Bartec Auto ID TECH500 User manual

Bartec Auto ID Ltd. SW Version: R.58.0 (English) 2018

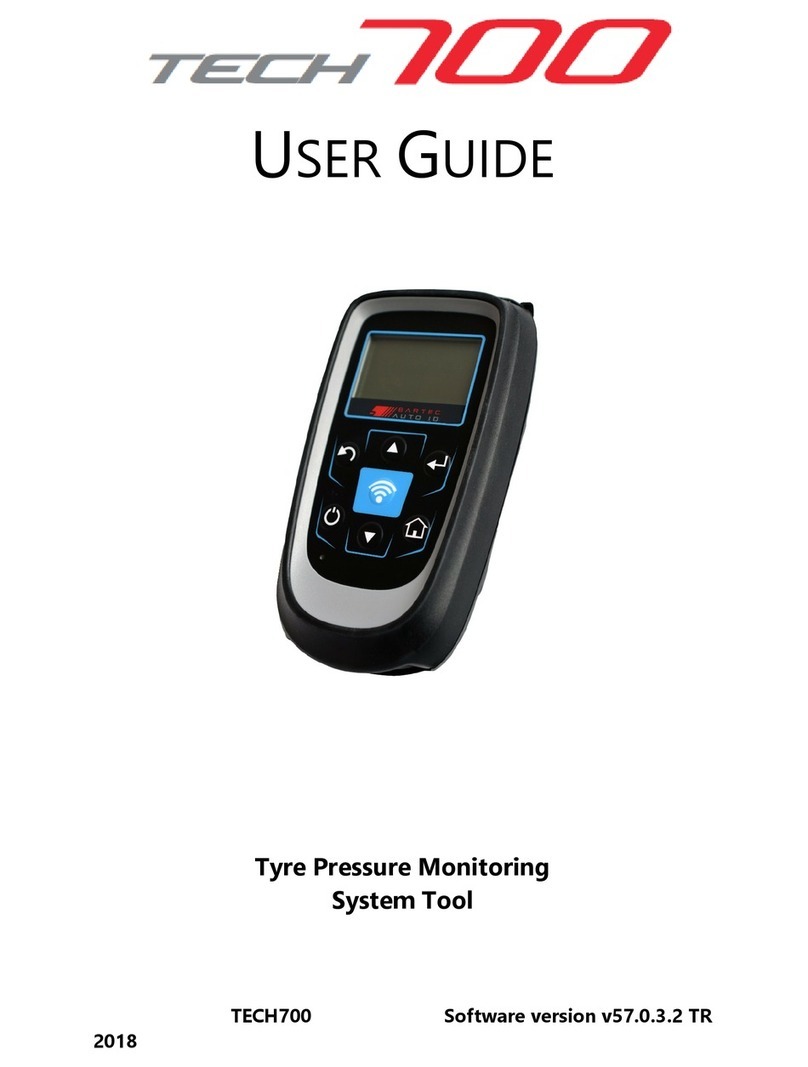

TECH500

Tyre Pressure Monitoring System Tool

User Guide

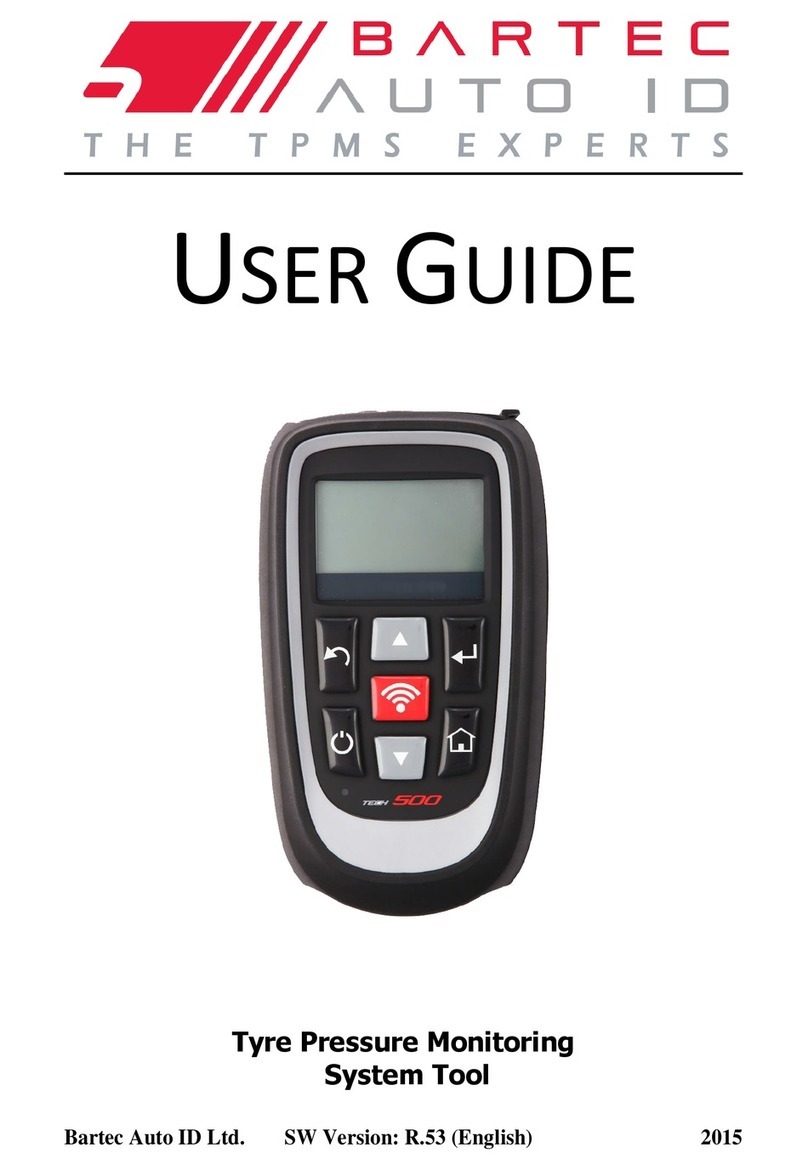

SD Card

Display

Up/Down

navigation

Back/Esc

On/Off:

hold down for

a few seconds

Mini USB

Test:

commence a TPM

test, only works on

Vehicle Audit Screen

Enter

Home:

returns to

Home menu

Rubber housing

OBD cable

connector

TECH500 User Guide R.58.0 2018

2 |P a g e

FOREWORD

Dear customer,

Thank you for having chosen one of our tools. We are certain that it will give the utmost

satisfaction and be a great help on the job.

Please become fully familiar with the instructions in this user’s manual. It should be

kept ready to hand for consultation whenever required.

CE COMPLIANCE

Type Designation: Tech500SDE

Description/Intended Use: Hand Held Tyre Pressure Measurement Tool/used to activate, decode data

from, and display information about tyre pressure monitoring devices. Also used to communicate with

some vehicles OBD2 ports.

Hereby, Bartec declares that the product referenced above is in compliance with the essential

requirements of Directive 1999/5/EC, on the approximation of the laws of the member states

relating to Directive 1999/5/EC.

TECH500 User Guide R.58.0 2018

3 |P a g e

LIST OF CONTENTS

FOREWORD ...............................................................................................................2

LIST OF CONTENTS ...................................................................................................3

IMPORTANT NOTICES................................................................................................4

SAFETY PRECAUTIONS...............................................................................................4

BEFORE GETTING STARTED.......................................................................................6

KIT COMPONENTS.....................................................................................................6

CHARGING TOOL.......................................................................................................7

POWER ON/OFF SEQUENCE...................................................................................7

HOME MENU.............................................................................................................7

SELECT VEHICLE ........................................................................................................7

1/6 CHECK SENSOR..................................................................................................8

2/6 PROGRAMMABLE SENSOR .............................................................................. 10

3/6 RELEARN ......................................................................................................... 12

4/6 OBD DIAGNOSTICS........................................................................................ 13

