Barrus ShireZ Electric 6HP User manual

ORIGINAL INSTRUCTION

RDG603A74 - Issue 4

ELECTRIC OUTBOARD MOTOR

OPERATORS MANUAL

For the following engine models:

6HP

10HP

20HP

RDG603A74 - Issue 4 Page 2 of 97

SAFETY

Barrus is concerned for your safety. We use safety statements throughout the manual to call

your attention to the potential hazards associated with the operation of your electric

propulsion outboard.

Follow the precautions listed throughout the manual before operation, during operation and

during servicing/maintenance procedures for your safety, the safety of others and to protect

the performance of your engine.

Safety alert symbols appear throughout the manual. It means attention, be alert as your safety

is involved. Please read and follow the message that appears after the safety alert symbol.

NOTICE:

This indicates a situation which can cause damage to the

machine, personal property and/or the environment or cause the

equipment to operate improperly

CAUTION:

This indicates a hazardous situation which, if not avoided, could

result in minor or moderate injury.

WARNING:

This indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

DANGER:

This indicates a hazardous situation which, if not avoided, will

result in death or serious injury.

RDG603A74 - Issue 4 Page 3 of 97

Engine Details

Engine Model Number:

Engine Serial Number:

Please enter your engine model number and serial number in the space provided above.

Please quote the engine identification number during any enquiry or when ordering spare

parts. Information about the engine serial number and its location on the engine can be found

in SECTION 2 of the manual.

This manual is for the following engine models:

•EZ-S06T (SHIRE6EZTILLPDI)

•EZ-S06R (SHIRE6EZREMPDI)

•EZ-S10T (SHIRE10EZTILLPDI)

•EZ-S10R (SHIRE10EZREMPDI)

•EZ-S20T (SHIRE20EZTILLPDI)

•EZ-S20R (SHIRE20EDREMPDI)

*Note: T = Tiller Steer, R = Remote Steer

Description

This range of electric outboards are unique in their design. Using a D.C. brushless, water-

cooled 48v electric motor, which is mounted horizontally on top of the outboard leg. Drive is

transferred by a heavy-duty toothed belt to the prop shaft. This gives an efficient and trouble-

free method of power delivery. The outboard leg has internal waterways built into it through

which cooling water (with anti-freeze) is pumped, circulated through the motor, and flows

down the inside of the leg, to be cooled by heat transfer. There is no traditional type impeller

to wear out or change. Salt, silt, and sand does not enter the motor and, as long as the anti-

freeze levels are maintained, there is no danger of frost damage in the winter. This results in

your electric outboard requiring far less maintenance than a conventional petrol unit.

They can be tiller or use an inboard shift and steering system, and optional propellers are

available. Bluetooth performance monitoring system is used to indicate main parameters.

RDG603A74 - Issue 4 Page 4 of 97

Engine specifications, Benefits and Optional extras

Specifications:

•48 Volt electric outboard

•CE Marked

•UKCA Marked

•Water cooled brushless electric motor

•Variable speed

•Adjustable leg length from short to long shaft

•Outboard tilt lock

•Adjustable transom angle position

•Mercury marine compatible prop shaft spline

•Safety lanyard

•Replaceable anode

Benefits:

•Variable speed ranges. Can be locked for commercial and hire boat situations

•Coolant is anti-freeze water mix

•No canal, river or sea water enters the system

•No problems in shallow or dirty water

•No water pump impeller to replace

•Replaceable skeg

•Belt drive –no shaft gears or oil changes required

•Spare props of different sizes readily available

•Motor overload cut out

•Spare parts readily available

Optional extras:

•Lithium Ion Polymer batteries available

•Multiple battery packs can be linked

•Remote shift throttle lever for inboard steering position

•Cable steering system for inboard steering wheel application

•Larger skeg rudder

•Other options not listed here are available

RDG603A74 - Issue 4 Page 5 of 97

Operators Manual

NOTICE:

THIS MANUAL FORMS AN INTEGRAL PART OF THE OUTBOARD IT ACCOMPANIES,

IF A TRANSFER OF TITLE OCCURS, IT MUST ALWAYS BE HANDED OVER TO THE

NEW OWNER.

Thank you for purchasing this electric outboard motor from Barrus. This manual has been

compiled to help you to operate your outboard and its associated parts with safety and

pleasure. Please read it and familiarise yourself with the outboard and its parts before

operation.

