Blancett B2800 Standard User manual

B2800 FLOW MONITOR

- For Gas or Liquid Meters -

PROGRAMMING AND INSTALLATION

MANUAL

Advanced - Version 1.05

8635 Washington Ave.

Racine, Wisconsin 53406

Technical Toll-Free: 877.722.4631

Sales Toll-Free: 800.235.1638

Phone: 817.426.2888 Fax: 817.426.5303

www.blancett.com

2

TABLE OF CONTENTS

Introduction……………………..…………………..3

Features……………………………………………...4

Specifications………………………..…………….....5

Operating the Monitor……………..…………….....6

Advanced Programming Mode……………………..6

Programming……..………………….….…...6

4-20 mA Programming...…….…..…….……11

Linearization………………………………...13

Password………………....……………..……14

Battery Replacement………………………..16

Additional Input Options…………………………...16

Wiring Diagram………….………………………….17

Mounting Options…………………………………...19

Troubleshooting……………………………………...21

General Notes on Scaling……………………………22

Part Numbering Information……………………….25

Installation Drawing…………………………………26

Statement of Warranty……………………………...27

Notice: Blancett reserves the right to make any changes or

improvements to the product described in this manual at any

time without notice.

3

INTRODUCTION

The B2800 Flow Monitor is a state-of-the-art, microprocessor

based flow monitor, designed to provide the user with exceptional

flexibility at a very affordable price. Though designed for use

with Blancett Flow Meters, this display can be used with almost

any flow meter producing a low amplitude AC output or contact

closure signal(s).

This flow monitor is capable of accepting a low-level frequency

input for calculating flow rate and total. These calculations can

then be displayed in the desired units of measurement. All B2800

flow monitors come pre-calibrated, from the factory, if ordered

with a Blancett Flow Meter. If required, however, it can easily be

re-configured in the field. The monitor’s large 8 digit by .75” nu-

meric liquid crystal display makes extended range viewing practi-

cal. The second 8 digit by .38” alphanumeric display provides for

selectable units viewing in run mode and prompts for variables in

programming mode. Finally, the user can choose between dis-

playing rate, total, or alternating between both rate and total.

4

FEATURES

• Displays Rate and/or Total

• Large 0.75 Inch, 8 Digit Display for Easy Viewing

• Simple, Front Panel Programming

• Various Mounting Styles Available

• 10 Point Linearization Capability

• Gas Measurement Software Included

• NEMA 4X Suitable for Outdoor Mounting

• Intrinsically Safe

• Microprocessor Based, Low Power Components

• 2 Power Options – 1.5V “D” Size Battery or 4-20 mA Loop

• Automatic Decimal Point Locating

• Lead Zero Blinking

• Surface Mount Technology Use Throughout

5

SPECIFICATIONS

Power Supply Options:

Battery Powered: 1 “D” size 1.5 Volt alkaline battery

Loop Powered: 4-20 mA loop power

Power Consumption:

Battery Powered: Less than 1 milliwatt

Loop Powered: 25 mA (Maximum)

Alphanumeric Rate and Total Display:

8 digit, .75” high numeric display

8 character, .38” high alphanumeric display

Pulsed Output Signal:

Outputs one pulse for each increment of the least significant totalizer digit

Max. Voltage: 30Vdc

Pulse Type: Opto-Isolated open collector transistor

Pulse Width ON State: 0.9V drop @ 5.0mA or 0.7V drop @ 0.1A

Magnetic Pick-up Inputs:

Frequency Range: 0 to 3500 Hz

Trigger Sensitivity: 30 mV p-p

Over Voltage Protected: ±30 VDC

Frequency Measurement Accuracy: ±0.1%

Temperature Drift: 50 ppm / ºC (Max)

Analog Output (Loop Powered Version):

4-20 mA Current Loop

Resolution: 1:4000

Transient Overvoltages: Category 3, accordance with IEC664

Pollution Degree: 2, in accordance with IEC664

Mounting Classification:

Meter Mount: NEMA 4X Enclosure

Remote Mount: NEMA 4X Enclosure

Swivel Mount: NEMA 4X Enclosure

Environmental:

Operating Temperature: -22 ºF to 158 ºF (-30 ºC to 70 ºC)

Humidity: 0-90% Non-condensing

Certifications:

