Barista Technology PUQpress Operating instructions

Maintenance & repair manual

Puqpress -

Precision coffee tamper

VERSION 2.0.4

DATE: 14-12-2016

2

TABLE OF CONTENTS

1Introduction.......................................................................................................... 3

1.1 Warranty........................................................................................................ 3

1.2 Model types................................................................................................... 3

1.3 Revision status.............................................................................................. 3

2Operating faults.................................................................................................... 4

3Replacement of various components................................................................... 5

3.1 Replace drive unit.......................................................................................... 5

3.2 Replace induction sensor.............................................................................. 9

3.3 Clean tamper base (daily cleaning)............................................................. 12

3.4 Remove tamper base and clean cavity (weekly cleaning)........................... 13

3.5 Adjust lower clamp ...................................................................................... 15

3.6 Adjust tamping force.................................................................................... 17

4Changing tamper base....................................................................................... 18

4.1 Upper clamp types....................................................................................... 18

4.2 Determine upper clamp type ....................................................................... 18

4.3 Espresso machine brand and tamper diameter........................................... 19

5Exploded view: Total assembly.......................................................................... 19

6Order spare parts............................................................................................... 20

6.1 Order procedure.......................................................................................... 20

6.2 Recommended spare parts......................................................................... 20

6.3 Part list (all parts)......................................................................................... 21

3

1 INTRODUCTION

In this document the repair and maintenance of the Puqpress precision coffee tamper

is described. The unit is maintenance free and only has to be cleaned daily. However

due to extensive use various components wear and can break. The sequence of

replacing components is described in detail. The first step is to find the cause of the

problem. Various possible defects are listed in section 2. If the defect is not listed in

section 2, please contact us via service@puqpress.com.

All repairs should be executed by mastered people with knowledge of electrical and

mechanical components.

1.1 Warranty

As agreed by the Exclusive distribution agreement, section 6.7, the warranty period of

the product is 12 month and/or 100.000 tamping cycles (whichever first occurs).

Repairs after this period are not covered by the supplier.

The most common failure mode is the drive unit.After many cycles the drive unit wears

and can break. Replacement of drive unit can be found in section 3.1.

1.2 Model types

Many different models are available. The main difference is the tamper base diameter,

upper clamp type and power cable. All important components are similar for every

model type.

1.3 Revision status

Revision 2.0.1: Initial issue

Revision 2.0.2: Errors updated

Revision 2.0.3: Assembly sequence updated.

4

2 OPERATING FAULTS

DEFECT CAUSE REMEDY SECTION

Tamper disk does

not move, unit is ON

and display is

working

Fault in drive unit Replace drive unit 3.1

Fault in induction

sensor Replace induction

sensor. 3.2

Tamped surface is

not even Tamper base is dirty Clean tamper base 3.3

Cavity upper clamp

is dirty Remove tamper base

and clean cavity 3.4

Tamping is not level

Lower clamp not

correctly set and

portafilter can rotate

Adjust lower clamp 3.5

Tamping force is too

low Force setting too low Adjust tamping force on

display 3.6

Fault in drive unit Clean drive unit 3.1

Fault in drive unit Replace drive unit 3.1

Tamper diameter

not correct

Change to other

tamper base

diameter

Change tamper base 4.1

Change from 58mm

base to 53mm or

53mm to 58mm

Change tamper base

AND upper clamp type 4.2

Components are

missing Various

Find missing

component in exploded

view or part list and

order spare parts

5 / 6.3

5

3 REPLACEMENT OF VARIOUS COMPONENTS

3.1 Replace drive unit

Step

Description

1

Switch the device ON and activate the CLEAN mode. Tamper

base goes down. Switch OFF and remove power cable.

