARM POSITION (UAP) HAS BEEN

ADJUSTED AS DESCRIBED IN 4.2.2, SO THAT LEVEL (B) AND (E) FORM AN RIGHT ANGLE.

•THAT THE BEAM SPLITTER (30) HAS BEEN ADJUSTED CORRECTLY AS DESCRIBED IN 4.2.3.. IT

IS NOT NECESSARY TO PERFORM THE ADJUSTMENT PROCEDURE BEFORE EACH WORKING

PROCESS BUT TO CHECK IT OCCASIONALLY.

2.4 Purpose of the Equipment; Warning Against Misuse;

Warranty Conditions

The FINEPLACER®equipment is intended only for industrial and skilled trade use and

must be run and serviced by qualified personnel only. Everyone must observe the

caution, circumspection, and responsibility required to run this equipment, consisting

of mechanical, optical, mains powered, electromechanical and electrical heating

appliances, and possibly using compressed air or an inert gas. Operators must not be

under the influence of alcohol or other drugs and must not allow their attention to be

distracted.

FINEPLACER®equipment is designed to be used solely for work on components and

substrates in the way intended in a configuration agreed with Finetech and together

with Finetech approved equipment. In other cases it must be expressly agreed in

writing with Finetech GmbH, Berlin, Germany, under the conditions stated in the

manual. Any other use, changes, use of foreign controls or procedures not laid down

in this manual may cause risks. Any single, complete FINEPLACER®Base Module in

proper working condition, with or without additional optional Finetech modules, is

considered to be one apparatus. Modules are not considered to be independent

FINEPLACER®lambda

Rev-Nr. 1.1

8

equipment and must not be run without being combined with our Base Module as

specified.

National and international standards and regulations for minimizing the risk of

serious injury are, as far as possible, taken into account in the development and

production of this equipment as applicable to ("Conformity", "CE"), but danger

caused by improper use or by breakdown remains.

The operator of the equipment is responsible for carrying out safety checks as stated

in the manual and should not hinder or diminish these by conditions of the working

place and its surroundings.

Manufacturer and contractor are not liable for damages or injuries caused by

improper use or unsuitable work.

The FINEPLACER®comes with a year’s guarantee that equipment will be free from

malfunctioning, material defects, and manufacturing faults, under the condition that

the equipment is used for its intended purpose only and under the specified

conditions of use, and does not extend to tools, wear and tear, glass, bulbs and

rubber parts. During the guarantee period, equipment that does not work perfectly

will be repaired or exchanged free of charge.

The guarantee only covers the aforementioned FINEPLACER®equipment, but no

consequential damage of any kind arising from breakdown, malfunction or improper

use of the equipment.

2.5 General Safety Instructions: Mass/ Weight

Some of the FINEPLACER®modules are heavy and may cause damage or be

damaged by inattentive transportation or use.

Before setting up the system, make sure that the working table can bear sufficient

load to carry the machine and its accessory. Further, check if the table is mounted in

a technically correct manner. In case of using a height adjustable table, check the

safety clamping of the height adjustment mechanism. Commercial damage or

personal injury caused by neglecting the above safety measures is not covered by

Finetech's responsibility.

Arrange cables and hoses so that nobody can get caught.

If you want to move the machine, first disconnect all cables and hoses and take the

positioning table off the base plate.

Before moving the air-bearing positioning table both hands have to be placed at the

table.

Press the pedal to move the table and keep both hands always at the table while

moving it around.

FINEPLACER®lambda

Rev-Nr. 1.1

9

Under no cirscumstances press the pedal unless both hands are on the

positioning table. Risk of damage or injury.

With activated air cushion, the positioning table’s outer edges can be moved beyond

the edges of the base plate.

Make sure that the table is not placed in an extreme position that is unsuitable for

work.

Damage can occur here due to incorrect behavior of the operator (by leaning or

putting weight on the table).

Make sure the base plate has been adjusted correctly (see 3.2 Major Assemblies of

the Basic Equipment).

2.6 Safety Regarding Electrical Mains Power

Be cautious of electrical hazards:

No wet hands, no children, no plants and no animals should come into contact with

any machine part. Always keep the equipment dry. No thin or small electrical

conducting parts (e.g. cut wires, washers) should come in the close vicinity of the

machine's electrical equipment, into connectors, or especially into ventilation slots.

Before you disconnect from the mains:

•Lay down the pivot arm and switch OFF the electrical power.