The information and recommendations given in this manual are based on the latest

information available at the time of publication. Barrus reserve the right to change the

specification of its products and manuals without prior notice.

Depending upon the equipment specification of the outboard and accessories fitted, there

may be discrepancies or differences with the information presented in this handbook. No

claims may be pursued in this respect.

Ensure that you read and understand the contents of the manual before attempting tooperate

the unit.

Disclaimer: All product, product specifications and data are subject to change without notice

to improve reliability, function, design or otherwise. All product information is correct at the

time of issue.

RDG603A74 - Issue 4 Page 6 of 97

WARRANTY

This Limited Warranty provides coverage for one (1) year or 500 hours (whichever occurs

first) for all commercial applications and two (2) years for leisure customers. This is for

mechanical parts and electrical parts from the date of warranty registration. The warranty is

for non-serviceable items. The repair or replacement of parts, or the performance of service

under this warranty, does not extend the life of this warranty beyond its original expiry date.

To ensure that you have been registered for your warranty, please detach and fill in the form

on the back of this manual. Return it to the address given or email to

The Warranty will only apply if the following have been carried out and the registration form

has been completed and returned to Barrus.

CONDITIONS THAT MUST BE MET IN ORDER TO OBTAIN WARRANTY COVERAGE

Warranty coverage is only available from Barrus or an authorised dealer in the country in

which the sale occurred. Routine maintenance outlined in the Owner’s Manual must be

performed using genuine parts (such as belt tension gauges) in order to maintain warranty

coverage. If the customer does not carry out normal maintenance or makes unauthorised

alterations or modifications the warranty coverage will become void, Barrus reserves the right

to make future warranty coverage possible only with proof of proper maintenance.

WARRANTY CLAIMS

Warranty claims shall be made directly to Barrus or by an authorised dealer.

The dealer will then arrange for the inspection and any necessary repairs. If the repairs

carried out are not covered by the warranty, the purchaser shall pay for all related labour and

material, and any other expenses associated with that service.

WHAT IS NOT COVERED

This limited warranty does not cover routine maintenance items, adjustments, normal wear

and tear, damage caused by abnormal use (such as operating in shallow water), operation

of the product in a manner inconsistent with the recommended operation/duty cycle section

of the Owner’s Manual, accident, submersion, improper installation (proper installation

specification and techniques are set forth in the Operations and First time running sections

in this manual), use of an accessory or part not manufactured or sold by us, or alteration or

removal of parts. Expenses related to crane-out, launch, towing, storage, telephone, rental,

inconvenience, slip fees, insurance coverage, loan payments, loss of time, loss of income, or

any other types of accidental or consequential damages are not covered by this warranty.

RDG603A74 - Issue 4 Page 7 of 97

Index Page

SECTION 1 –Safety Precautions..................................................................................... 10

1. General..................................................................................................................... 10

2. Lifting........................................................................................................................ 10

3. Rotating Parts........................................................................................................... 10

4. Propeller ................................................................................................................... 11

5. Electrics.................................................................................................................... 11

6. Batteries.................................................................................................................... 11

7. Safety Lanyard.......................................................................................................... 12

8. Motor Overload......................................................................................................... 13

9. Modifications............................................................................................................. 13

10. Boat .......................................................................................................................... 13

11. Passenger Training................................................................................................... 13

12. Terminal Crimping .................................................................................................... 14

13. Applicable Standards................................................................................................ 14

SECTION 2 –Component Identification.......................................................................... 15

1. Tiller Control Model................................................................................................... 15

2. Tiller Control ............................................................................................................. 15

3. Remote Control Model (Option)................................................................................ 16

4. Speed and Direction Control Lever (Option)............................................................. 16

SECTION 3 –Installation.................................................................................................. 17

1. Unpacking the Outboard Motor................................................................................. 17

2. Filling Outboard Motor with Coolant.......................................................................... 20

3. Adjusting the Outboard Motor Transom Height......................................................... 21

4. Mounting of the Outboard Motor............................................................................... 22

5. Adjusting the Outboard Steering Lock...................................................................... 23

6. Adjusting the Outboard Angle................................................................................... 23

7. Battery Selection....................................................................................................... 24