5/6 TECHNICAL INFORMATION ............................................................................. 14

6/6 REVIEW VEHICLE DATA .................................................................................. 15

RECENT VEHICLES .................................................................................................. 15

VEHICLE DATA........................................................................................................ 16

TOOLKIT ................................................................................................................. 16

MY TOOL................................................................................................................ 17

REGISTRATION ........................................................................................................ 18

UPDATING THE TOOL VIA USB CABLE.................................................................. 20

UPDATING YOUR TOOL VIA WIFI......................................................................... 21

CHANGING FROM EU TO US VEHICLE COVERAGE............................................... 21

TPMS DESKTOP .................................................................................................... 22

APPENDIX ............................................................................................................... 24

TECHNICAL SPECIFICATION.................................................................................... 25

BARTEC PRODUCT RANGE &ACCESSORIES........................................................... 26

TECH500 User Guide R.58.0 2018

4 |P a g e

IMPORTANT NOTICES

SAFETY DEFINITIONS

All Danger, Warning, Important, and Note messages must be followed for your safety. These

safety messages are in the following form

DANGER: Means you may risk possible loss of life.

WARNING: Means you may risk possible bodily harm.

CAUTION: Means you risk damage to the vehicle or the tool.

These safety messages cover situations Bartec is aware of. Bartec cannot know, evaluate and

advise you as to all the possible hazards. You must be certain that any conditions or service

procedures encountered do not jeopardise your personal safety.

COPYRIGHT

No part of this manual may be reproduced, stored in a retrieval system or transmitted, in any

form or by any means, electronic, mechanical, photocopying, recording, or otherwise, without

the prior written permission of Bartec.

DISCLAIMER

All information, illustrations, and specifications contained in this technical instruction manual

are based on the latest information available at the time of publication. The right is reserved to

make changes at any time without obligation to notify any person or organization of such

revisions or changes. Further, Bartec shall not be liable for errors contained with the furnishing,

performance or use of this material.

SAFETY PRECAUTIONS

Read carefully the installation, operating and maintenance instructions in the Operator’s

manual.