•To connect the mains, first put the (female) plug into the control box socket,

and then the other (male) plug into the (wall) outlet; disconnecting in reverse

order.

•Never pull/push leads and hoses with the lead outside the plug. Always hold

the plug in your hand.

Two-handed handling of the positioning table

FINEPLACER®lambda

Rev-Nr. 1.1

10

Protect power cords from being stepped on, driven over, crushed, cut, split etc.

especially when they are live. Only use power cords with an earth contact. Before

connecting to the mains, check the correct voltage (see technical data)!

Before changing lamps, switch off the power and wait for it to cool down.

Before changing fuses find the cause of the fault, and pull out the mains power plug!

In case of equipment trouble, switch off the mains power and call for qualified

maintenance personnel.

Electrical equipment casings must only be opened by a qualified electrician!

If using a computer to run FINEPLACER®Modules, we recommend that it is not

supplied by the mains outlet of the placer control box to prevent unintentional shut

down of the computer when turning off the FINPLACER®Modules.

2.7 Electrostatic Discharge, Electromagnetic Compatibility

Protection of ESD sensitive devices is the responsibility of the user. This means that

the FINEPLACER®has to be operated in an ESD protected area (EPA according to

IEC 61340) in any cases when ESD sensitive devices are handled. The equipment is

prepared in so far as electrostatic charges are deflected to the ground terminal.

FINEPLACER®s and their modules conform to EC Directive of Electromagnetic

Compatibility (EMC).

Magnetic fields being beyond the limits of the above directive could anyhow influence

the function of Finetech heating modules resulting in temperature deviation or

unexpected program stops.

2.8 Heat and Fire Hazards, Risk of Burns

Heating plates and other heating accessories may cause heat and fire hazards by

improper use and in the case of equipment defects. Therefore, heating equipment

must only be worked under supervision and be switched off if not in use.

During operation, heating plates, lamps and their adjacent parts may become hot; up

to approximately 400°C, and should not be touched, please use suitable tools.

Heating modules may damage substrates and devices in the case of excessive

temperature/time dosage, especially if heating plates are used. Excessive heat may

produce fumes or smoke resulting in health hazards. Therefore, measure heat

carefully, especially when using the manually controlled modules, and stop heating in

good time. Increase temperature and time settings cautiously so as not to damage

components and substrates.

Never run FINEPLACER®heating modules differently from rules given in the instruc-

tions! Never use their heat abusively against people or heat sensitive

material! Keep the direct flow of heated gas away from people and temperature

sensitive parts!

FINEPLACER®lambda

Rev-Nr. 1.1

11

If there is any sign of increasing overheating (if display shows values much higher

than set value, or heating period is longer than programmed, or ERROR light comes

on etc.), switch off the equipment and call for qualified maintenance personnel!

Heating should be stopped in case of danger caused by any heated modules. This

can be done by erecting the pivot arm, pushing the STOP key, or switching OFF the

module itself immediately (see the respective module instructions).

As long as the pivot arm is erected, the heating should not be able to be switched

ON (so as not to warm up the optics unnecessarily).

2.9 Conditions of Work Area; Other Possible Hazards

On installation of the equipment, please carefully inspect the surrounding area for

possible dangers arising for people, equipment, or work pieces.

Environmental temperature conditions below 15°C or over 35°C should be avoided

during work with the FINEPLACER®. Lower temperatures could cause functional

trouble, higher temperatures could cause overheating of the control circuits - ensure

sufficient cooling breaks. Temperature changes could influence the positioning

accuracy.

Because of the high optical magnification required in some cases, intensity and beam

concentration of the built-in illumination equipment may be rather high. On installing

and running the FINEPLACER®beware of dazzling the eyes of the operator or people

in the vicinity.

Always take care to avoid condensing water.

The optionally mounted Target Finder's Laser beam is directed downwards. During

normal operation it only runs for short periods of time and is fundamentally not

hazardous because of its low power (< 1 mW, c l as s 2 product). However, you should

avoid looking directly into the beam. Dazzling might be caused by unfavorable

circumstances such as multiple reflections on metallic support plates.

Install hoses and electrical cabling free of mechanical tension and so as not to catch

someone or to tear down parts of the equipment.

Hoses as well as compressed gas couplings and connectors should be handled

cautiously and with care and protected against damage. Protect eyes and ears when

connecting or disconnecting live gas hoses.