CSA: Class I, Div 1 Groups C, D; Class II, Div 1 Groups E, F, G

UL: Class I, II, III Div 1 Groups C, D

CE: IEC 61326-1

Units of Measure:

Gallons, Oil Barrels, Liters, Cubic Meters, MGal, Cubic FT, MCF,

MMCF Megltrs, Acre FT, Liq. Barrels, LBS, KGS

Time Intervals: Day, Hour, Minute, Second

6

OPERATING THE MONITOR

The monitor has two modes of operation referred to as the RUN

mode and the PROGRAM mode. Both the run mode and the pro-

gram mode display screen enunciators confirming the state of the

monitor. A quick glance at the lower left hand corner of the LCD

screen will confirm operating status. Normal operation will be in

the run mode. To access the programming mode, press the

MENU button until the first programming screen is displayed.

After programming the display with the necessary information, a

lock out feature can be turned on to prevent unauthorized access

or changing the meter’s setup parameters.

ADVANCED PROGRAMMING MODE

Keys:

MENU – Switch between RUN & PROGRAMMING modes

UP Arrow – Scrolls through programming sub-menus in for-

ward direction and increments numeric variables

RIGHT Arrow – Scrolls through programming sub-menus in

reverse direction and moves the active digit to the right

ENTER – Used to enter sub-menus, save programming infor-

mation and in the reset process

If your monitor was ordered with a Blancett flow meter, the two

components ship from the factory, calibrated as a set. If the moni-

tor is a replacement, the turbine’s K-factor has changed, or the

monitor is being used with some other pulse generating device,

programming will be necessary.

Programming Using Pulse Output Turbine

Flow Meters

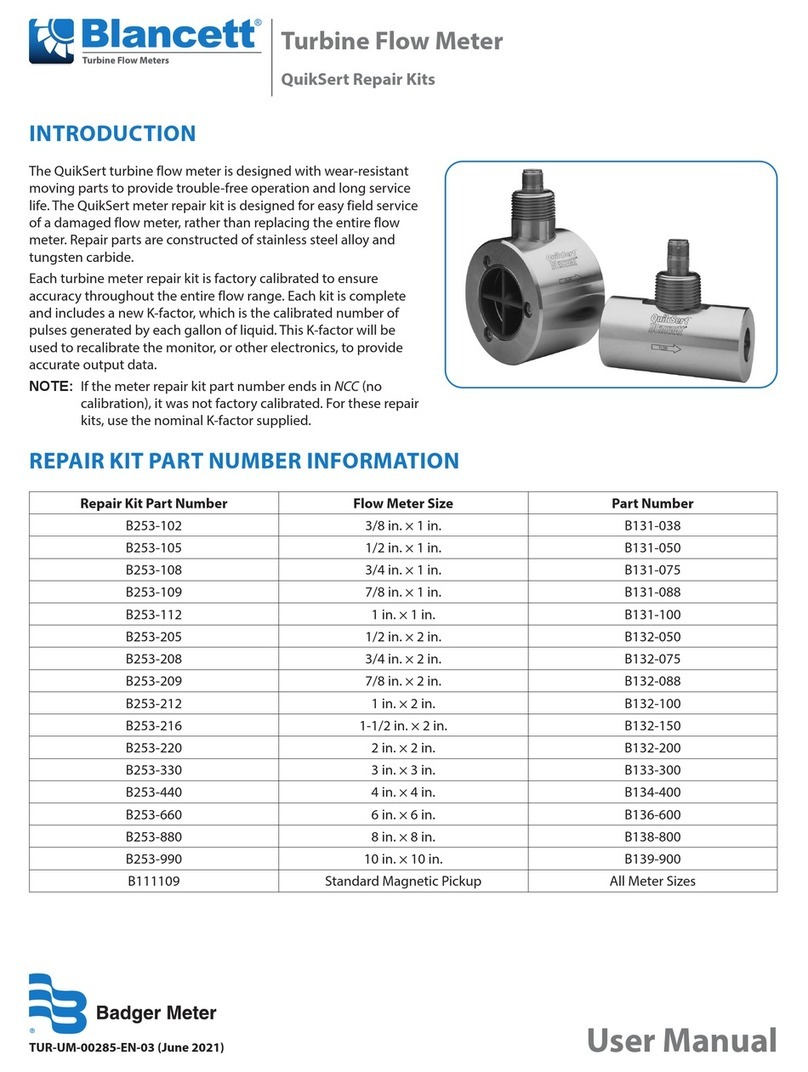

Each turbine flow meter is shipped with either a K-factor value or

frequency data. If frequency data is provided, the data must be

converted to a K-factor before programming; otherwise, 10 Point

Linearization must be used to program the monitor. (See “General

Notes on Scaling” at the end of this manual). K-factor informa-

7

tion, when supplied, can usually be found on the neck of the flow

meter or stamped on the body. The K-factor represents the num-

ber of pulses per unit of volume. The K-factor will be needed to

program the monitor readout.