Do not allow unqualified persons to use this equipment. This will prevent injury to persons and

damage to the equipment.

The work place must be dry, sufficiently lit and well ventilated.

Do not forget that breathing carbon monoxide (odourless) can be very dangerous and even

fatal.

When working on the vehicle:

Wear suitable clothing and act in such a way as to prevent industrial accidents.

Before starting, check to be certain the gear shift is in neutral (or in PARK (P) if the

transmission is automatic) and put the handbrake on and check to be sure the wheels

are completely locked.

Do not smoke or use naked flames when working on a vehicle.

Wear safety glasses to protect your eyes from dirt, dust or metal chips.

TECH500 User Guide R.58.0 2018

5 |P a g e

Disposing of equipment

Do not dispose of this equipment as miscellaneous solid waste but arrange to have

collected separately.

The re-use or correct recycling of electronic equipment (EEE) is important in order to

protect the environment and human health.

In accordance with European Directive WEEE 2012/16/EU, special disposal points are

available for waste electrical and electronic equipment.

Public administrators and producers of electrical and electronic equipment are involved

in facilitating the re-use and recovery of waste electrical and electronic equipment

through these collection activities and use of appropriate planning arrangements.

Unauthorised disposal of waste electrical and electronic equipment is punishable by

law with appropriate penalties.

Disposing of batteries

The Tech 500 contains a Lithium Polymer rechargeable battery which is not accessible

to the user.

Batteries must be recycled or disposed of properly. Do not throw batteries away as part

of normal refuse disposal.

Do no throw batteries on to an open fire

Correct use of the tool

Do not expose the tool to excessive moisture.

Do not use the tool near sources of heat or polluting emissions (stoves, ovens, etc.).

Do not drop the tool.

Do not allow the tool to come into contact with water or other liquids.

Do not open the tool or attempt to perform maintenance or repair operations on any

internal parts.

You are advised to keep the packaging and to re-use it if the tool is moved to another

site.

When using the tool remember:

Do not subject the tool to magnetic or electric interference.

Reception, maintenance and guarantee:

Inspect the tool when delivered. Damage sustained during shipment is not covered by the guarantee.

Bartec will accept no responsibility for material or bodily harm resulting from inappropriate use of

the product, failure to maintain it, or incorrect storage conditions.

Bartec provides training for clients desirous of acquiring the knowledge required for the correct use of

its products.

Only personnel authorized by Bartec are permitted to make any repairs that may be necessary. This

tool is guaranteed against any manufacturing fault for 12 months as of date of invoice (parts and

labour) only if product has been correctly used. Serial number must stay readable and proof of

purchase must be retained for presentation upon request.

Bartec Auto ID Ltd

Unit 9

Redbrook Business Park

Wilthorpe Road

Barnsley

S75 1JN

+44 (0) 1226 770581

TECH500 User Guide R.58.0 2018

6 |P a g e

BEFORE GETTING STARTED

1. Charging

NOTICE: Only use the power supply or USB cable that is included in the TECH500 tool kit to

charge this tool. The use of un-approved power supplies may damage it and will void the tool

warranty.

2. Registration

The Bartec TECH500 can be registered at https://tools.bartecautoid.com/ . Follow the on-

screen prompts filling in the information and tool serial number. A valid serial number and

supplier is required to process the registration, which can take up to 24hrs once submitted.

3. Update

Once the tool is registered, verify the software level loaded to the level available online and

update the tool if necessary.

KIT COMPONENTS

The TECH500SDE kit inside the tool box includes:

TPMS activation tool

OBD II cable

USB cable

Battery charger

Bluetooth Stick

User Manual

Identifying Kit Components and Features

The TECH500SDE tool is battery operated and generates a low-frequency magnetic field to

activate tyre sensors. It receives UHF radio signals from the tyre sensors typically at 434MHz.

User

manual

USB

Cable

OBD II

cable

TPMS

activation

tool

Bluetooth

Stick

Battery

charger

TECH500 User Guide R.58.0 2018

7 |P a g e

CHARGING TOOL

The TECH500 is shipped with a charged battery. It is recommended that the tool is charged 2+

hours before first use. For optimum performance, always keep it sufficiently charged.

When there is an insufficient amount of power remaining in the battery, the TECH500 will

flash its battery icon for two seconds, save all of the TPM Data and then power itself off.

POWER ON/OFF SEQUENCE

Auto power off is after 5 minutes of inactivity.

The unit automatically powers up when the charger or USB port is in use –auto power off is

not operational. The tool cannot be operated when plugged in.

HOME MENU

Select Vehicle

Used to start a new Service

Recent Vehicles

Used to resume an incomplete service

Vehicle Data

Used when reviewing read data

Toolkit

Used to test the remote car key or to use the UHF Monitor

My Tool

Used for settings and tool information

SELECT VEHICLE

To start a new service and see all service functions available for the car that needs TPMS

maintenance, press “Select Vehicle” in the Main Menu and continue with choosing the

required make, model and year combination.

