Safety Information ........................................................................................................................................................3

Alert Boxes ............................................................................................................................................................3

Warnings................................................................................................................................................................3

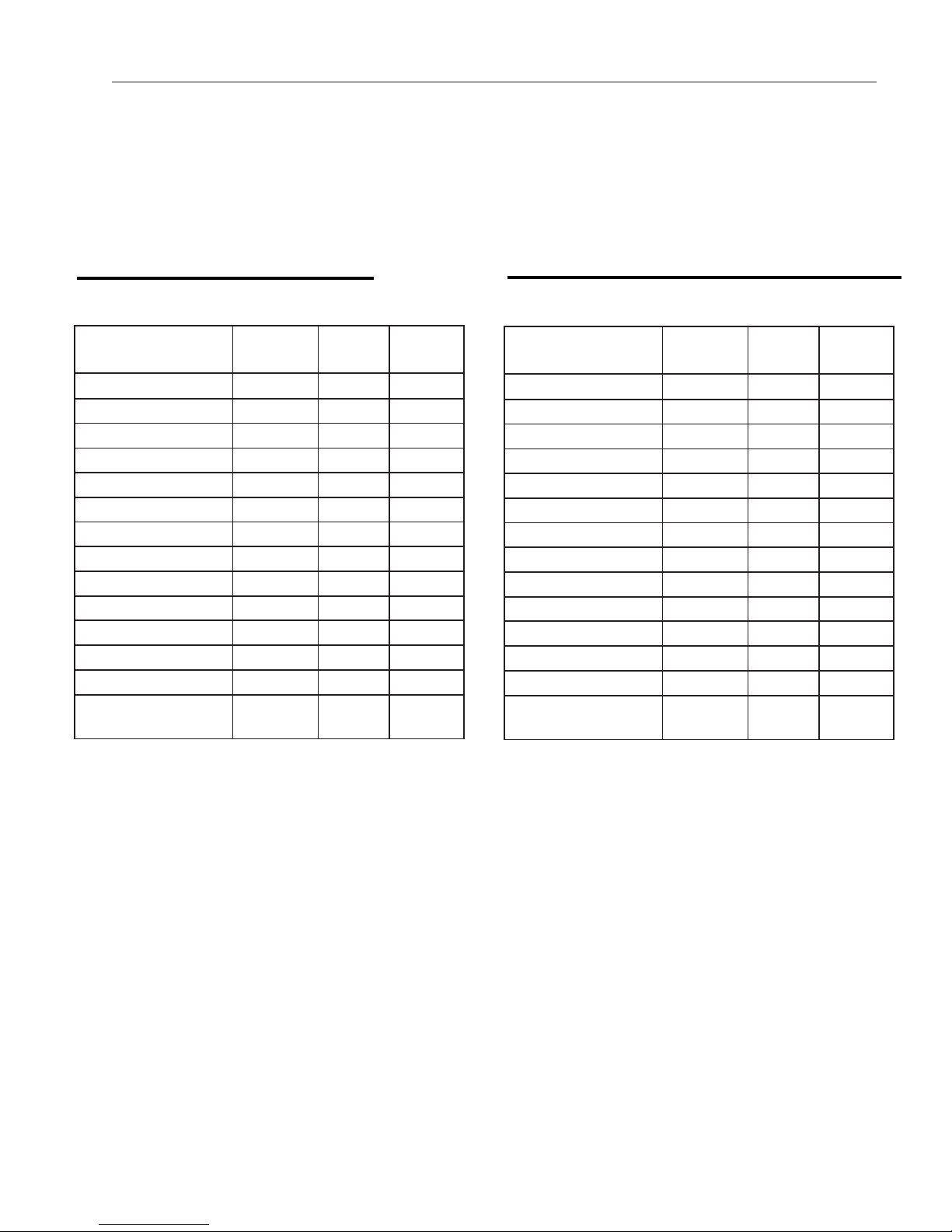

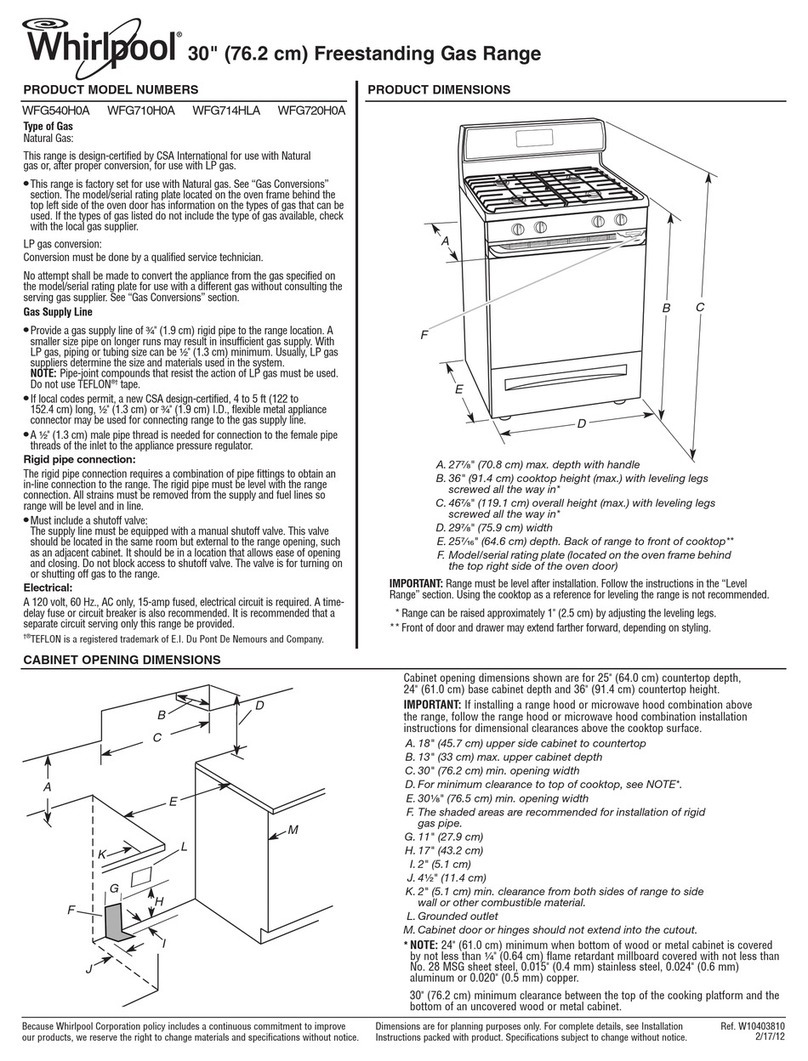

General Specifications..................................................................................................................................................5

Hot Plate Specifications ........................................................................................................................................5

Stirring Hot Plate Specifications ............................................................................................................................5

Heating Specifications ..........................................................................................................................................6

Stirring Speed Specifications ................................................................................................................................6

Environmental Conditions......................................................................................................................................7

Declaration of Conformity ......................................................................................................................................7

Introduction ..................................................................................................................................................................8

General Usage ......................................................................................................................................................8