ENTER PROGRAMMING MODE – Change to program-

ming mode by pressing the MENU button once. The mode

indicator will change from RUN to PROGRAM.

Note: If any input value exceeds the meters capabilities for that

particular parameter, the LIMIT indicator will begin to flash

indicating an invalid entry. Press ENTER once to return to the

parameter’s entry screen to reenter the value.

8

SELECT THE METER SIZE – At the METER prompt,

press the ENTER button once. The current meter size number

will begin to flash. Using the arrow keys, scroll through the

size choices until you find the bore size of your meter. Press

ENTER once to save the meter size choice.

SELECT THE DISPLAY FUNCTION – The monitor can

display RATE or TOTAL or alternate between BOTH rate

and total. At the DISPLAY prompt, press the ENTER key

once. The monitor now shows the display mode currently in

effect. If the current selection is correct, press the ENTER key

to advance to the next parameter. To change to an alternate

display mode, use the arrow keys to scroll to the desired dis-

play mode and press ENTER to save the choice.

SELECT THE RATE UNITS OF MEASURE – The moni-

tor allows the choice of many common rate units. (See the

specifications for a complete listing of the unit choices.) At

the RATE UNT prompt, press the ENTER key once. The

monitor now shows the rate units of measure the display is

currently set for. If the current selection is correct, press the

ENTER key to advance to the next parameter. To change to

an alternate unit, use the arrow keys to scroll to the desired

rate unit and press ENTER to save the choice.

SELECT THE RATE [TIME] INTERVAL – The term

Rate implies that something is occurring over a period of

time. Most people are familiar with the rate of speed of a car

reported in miles per hour (MPH). The same concept holds

true for a flow meter. The time choices are SEC (seconds),

MIN (minutes), HOUR (hours), and DAY (days). At the

RATE INT prompt, press the ENTER key once. The monitor

now shows the time interval the display is currently set for. If

Note: The meter connection size and the bore size are different.

For example, many of the 1” NPT turbines have bore sizes that

range from 3/8” up to 1”. Be sure to use the correct bore size or

the meter could report incorrect flows and totals.

9

the current selection is correct, press the ENTER key to ad-

vance to the next parameter. To change to an alternate time

interval, use the arrow keys to scroll to the desired time inter-

val and press ENTER to save the choice.

SELECT THE TOTAL UNITS OF MEASURE – If a flow

amount is desirable, the units for the total must first be cho-

sen. The monitor allows the choice of many common totaliza-

tion units. (See the specifications for a complete listing.) At

the TOTL UNT prompt, press the ENTER key once. The

monitor now shows the total units of measure the display is

currently set for. If the current selection is correct, press the

ENTER key to advance to the next parameter. To change to

an alternate unit, use the arrow keys to scroll to the desired

totalization unit and press ENTER to save the choice.

SELECT THE TOTAL’S DISPLAY MULTIPLIER – The

monitor has a very versatile display that has the ability to ac-

cumulate the flow total in multiples of ten. For example, if the

most desirable totalization unit is 1,000 gallons, the monitor

can easily be set up for this requirement. Once the unit is back

in RUN mode, every time the total display is incremented by

one digit the actual total would be an additional 1,000 gallons.

At 1,000 gallons the total display would read 1, at 3,000 gal-

lons the total display would read 3, etc. This feature elimi-

nates having to look at a total, counting the digits and men-

tally inserting commas for each 1000 multiple.

At the TOTL MUL [Multiple] prompt, press the ENTER key

once. The monitor now shows the multiplier the total display

Note: If flow rate is the only measurement of interest, skip to

KFAC UNT to complete the programming process.

Note: This unit of measure does not have to reflect the rate unit

you have previously chosen. (Example: Rate Units = Gallons,

Total Units = Barrels).