8. Lithium Ion Polymer (LiFePO4) Batteries.................................................................. 25

RDG603A74 - Issue 4 Page 8 of 97

9. Battery Features (EB-4830 / EB-4850)..................................................................... 28

10. Lithium Ion Polymer (LiFePO4) Batteries Precautions (EB-4830 / EB-4850)............ 31

11. Lithium Ion Polymer (LiFePO4) Batteries Warnings (EB-4830 / EB-4850)............... 31

12. Battery Re-Booting ................................................................................................... 32

13. Battery Type Selection.............................................................................................. 32

14. Anderson Type Connectors...................................................................................... 32

15. Battery Installation .................................................................................................... 33

17. Connecting Speed and Direction Control Lever (Option).......................................... 34

SECTION 4 –Operation.................................................................................................... 35

1. General..................................................................................................................... 35

2. Starting Procedure (Outboard Motor with tiller control)............................................. 36

3. Starting Procedure (Outboard motor with speed and direction control lever)............ 37

4. Stopping Procedure (Outboard Motor with tiller control)........................................... 38

5. Stopping Procedure (Outboard motor with speed and direction control lever).......... 38

6. Tilting the Electric Outboard...................................................................................... 39

7. Application Downloads and Information.................................................................... 41

SECTION 5 –Maintenance............................................................................................... 44

1. General..................................................................................................................... 44

2. Removing propeller................................................................................................... 44

3. Installing propeller..................................................................................................... 44

4. Checking coolant level.............................................................................................. 45

5. Belt Tension.............................................................................................................. 45

SECTION 6 –Transportation and Storage...................................................................... 49

1. Transporting.............................................................................................................. 49

2. Storage..................................................................................................................... 49

SECTION 7 –Wiring Diagrams ........................................................................................ 50

1. Wiring Diagram for Electric Propulsion Outboard ..................................................... 50

SECTION 8 –Technical Data ........................................................................................... 52

1. Outboard Data.......................................................................................................... 52

2. Dry Weight of Engine Data ....................................................................................... 52

RDG603A74 - Issue 4 Page 9 of 97

3. Shipping Weight and Packaging Dimensions ........................................................... 52

4. Outboard Dimensions............................................................................................... 54

SECTION 9 –System Protection Characteristics .......................................................... 56

SECTION 10 –Spare Parts............................................................................................... 58

SECTION 11 –Security Products.................................................................................... 63

1. STAZO Nutlock......................................................................................................... 63

2. STAZO Security Chain.............................................................................................. 63

3. STAZO Bracket Nut.................................................................................................. 63

4. STAZO Outboard Lock ............................................................................................. 64

5. Talamex Outboard Motor Lock ................................................................................. 65

SECTION 12 –Special Tools............................................................................................ 66

SECTION 13 –Declarations ............................................................................................. 69

1. Declaration of Conformity for Recreational Craft Propulsion Engine with the

requirements of Directive 2012/53/EU. (CE Marking)............................................... 69

2. Declaration of Conformity for Recreational Craft Propulsion Engine with the

requirements of the Recreational Craft Regulations 2017 (UKCA Marking) ............. 71

3. LiFEP04 Battery TUV Safety Data Sheet.................................................................. 73

RDG603A74 - Issue 4 Page 10 of 97

SECTION 1 –Safety Precautions

1. General

NOTICE:

NEVER PERMIT ANYONE TO OPERATE THE OUTBOARD WITHOUT PROPER

TRAINING.

Ensure that the engine battery isolator switch is in the off position before connecting the

battery, carrying out any maintenance or repairs. Also, when the outboard is not in

use.

2. Lifting

DANGER:

CRUSH HAZARD! NEVER STAND UNDER A HOISTED ENGINE. IF THE HOIST

MECHANISM FAILS, THE ENGINE WILL FALL ON YOU, CAUSING SERIOUS INJURY

OR DEATH.

•Note: Suitable safe lift equipment must be used to lift, move, and mount the outboard

onto the boat.

•The batteries used for the outboard will be heavy. Make sure safe lifting procedures

or suitable cranes or hoists are used when moving and installing them.