2

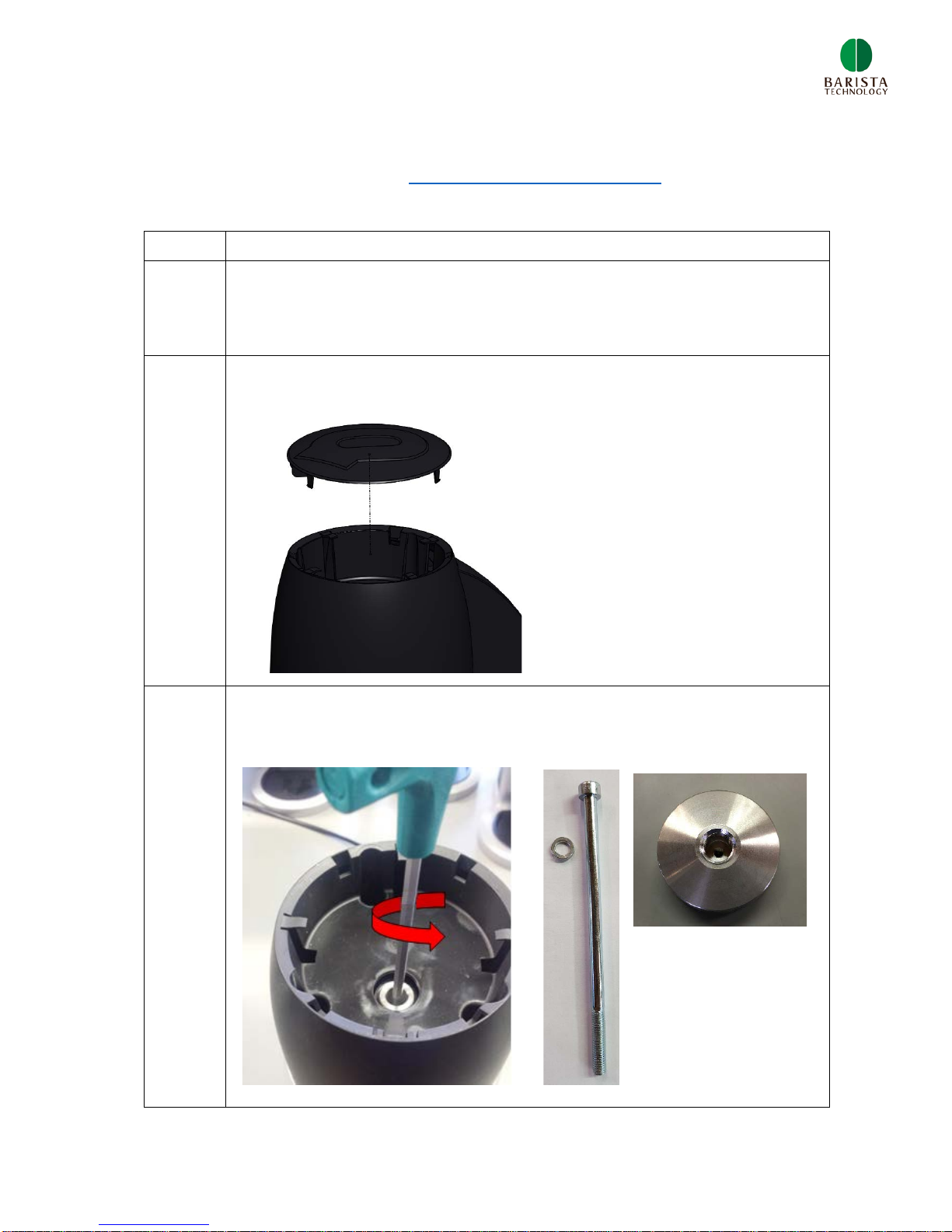

Remove main housing – top cover

3

Remove the hexagon bolt M5x100 + spring washer M5 using the

Allen key 4mm.

Remove the tamper base.

NOTE: Tamper base has left-hand screw thread!

6

4

Remove the main housing – middle cover which is mounted to the

main body with 3 cross head cap screws M4x10

5

Unscrew 2 screws as is shown in the figure below.

6

Open the main housing – back cover.

NOTE: the push buttons (red) are fragile

so be careful when opening back cover.

7

7

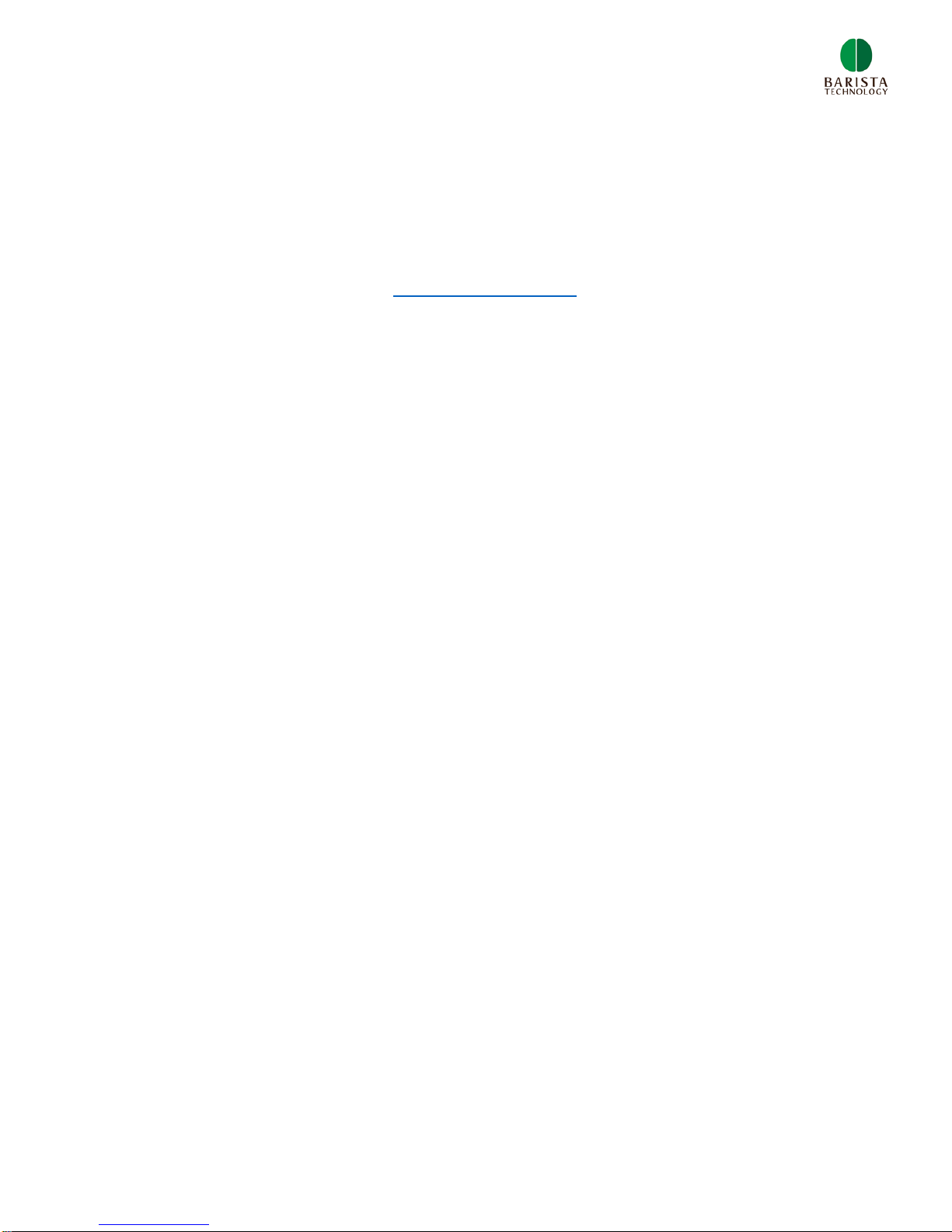

Disconnect the earthing cable from

the DC worm gear motor.

