622GT Owner’s/Operator’s Manual

SERVICE

INFORMATION

1. Check the reservoir level using the sight glass on the top of the tank. If required, add to reservoir

with tractor transmission hydraulic oil (AW or ISO rating of 68 is recommended). Recheck oil level

after the tiller has been run and oil has been circulated through the tine motor. Routinely check

level thereafter. DO NOT OVERFILL THE TANK.

2. Change the hydraulic oil filter after the first 50 hours of use. Change it after every 200 hours

thereafter.

3. Check the tine bolts after each use and tighten as needed. Check all hydraulic fittings for leaks

and tighten if necessary.

4. Tines should be changed as often as needed for the machine to do a satisfactory and efficient tilling

job. Use Loctite stud and bearing adhesive/sealant on tine bolt threads to prevent loosening.

5. The grease zerk on the end of the tine frame should be greased after every 4 to 8 hours of use.

6. The grease zerks on the wheels should be greased monthly.

IMPORTANT: The engine is normally serviced prior to shipping. However, shipping regulations

may prohibit this. Check levels and add oil and fuel as required before starting. Service according to

the engine manual before starting.

IMPORTANT: If the couplers between the engine and the pump are moved or removed for

any reason, it is CRITICAL that they have a 1/16” gap between them when reinstalled. Failure

to have this gap will result in rapid wear and failure of your pump!

NOTE: It is very important to move the fuel shutoff lever to the closed position after

stopping the engine. Failure to do so could cause fuel to leak down into the cylinder and

crankcase. Damage resulting from this will void your engine warranty and not be covered.

WARNING: Running the tiller without hydraulic oil will cause serious damage to the hydraulic pump.

CHECK RESERVOIR LEVEL BEFORE STARTING THE MACHINE.

BARRETO MANUFACTURING,

INC.

EQUIPMENT

WARRANTY

Barreto Manufacturing, Inc. warrants all BARRETO equipment to be free of defects in material and

workmanship for a period of one (1) year, dating from delivery to the original user.

This Warranty is in lieu of all other warranties, whether written or implied, and is limited to:

1. Replacement of parts returned to the dealer and/or factory and determined defective upon

inspection. (Replacement for parts to dealers shall be at dealer cost plus shipping charges.)

2. Time for pick-up and/or delivery, transportation or service calls by dealers is excluded.

Manufacturer reserves the right to determine reasonable time required for repair.

Warranty does not apply to damage caused by abuse or neglect. Time and materials required for normal

maintenance and service are also excluded from warranty coverage.

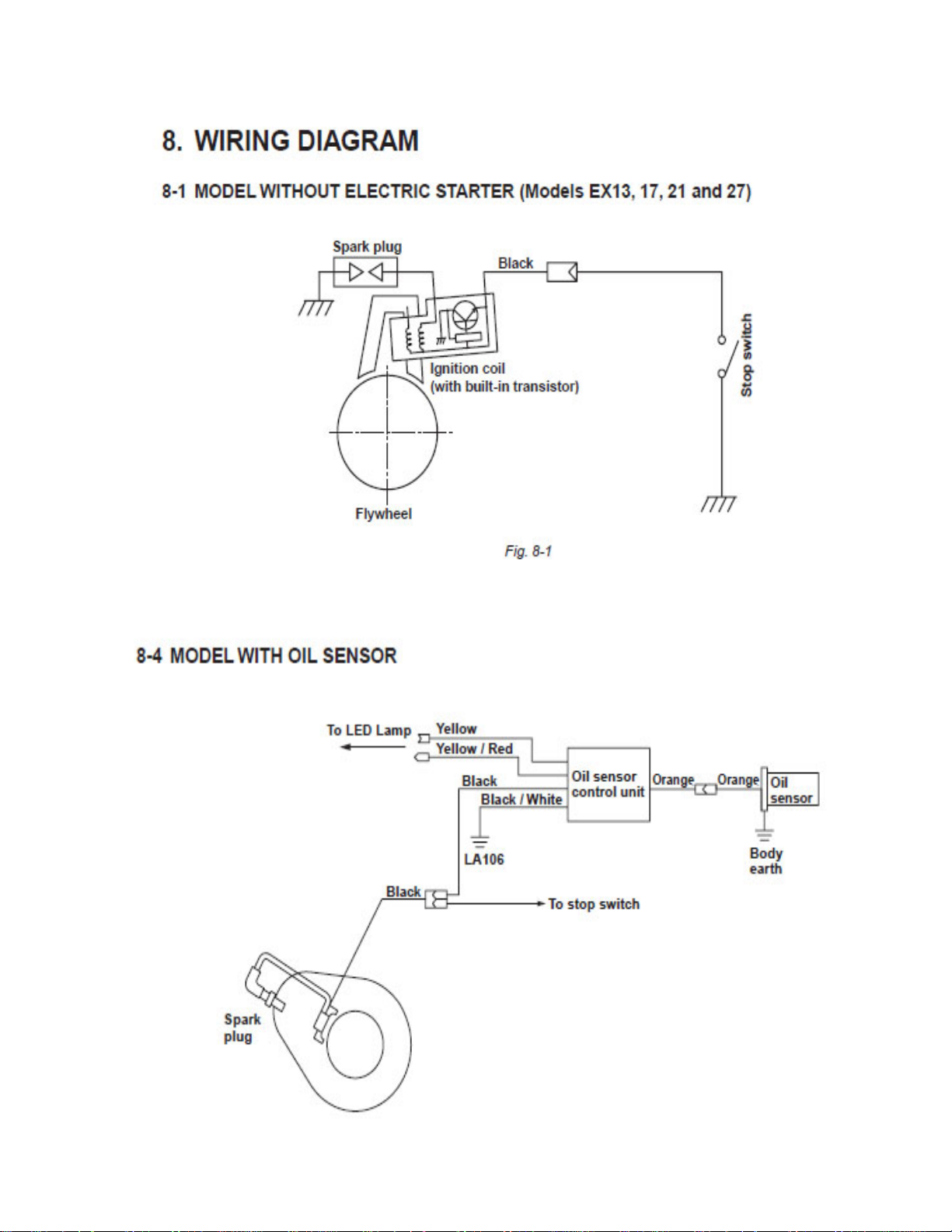

Engines, engine accessories, batteries and tires are warranted by the original manufacturers and

are not covered by the Barreto Equipment Warranty. Wear parts such as tiller tines, sprockets,

bearings, trencher chain parts including teeth, stump grinder cutting teeth & holders, etc. are also

excluded unless it can be determined that a defect has contributed to premature wear.