Enter Vehicle Registration: This can be enabled or disabled in My Tool > Workflow.

To verify the year of manufacturing, it is possible to use the VIN. See Appendix A –page 24

Select Make

Jeep

Kia

Lada

Lamborghini

Lancia

Land Rover

1/70

Select Model

D5 LCV

Defender

Discovery

Discovery Sport

Evoque

Freelander

6/10

Select Year

07/2011>10/2016

11/2016>

1/1

07/2011>10/2016 Evoque

Check Sensor

Programmable Sensor

Relearn

OBD Diagnostics

Technical Information

Review Vehicle Data

1/6

TECH500 User Guide R.58.0 2018

8 |P a g e

The service menu consists of the following points and will only show functions that

are applicable for the preselected make model year combination.

All captured data will be stored automatically.

1/6 CHECK SENSOR

Use this function to test the fitted sensors before continuing with further steps.

LF activated sensors

To test a sensor the tool should be placed alongside the valve stem and the ‘Test’ key

pressed.

Tool Positioning

Do NOT touch the metal rim. The tool needs to point through the rubber at the sensor.

(Note: with Ford Banded sensors the tool should be held 180°/opposite from the stem’s

position)

Non-LF activated sensors (some Beru sensors up to 2009)

If the tool requires rapid tyre deflation (of the order of 10psi or 0.5bar), then deflate the tyre

and place the tool alongside the stem while pressing the test key.

During testing, the screen confirms the sensor type being tested and displays a progress bar.

Different makes of Sensors respond at different speeds/ time intervals.

Sensor Test

Toolkit

The tool tries to read all possible sensor types that could be fitted to

the selected Make. The search will identify that the sensor is working,

although it may not be the correct sensor for a particular Make, Model

and Year combination.

Enter for valve condition

Press Test to activate

Selected wheel.

Processing order:

Left Front,

Right Front,

Right Rear,

Left Rear

TECH500 User Guide R.58.0 2018

9 |P a g e

Possible Reading Scenarios

Note that if a faulty Sensor has been replaced, some method of relearn procedure will need to

be followed, as explained later in this manual.

Successful Sensor Read

Sensor was successfully activated and

decoded. Displays pressure (in Bar or PSI) at

wheel location.

Failed Sensor Read

No Sensor Activation or Decode. May be wrong

sensor fitment or non-functioning sensor. Tool will

prompt to attempt reading the sensor 3 times.

Duplicate ID

A Sensor with a duplicate ID has been read. Tool will

direct to re-read those sensors.

Wrong Sensor Type

A Sensor was activated and decoded, but

does not match the protocol for the Make Model

Year that the tool was set-up for.

No Pressure

Low Sensor Battery

Sensor’s internal battery has dropped below a

certain voltage threshold.

TECH500 User Guide R.58.0 2018

10 |P a g e

Valve Condition

Press enter at the particular wheel position to select the Valve condition.

Successful Sensor Read

When all four wheels have been read, the tool will automatically save all Data and come up

with the following three options.

Send

Sends the data to the Service Centre or TPMS Desktop

Print

Sends the data immediately to the Bluetooth printer that will print

out the report.

Continue

Will let you exit the menu to continue with further steps

2/6 PROGRAMMABLE SENSOR

The “Programmable Sensor” Point on the service menu enables the function of programming

aftermarket replacement sensors like the HUF IntelliSens or the Schrader EZ-sensor. Even

when they are already mounted in a wheel or programmed to another vehicle.

The user can choose from a selection of sensors which match the preselected MMY.

03/2014>12/2018 C Class

Check Sensor

Programmable Sensor

Relearn

OBD Diagnostics

Technical Information

Review Vehicle Data

2/6

Universal Sensors

Schrader EZ-sensor

Huf intelliSens UVS

Huf IntrlliSens ECS

ProSens

UniSens by repstar

Alligator sens.it

1/3

Select Sensor Type

EZ-sensor Clamp-in 2020

EZ-sensor Snap-in 1000

EZ-sensor 2.0 Clamp-in 2210

EZ-sensor 2.0 Snap-in 1210

EZ-sensor 2.0 Clamp-in 2200

1/5

EZ-sensor Clamp-in 2020

Copy/Clone Set

Create ID

Copy/Clone ID

Enter ID Manually

Copy Using stored data

1/5

Valve Condition

Sensor OK

Corroded Stem

1/2

Enter for valve condition

Press Test To Activate

TECH500 User Guide R.58.0 2018

11 |P a g e

Copy/Clone Set

Used to Copy/Clone a winter tyre set with the same ID´s as the summer

tyre set. Requires the reading of the old sensor to program the same ID on

the replacement sensor to avoid the relearning process.

Create ID

Used to create a single sensor with a new ID. Can be repeated as many

times as requested. The ID needs to be relearned to the vehicle’s ECU. The

following pages will describe this procedure.

Copy/Clone ID

Used to Copy/Clone a single ID. Can be repeated as many times as

requested. Requires the reading of the old sensor to program the same ID

on the replacement sensor to avoid the relearning process.

