Barnstead HP2625R User manual

Type HP2600

Hot Plate

OPERATION MANUAL

AND PARTS LIST

Series 26

Model # Voltage

HP2625R 100

HP2624R 240

HP2620R 240

HP2620R-26 120

1

LT26X4 • 2/28/05

IMPORTANT INFORMATION

This manual contains important operating and safety information. The user must carefully

read and understand the contents of this manual prior to the use of this equipment.

Safety Information ..............................................................................................................................................3

Alert Signals..................................................................................................................................................3

Warnings ......................................................................................................................................................3

Introduction..........................................................................................................................................................5

Intended Use ................................................................................................................................................5

Principles of Operation ................................................................................................................................5

General Specifications ........................................................................................................................................6

Installation ..........................................................................................................................................................7

Site Selection................................................................................................................................................7

Operation ............................................................................................................................................................8

Dial (Power) Switch) ....................................................................................................................................8

Dial (Control)Switch ......................................................................................................................................8

Maintenance and Servicing ................................................................................................................................9

Control Switch Replacement ........................................................................................................................9

Heating Element Replacement ....................................................................................................................9

Trouble Shooting ..............................................................................................................................................11

Exploded View ..................................................................................................................................................12

Replacement Parts Listing ................................................................................................................................13

Ordering Procedures ........................................................................................................................................14

Warranty ............................................................................................................................................................16

2

Table of Contents

Your Thermolyne Hot Plate has been designed with func-

tion, reliability, and safety in mind. It is the user’s respon-

sibility to install it in conformance with local electrical

codes. For safe operation, please pay attention to the

alert signals throughout the manual.

Warnings

To avoid personal injury:

1. Do not immerse unit for cleaning.

2. As with all laboratory equipment, appropriate

safety clothing, glasses, gloves and coats

should be worn when operating hot plates.

Always use appropriate hand and eye protection

when handling hazardous chemicals.

3. DO NOT remove or modify grounded power

plug. Use only properly grounded outlets to

avoid shock hazard. Not rated for use in haz-

ardous atmospheres.

4. Do not use in the presence of flammable or

combustible chemicals; top surface and ele-

ment can reach the “Flash Point Temperature” of

many chemicals. These hot plates are not explo-

sion proof. Fire or explosion may result. Unit

contains components which may ignite such

materials.

5. “Caution: Hot Surface. Avoid Contact.” The sur-

face of the hot plate will remain hot without visu-

al indication for some time after use.

To avoid electrical shock:

1. Always use a properly grounded electrical outlet

with correct voltage and current handling capaci-

ty.

2. Always disconnect the unit from the power sup-

ply prior to maintenance and servicing.

3. Refer servicing to qualified personnel.

3

Safety Information

Alert Signals

Caution

This unit is not recommended for use

in highly corrosive atmospheres.

Corrosive spills and fumes may dam-

age top and internal components.

Space unit 12 inches away from com-

bustible materials under any condi-

tions.

Warning

Warnings alert you to a

possibility of personal injury.

Caution

Cautions alert you to a possibility of

damage to the equipment.

Note

Notes alert you to pertinent facts and

conditions.

Hot Surface

Hot surfaces alert you to a

possibility of personal injury if you

come in contact with a

surface during use or for a

period of time after use.

Please note the following WARNINGS:

Warning

This warning is presented for compliance with California

Proposition 65 and other regulatory agencies and only

applies to the insulation in this product. This product con-

tains refractory ceramic, refractory ceramic fiber or fiber-

glass insulation, which can produce respirable dust or

fibers during disassembly. Dust or fibers can cause irrita-

tion and can aggravate preexisting respiratory diseases.

Refractory ceramic and refractory ceramic fibers (after

reaching 1000°C) contain crystalline silica, which can

cause lung damage (silicosis). The International Agency

for Research on Cancer (IARC) has classified refractory

ceramic fiber and fiberglass as possibly carcinogenic

(Group 2B), and crystalline silica as carcinogenic to

humans (Group 1).