8

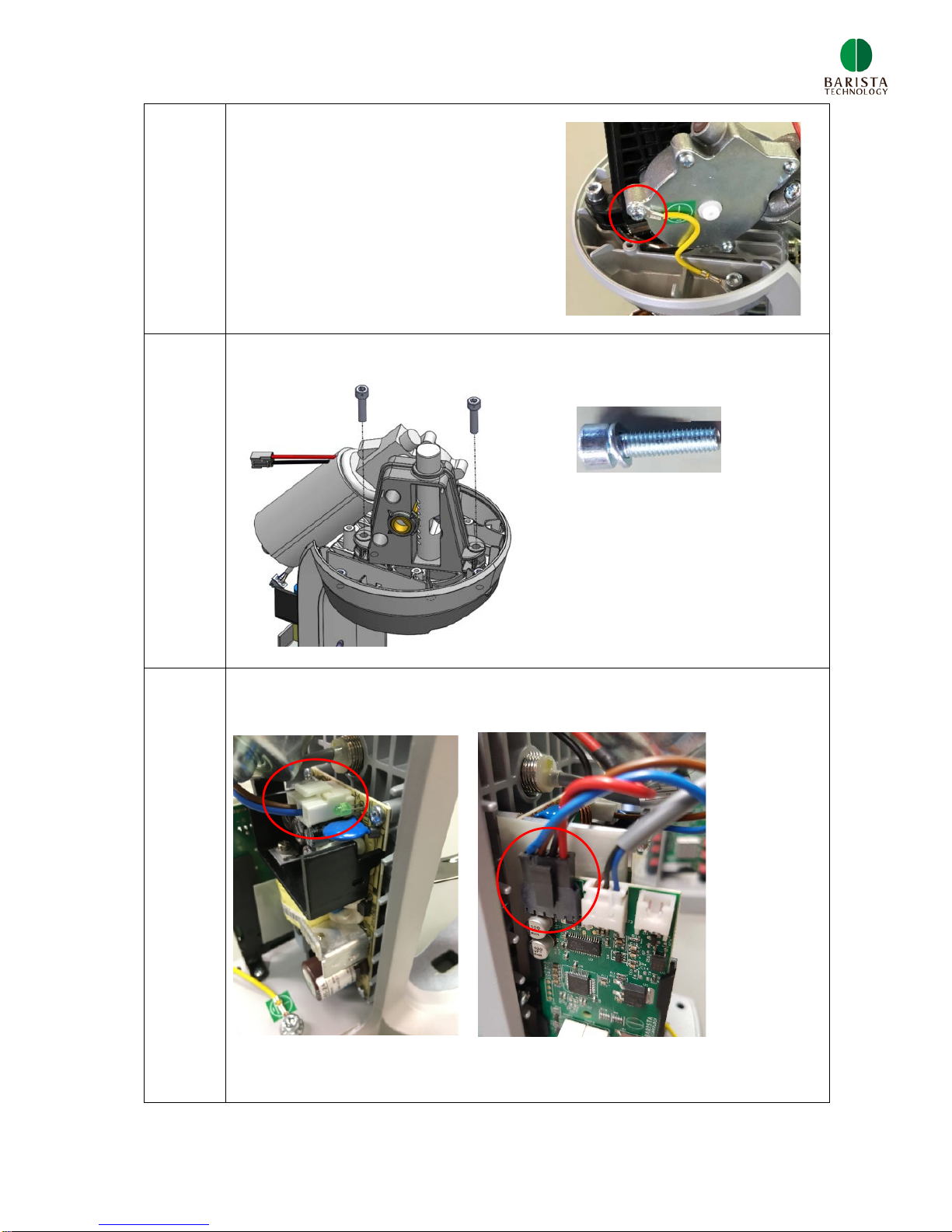

Unscrew 2 hexagon head cap screws M5x25.