In case of using inert gases, insure there is sufficient ventilation of the working area!

The pressure of compressed gas for cooling purposes should be set to an adequate

level so as not to exceed a tolerable noise level. If this is not possible, use ear

protectors.

FINEPLACER®lambda

Rev-Nr. 1.1

12

ATTENTION!SUPPLY MEDIA LIKE,E.G., COMPRESSED AIR OR INERT GAS,MUST HAVE A QUALITY

ACCORDING TO THE STANDARDS DEFINED IN DIN ISO 8573-1, CLASS 4, WITH REGARD TO OIL,

WATER,AND PARTICLE CONTENTS.OTHERWISE,SERIOUS MALFUNCTIONS MUST BE EXPECTED AND

PARTS OF THE EQUIPMENT CAN BE DAMAGED.ANY DAMAGE DUE TO INSUFFICIENT MEDIA PURITY WILL

NOT BE COVERED BY WARRANTY

.

Comply with the special safety conditions given with the descriptions of the modules.

With the Finetech Bonding Force Applicators in particular, beware of bruising fingers

or damaging the work piece.

Air purity according to DIN ISO 8573-1, Class 4, stands for the following demands:

•Particle size 15 µm

•Particle density 8 mg/m³

•Pressure dew-point 3°C

•Water content 6000 mg/m³

•Oil content 5 mg/m³

FINEPLACER®lambda

Rev-Nr. 1.1

13

3The FINEPLACER®System

3.1 Introduction

Like every FINEPLACER®, the lambda has been designed for versatile use and ease

of operation and maintenance, and is made up of functional modules. The operator

should thoroughly understand the function and control of each module and tool in

the system before using it.

The numbers of machine parts given in brackets correspond to the numbers in table

2 of this text.

The Flip Chip Bonder consists of the following parts:

•Base Module with base plate (70), support arm (71), stationary beam splitter

optics (30), illumination, camera (18) and positioning table (29), further placer

Control Box (39), table foot switch (64) and vacuum foot switch, as well as

cables and hoses.

•Vision modules, e.g. or MIRAGE (37) or side camera with common video

monitor.

•Process Modules, e.g. placer arm (27) with positioning head (20), Ultrasonic

or ACF Module.

•Auxiliaries, e.g. optional pipette (24) or Target Finder.

FINEPLACER®s may be additionally equipped with various optional modules, mostly

to be retrofitted easily to adapt to customer's requirements.

3.2 Major Assemblies of the Basic Equipment

3.2.1.1 Base Plate (70)

The base plate carries the support arm (71) and the pivot bearing with the pivot arm

(27). Optionally it is possible to add an ultrasonic transducer to the pivot arm.

The base plate serves as the highly precise finished gliding plane for the positioning

table (29), and also contains an electromagnet which holds the table in position

when the air cushion is deactivated and allows the θfine rotation.

FINEPLACER®lambda

Rev-Nr. 1.1

14

The base plate rests on foot screws which are used to level it.

Align the base plate in a way that it slightly slopes backwards, away from the

operator.

The incline should be between 0.1 mm/m and 0.3 mm/m.

Use a circular level for alignment.

Alternatively, use a spirit level.

Make sure there is no horizontal tilt.

The table should always slowly slide away from the operator towards the machine

when the air cushion is activated. After adjusting the angle of slope, test this

movement carefully with both hands on the positioning table.

Example: Machine base plate, adjusted with spirit level

Example: Machine base plate, adjusted with circular level

Foot screw at base plate

FINEPLACER®lambda

Rev-Nr. 1.1

15

It is strictly prohibited to work with the machine before this setting has been made!

3.2.1.2 The Height Adjustable Positioning Table

•... rests on the base plate (70). It carries the height adjustable tracks used to

clamp in a substrate, a substrate support plate or a FINEPLACER®heating

plate to hold the substrate.

•... will secure the substrate position by its mass and its friction against the

base plate (70), supported by the electromagnet buried in the base plate.

•... can be moved easily for coarse positioning on an air cushion so that it may

float above the base plate (70), using the micrometer screws (50) and (51) as

temporary handles. Once coarse positioning is achieved, releasing the foot

switch will lock the table in the optical axis.

•... can be fine aligned using the x and y micrometer screws.

•... can be rotated around the optical axis to achieve θcorrection, prevented

against accidental x or y shifting by the electromagnet.