The insulating materials can be located in the door, the

hearth collar, in the chamber of the product or under the

hot plate top. Tests performed by the manufacturer indi-

cate that there is no risk of exposure to dust or respirable

fibers resulting from operation of this product under nor-

mal conditions. However, there may be a risk of exposure

to respirable dust or fibers when repairing or maintaining

the insulating materials, or when otherwise disturbing

them in a manner which causes release of dust or fibers.

By using proper handling procedures and protective

equipment you can work safely with these insulating

materials and minimize any exposure. Refer to the appro-

priate Material Safety Data Sheets (MSDS) for informa-

tion regarding proper handling and recommended protec-

tive equipment. For additional MSDS copies, or additional

information concerning the handling of refractory ceramic

products, please contact the Customer Service

Department at Barnstead International at

1-800-553-0039.

4

SAFETY INFORMATION

Warning

Refer servicing to qualified personnel.

Intended Use

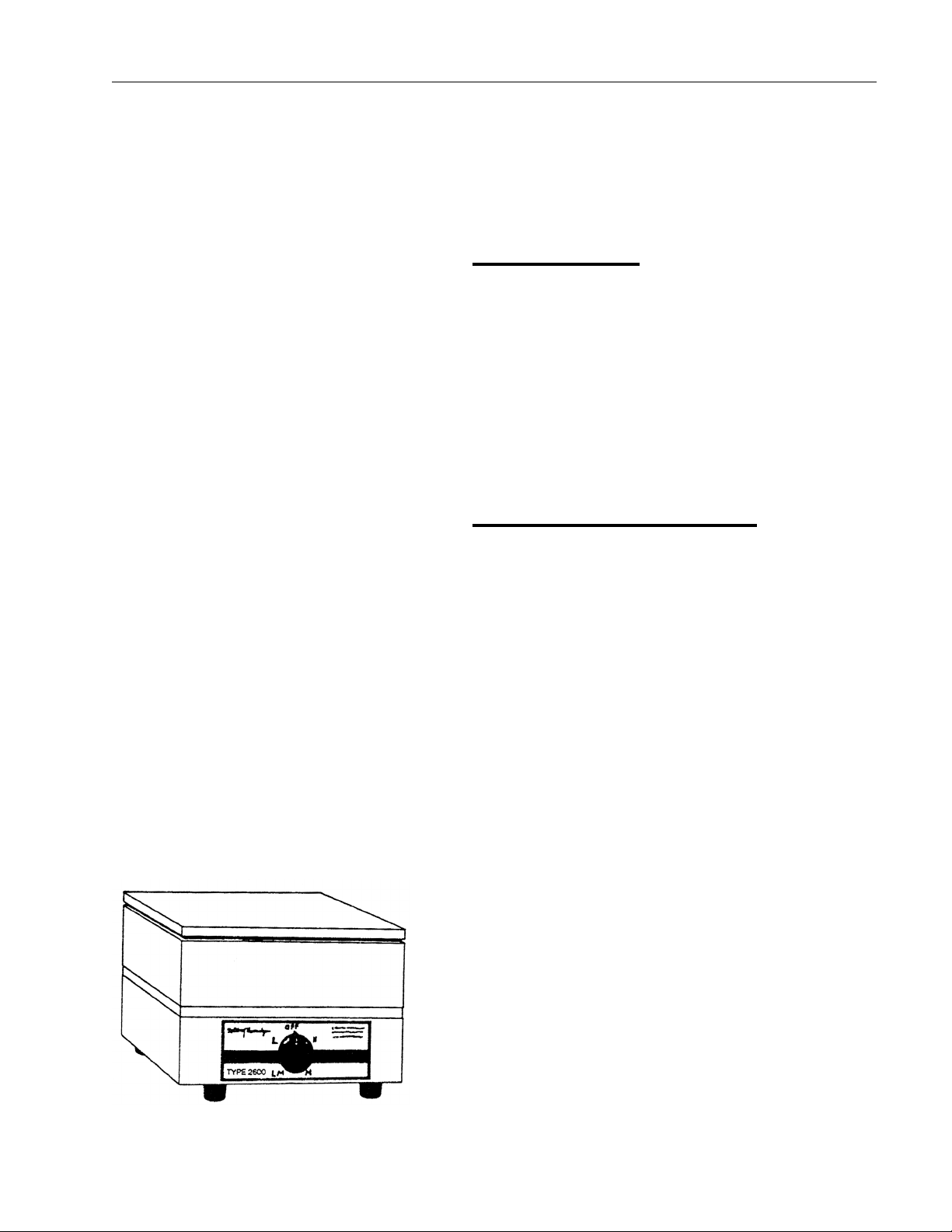

The Type 2600 hot plate is a heavy duty hot plate intend-

ed for procedures requiring temperatures from 425°F to

900°F (482°C). These hot plates are not to be used in the

presence of explosive vapors; this device contains com-

ponents which may ignite such materials.

The unit consists of 1) a heated plate, 2) a four position

temperature switch and, 3) a three wire cord and plug.

See Figure 1 for the overall shape and general features of

the unit.

Principles of Operation

The top metal plate is heated by a resistance heater

embedded in a refractory material. The plate is made of

cast iron to withstand heavy loads and is suitable for use

with glass or metal vessels. The temperature of the plate

is controlled by a four position temperature switch. This

switch is used to select varying resistive loads that will

vary the watts input. The case supports the top plate, and

houses insulation, electrical connections, and temperature

control switch.