9

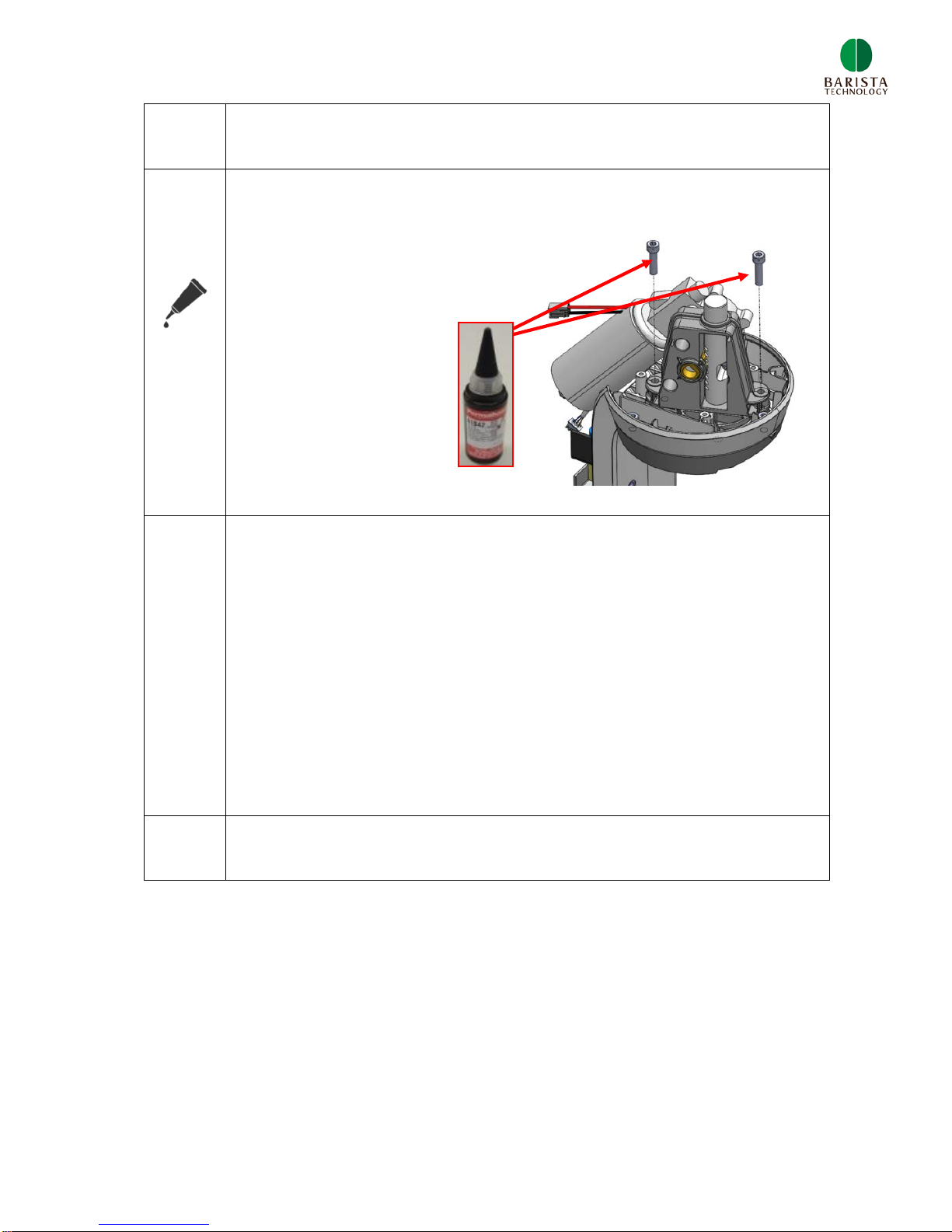

Disconnect the connectors as are shown in the figures below.

8

10

Remove the drive unit and replace the drive unit with a new unit.

11

Mount the upper clamp to the main body with 2 hexagon head cap

screws M5x25.

Apply Permabond A1042

on screw threads.

12

Connect both connectors, see step 9.

Fasten the earthing cable to the DC motor, see step 8.

Mount the main housing – back cover, see step 5.

Mount the main housing – middle cover, see step 4.

Mount the tamper base, see step 3.

Mount the main housing – top cover, step 2.

13

Check functioning of new drive unit

9

3.2 Replace induction sensor

Step

Description

1

Remove main housing – top cover

2

Remove the main housing – middle cover which is mounted to the

main body with 3 cross head cap screws M4x10

3

Unscrew 2 screws as is shown in

the figure below.

10

4

Open the main housing – back cover.

NOTE: the push buttons (red) are fragile

so be careful when opening back cover.

5

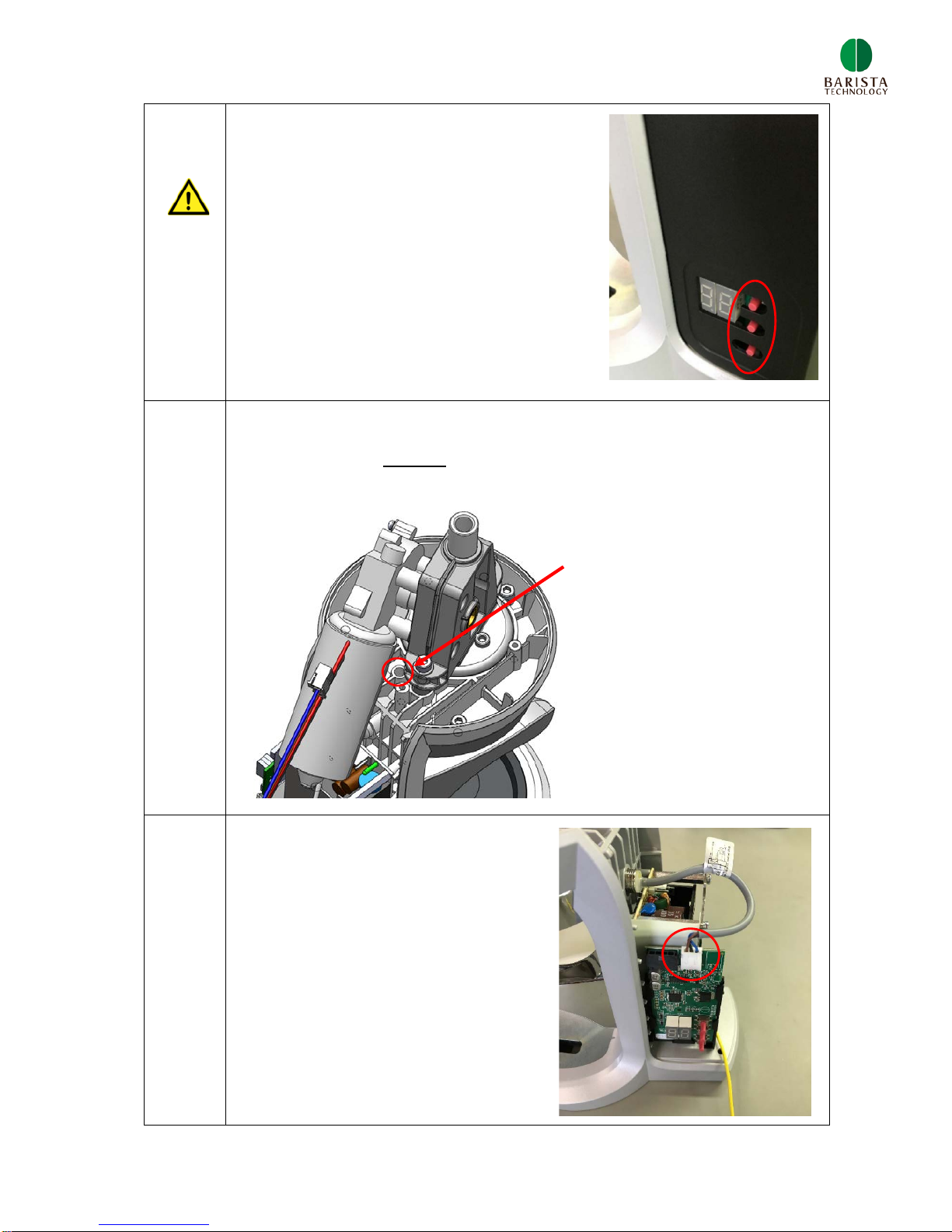

The sensor is fixed with a set screw M5. Unscrew the set screw

using Allen key 2.5mm via the

hole as shown below. The drive

units doesn’t need to be removed.