A fundamental rule is that the height of the placement surface of the substrate must

be equal to that of the pivot arm axis. To achieve this with substrates to be laid onto

heating plates or support plates, the continuously height adjustable tracks of the

positioning table have to be used to maintain the correct working height.

Table movement direction with activated air cushion

FINEPLACER®lambda

Rev-Nr. 1.1

16

3.2.2 Support Arm (71), holding the following parts:

•Vision/observation devices, basically consisting of the stationary mounted

beam splitter optics (30), providing the dual image overlay, and a video option

for vertical view, are used to view the super-imposed image of the substrate's

pads and the corresponding component leads.

•Lighting: COAX-Illumination and diffuse illuminationis standard, a Target

Fínder (AC1) is integrated.

•The pivot bearing for the pivot arm (27). Zero play of the bearing and stiffness

of the arm are fundamental for the lambda's outstanding placement accuracy.

•The connector for electromagnet, and air for the table (4).

•The adjustment means for beam splitter (31), (32), arm-UAP (72) and arm-

LAP (89).

•Target Finder (AC1), pointing to the placement area (TARGET) on the

substrate.

•Optional: Force Applicators (e.g. FD2).

3.2.3 Pivot Arm (27)

The pivot arm may be e.g. a pivot arm (27); further special arms are available, e.g.

FE1. for ultrasonics application (chip bonding). Pivot arms have their own cables and

hoses for energy transportation and control. Each arm is equipped with a hose for

the vacuum holding the component to be placed in the positioning head, e.g. (20),

and signal cabling for arm tilt switch. The tilt switch sensing the arm position,

(erected or laid down), influences many equipment functions, e.g. switching vacuum

by pipette.

The arm is only mounted to the pivot log by 2 screws (148) so it may be changed

easily if required.

Fine-θ-Adjustment-pivot arms are available.

Attention: Pivot Arm Interlock (for manual configurations)

For FINEPLACER®lambda systems in manual configuration, a specific magnetic

interlock mechanism ensures that the pivot arm can only be swivelled down as long

as the optics shifting is in swivel position.

This safety function prevents the pivot arm from swivelling down and possibly hitting

and damaging the optics while the optics shifting is not in swivel position.

FINEPLACER®lambda

Rev-Nr. 1.1

17

3.2.4 Placer Control Box

The Placer Control Box is an essential part of any FINEPLACERBasic Module. It

generates and reacts to all signals for operating the placer, as well as supplying it

with compressed air and a vacuum.

The Placer Control Box contains the following basic functional groups:

1. mains connection

2. displays and operating elements

3. generation of vacuum for fixing devices and compressed air for the

positioning table air cushion

4. placer support, consisting of:

•lighting control

•supervision of pivot arm

Magnetic interlock

Optics shifting in swivel position. Pivot arm

can be swivelled down.

Optics shifting in working position (each

position apart from swivel position).

Pivot

arm cannot be swivelled down.

FINEPLACER®lambda

Rev-Nr. 1.1

18

•locking electromagnet control

•Target Finder control

5. camera control and power supply for options

6. RS 232 interface

7. Finetech Module Interface (FMI) for connecting Finetech modules

3.3 Short Description of Basic Functions and Directions For

Installation

3.3.1 Mains Connection

The Placer Control Box has to be connected to the mains via the POWER IN plug in

the rear panel of the box using the supplied cable.

As soon as the Placer Control Box is switched on, the rear mains outlet AUX POWER

OUT is energized. Please connect all additional control boxes via the supplied

multiple box plugged into AUX POWER OUT so all FINEPLACER-modules are

switched on at the same time.

Check your mains voltage! The box must not be connected to mains

voltages different to those indicated on the rear panel's type plate.

The socket 'POWER IN' contains a fuse which exclusively serves to protect the Placer

Control Box but not all the other control boxes connected to the multiple socket.

Please take care never to exceed the maximum output current of 10 A

at 230 V or 15 A at 115 V (resistive load) respectively delivered by the

AUX POWER OUT socket.

There are two different green LED's. The LED 'LINE' indicates the presence of the

mains voltage whereas the LED 'ON' shines as soon as the equipment is switched on.

3.3.2 Displays and Operating Elements

The LED 'VACUUM STATUS' and the interior red lit switch 'VACS OFF' is used for

indication and further control of the vacuum. More detailed information about the

meaning and function of these elements is given in the following operating

instructions of the Placer Control Box (see below).