5

Introduction

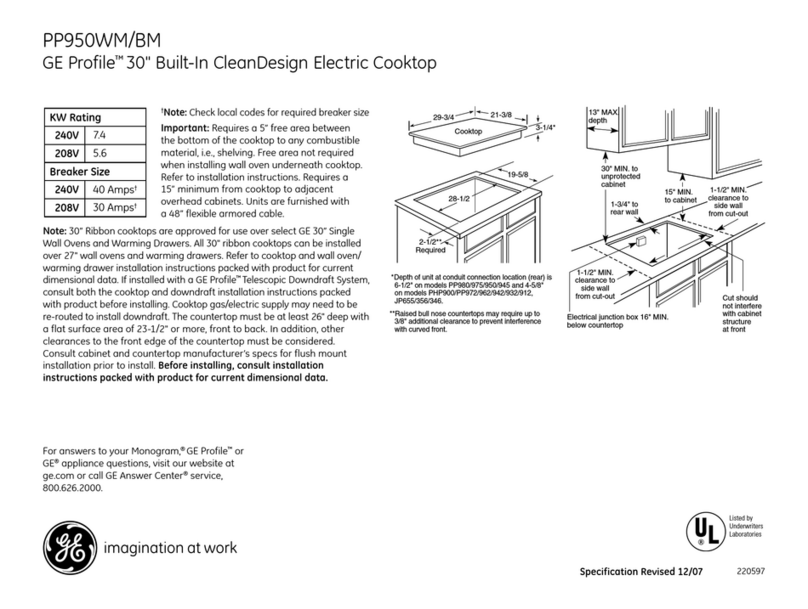

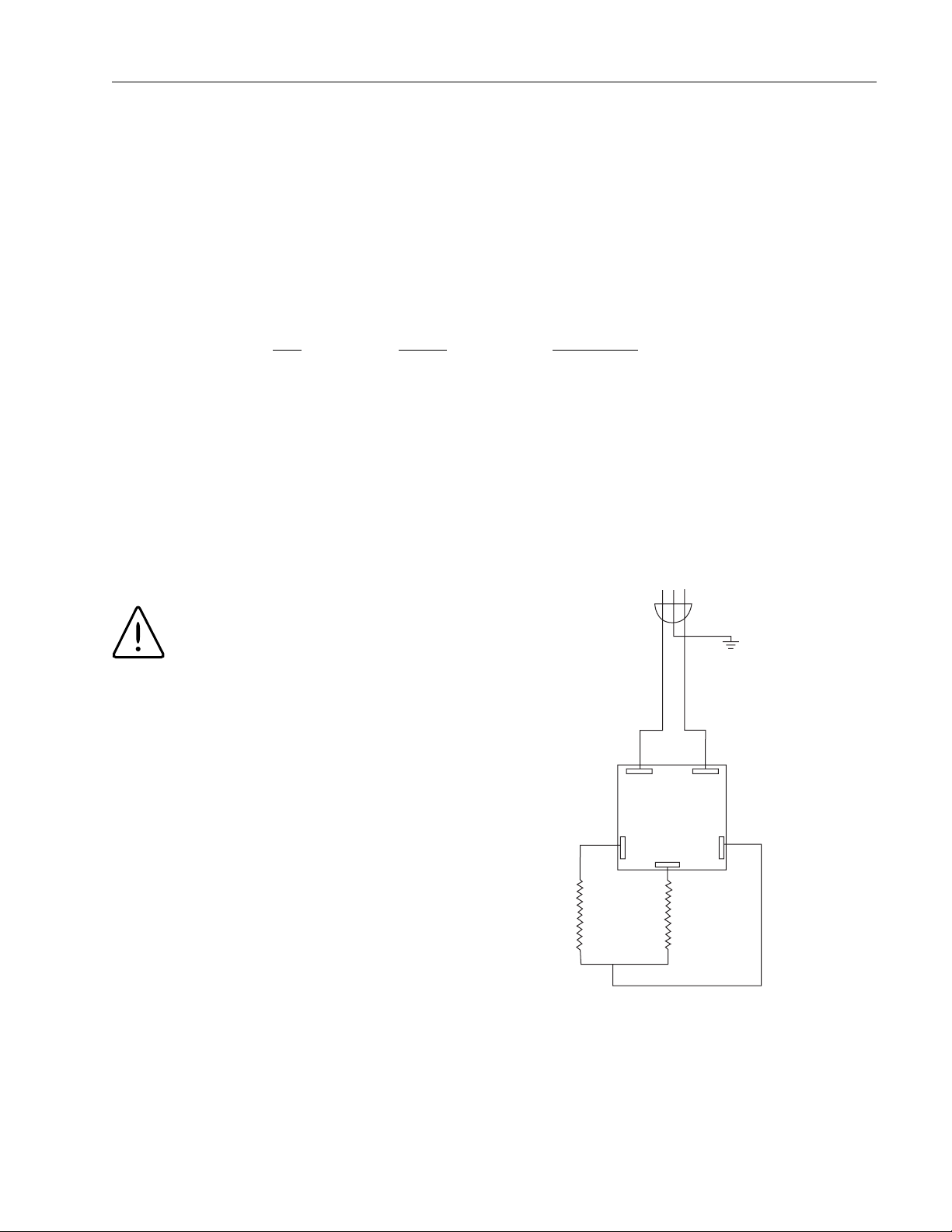

Figure 1: Type HP2600 Hot Plate

Model Number HP2620R HP2620R-26 HP2624R HP2625R

Dimensions in.(cm)

Top Plate 9 x 9 (23 x 23) 9 x 9 (23 x 23) 9 x 9 (23 x 23) 9 x 9 (23 x 23)

Overall

Width 9 (23) 9 (23) 9 (23) 9 (23)

Height 6.25 (15.9) 6.25 (15.9) 6.25 (15.9) 6.25 (15.9)

Depth 10 (25.4) 10 (25.4) 10 (25.4) 10 (25.4)

Weight lb. (kg) 14.25 (6.4) 14.25 (6.4) 14.25 (6.4) 14.25 (6.4)

Electrical Ratings

Volts 240 240 100 120

Amps 4.5 4.5 9.8 9.0

Watts 1080 1080 975 1080

Phase 1 1 1 1

Frequency 50/60 50/60 50/60 50/60

Max. Temp. 900°F (482°C) 900°F (482°C) 900°F (482°C) 900°F (482°C)

6

General Specifications

Note

• All models supplied with 3-wire cord and plug.

• (-26 model) supplied with a European cord set.

• The cast iron top plate used on all models is suitable for use with glass or metal vessels.

Site Selection

Install hot plate on a sturdy surface and allow space for

ventilation.