Enter ID Manually

Used to create a Sensor with a new ID that can be typed in manually. This

option only appears for some sensors. If it is not possible to copy the ID,

enter the same ID manually, which is written on the sensors body.

Copy Using

stored data

Gives you the option of using stored IDs either read from the TPMS sensors

or from the vehicle OBD

The current coverage list is available at www.bartecautoid.com

The user has the option to either create or copy the ID.

Notice: Sensors need to be read before copying.

Sensors that can be programmed by the tool may have slightly different procedures and times.

Recommended sensor position for programming:

TECH500 User Guide R.58.0 2018

12 |P a g e

3/6 RELEARN

To find out which relearn type is available for a vehicle, just turn on the tool and select Relearn.

Or refer to the current coverage list at www.bartecautoid.com > Downloads.

Stationary Relearns:

Stationary Relearns use the vehicles on-board TPMS system to listen for transmissions from

sensors while the vehicle is in a “Learn Mode”.

Once the vehicle is in Learn Mode, use the tool to activate the sensors. The vehicle will listen

for the sensor IDs and learn them to the vehicle.

Active (Drive) Relearns:

Some vehicles can be reset by driving. Refer to the on-screen relearn procedures for details on

how far/long to drive. It can take up to 20 minutes to relearn the sensor IDs.

OBD Relearns:

OBD connection allows the TECH500 to directly program the vehicle electronics module with

sensor IDs.

Note that not all vehicles support vehicle communications modes.

OBD can be connected when all sensors are successfully read and the message “All Sensors

OK” is displayed.

Please use the “Technical Information” menu and select “View Vehicle Info” to find the OBD

location.

Relearn Information:

This contains extra information about the relearn for the selected vehicle, which can assist you

if you have any problems. An example would be for some Toyota and Lexus vehicles which use

a summer and winter tyre set.

After selecting a Relearn method, follow the instructions given by the tool to relearn Sensors.

07/2011>10/2016 Evoque

Check Sensor

Programmable Sensor

Relearn

OBD Diagnostics

Technical Information

Review Vehicle Data

3/6

Select Relearn Type

Relearn –OBD

Relearn - Drive

1/2

Enter for valve condition

Press Test To Activate

Selected tyre.

Processing order:

Left Front,

Right Front,

Right Rear,

Left Rear

Relearn Toolkit

(Explanation below)

TECH500 User Guide R.58.0 2018

13 |P a g e

As well as the pressure and temperature, we also display the “mode” of the sensor. In some

cases the mode cannot be changed and isn’t important, but in some cases it will need to be

changed in order for the relearn to work.

For example if sensors for a vehicle show “Park” or “Drive” they are already in the correct mode.

Otherwise use the “Set to Park” command in the Relearn Toolkit. If the sensors are shown as

Ship, Off or Test mode, put them in Park mode, using the “Set to Park” command in the Relearn

Toolkit.

To access the Relearn Toolkit, use the up and down arrows to select the spanner symbol in the

top left corner.

Special service advice for Toyota Models:

Toyota ECU

Reset

If at any time the vehicle TPMS Reset button is pressed with the new

sensor IDs fitted, the ECU OBD relearn will not work until the Toyota

ECU Reset is selected (with the tool connected to OBD). The TPMS

Reset button should only be used to set new tyre pressures, and on

some vehicles to change between winter and summer ID sets.

Special service advice for Kia and Hyundai Models:

Reset YD Sensor

For some Kia and Hyundai vehicles with the newer low line TRW YD

sensors, this allows you to put the sensors back into the correct mode

(Sleep or Rest) to work with the vehicle.

These specific Service advices will only appear if applicable for the preselected Make,

Model and Year combination.

4/6 OBD DIAGNOSTICS

OBD

Diagnostics

This option will only be

listed for vehicles that

Bartec has OBD

coverage for. It reads

information from the

vehicle such as the VIN,

DTCs (Diagnostic

Trouble Codes) and the

IDs of the sensors.

07/2011>10/2016 Evoque

Check Sensor

Programmable Sensor

Relearn

OBD Diagnostics

Technical Information

Review Vehicle Data

4/6

Relearn Toolkit

OBD

Set Sensor to Park Mode

2/4

Press Test To Activate

Left Front

TECH500 User Guide R.58.0 2018

14 |P a g e

5/6 TECHNICAL INFORMATION

Sensors do not have to be read to access the following information.

View Replacement Parts

Used to show all Replacement Sensor part numbers that can be

fitted to the preselected MMY

View Service Kits

Used to show all Replacement Service Kit part numbers that

can be fitted to the preselected MMY

View Sensor

Characteristics

Used to show technical sensor information of the sensor that

needs to be fitted. e.g. Nut torque settings

Technical

Information

Gives detailed

information about

replacement parts,

service kits, sensors,

vehicles and service

tips.

View

Vehicle

Information

This option provides

information about the

Relearn method, the

OBD port location and

if there are

programmable Sensors

for the preselected

MMY available.