10

is currently set for. If the current selection is correct, press the

ENTER key to advance to the next parameter. To change to

an alternate multiplier, use the arrow keys to scroll to the de-

sired multiplier unit and press ENTER to save the choice.

Multiplier Choices – 0.01, 0.1, 1, 10, 100, 1000, 10000,

100000, and 1000000 Units

ENTER THE METER’S K-FACTOR UNIT – At the

KFAC UNT prompt, press the ENTER key once. The display

now shows the current K-factor unit. If the current selection is

correct, press the ENTER key to advance to the next parame-

ter. For meters calibrated in gallons use PUL/GAL. For me-

ters calibrated in cubic meters use PUL/M3 (pulses per cubic

meter), etc. To change to an alternate K-factor unit, use the

arrow keys to scroll to the desired K-factor unit and press the

ENTER key to save your choice.

ENTER THE METER’S K-FACTOR – (Note: The K-

factor supplied with your meter or calculated from cali-

bration data will be needed to complete this step.)

At the K FACTOR prompt, press the ENTER key once. The

most significant digit in the K-factor will begin to flash. Us-

ing the UP arrow key, increment the display digit until it

matches the meter’s K-factor digit. If the current selection is

correct, press the RIGHT arrow key to advance to the next

digit. Repeat this process unit all K-factor digits have been

entered. Press ENTER once to save the K-factor.

SCALE FACTOR – At the SCALE F prompt, press the EN-

TER key once. The current Scale Factor will begin to flash. If

the current selection is correct, press the ENTER key to ad-

Note: Unless otherwise specified, turbine flow meters are

supplied with K-factors measured in pulses per gallon

(PUL/GAL).

11

vance to the next parameter. The scale factor is used to force a

global change to all variables. For example, under operating

conditions the display is reading a consistent 3% below the

expected values at all flow rates. Rather than changing all pa-

rameters individually, the scale factor can be used to compen-

sate for the 3% offset. The scale factor would be set to 1.03 to

correct the readings. The range of scale factors is from 0.5 to

1.5. The default scale factor is 1.00.

METER TYPE – At the METERTYP prompt, press the EN-

TER key once. The current meter type will be displayed as

“Liquid” or “GAS.” If the current selection is correct, press

the ENTER key to advance to the next parameter. If “GAS” is

selected you must then enter your Operating Pressure and Op-

erating Temperature before advancing to the next parameter.

DAMPING FACTOR – At the DAMPING prompt, press the

ENTER key once. The current Damping setting will begin to

flash. If the current selection is correct, press the ENTER key

to advance to the next parameter. The Damping Factor is in-

creased to enhance the stability of the flow readings. Damping

values are decreased to allow the flow meter to react faster to

changing values of flow. This parameter can take on any

value between 0 and 99 with 0 being the default.

TOTALIZER PULSE OUTPUT – The pulse output pa-

rameter can be either enabled or disabled. When enabled this

output generates 20mS duration pulse for every time the least

significant digit of the totalizer increments (20Hz Max). The

amplitude of the pulse is dependent on the voltage level of the

supply connected to the pulse output and is limited to a maxi-

mum 30 VDC.

FLOW 4MA SETTING – When the loop powered option is

ordered, the flow rate that corresponds to 4mA must be set. If

the current selection is correct, press the RIGHT arrow key

once to advance to the next parameter. If adjustment is re-

quired, press the ENTER key once at the FLOW 4MA

12

prompt. The most significant digit will begin to flash. The

RIGHT arrow key moves the active digit one place to the

right for each press of the key. The UP arrow key increments

the active digit one integer for each press of the key. When

the correct 4mA flow rate has been entered, press ENTER

once to store this value and move to the next parameter.

FLOW 20mA SETTING – Follow the same programming

procedure as the FLOW 4MA except for the flow rate setting.

In this case, the maximum rate of flow for the meter should be

used.