The electrical specifications are listed on the specification

plate on the side of the hot plate. Consult Barnstead

International if your electrical service is different than

those listed on the specification plate. Prior to connecting

your Type 2600 hot plate to your electrical supply, be sure

the dial switch is in the OFF position.

7

Installation

Caution

Allow at least three inches of space

between the hot p!ate and any vertical

surface.This permits the heat from hot

plate to escape so as not to create a

possible fire hazard.

Gross weight of items placed on top of

the hot plate should not exceed 35 lb.

Warning

To avoid electrical shock, this unit

must always use a properly grounded

electrical outlet with correct voltage

and current handling capacity.

Dial (Power) Switch

The power is turned ON or OFF by means of the dial

switch. The hot plate is ON with either a clockwise or

counterclockwise movement of the dial beyond the OFF

mark.

Dial (Control) Switch

The control knob has four heating positions and an OFF

position. Position “L” holds approximately 425°F (218°C),

“LM” - 600°F (316°C), “M” 675°F (357°C), and “H” - 900°F

(482°C). If fast heating is desired, turn the knob to “H”

until the required temperature is attained, then to the

proper lower setting. If slow heating is desired, start with

the knob on “L” and increase to higher settings gradually.

To turn off hot plate, turn dial fully clockwise or counter-

clockwise to the OFF position.

8

Operation

Warning

Do not use in the presence of flamma-

ble or combustible chemicals; top sur-

face and element can reach the “Flash

Point Temperature” of many chemi-

cals. These hot plates are not explo-

sion proof. Fire or explosion may

result. Unit contains components

which may ignite such materials.

Hot Surface

“Caution: Hot Surface. Avoid Contact.”

The surface of the hot plate will

remain hot without visual indication for

some time after use.

Control Switch Replacement

1. Disconnect hot plate from power supply.

2. Turn hot plate upside down and remove bottom

cover.

3. Remove the knob and the nut securing control.

4. Disconnect six wires from control switch. Identify

or mark wires disconnected to ensure proper

placement and connection when reinstalling.

Remove defective control switch.

5. Reconnect the wires removed in step (4) to the

new control switch. Secure control switch with

the nut and the knob.

6. Replace bottom cover and secure with four

screws.

7. Turn hot plate upright and reconnect to power

supply.

Heating Element Replacement

1. Disconnect hot plate from power supply.

2. Turn hot plate upside down and remove bottom

cover.

3. Remove the knob and the nut securing control.

4. Disconnect six wires from control switch. Identify

or mark wires disconnected to ensure proper

placement and connection when reinstalling.

Remove the control switch.

5. Bend the element leads straight up and then

remove in order, the control case, insulating

spacer, top section of case, insulating plate, and

insulating block.

6. Remove defective heating element and insert

new element in the same position. Remove

9

Maintenance and Servicing

Warning

To avoid electrical shock, always dis-

connect from power supply before

maintenance and servicing. Refer

servicing to qualified personnel.

Note

Perform only maintenance described

in this manual. Contact an authorized

dealer or our factory for parts and

assistance.

