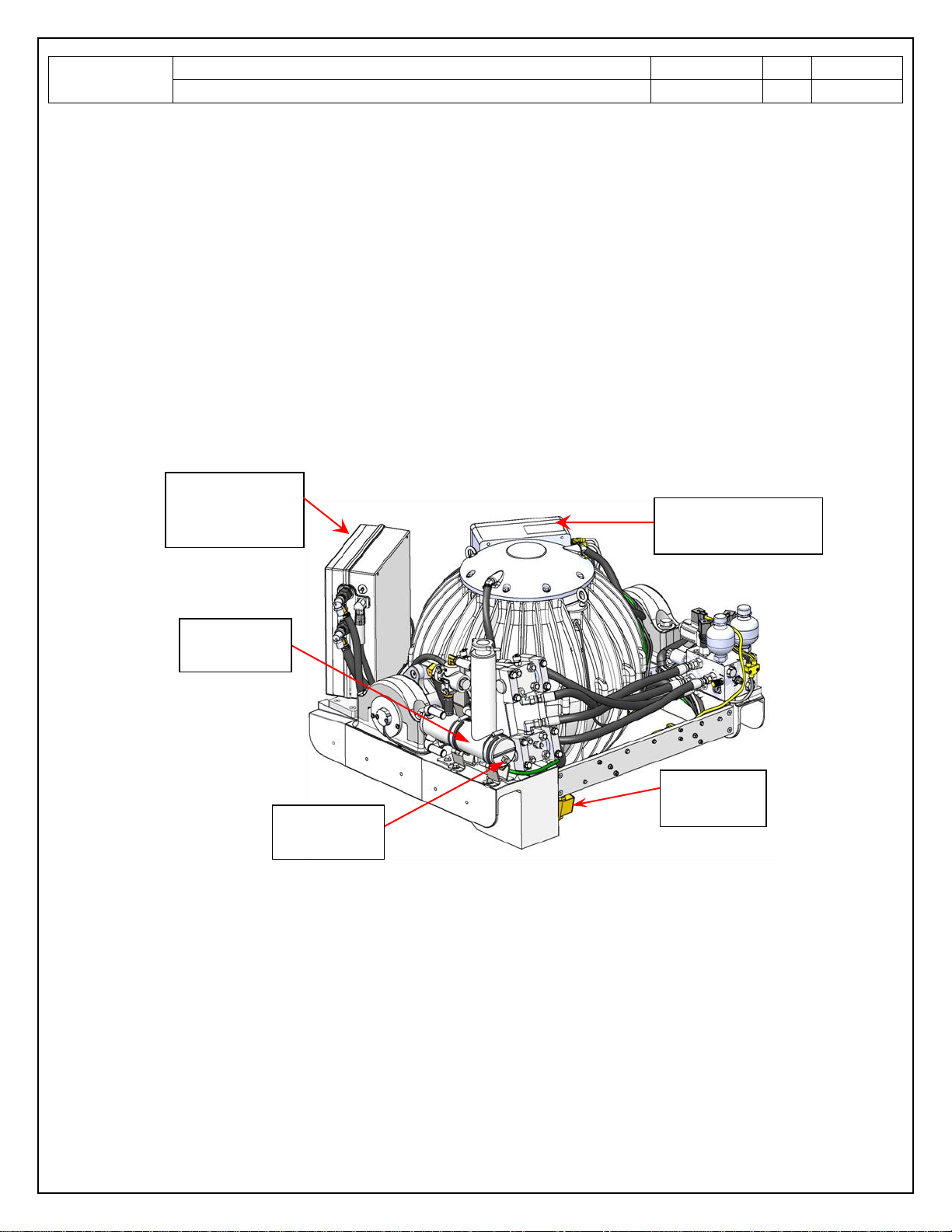

Procedure: ANNUAL INSPECTION INSTRUCTIONS

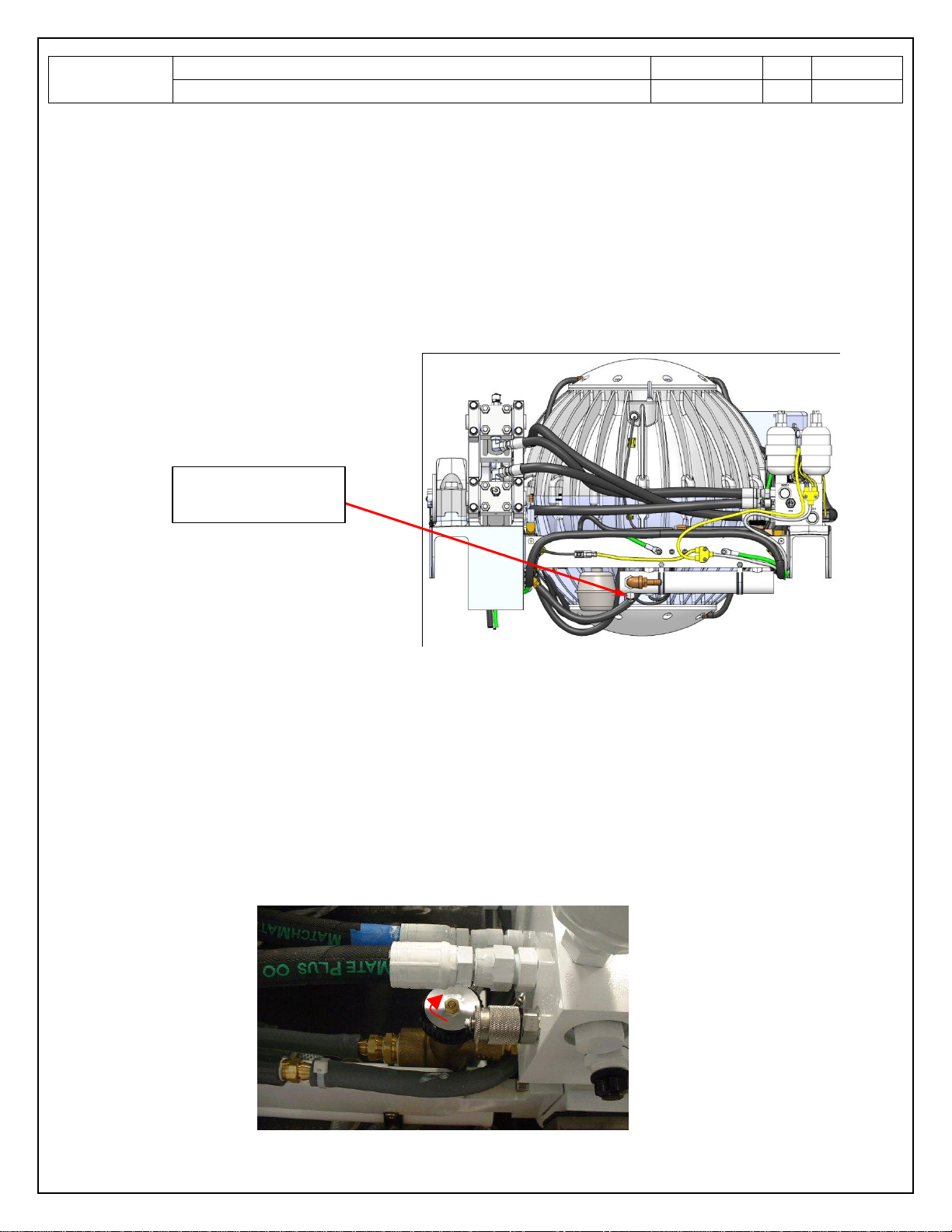

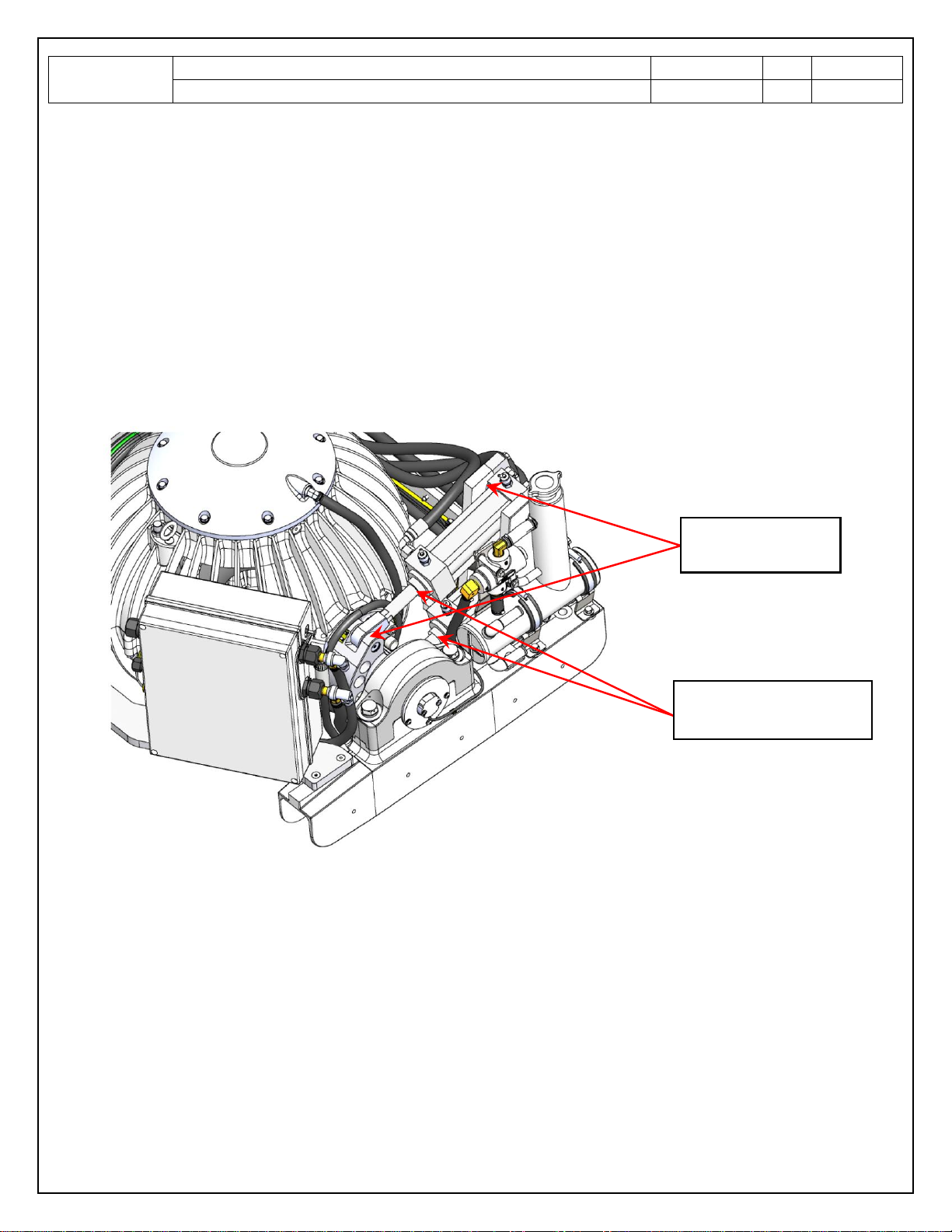

Inspect heat exchanger and fittings for any leaks or severe corrosion. The heat exchanger is

located alongside the brake cylinders on the units foundation as shown in below image. Insure

seawater cooling hoses are isolated from incoming seawater (i.e: close sea-cock) and disconnect

seawater inlet and outlet hoses. Remove plug containing zinc anode on the heat exchanger and

inspect. If erosion is estimated to be more that 50%, replace anode. If zinc anode is gone, make

point to inspect every 2 months until erosion rate is determined. The anode is a 3/8 inch diameter x

¾ inch long pencil in a ¼” NPT plug. Contact Seakeeper Service Dept. to obtain the replacement

anodes. Apply Teflon paste pipe thread sealant or Teflon pipe thread tape to the plug threads when

re-installing.