3. Rotating Parts

WARNING:

SEVERE HAZARD! KEEP HANDS AND OTHER BODY PARTS AWAY FROM

MOVING/ROTATING PARTS. WEAR TIGHT FITTING CLOTHING AND KEEP YOUR

HAIR SHORT OR TIE BACK. REMOVE ALL JEWELLERY BEFORE COMMENCING

WORK. CHECK BEFORE STARTING THE OUTBOARD THAT ANY TOOLS OR RAGS

USED DURING MAINTENANCE HAVE BEEN REMOVED FROM THE AREA.

RDG603A74 - Issue 4 Page 11 of 97

The outboard and its accessories are not intended to be put into operation until they are

integrated into the boat as a whole. The top cowl must always be fitted whilst the motor is

running.

4. Propeller

CAUTION

•The propeller has sharp edges which can cause injury even when it is stationary. If

there is someone in the water near the motor, it must be switched off.

•If the propeller is damaged, itmay become unbalanced and cause either bad vibrations

or the outboard to fail. Do not use the outboard in this situation.

5. Electrics

CAUTION

•Do not touch any electrical parts while operating the motor. The electrical parts may

cause shock or electrocution.

•Ensure all electrical connections are insulated against accidental short circuit.

6. Batteries

DANGER:

EXPLOSION HAZARD! NEVER SHORT OUT THE BATTERY TERMINALS,

INCLUDING WHEN CHECKING THE REMAINING BATTERY CHARGE THIS WILL

RESULT IN A SPARK AND MAY CAUSE AN EXPLOSION OR FIRE.

RDG603A74 - Issue 4 Page 12 of 97

WARNING:

BURN HAZARD! BATTERIES CONTAIN SULPHURIC ACID. NEVER ALLOW

BATTERY FLUID TO COME IN CONTACT WITH SKIN, EYES OR CLOTHING. SEVERE

BURNS COULD RESULT. MAKE SURE THE CORRECT PERSONAL PROTECTION

EQUIPMENT IS WORN.

•Batteries can produce explosive gases; keep sparksand flames away from the battery.

NO SMOKING

•Lead acid batteries contain sulphuric acid; if splashed on skin or eyes, flush well with

water and seek medical advice.

•Keep battery tops and battery compartment ventilated at all times.

•If disconnecting the battery; remove the earth lead FIRST; and re-connect it last.

•If charging the battery; ensure that the charger is switched off before connecting and

disconnecting.

•Do not tip the battery on its side.

•Please see label on battery or manufacturer’s instructions for specific information.

•A battery master (on/off) switch must be installed in the system.

7. Safety Lanyard

WARNING:

•The magnetic safety lanyard tag should always be attached to the stop switch area

on the outboard tiller or remote shifter and the person operating the boat before the

motor is started. This will prevent the outboard from operating if the operator falls

overboard or leaves the helm.

RDG603A74 - Issue 4 Page 13 of 97

Figure 1: Safety Lanyard

The outboard will not operate if the safety lanyard is not in place. Ensure there

is a spare one on board the boat and that passengers know where it is located.

8. Motor Overload

•If the motor is excessively overloaded (by either extended running at high speed or

using a propeller which is too big for the application) the motor will stop.

•If the motor stops all drive will be lost, which may be hazardous.

•If the motor stops, move the speed control lever to the stop position. Slowly move the

speed control to the drive position which will start the motor again.

•Continue at a reduced speed until the initial cause of the overload has been resolved.

9. Modifications

Do not attempt to modify the outboard motor as this is likely to reduce safety and reliability.

Any modifications will mean that the outboard will not be liable for warranty and maybe illegal

to use.

10.Boat

•Ensure the boat, that the outboard motor is being fitted to, has the capability of

accommodating the power and weight of the unit. (including the batteries).

•Ensure that any requirements of the boat manufacturer are adhered to.

•Consider location of the batteries in regard to weight distribution within the boat.

11.Passenger Training

•Ensure that at least one Passenger is trained to operate the boat in the event of an

emergency.

RDG603A74 - Issue 4 Page 14 of 97

12.Terminal Crimping

Ensure that a professional type crimping tool is used for crimping all heavy-duty cable

connections. Failure to do so can result in poor performance, system failure, terminal

overheating or in some cases melting of plastic terminal plugs or even fires.

13.Applicable Standards

Ensure that the fitting and installation of the electric outboard motor, batteries, battery

storage, cables and control systems comply with all relevant local, national, and international

standards.