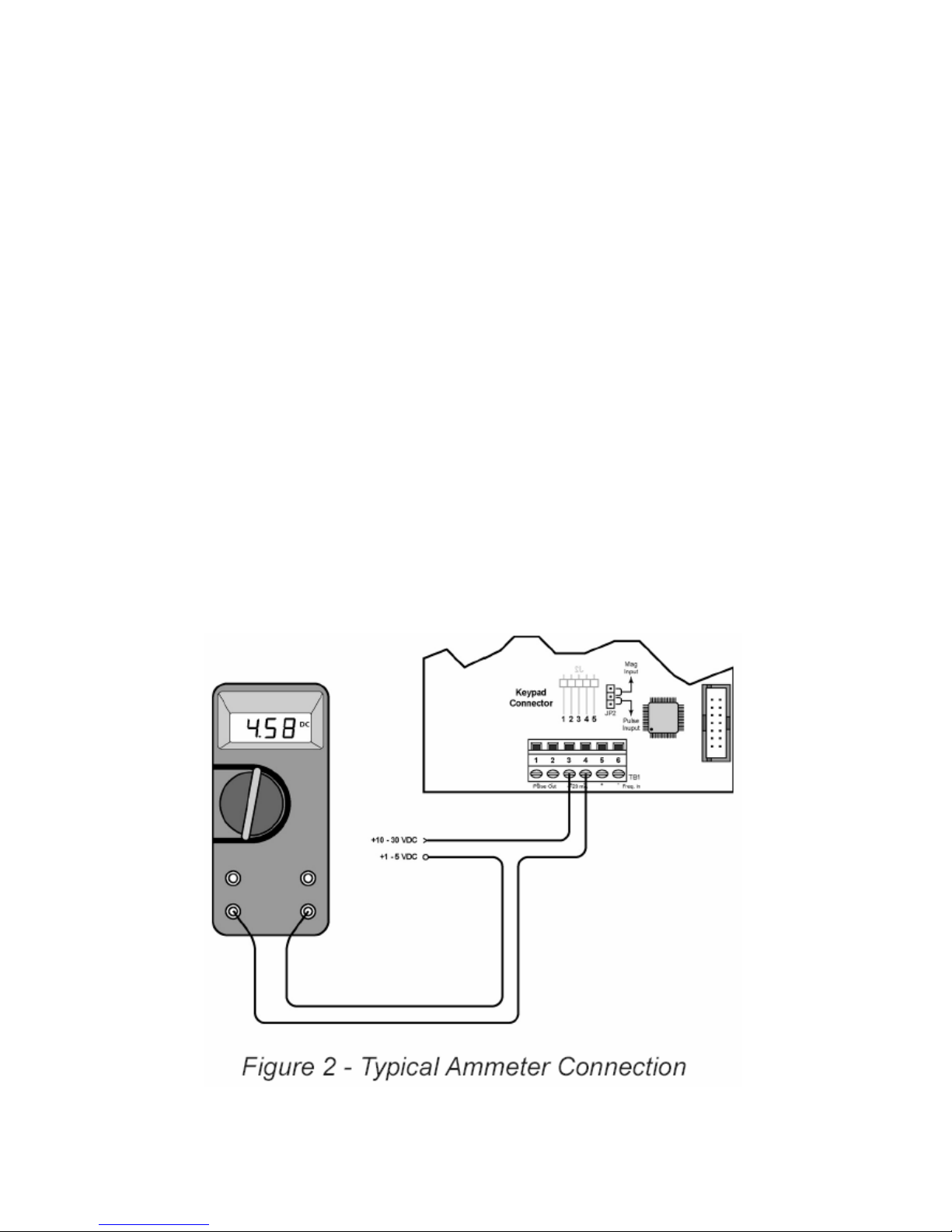

4-20mA CALIBRATION – When ordered with a 4-20mA

output, this menu item allows the fine adjustment of the 4-

20mA output. The 4mA setting is typically between 35 and

50. To set the 4mA value, connect an ammeter in series with

the loop power supply. At the 4-20CAL prompt, press EN-

TER once. This display will now show a steady NO indica-

tion. Press the UP arrow key to change to a flashing YES dis-

play. Press ENTER once to access the 4mA fine adjustment.

13

4mA ADJUSTMENT – While monitoring the ammeter, ad-

just the 4mA value to obtain a 4mA reading. The UP arrow

key increments the value and the RIGHT arrow key decre-

ments the value. When a steady 4mA reading is obtained on

the ammeter, press the ENTER key to lock in this value and

move to the 20mA adjustment.

20mA ADJUSTMENT – The 20mA adjustment is performed

using the same procedure as the 4mA adjustment.

While monitoring the ammeter, adjust the 20mA value to ob-

tain a 20mA reading. The UP arrow key increments the value

and the RIGHT arrow key decrements the value. When a

steady 20mA reading is obtained on the ammeter, press the

ENTER key to lock in this value and move to the next pa-

rameter.