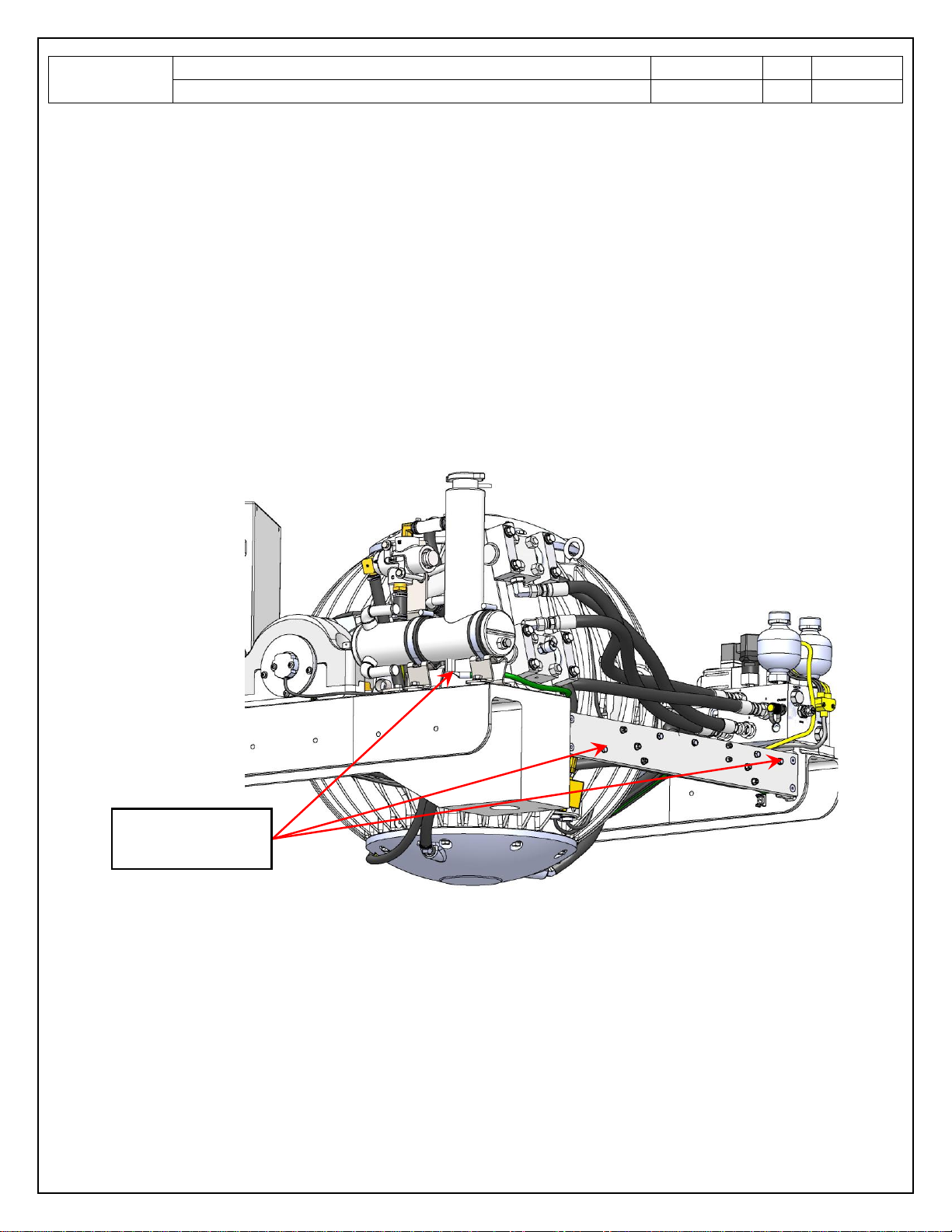

Flush heat exchanger with fresh water to insure there are no internal blockages. Once flushing is

complete , make certain to secure seawater inlet / outlet hoses to the heat exchanger with

appropriate hose clamps and open the appropriate sea-cock for the water intake.