RDG603A74 - Issue 4 Page 15 of 97

SECTION 2 –Component Identification

1. Tiller Control Model

Figure 2: Tiller Controlled Outboard

2. Tiller Control

Figure 3: Tiller Control

Note: A number of optional extras may be fitted to the engines, that are not shown here.

Note: The serial number can be found on the back of the motor.

Note: The On/Off Power Button is illuminated green when it is in the on position.

Description*

1

Engine Cowl

2

Tiller Control

3

Transom Mounting Bracket

4

Leg

5

Anti-Cavitation Plate

6

Prop Shaft Casing

7

Propeller

8

Skeg

9

Anode

Description*

1

Speed Control Twist Grip

2

Direction Display

3

Safety Lanyard

4

Mode Switch

5

On/Off Power Button

6

Neutral Position Indicator

RDG603A74 - Issue 4 Page 16 of 97

3. Remote Control Model (Option)

Figure 4: Remote Controlled Outboard

Note: A number of optional extras may be fitted to the engines, that are not shown here.

4. Speed and Direction Control Lever (Option)

Figure 5: Control Lever

Figure 6: Extension Cable

Description*

1

Steering Wheel

2

Speed and Direction Control Lever

3

Steering Cable

4

Electric Outboard

Description*

1

Safety Lock Button

2

Control Grip

3

Connecting Cable

4

Safety Lanyard

5

Mode Switch

6

On/Off Power Button

7

Extension Lead Connecting Plug

8

Extension Cable (3.1 Metres)

RDG603A74 - Issue 4 Page 17 of 97

SECTION 3 –Installation

NOTICE:

REFER TO THE BARRUS MANUAL PRIOR TO INSTALLING THE ENGINE.

1. Unpacking the Outboard Motor

•The outboard motor will arrive in a wooden box. Section 8.3 details shipping weight

and packaging dimensions. Use suitable personal protective equipment for unboxing.

Figure 7: How the outboard motor will arrive

•Stand the box upright as shown in Figure 7.

•Use a screwdriver to open the wooden box carefully. Don’t damage the wooden box.

•Make sure to remove all screws or staples from the box.

•Using a crane, two people will be required to remove the engine from the box.

Figure 8: Opening the wooden box

RDG603A74 - Issue 4 Page 18 of 97

•Check to make sure the following parts are in the box:

1. Outboard Motor

2. Anderson Type Cable Connector (Qty 1)

3. Safety Lanyard

4. Transom Mounting Bolts and Tools

5. Speed and Direction Control Lever and Steering Kit (Remote Steering Only)

Figure 9: Items in the wooden box

Note: The outboard does not arrive as pictured above. Some assembly is required, such as

fitting of the propeller and skeg. Propeller fitting instructions can be found on pages 45 and

46.

Note: There is a right-handed speed and direction control lever available at an additional

cost.

