OPERATION MANUAL

Minichiller® V2.4.0en/09.08.21//1.30

2.9.1 Connecting an externally closed application ..................................................31

2.10 Connecting to the power supply ................................................................... 31

2.10.1 Connection using socket with protective earth (PE).......................................31

2.10.2 Connection via hard wiring .............................................................................32

3Function description 33

3.1 Function description of the temperature control unit ................................... 33

3.1.1 General functions............................................................................................33

3.1.2 Other functions...............................................................................................33

3.2 Information on the thermal fluids ................................................................ 33

3.3 To be noted when planning the test ............................................................. 34

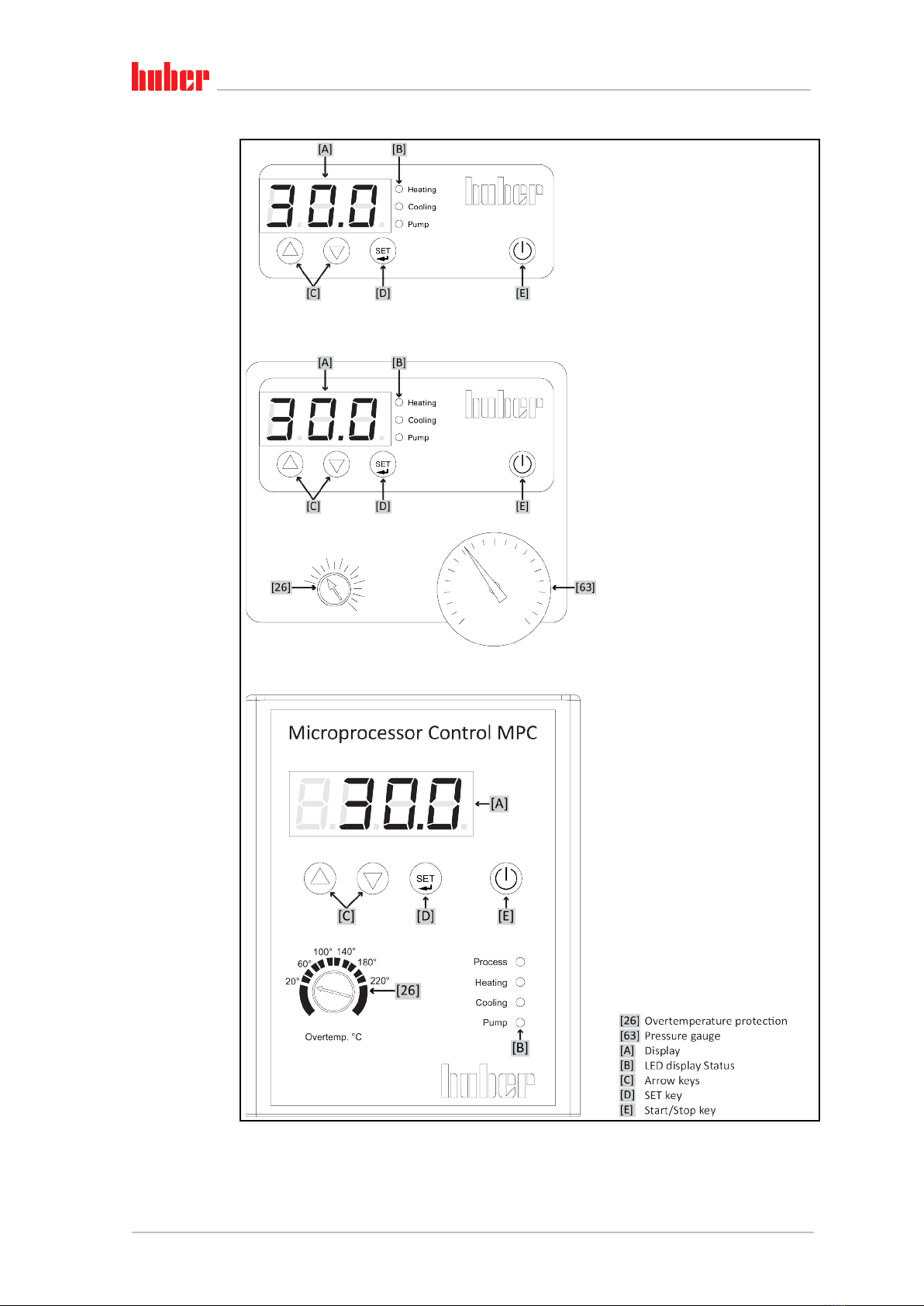

3.4 Display and control instruments................................................................... 35

3.4.1 Display.............................................................................................................35

3.4.2 LED display status ...........................................................................................35

3.4.3 Arrow keys ......................................................................................................35

3.4.4 SET key ............................................................................................................35

3.4.5 Start/Stop key .................................................................................................35

3.5 Menu function ............................................................................................. 35

3.6 Function examples ....................................................................................... 36

3.6.1 Display setpoint ..............................................................................................36

3.6.2 Set/change setpoint........................................................................................36

3.6.3 Changing the Auto-Start function ...................................................................36

4Setup mode 37

4.1 Setup mode ................................................................................................. 37

4.1.1 Turning on the temperature control unit .......................................................37

4.1.2 Turning off the temperature control unit.......................................................37

4.1.3 Setting the overtemperature (OT) protection ................................................37

4.1.3.1 General information on the overtemperature protection .........................37

4.1.3.2 Setting the overtemperature protection....................................................38

4.1.4 Testing the overtemperature protection for functionality.............................38

4.1.5 Setting the setpoint ........................................................................................39

4.2 Filling, venting and draining ......................................................................... 39

4.2.1 Filling and venting externally closed application ............................................39

4.2.1.1 Filling and venting with >Sight glass< [23] .................................................40

4.2.1.2 Filling and venting with >Level indicator and drain< [38] ..........................41

4.2.2 Draining externally closed applications ..........................................................42

4.2.2.1 Draining with >Sight glass< [23] .................................................................42

4.2.2.2 Draining with >Level indicator and drain< [38] ..........................................43

5Normal operation 44

5.1 Automatic operation .................................................................................... 44

5.1.1 Temperature control.......................................................................................44

5.1.1.1 Starting the temperature control process..................................................44

5.1.1.2 Ending the temperature control process ...................................................44

6Interfaces and software update 45

6.1 Interfaces on the temperature control unit (optional)................................... 45

6.1.1 RS232 jack .......................................................................................................45

7Service/maintenance 46

7.1 Displays in the event of faults....................................................................... 46

7.2 Maintenance................................................................................................ 47