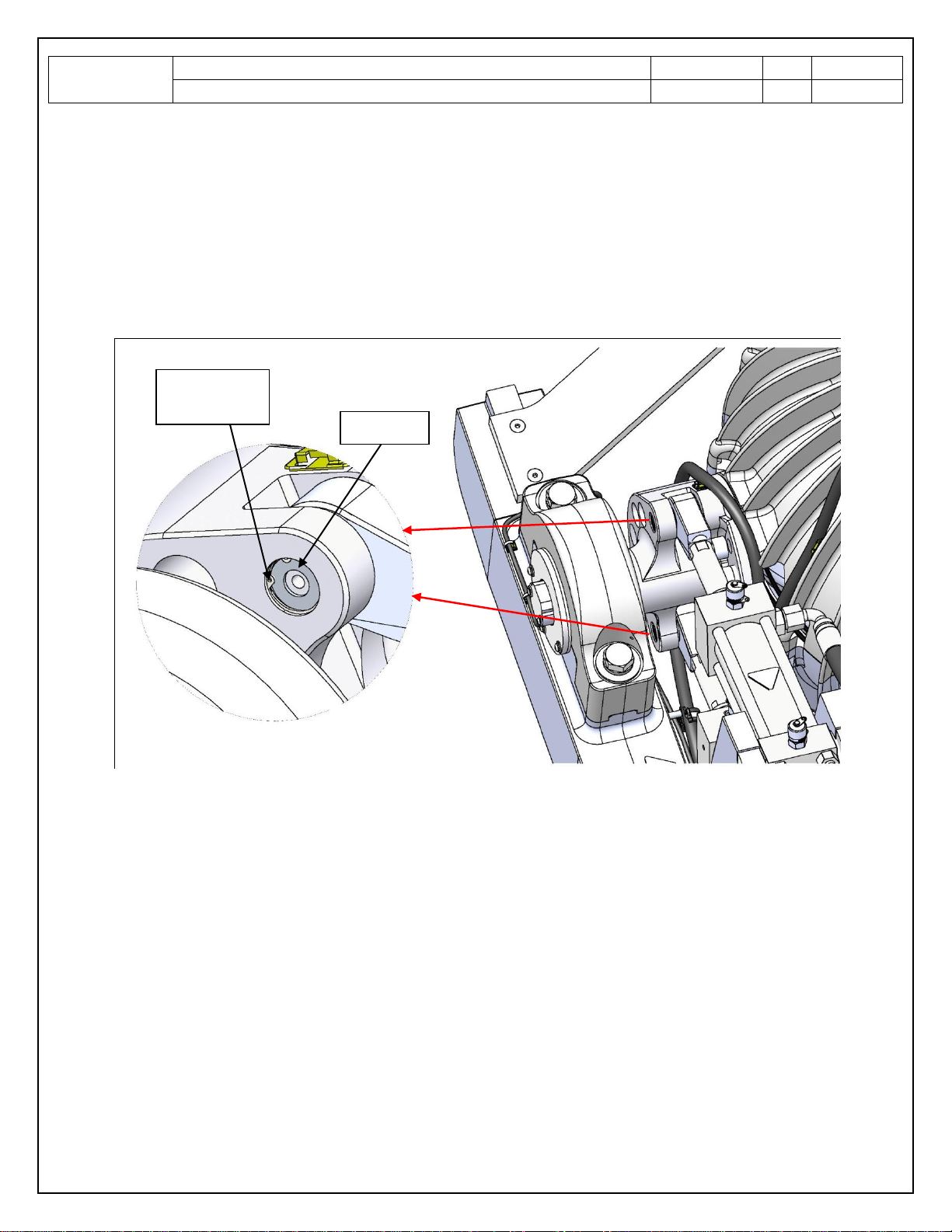

Inspect gyro sea water cooling pump for proper operation. Observe overboard discharge for

normal flow. Minimum required flow is 4 GPM ( 15.1 LPM) Obvious low flows may indicate flow

restrictions.