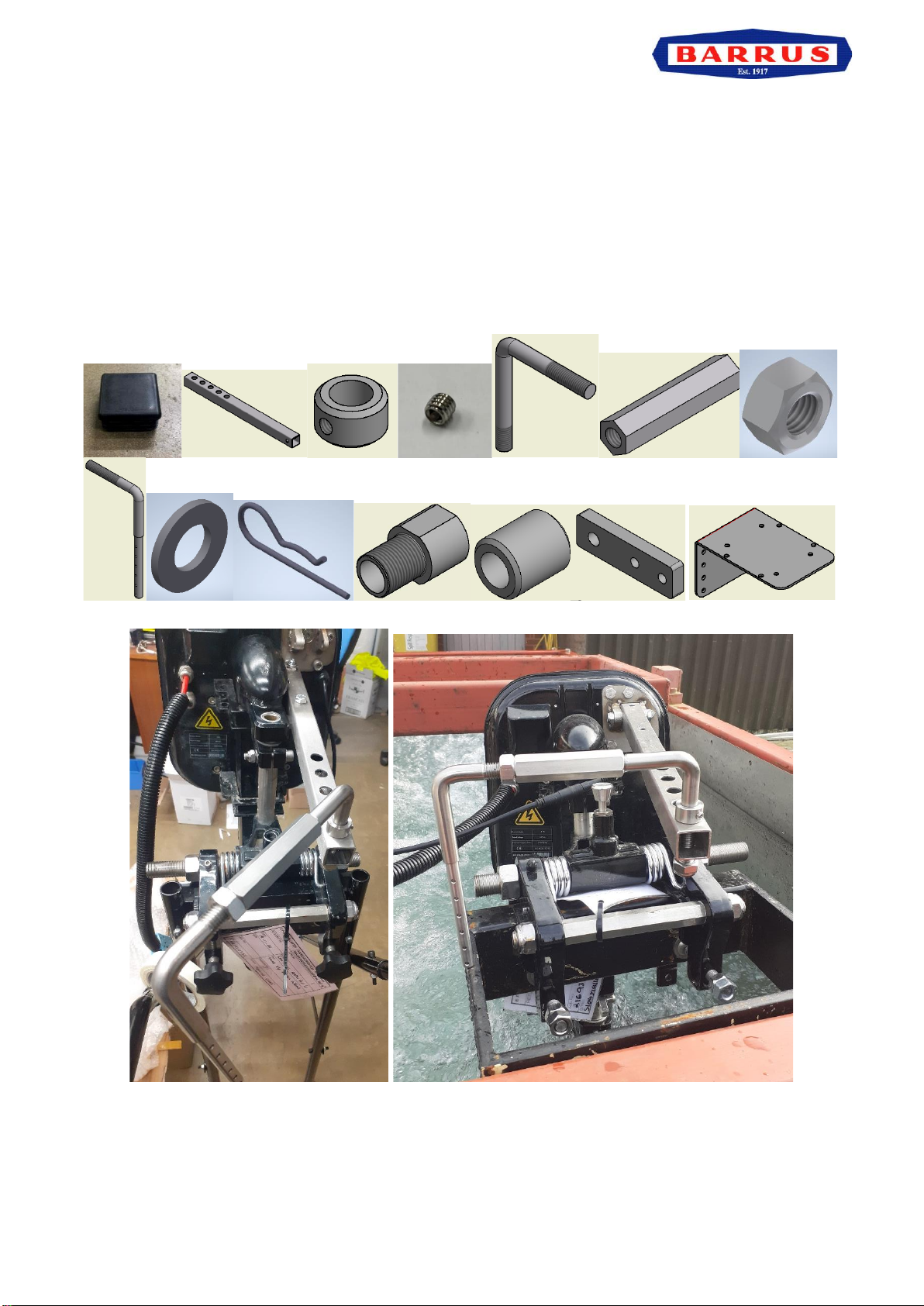

•For remote steering/control application, the steering kit should contain:

1. Square Rubber bung

2. Steering Arm

3. Locking Spacer

4. Grub Screw

5. Steering Arm Left

6. Threaded Adjuster

RDG603A74 - Issue 4 Page 19 of 97

7. M12 Nuts

8. Steering Arm Right

9. Washers (2 Sizes)

10.R- Clips

11.Steering extension

12.Steering Spacer

13.Steering Arm Bracket

14.Shifter Mounting Bracket

Figures 10 & 11: Ridged Steering Set up (Left) and Flexy Steering Set up (Right)

•The steering kit can be attached to the motor in two different ways, depending on the

1

2

3

4

5

6

7

8

9

10

11

13

12

14

RDG603A74 - Issue 4 Page 20 of 97

rigidity required from the system.

•The rigid set up (Figure 10) uses parts 12 and 13 in the steering kit list and attaches

to the motor in two places.

•The flexy set up (Figure 11) uses the existing steering bracket that is also used for

the tiller control.

2. Filling Outboard Motor with Coolant

•Ensure the propeller is not fitted.

•Remove the engine cowl from the outboard motor. (Figure 2)

•Remove the coolant cap from the outboard motor. (Figure 12)

•Switch the outboard on, using the on/off switch (Figure 3, button 5) the button will then

be illuminated green, this starts the pump, then immediately begin filling with coolant.

•Fill the coolant tank with standard high-quality antifreeze and clean water at 50:50 mix

ratio.

Ensure the engine is in the neutral position. Do not engage forward or

reverse.

•After one minute switch off the power then add coolant again.

•Switch on the power again to allow the pump to circulate the coolant.

•These stages may need to be repeated multiple times to ensure the tank is full, and

all air is removed.

Ensure the coolant tank is full before operating the outboard.

Figure 12: Coolant Cap

Coolant

Cap

This manual suits for next models

8

Table of contents

Other Barrus Outboard Motor manuals