4-20mA TEST – The monitor contains a diagnostic routine

that allows the simulation of mA values between 4 and 20 to

check output tracking. At the 4-20TEST prompt the arrow

keys change the simulated mA output increments of 1mA.

The ammeter should track the simulated mA output. If a 4-

20mA test is not necessary, press ENTER once to move to the

next parameter.

LINEARIZATION – Enhanced accuracy can be obtained by

linearization of the display. The linearization routine will ac-

cept a maximum of ten points. Linearization requires addi-

tional calibration data from the meter to be used with the

monitor. Typically, calibration information can be obtained in

three, five, and ten points from the flow meter’s manufacturer.

If linearization is not needed, pressing the RIGHT arrow key

will take you to the next parameter. (See “General Notes on

Scaling” for more information).

Number of Points – At the LINEAR prompt, press EN-

TER once. The NUM PTS number will be displayed.

Press ENTER to set the number of points you wish to use.

Again, the UP arrow key increments the value and the

14

RIGHT arrow moves the cursor between digits. When the

number of points has been input, press the ENTER key

once to move to the first linear segment.

Press the ENTER key once and the first linear point’s fre-

quency input will begin to flash (FREQ 1). Enter the fre-

quency for the first linear point using the arrow keys.

When the frequency value input is completed, press EN-

TER once again to change to the coefficient value for the

first linear point.

The coefficient is the value applied to the nominal K-

factor to correct it to the exact K-factor for that point. The

coefficient is calculated by dividing the actual K-factor for

that point by the average K-factor for the flow meter.

Coefficient = Actual K-factor ÷ Average K-factor

At the COEFF prompt, enter the coefficient that corre-

sponds to the frequency value previously entered. Press

ENTER once to move to the next scaling point.

Continue entering pairs of frequency and coefficient

points until all data has been entered. Press the MENU

key twice at the NUM PTS prompts to exit to the LIN-

EAR prompt. Press the RIGHT arrow key to move to the

next parameter.

PASSWORD – Password protection prevents unauthorized

users from changing programming information. Initially, the

password is set to all zeros. To change the password, press

ENTER once at the password prompt. The first digit of the

password value will begin to flash. Using the arrow keys as

previously described, enter the password value. Pressing EN-

TER once will store the password and take you back to the

RST PSWD screen.

Note: This password will allow users to reset totals.

15

RST PSWD – Reset Password protection prevents unauthor-

ized users from manually resetting the flow monitor’s accu-

mulated totals. Initially, the password is set to all zeros. To

change the password, press ENTER once at the password

prompt. The first digit of the password value will begin to

flash. Using the arrow keys as previously described, enter the

password value. Pressing ENTER once will store the pass-

word and take you back to the METER size screen, pressing

MENU exits the programming mode. The B2800 Flow Moni-

tor is now ready for use with its companion meter. Note: en-

tering a password in the Password screen and leaving the

password blank in the RST PSWD screen would allow for

total resets (not requiring password) and restrict programming

modification.

RESET TOTAL – To reset the monitor total display, in run

mode press the MENU and ENTER simultaneously until TO-

TAL RST starts to flash. The TOTAL RST will stop flashing

and the display will return to the run mode at the conclusion

of the procedure.

STORE TOTAL – The current total can be manually stored

in the monitor’s flash memory. This procedure may be desir-

able prior to changing the settings or replacing the battery.

Press and hold the ENTER key for 2 seconds. The display

will respond with a flashing TOTALSVD and then return to

the run mode.

AUTOMATIC STORE TOTAL – The monitor is equipped

with a store total feature that works automatically, saving the

current total to flash memory. The frequency of saves depends

on the power supply option chosen

Battery Powered: Once per hour and just before a low

battery condition turns the unit off.

Loop Powered: Once every ten minutes.

16

Battery Replacement – Battery powered monitors use a sin-

gle 1.5V, “D” size, alkaline battery. When replacement is nec-

essary, use a clean fresh battery to insure continued trouble

free operation. It is recommended that the total be saved to

memory before the battery is removed. (See “Store Total” in

the programming section of this manual.)

Unscrew the two captive screws on the front panel to gain ac-

cess to the battery. Replace the battery being sure to observe

the proper polarity, and then re-fasten the front panel.