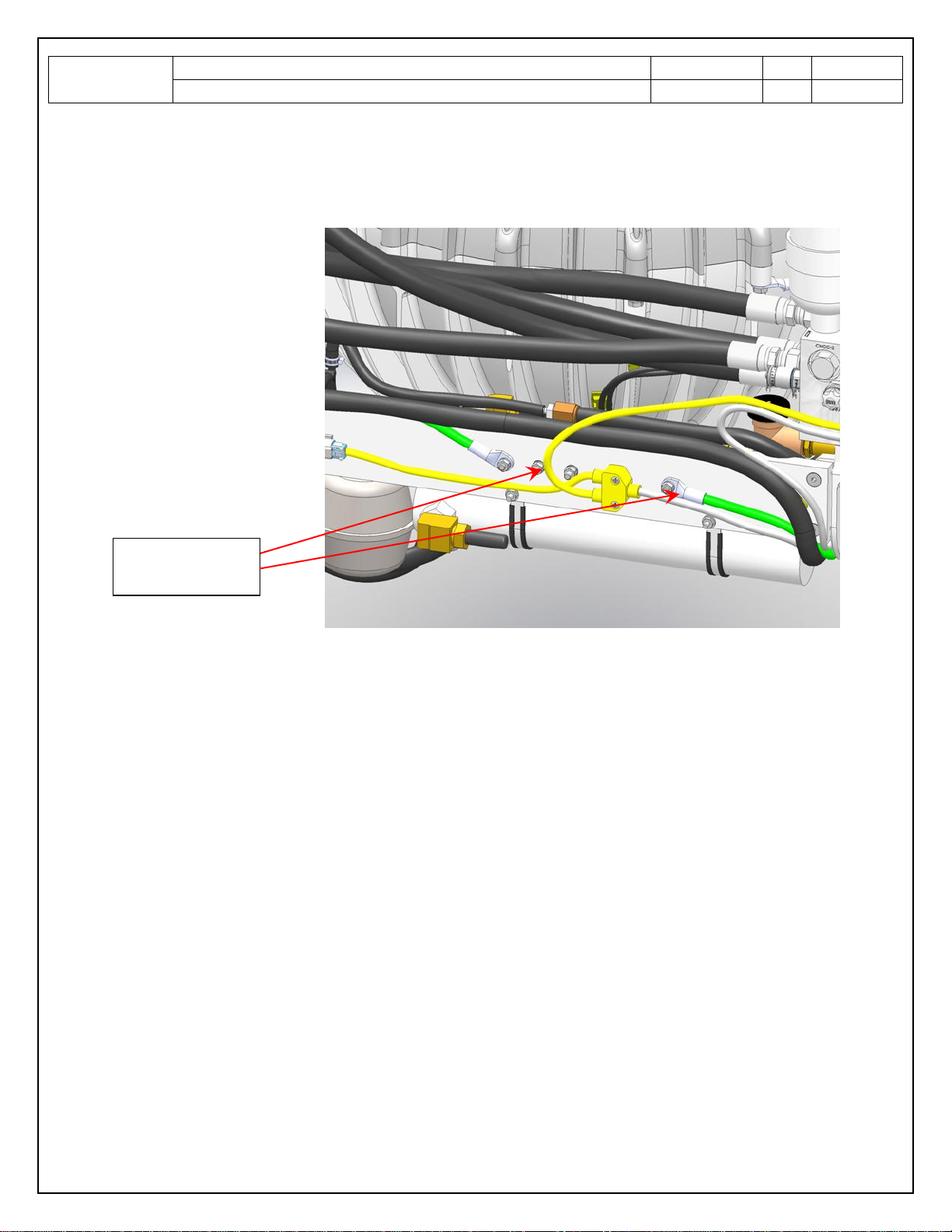

Inspect all hoses and fittings for damage / chafing –in the event a hose needs to be replaced,

contact Seakeeper Service Dept. for hose specifications and guidelines for replacing any cooling

hose.

Inspect bilge area under gyro for any indication of coolant leaks .