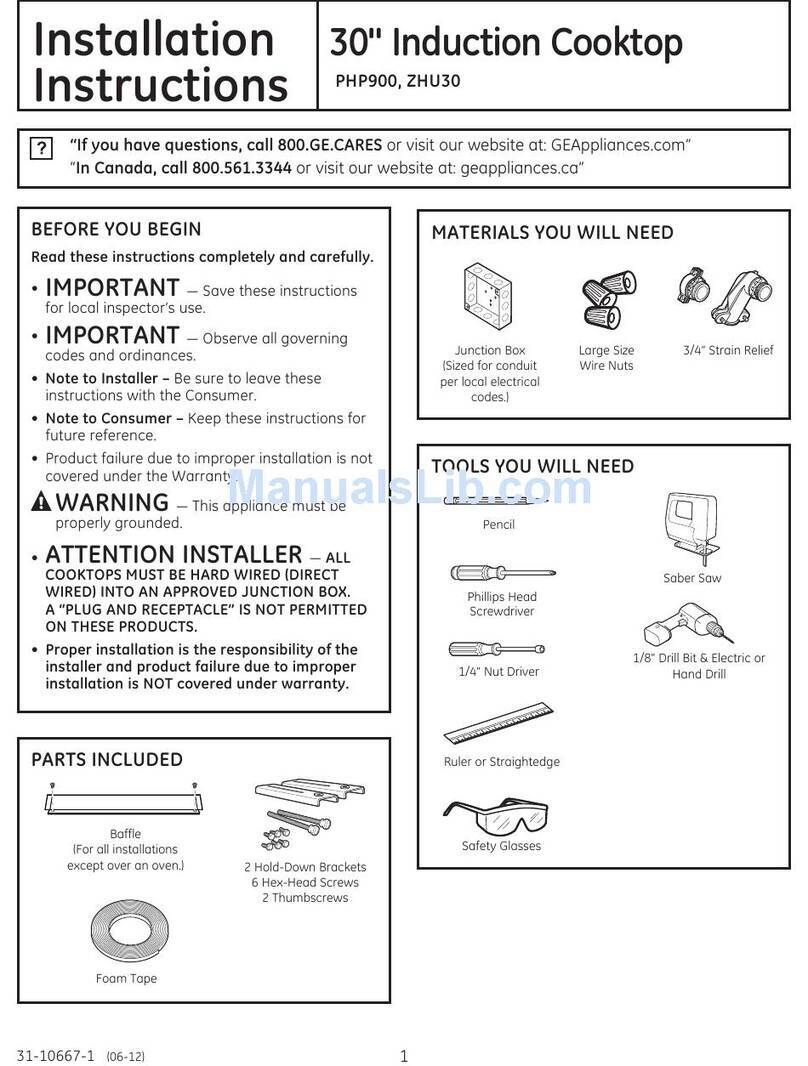

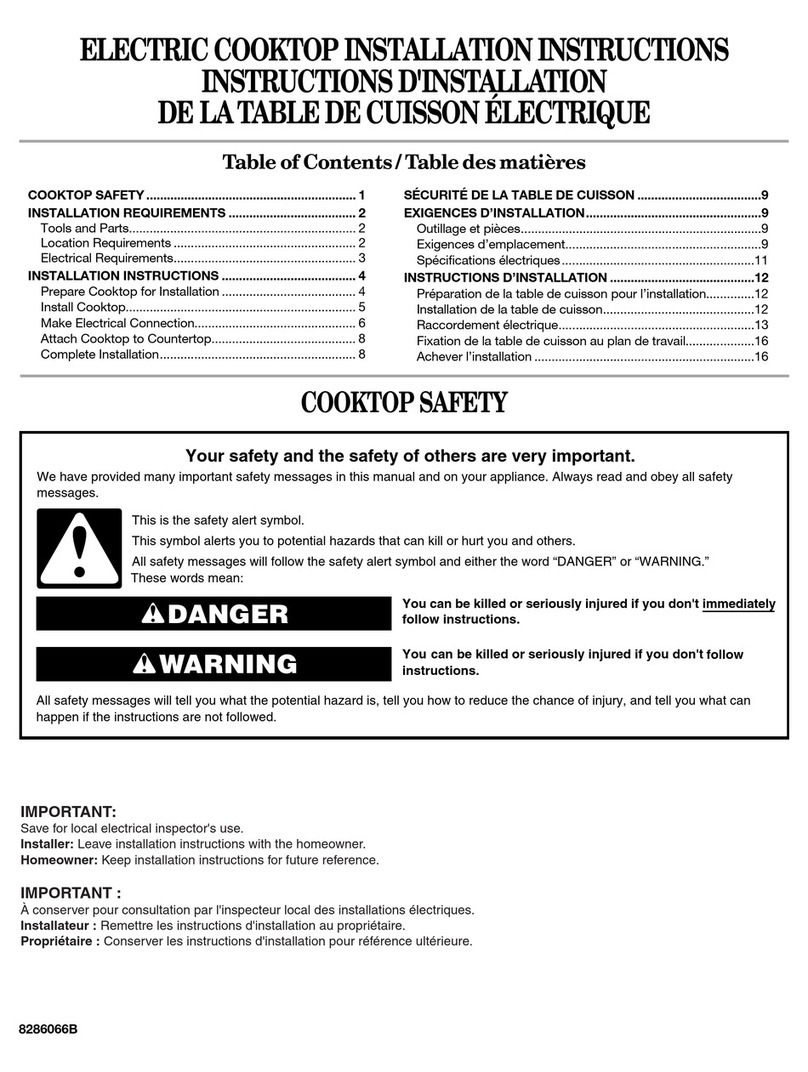

Unpacking and Installation ..........................................................................................................................................9

Unpacking..............................................................................................................................................................9

Installation..............................................................................................................................................................9

SUPER-NUOVA Hot Plate Control Panel............................................................................................................10

SUPER-NUOVA Stirring Hot Plate Control Panel ..............................................................................................10

Control Panel ......................................................................................................................................................11

Principles of Operation ..............................................................................................................................................12

Operation ................................................................................................................................................................13

Power Button ......................................................................................................................................................13

Setting the Stirring Speed....................................................................................................................................13

Setting the Temperature ......................................................................................................................................14

Controlling Solution Temperature with an External Probe ..................................................................................15

Using Preset Programs ......................................................................................................................................16

Heating Metal Vessels and Sand Baths ..............................................................................................................16

Setting the Timer ................................................................................................................................................16

Power Interruption Protection ..............................................................................................................................17

Using the Probe with the Temperature Display for Stirring-only Applications ....................................................17

RS232 Output ......................................................................................................................................................18

Using HyperTerminal w/RS232 ....................................................................................................................19

To Capture Data w/HyperTerminal ................................................................................................................20

Service and Calibration ..............................................................................................................................................21

Service Menu ......................................................................................................................................................21

Over-Temperature Set Point - OSP ..............................................................................................................22

Temperature Probe Calibration - CAL ..........................................................................................................23

System Method of Calibration ................................................................................................................24

Oil Bath Method of Calibration ................................................................................................................25

Thermometer Mode - Prb..............................................................................................................................26

Timer Shutdown - End ..................................................................................................................................27

Probe Temperature Limit - PL ......................................................................................................................28

Probe Response - Pr ....................................................................................................................................29

Set Point Limit - SL ......................................................................................................................................29

Error Disable - Err ........................................................................................................................................30

Factory Defaults - deF ..................................................................................................................................31

Model Selection - SEL ..................................................................................................................................32

Flash Upgrade - FLS ....................................................................................................................................33

General Cleaning Instructions ............................................................................................................................33

Troubleshooting Guide ..............................................................................................................................................34

Error Codes ........................................................................................................................................................34

Exploded Views ..........................................................................................................................................................36