Pushing the selector switch 'PIPETTE MODE' changes the working method of the

pipette.

In the case of the lambda standard configuration the revolution transmitters 'HEAD'

is without function, and works only in combination with optional illumination

modules.

FINEPLACER®lambda

Rev-Nr. 1.1

19

The light intensity can be used because the light of head and target is balanced by

an optical shutter. For further information, refer to the operating instructions (see

below).

3.3.3 Generation And Connection Of Vacuum And Compressed Air

The built in vacuum pump operates permanently as soon as the Placer Control Box is

switched on. It supplies the placer and the pipette alternately.

In the case of placement only, the hose connector of the pivot arm is directly

connected to the socket HEAD VACUUM OUT of the Placer Control Box. In the case

of thermo compression, HEAD VACUUM OUT is connected to the Control Box of the

Heated Pick-and-Place Tool using a supplied hose. The pipette is always connected to

the plug PIPETTE.

The compressed air, necessary for the positioning table, is provided at the TABLE AIR

OUT connector.

3.3.4 Placer Support

The locking electromagnet holding the positioning table and the optional Target

Finder are connected to the SUB-D socket of the Placer Control Box via a 25-pin plug.

The Target Finder is switched on as long as the foot switch is pressed to move the

positioning table while the pivot arm is in its upright position.

The electrical cable of the pivot arm is directly connected to the socket PIVOT ARM.

The foot switch for coarse positioning is connected to the socket TABLE FOOT

SWITCH. An additional foot switch, used for controlling the pipette, may be

connected to the PIPETTE FOOT SWITCH plug. For further information, refer to the

operating instructions (see below).

3.3.5 Camera Control and Power Supply For Options

The 12 V camera power supplies of two video modules (if existing), must be

connected to the output sockets CAMERA I and CAMERA II. They are switched on

alternately depending on the position of the pivot arm: CAMERA I is on when the

arm is in the upright position, CAMERA II is on when the arm is horizontal.

At the socket OPTION OUTPUT, 12 V DC is provided continuously for driving optional

devices with a max. current of 600 mA. This output is short protected by an

automatic recovery circuit breaker.

FINEPLACER®lambda

Rev-Nr. 1.1

20

3.3.6 RS-232 Interface

The Placer Control Box possesses an RS 232 interface, its connector PC RS-232 is in

the back panel. It can be used for linking the PC to the Placer Control Box, allowing

modifications of the internal software, as well as communication between the PC and

every module connected to the placer Control Box.