View

Service

Tips

This option provides

information about the

specific meaning of

the TPMS light as well

as common

mechanical faults for

the preselected MMY.

07/2011>10/2016 Evoque

Check Sensor

Programmable Sensor

Relearn

OBD Diagnostics

Technical Information

Review Vehicle Data

4/6

Information

View Sensor Info.

View Vehicle Info.

View Service Tips

1/3

Sensor Information

View Replacement Parts

View Service Kits

View Sensor Characteristics

1/3

Information

View Sensor Info.

View Vehicle Info.

View Service Tips

2/3

Information

View Sensor Info.

View Vehicle Info.

View Service Tips

3/3

TECH500 User Guide R.58.0 2018

15 |P a g e

6/6 REVIEW VEHICLE DATA

Sensors and OBD need to have been read for data to be shown.

The menu gives direct access to specific screens that display the Vehicle data. This option is

helpful if the user wants to have a second look at the Sensor Data, OBD Data or wants to print

the data from the last processed vehicle via the Bluetooth printer.

RECENT VEHICLES

Recent

Vehicles

To resume to an

incomplete Service,

select one of the

previous serviced

vehicles by Year and

Model and continue

with the service menu.

07/2011>10/2016 Evoque

Check Sensor

Programmable Sensor

Relearn

OBD Diagnostics

Technical Information

Review Vehicle Data

4/6

Recent Vehicles

01/2010>12/2011,159

06/2018>01/2018,A110 S

1/2

TECH500 User Guide R.58.0 2018

16 |P a g e

VEHICLE DATA

This menu gives access to specific screens that display the previous read Vehicle Data sorted

by registration or model as detailed above.

List by Registration

This option is only useful if a registration is entered with each

tested vehicle. It will sort the saved data by registration.

Search by Registration

Allows to search a vehicle with a specific registration. Use the

Up Arrow to start with upper case, the Down Arrow for

numbers and lower case, Test to enter the next character, and

Enter to start searching.

List by Model

Stored data will be sorted by model.

Upload Service Data

To enable Bluetooth, select “My Tool” > “Networks” >

“Bluetooth” and connect to TPMS Desktop to upload all stored

data.

Clear Service Data

Clears all data on the tool; any data not already sent to TPMS

Desktop will be transferred when next connected

If one data set is selected, it is possible to get further information about the sensor and the

OBD, to directly access the Program Sensor section and to print the data via the Bluetooth

printer.

TOOLKIT

RKE Test

Select RKE Test, hold the Key Fob and press the function buttons on

the Fob. The TECH500 will check only for a signal present. When

performing relearn processes that use the Key Fob it is important to

verify that the Key Fob is transmitting.

UHF Monitor

Allows operator to search for sensor signals. This feature is used for

advanced diagnostics to determine if signals may be causing issues

during sensor activation and vehicle relearns.

Passive Key

A passive key system allows the driver to (un)lock the vehicle’s doors

without touching a key and to start/stop the engine simply by pushing

the ignition button. This feature is used when the passive key system

doesn’t work. A working system will first show activity from the

vehicle, and then show a response from the key.

TECH500 User Guide R.58.0 2018

17 |P a g e

MY TOOL

Sub-menu containing important information and settings about the tool itself.

Settings

TPM ID

Select whether the tool displays the TPM ID in DECIMAL or

HEXIDECIMAL

Pressure

Change how pressure is displayed, choose between PSI or Bar.

Temperature

Select Celsius or Fahrenheit.

Display Contrast

Adjust tool display contrast.

Lang.

Select Language for tool.

Date/Time

Allows to set the date and time.

Restore Defaults

Reset all settings back to the factory default values.

Networks

Choose between Bluetooth and WiFi. To enable WiFi change the settings from Disabled to

Enabled.

To connect to a network, highlight Join Network and press Enter. Select the correct available

network displayed by highlighting it and pressing Enter. Use Up Arrow key to start with upper

case, Down Arrow key for numbers and lower case to enter the passphrase. ESC to go back a

position and Enter to enter the next character. TEST to connect. Special characters like β, ä, ö,

etc cannot be selected.

When connected, it is possible to check for updates.

To go ahead, press enter. To check later, press ESC.

Current network displays information about the network the tool is connected to.

For Bluetooth, please see section ‘TPMS Desktop’ (page 22).

Software Updates

WiFi Updates

Used to set the interval with which the tool should check for

updates via WiFi (Daily, Weekly, Monthly or Off).

Check Now

The tool connects, looks for an update and asks to press Enter to

Update. Press ESC to not go ahead.

Enter Update Mode

Used to install an update on the tool. See page 20 onwards for

update instructions.

Tool Info

Gives the operator the ability to view:

Software Version currently installed

Build Date of that Software

Serial Number of the tool

Language Region

Coverage Region

Switch to US coverage

Note: can only be used if US coverage is downloaded on the tool.

Usage

View the number of Power Cycles, Sensor Activations and OBD Relearns.