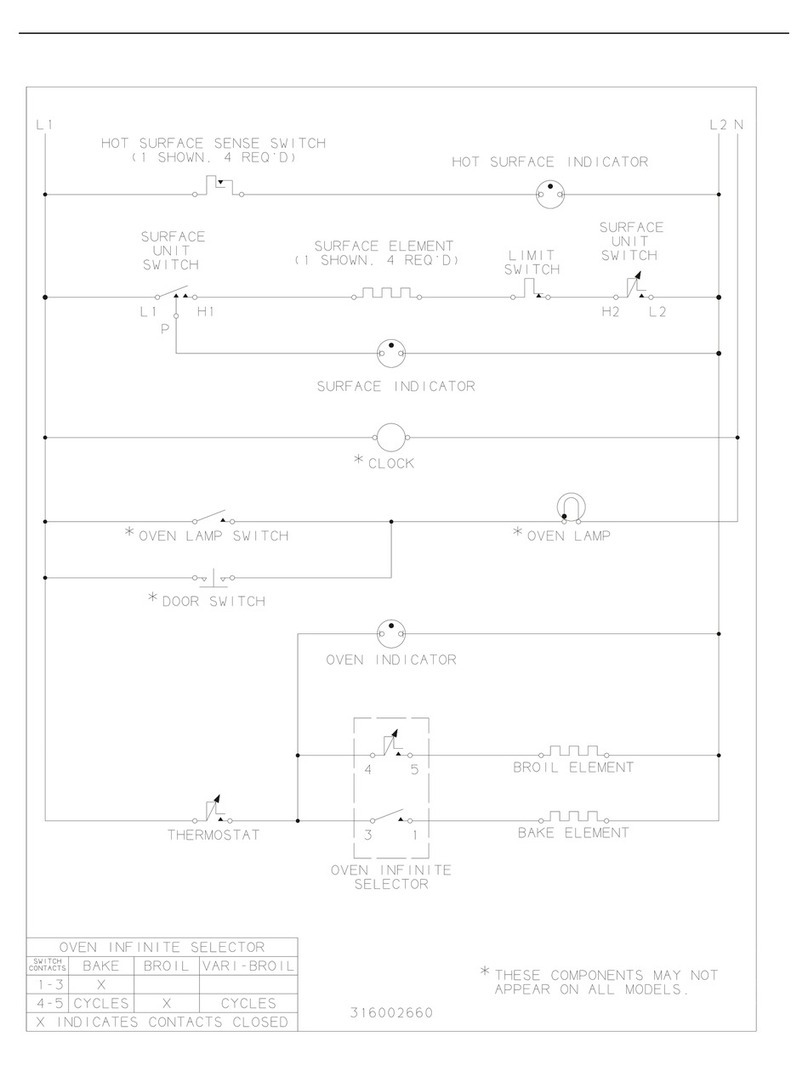

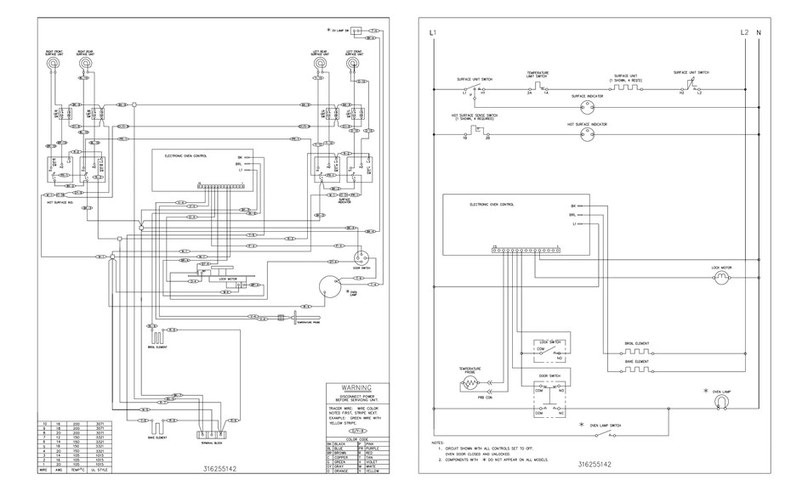

Wiring Diagram ..........................................................................................................................................................40

Replacement Parts List ..............................................................................................................................................42

Accessories ................................................................................................................................................................43

Ordering Procedures ..................................................................................................................................................44

Warranty ................................................................................................................................................................48

2

Table of Contents