6

Remove the induction sensor and

disconnect the connector.

11

7

Insert a new induction sensor and connect the sensor to the motor

controller PCB, see step 6.

8

Fasten the set screw M5, see step 5.

Critical: The sensor does not function when too much torque

is applied.

Check the position of the sensor after assembly

Correct

NOT correct NOT correct

9

Mount the main housing – back cover, see step 3

Mount the main housing – middle cover, see step 2.

Mount the main housing – top cover, step 1.

10

Check functioning of the new induction sensor.

12

3.3 Clean tamper base (daily cleaning)

Check our support videos: www.puqpress.com/support

Step

Description

1

Turn unit ON and push the CLEAN

button. Tamper base goes down

completely.

2

Clean the tamper base with a dry towel

or a brush.

3

Push the clean button again, tamper base goes up. Cleaning

finished.

13

3.4 Remove tamper base and clean cavity (weekly cleaning)

Check our support videos: www.puqpress.com/support

Step

Description

1

Switch the device ON and activate the CLEAN mode. Tamper

base goes down. Switch OFF and remove power cable.

2

Remove main housing – top cover

3

Remove the hexagon bolt M5x100 + spring washer M5 using the

Allen key 4mm.

14

4

Remove the tamper base.

NOTE: Tamper base has

left-hand screw thread

5

Clean cavity with a brush.

6

After cleaning:

- Mount tamper base, step 4

- Fasten tamper base with M5x100 hex. cap screw and spring lock

washer, step 3

- Mount main housing – top cover, step 2.

15

3.5 Adjust lower clamp

Check our support videos: www.puqpress.com/support

Step

Description

1

Insert power cable and switch the Puqpress ON. Tamper heads

moves to upper position.

2

Remove power cable.

3

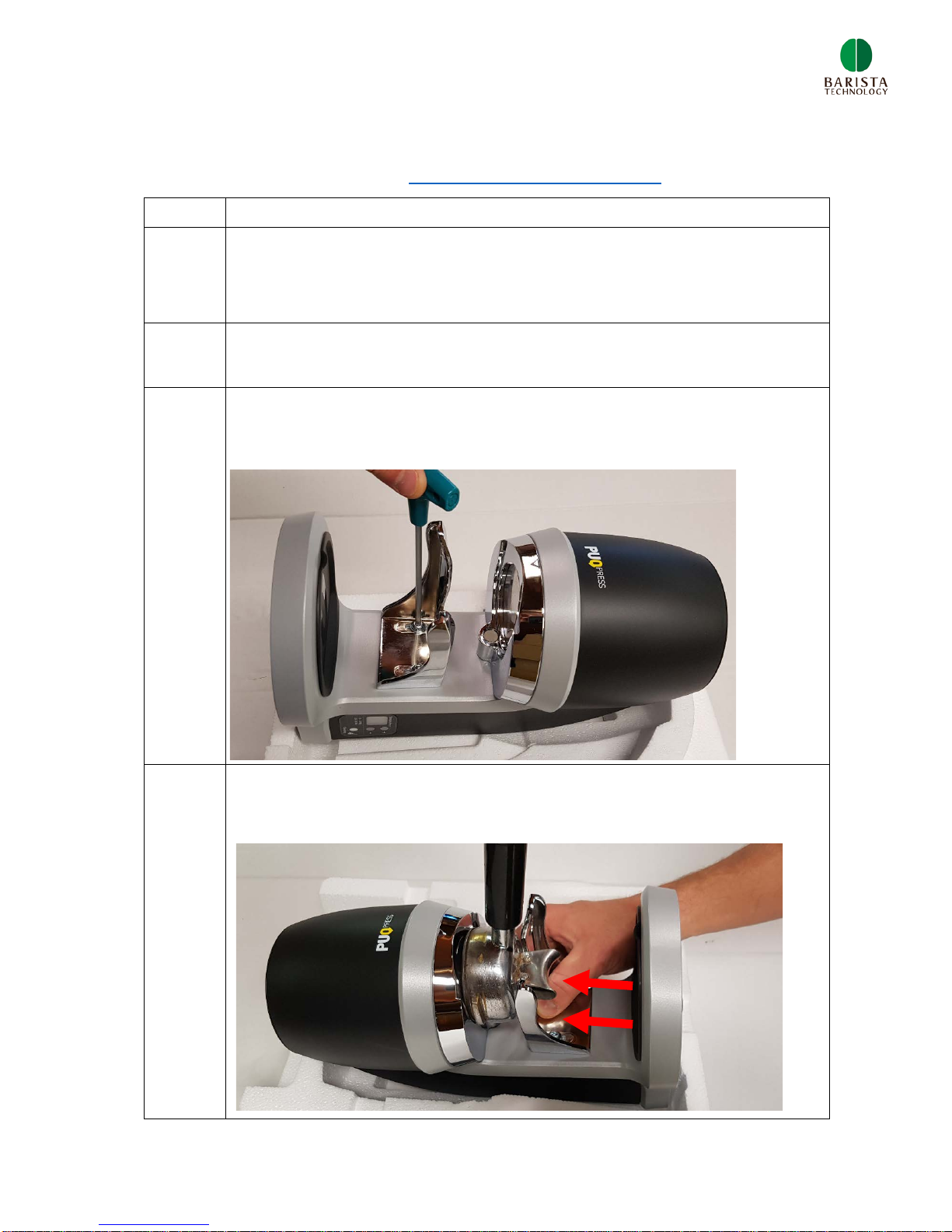

Put the unit with back side in the white packing box. Unscrew both

bolts as is shown below. You can find the right tool in the box.