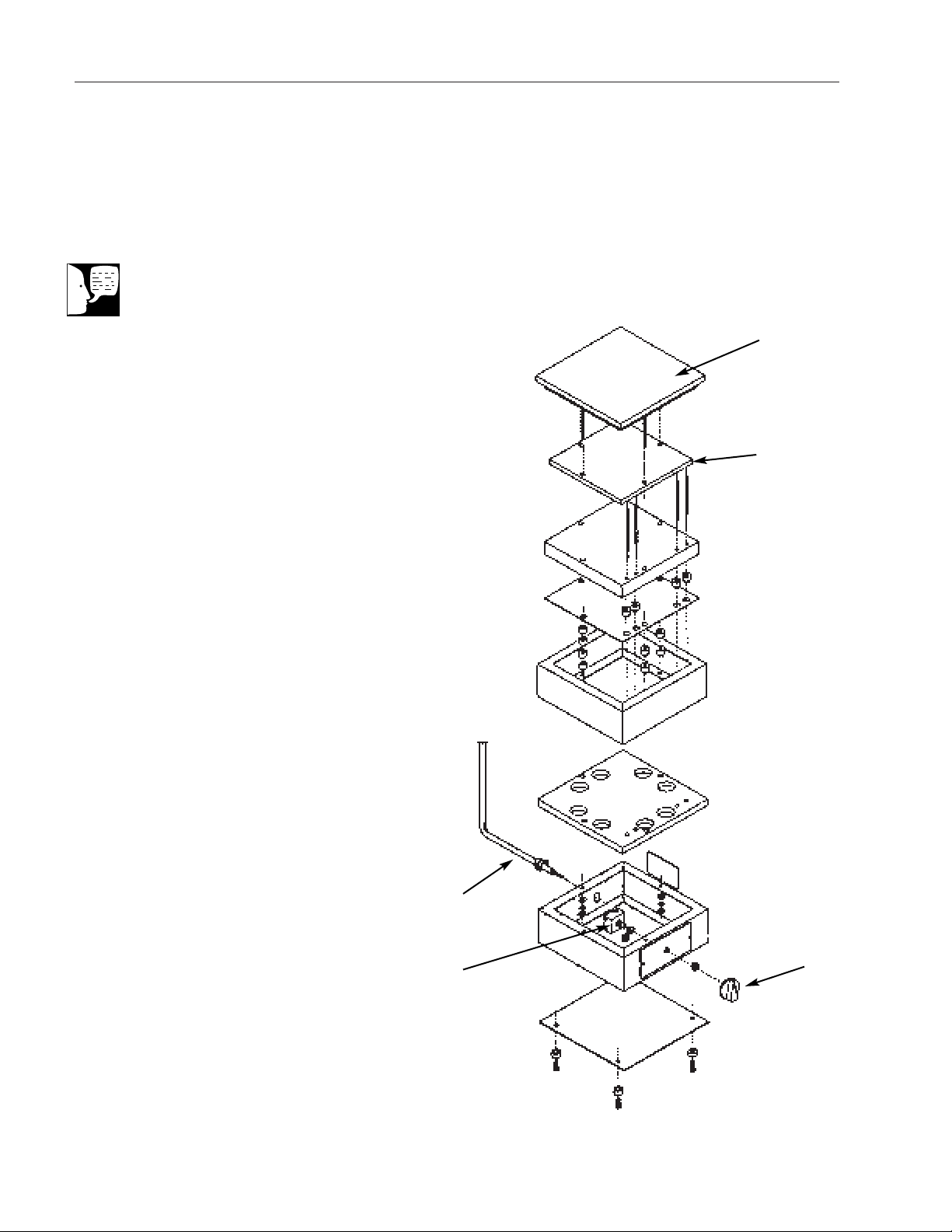

glass sleeving from element leads. (See explod-

ed view for placement of insulators, nuts and

washers).

7. Bend element leads straight up and replace in

this order, the insulating block, insulating plate,

top section of case, insulating spacer, and bot-

tom section of case.

8. Replace glass sleeving on element leads. (Two

inside leads are black, the two outside leads are

red.)

9. Reconnect the wires removed in step (4) to the

control switch. Secure control switch with the

nut and the knob.

10. Replace bottom cover and secure with four

screws.

11.Turn hot plate upright and reconnect to power

supply.

10

MAINTENANCE AND SERVICING

The Troubleshooting Tips section is intended to aid in defining and correcting possible service problems.

When using the chart, select the problem category that resembles the malfunction, then proceed to the possi-

ble causes category and take necessary corrective action.

Problem Possible Causes Solutions

Hot Plate does not heat. 1. No power. 1. Check power source and fuse.