TECH500 User Guide R.58.0 2018

18 |P a g e

Support

On screen reference for Bartec Auto ID Ltd support.

Workflow

Vehicle No.

Allows the user to select different formats of licence plates.

REGISTRATION

It is essential to register the tool as it enables the notification

of software updates and the ability to download update files to the

tool.

To register a tool, navigate to the Bartec TPMS website at

tools.bartecautoid.com/register.aspx .

The first page is the TPMS Tool Support page, showing the product range.

First select your product, then select ‘Register’ to create a new account. It is important to fill in

all fields completely and accurately. This information will help Bartec remain in contact

regarding updates and other important TPMS information. Choose a username (without a

space) and password.

If the details are accepted, this message will show:

The following email should arrive within a few minutes:

When clicking ‘Confirm account’ it will bring the user back to the website and the following

page will show that the registration was successful. Click on ‘this page’ to log in.

TECH500 User Guide R.58.0 2018

19 |P a g e

After Login, the personal settings will show, which can be changed as required.

Selecting Tools gives the user the option to register a new tool. The serial number is printed

on the back of the tool or in ‘My Tool’ menu ‘Tool Info’.

Note that this Serial Number is validated by the website and it must be entered correct.

If the number is accepted the user will see the tool listed, along with a Download button which

will allow to get the latest software version:

Selecting ‘Download’generates a version of the software locked to the serial number only and

gives a standard download message (dependent on the browser) to save the software file. After

saving the file, continue with the update process as described in the following.

TECH500 User Guide R.58.0 2018

20 |P a g e

UPDATING THE TOOL VIA USB CABLE

The tool is compatible with PCs running Windows operating systems.

Find a detailed written and video guide at www.bartecautoid.com > TPMS Dropdown menu >

TPMS Support > SW Update Guide.

Step 1:

Power on the TECH500, select My Tool from the

Main Menu, select Software Updates and select Enter

Update Mode.

Tool will prompt user to “Insert USB Lead to Transfer

Update Files” and connect to the PC.

Step 2:

The tool should open a window on the computer screen which is seen as a Removable Disk.

OR: To open window, navigate to My Computer and open the removable disk.

Step 3:

Copy and Paste or Drag and Drop the saved Update

file (*.mfu) into the Removable Disk Window.

Note: Every tool needs its own unique update file.

The file can only be used for the specific tool

identified by the serial number.

Step 4:

The tool will load the update file to the operating

system.

Once the verification is complete the update finishes and the tool can be unplugged.

Step 5:

The tool is now updated and ready to go. The software version can also be checked in the Tool

Info screen.

Trouble Shooting Tips:

If Windows does not recognize the tool, please check that the USB cable is connected,

that the tool is in update mode, and that there are no unnecessary update files on your PC

available.

Make sure the right update file is used.

Do not delete any files that may already be in the removable disk window.

UPDATE MODE V5

INSERT USB LEAD

TO TRANSFER

UPDATE FILES

Table of contents

Other Bartec Auto ID Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Chauvin Arnoux