4

Insert the portafilter and push the lower clamp upwards. Fasten

both bolts slightly

16

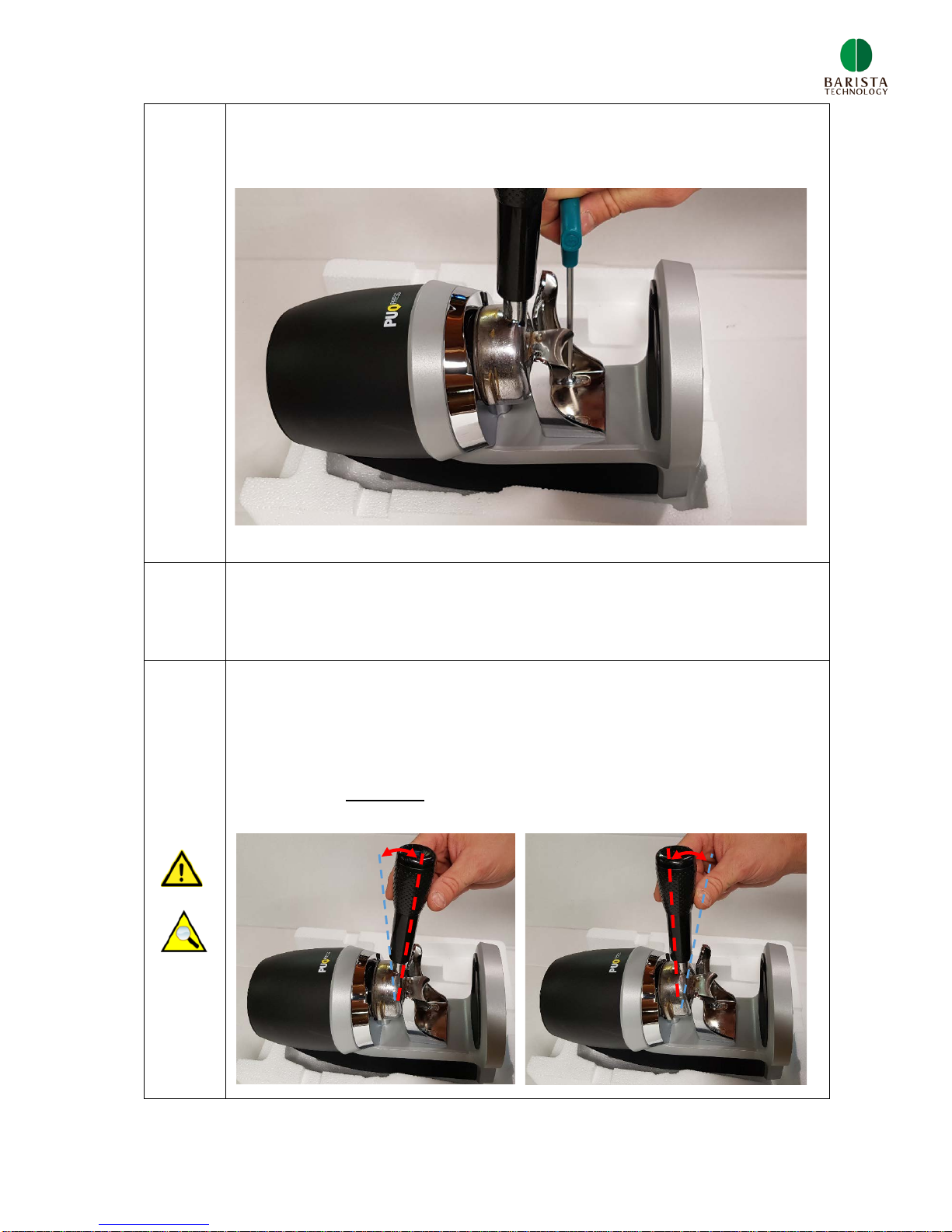

5

Insert the portafilter a few times and check if it’s properly clamp

between the upper and lower clamp. Fasten both bolts firmly.

6

Insert the portafilter again and check fitting. Lower clamp might be

moved during fastening of bolts.

7

Incorrect setting:

The portafilter should be clamped properly to ensure level

tamping. Movement of portafilter should be minimal. Pictures

below show incorrect setting

17

3.6 Adjust tamping force

Check our support videos: www.puqpress.com/support

Step

Description

1

Change tamping force with

+ / - push buttons.