2. Defective electrical hookup. 2. Repair electrical hookup.

3. Burned out heating element. 3. Replace defective heating element.

4. Defective control switch. 4. Replace control switch.

Hot Plate does not hold 1. Defective control switch 1. Replace control switch.

temperature

11

Troubleshooting

12

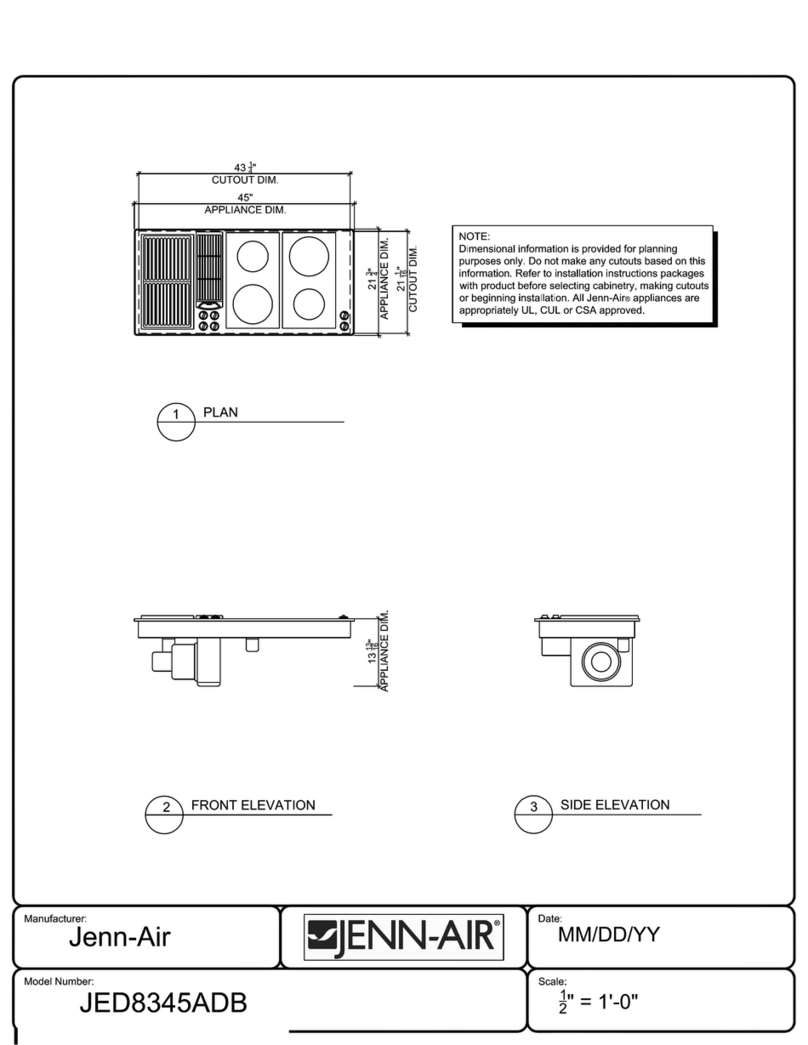

Exploded View

Note

When ordering replacement parts be

sure to order by part numbers - not by

key numbers.

Exploded View HP2600/Series

1

2

3

45

Model Type: HP2600

Product Name: Thermolyne Hot Plate

Series Number: 26

Key Part # Description

1PT26X1B Plate Assembly

2EL26X1 Element for HP2625R, 120V

EL26X2 Element for HP2620R & HP2620R-26, 240V

EL26X5 Element for HP2624R, 100V

3CR25X1 Cord Set for HP2625R 120V

CR26X1 Cord Set for HP2620R 240v

CR25X1 Cord Set for HP2624R, 100V

CR26X2 Cord Set for HP2620R-26, 240V

4SWX9 Switch

5KBX1 Knob

13

Replacement Parts

Warning

To avoid electrical shock, always dis-

connect from power supply before

maintenance and servicing. Refer

servicing to qualified personnel.

SWITCH

31

2

NL

1

ELEMENT

WHT BLK

LINE

Please refer to the Specification Plate for the complete

model number, serial number, and series number when

requesting service, replacement parts or in any corre-

spondence concerning this unit.

All parts listed herein may be ordered from the Barnstead

International dealer from whom you purchased this unit or

can be obtained promptly from the factory. When service

or replacement parts are needed we ask that you check

first with your dealer. If the dealer cannot handle your

request, then contact our Customer Service Department

at 563-556-2241 or 800-553-0039.