Chauvin Arnoux C.A 1310 user manual

ABB

ABB ProcessMaster wafer FEM610 Series Operating instruction

shumatt

shumatt CRT061 instruction manual

Honeywell

Honeywell FS24X Plus user manual

Salter

Salter 9141 WH3R instruction manual

PCB Piezotronics

PCB Piezotronics IMI SENSORS 605B61 Installation and operating manual

Dräger

Dräger Pac 3000 instruction manual

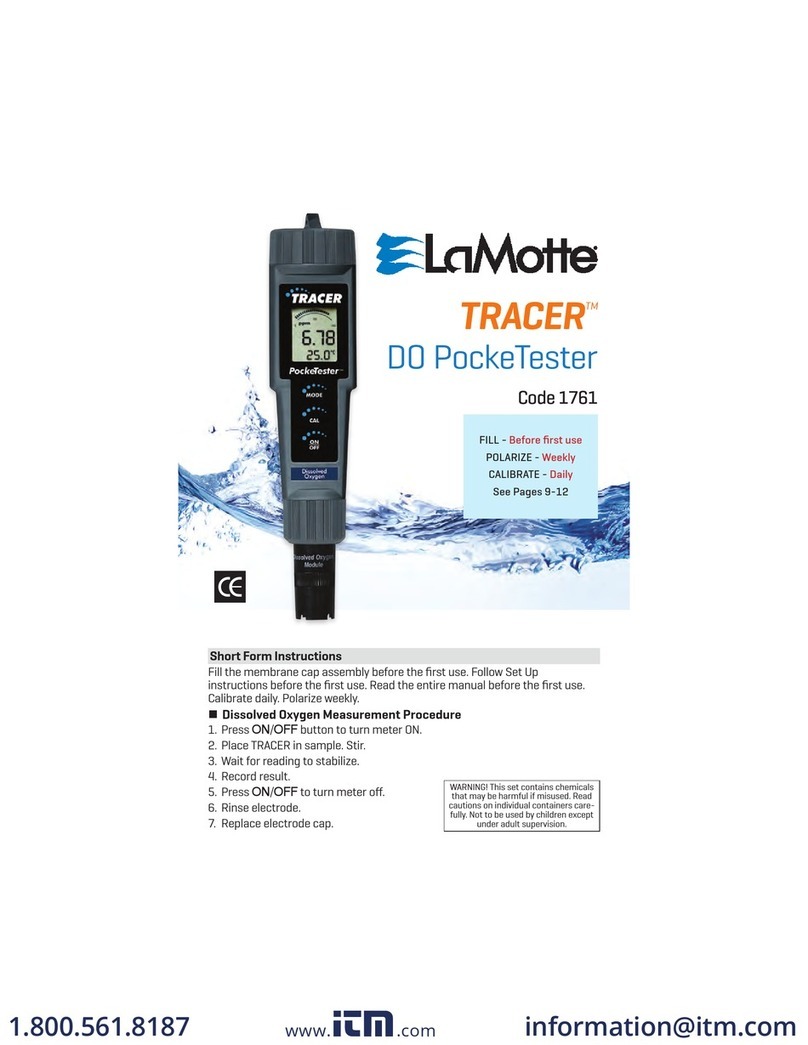

LaMotte

LaMotte Tracer PockeTester manual

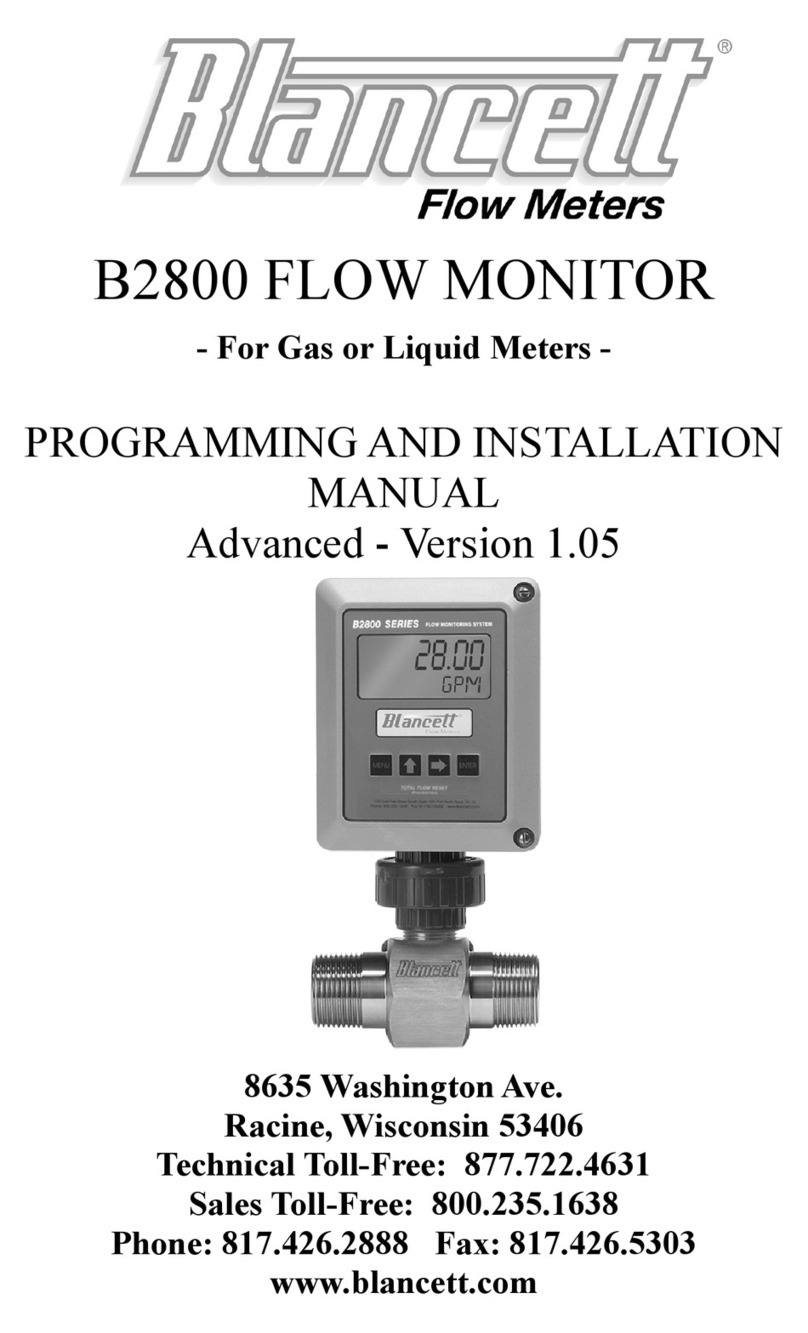

Blancett

Blancett B2800 Standard Programming and installation manual

Bosch

Bosch FSA 720 instruction manual

International Light Technologies

International Light Technologies BiliBlanket ILT750-BILI454 Operation manual

Xylem

Xylem wtw Cleaning Air Box -115 VAC operating manual