18

4 CHANGING TAMPER BASE

4.1 Upper clamp types

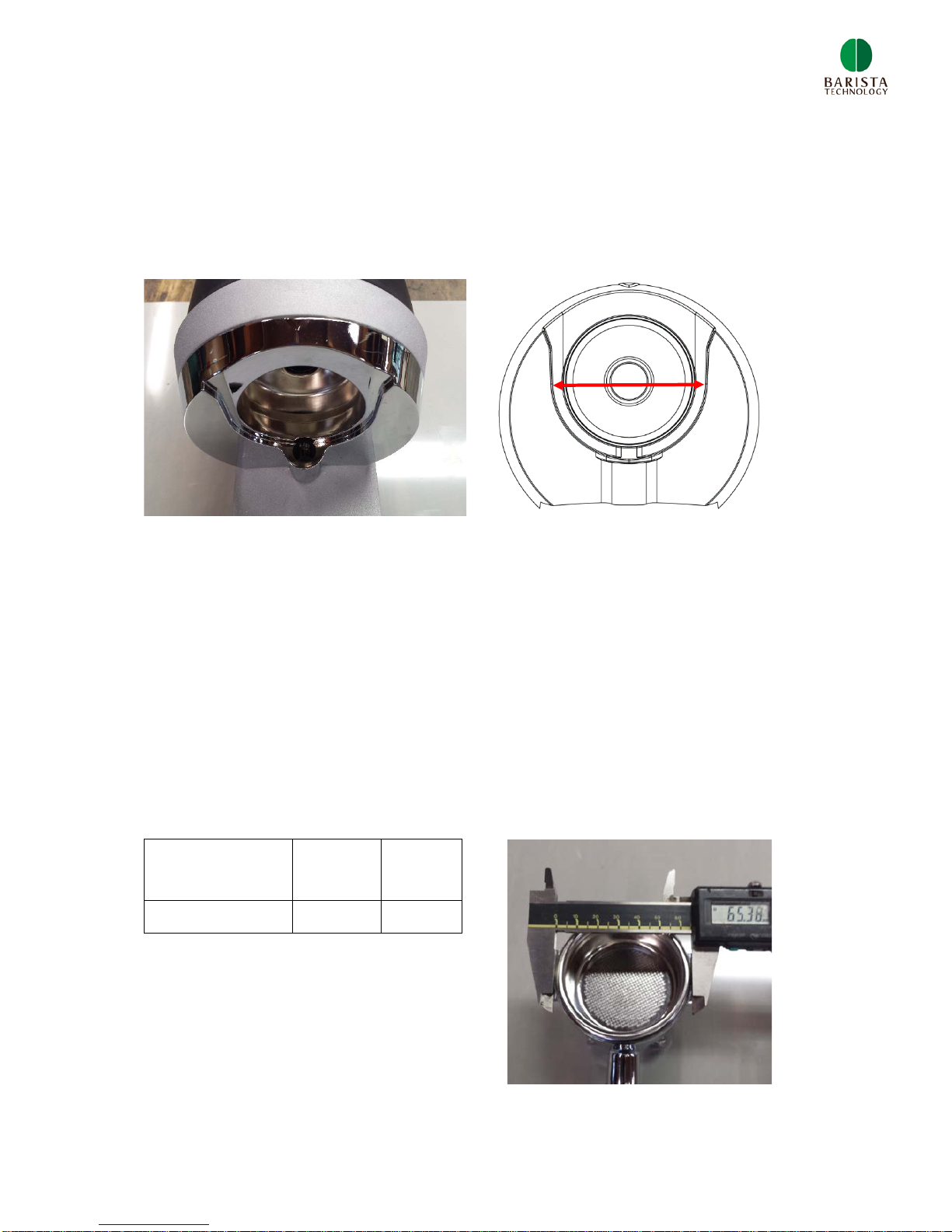

The type of upper clamp can be determined by measuring the diameter of the U-

shaped groove in the upper clamp, as is shown in figure below.

There are two types of upper clamps: 66 and 71mm. The size 71mm or 66mm is the

diameter (mm) of the U-groove, as is shown in figure 4.1 by the red arrow.

Why are we using two types of upper clamps? If the U-groove is too big compared to

the outer diameter of the filter basket, level tamping cannot be guaranteed.

4.2 Determine upper clamp type

The type of upper clamp is defined by the external diameter of the filter basket. In

order to determine the correct upper clamp type, measure the outer diameter of the

filter basket using a calliper.

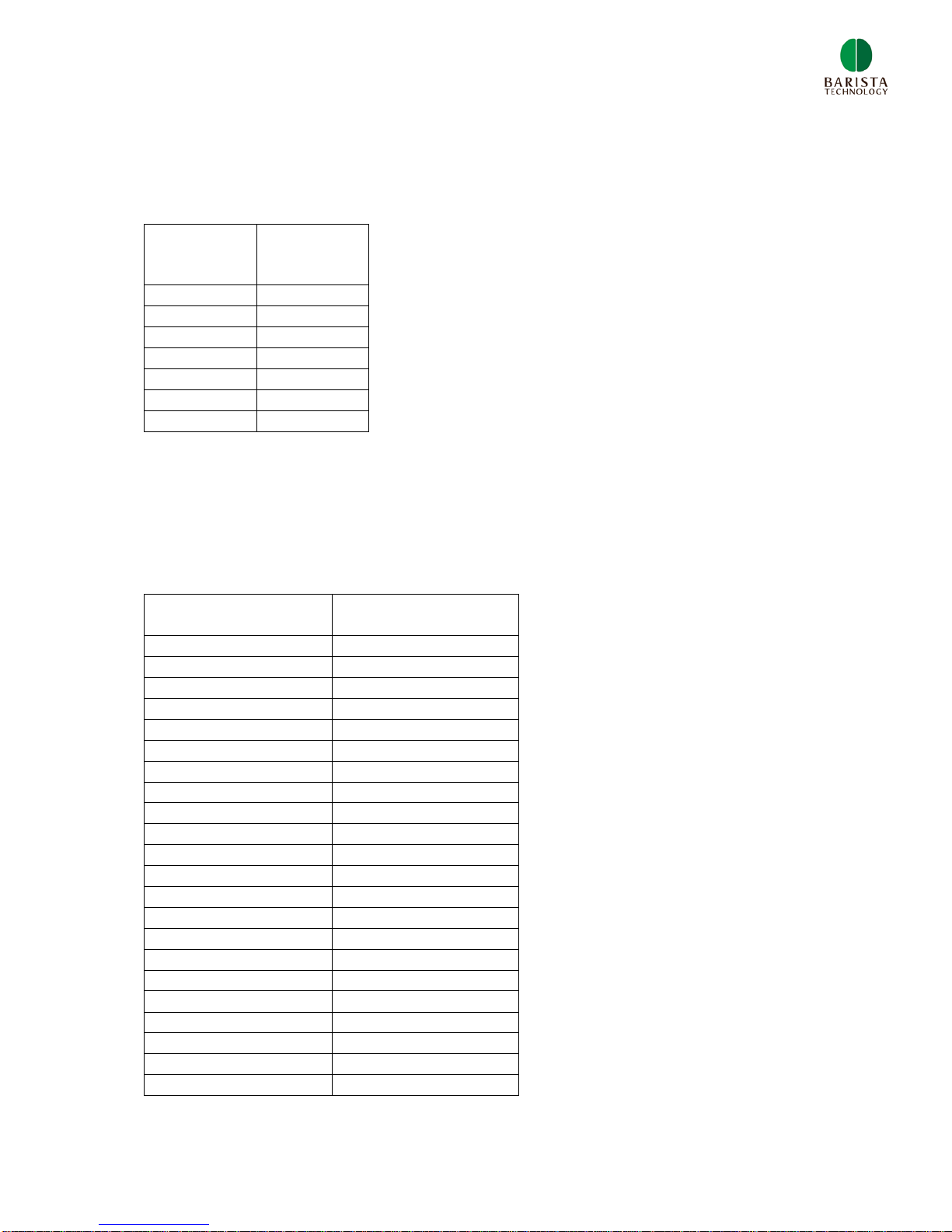

Choose the correct upper clamp type using table below:

Filter basket

outer diameter

[mm]

< 66,5 >66,5

Clamp type 66 71

19

In general the outer basket diameter scales with the inner diameter (tamper size). In

table below the tamper diameters are listed with the required upper clamp type:

Tamper

diameter

[mm]

Upper

clamp type

53

66

54

66

55

66

56

71

57

71

58

71

59

71

Some filter baskets are not standard and need another upper clamp size. Therefore

check the outer and inner diameter of the filter basket in order to pick the correct

setting.