Prior to returning any materials to Barnstead International,

please contact our Customer Service Department for a

“Return Materials Authorization” number (RMA). Material

returned without a RMA number will be refused. Minimum

invoice: $25.

14

Ordering Procedures

15

Barnstead International (“BARNSTEAD”) warrants that a product manufactured by Barnstead shall be free of

defects in materials and workmanship for two (2) years from the first to occur of (i) the date the product is sold by

BARNSTEAD or (ii) the date the product is purchased by the original retail customer (the “Commencement

Date”). Except as expressly stated above, BARNSTEAD MAKES NO OTHER WARRANTY, EXPRESSED OR

IMPLIED, WITH RESPECT TO THE PRODUCTS AND EXPRESSLY DISCLAIMS ANY AND ALL WARRANTIES,

INCLUDING BUT NOT LIMITED TO, WARRANTIES OF DESIGN, MERCHANT ABILITY AND FITNESS FOR A

PARTICULAR PURPOSE.

An authorized representative of BARNSTEAD must perform all warranty inspections. In the event of a defect

covered by BARNSTEAD’s warranty, BARNSTEAD shall, as its sole obligation and exclusive remedy, provide free

replacement parts to remedy the defective product. In addition, for products sold by BARNSTEAD within the con-

tinental United States or Canada, BARNSTEAD shall provide provide free labor to repair the products with the

replacement parts, but only for a period of ninety (90) days from the Commencement Date.

BARNSTEAD’s warranty provided hereunder shall be null and void and without further force or effect if there is

any (i) repair made to the product by a party other than BARNSTEAD or its duly authorized service representa-

tive, (ii) misuse (including use inconsistent with written operating instructions for the product), mishandling, con-

tamination, overheating, modification or alteration of the product by any customer or third party or (iii) use of

replacement parts that are obtained from a party who is not an authorized dealer of BARNSTEAD.

Heating elements, because of their susceptibility to overheating and contamination, must be returned to the

BARNSTEAD factory and if, upon inspection, it is concluded that failure is due to factors other than excessive

high temperature or contamination, BARNSTEAD will provide warranty replacement. As a condition to the return

of any product, or any constituent part thereof, to BARNSTEAD’s factory, it shall be sent prepaid and a prior writ-

ten authorization from BARNSTEAD assigning a Return Materials Number to the product or part shall be

obtained.

IN NO EVENT SHALL BARNSTEAD BE LIABLE TO ANY PARTY FOR ANY DIRECT, INDIRECT, SPECIAL, INCI-

DENTAL, OR CONSEQUENTIAL DAMAGES, OR FOR ANY DAMAGES RESULTING FROM LOSS OF USE OR

PROFITS, ANTICIPATED OR OTHERWISE, ARISING OUT OF OR IN CONNECTION WITH THE SALE, USE

OR PERFORMANCE OF ANY PRODUCTS, WHETHER SUCH CLAIM IS BASED ON CONTRACT, TORT

(INCLUDING NEGLIGENCE), ANY THEORY OF STRICT LIABILITY OR REGULATORY ACTION.

The name of the authorized Barnstead International dealer nearest you may be obtained by calling 1-800-446-

2555 Kerper Boulevard

P.O. Box 797

Dubuque, Iowa 52001-0797

Phone: 563-556-2241 or 800-553-0039

Fax: 563-589-0516

E-mail: [email protected]

www.barnstead.com

Two Year “Bumper to Bumper”

Warranty

This manual suits for next models

3

Table of contents

Other Barnstead Cooktop manuals

Popular Cooktop manuals by other brands

Fisher & Paykel

Fisher & Paykel MINIMAL CID834DTB4 installation guide

Frigidaire

Frigidaire 318203628 use & care

Avantco

Avantco ICBTM20 user manual

Concept2

Concept2 PDV 4660 manual

Blue Star

Blue Star RBCT304BSS Installation and user instructions

Silvercrest

Silvercrest SIKP 2000 C1 User manual and service information