Table of contents

Popular Industrial Equipment manuals by other brands

THERMA

THERMA Trapzilla TZ-1826 Installation & maintenance instructions

Oriental motor

Oriental motor EAC Series operating manual

Thomas&Betts

Thomas&Betts Elastimold Molded Vacuum Reclosers instruction manual

Tolomatic

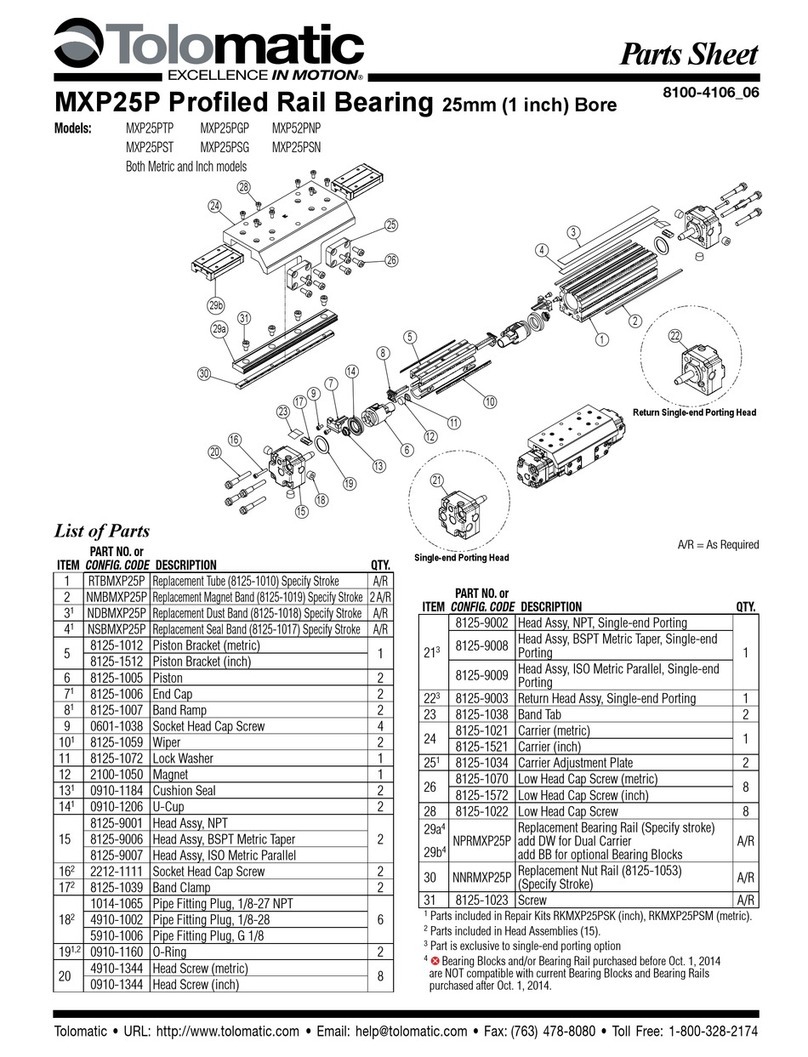

Tolomatic MXP25PTP instructions

Alfalaval

Alfalaval GJ 18 instruction manual

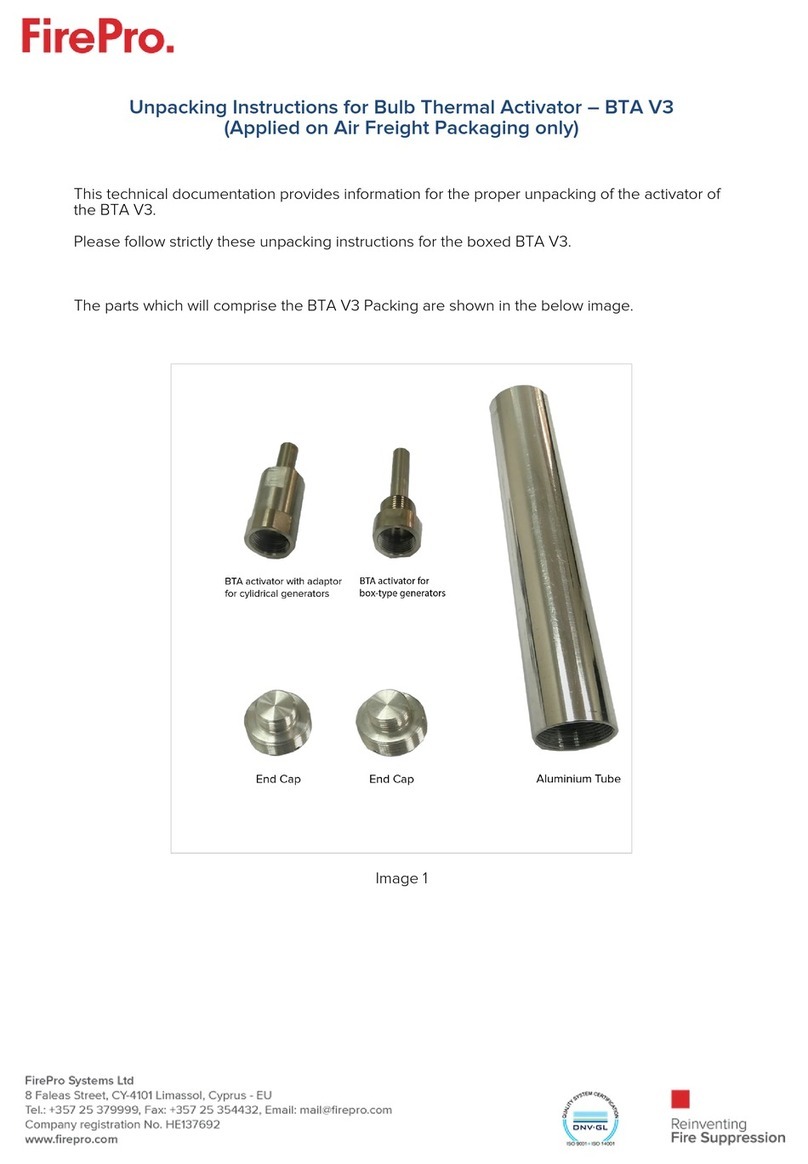

Fire Pro

Fire Pro BTA V3 unpacking instructions