4.3 Espresso machine brand and tamper diameter

Espresso machine

brand

Tamper base

diameter

Astoria

58

Bezzera

58

Brasilia

58

Caramali

58

Cimbali

57

Conti

58

ECM

58

Elektra

58

Expobar

58

Faema

58

Gaggia

58

La Marzocco

58

La Pavoni

56

Nuova Simonelli

58

Pasquini

57

Rancilio

58

San Marco

55

Spaziale

53

Synesso

58

Unic

56

Vibiemme

58

Wega

58

20

5 SOFTWARE SETTINGS

5.1 Tamping cycle counter

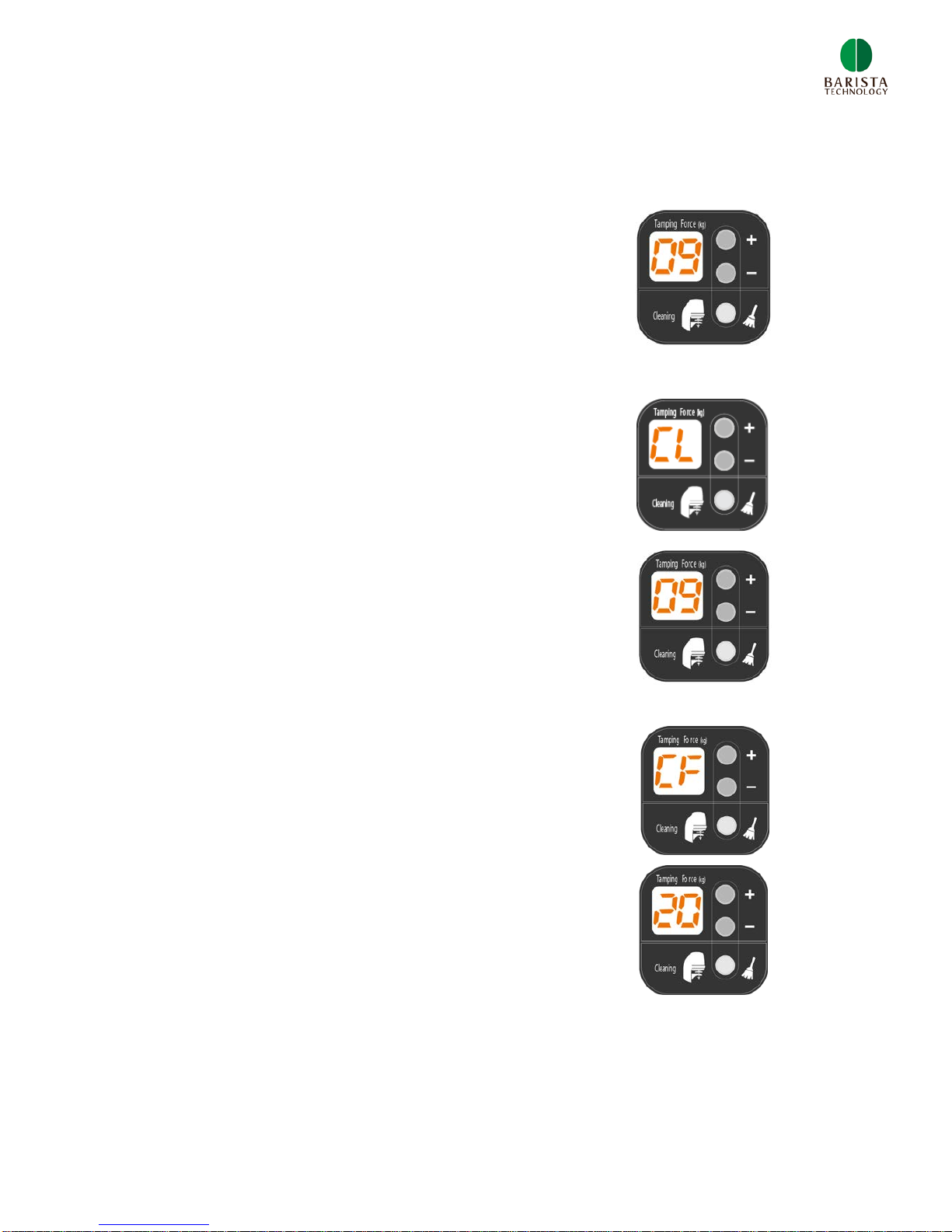

1) Turn unit ON and keep in standby mode

2) Hold + button & - button for 3 seconds.

3) Display blinks and shows a number. multiply this number

by 3000, max. cycle counter is 99*3000.

4) Cycle counter disappears after 5 seconds

5.2 Clean cycles counter

1) Turn unit ON and put unit in CLEAN modus (tamper disk

goes down)

2) Hold + button & - button for 3 seconds.

3) Display blinks and shows a number. multiply this number

by 5, max. clean cycle counter is 99*5.

4) Cycle counter disappears after 5 seconds

5.3 20 cycle run-in mode

1) Turn unit OFF. Hold CLEAN button and + button, and turn

unit ON. ‘CF’ appears on display.

2) Push + button

3) Unit start to tamp 20 times as run-in mode to remove any

initial friction in the system

Table of contents