30SG OPERATOR’S MANUAL 11/25/13 Page 6 of 24

SAFETY INSTRUCTIONS OVERVIEW (continued)

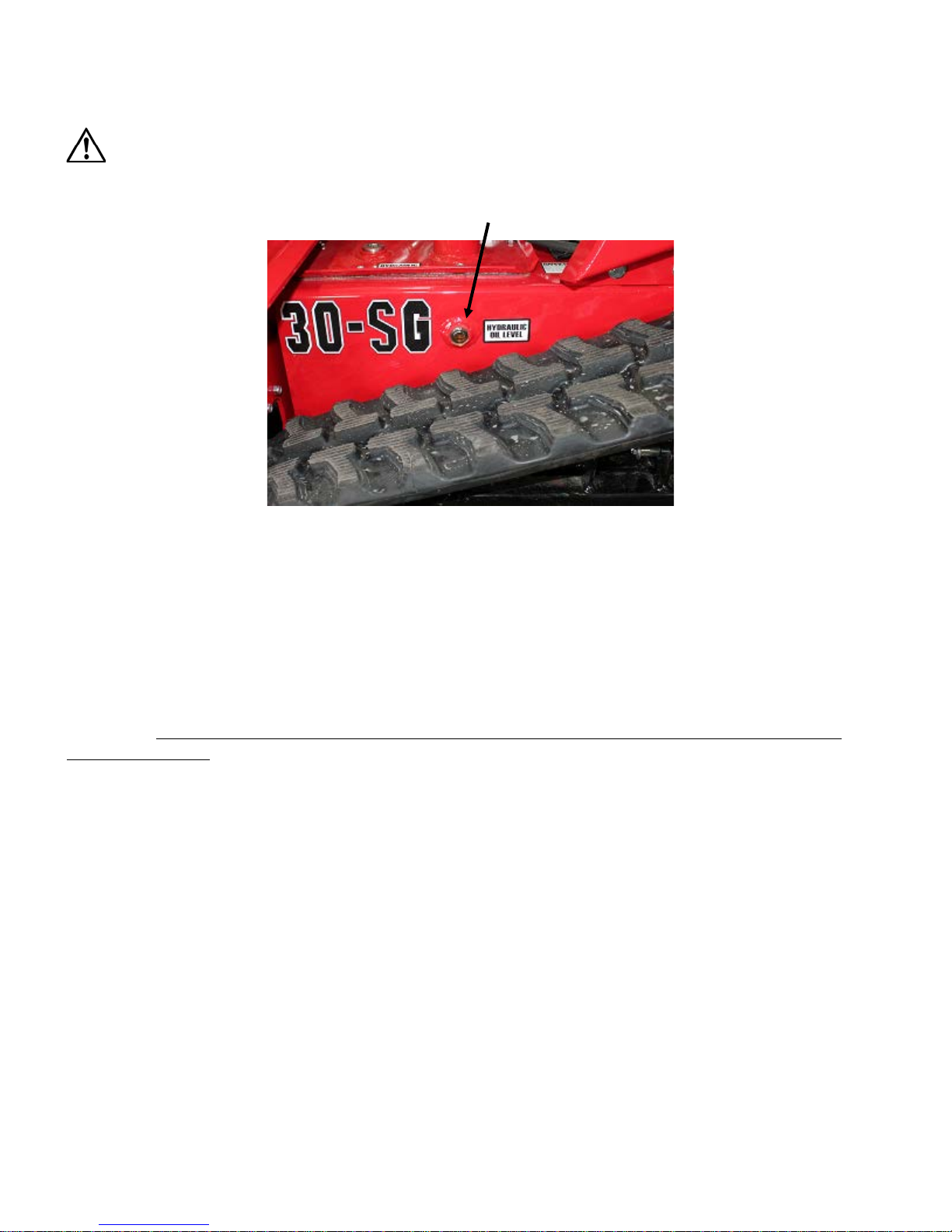

Avoid contact with hydraulic fluid.

WARNING: When machine is operating, hydraulic fluid is under extreme pressure and can get

under skin and burn or poison.

WARNING: Keep safety guards and shields in place while the engine is running and keep all

operator protection systems in place and in operational condition.

WARNING: Never store the equipment with petrol in the tank inside a building where fumes can

reach an open flame or spark. Allow the engine to cool before storing in an enclosure. To

reduce fire hazard, keep the engine, muffler, battery compartment and fuel storage area free of

any vegetative material and excessive grease.

Keep others away. If the job site is near a road or pedestrian path, warn and divert both motorized traffic

and pedestrians. As appropriate, use traffic flag personnel, signs, cones, and lighting devices to insure

safety.

Never allow anybody to ride on the machine.

Never lift machine over any person at any time.

WARNING: If machine should fall, it would crush anybody under it.

We recommend having a fire extinguisher suitable for petrol fires in the operating area.

BATTERY & ELECTRIC STARTER SAFETY INSTRUCTIONS

Shield entire face, especially your eyes, and wear rubber gloves to avoid acid burns whenever doing

anything with the battery. Battery caps must be tightly in place if the battery has removable caps.

WARNING: The battery contains sulfuric acid that can cause blindness and severe burns. Avoid

contact with eyes, skin, and clothing. If acid contacts eyes, call 911 immediately and flush eyes with

water for 15 minutes or until emergency medical help arrives. If acid contacts skin, flush area with plenty

of water. If acid is ingested, drink large quantities of water or milk then follow with milk of magnesia,

beaten egg, or vegetable oil, and get medical attention immediately.

Avoid contact with battery components. Wear rubber gloves and wash hands after handling any battery

components.

WARNING: Battery posts, terminals, and related accessories contain lead and lead compounds,

chemicals known to cause cancer and reproductive harm. Acid can cause blindness and severe burns

if leaked from the battery.

Do not charge or jump-start the battery near flames or sparks, or while smoking.

WARNING: Battery fumes are flammable and explosive. Avoid explosion hazard that could blind

and burn. Tools and jumper cable clamps can make sparks, so use them with care. Shield eyes and

face, and wear rubber gloves.

BATTERY MAINTENANCE is in the OWNER’S MANUAL.