ADDITIONAL INPUT OPTIONS

The B2800 Flow Monitor is capable of receiving Magnetic Pick-

up Input or a Contact Closure Input. Since most Blancett Flow

Meters utilize a magnetic pick-up, the monitor is shipped config-

ured for magnetic pick-up input. To change to a contact closure

input, remove JP2 from the Top two pins and jumper them to the

Bottom two pins.

See Figure 3

17

FIGURE 3 - CIRCUIT BOARD LAYOUT

18

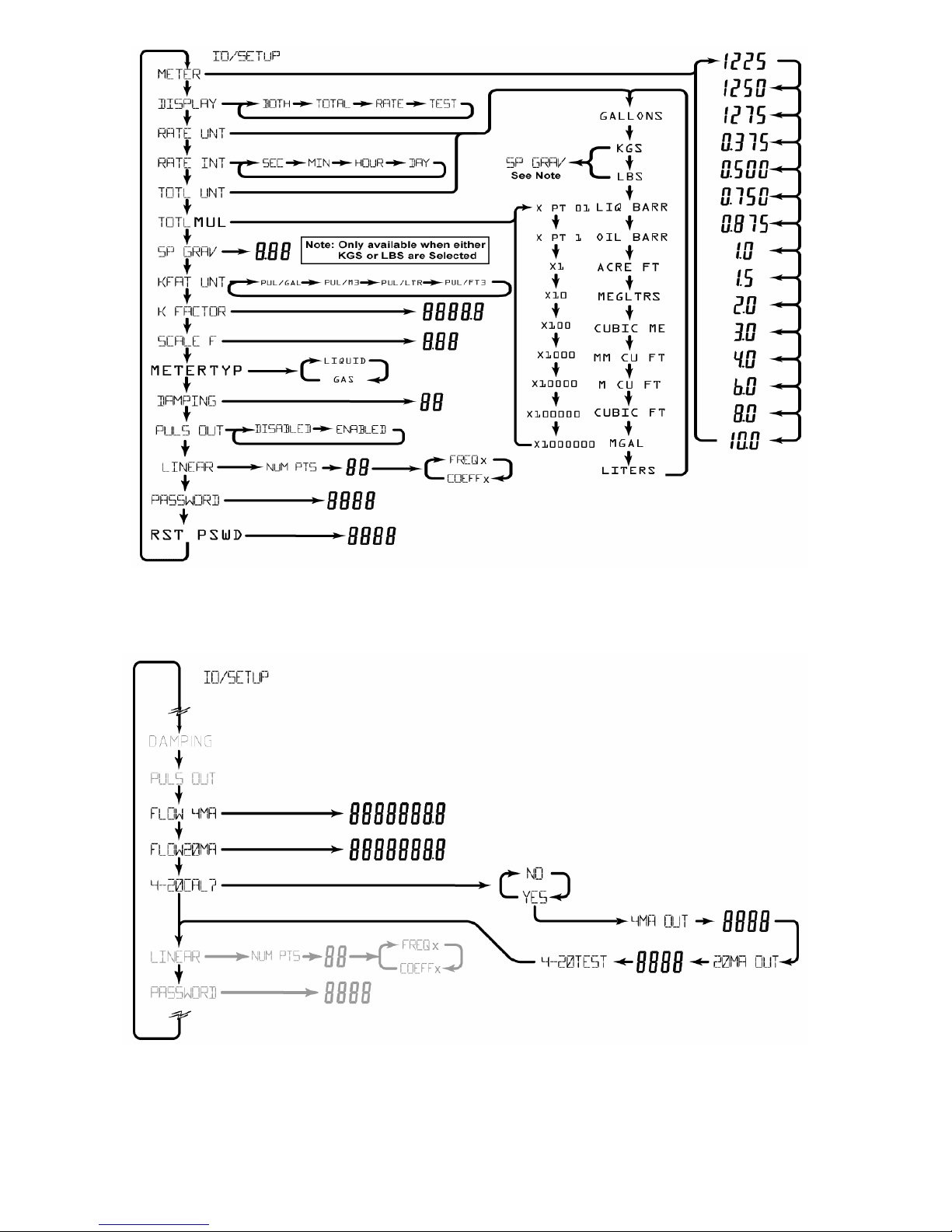

FIGURE 5 - 4-20mA PROGRAMMING

FIGURE 4 - PROGRAMMING MENU

19

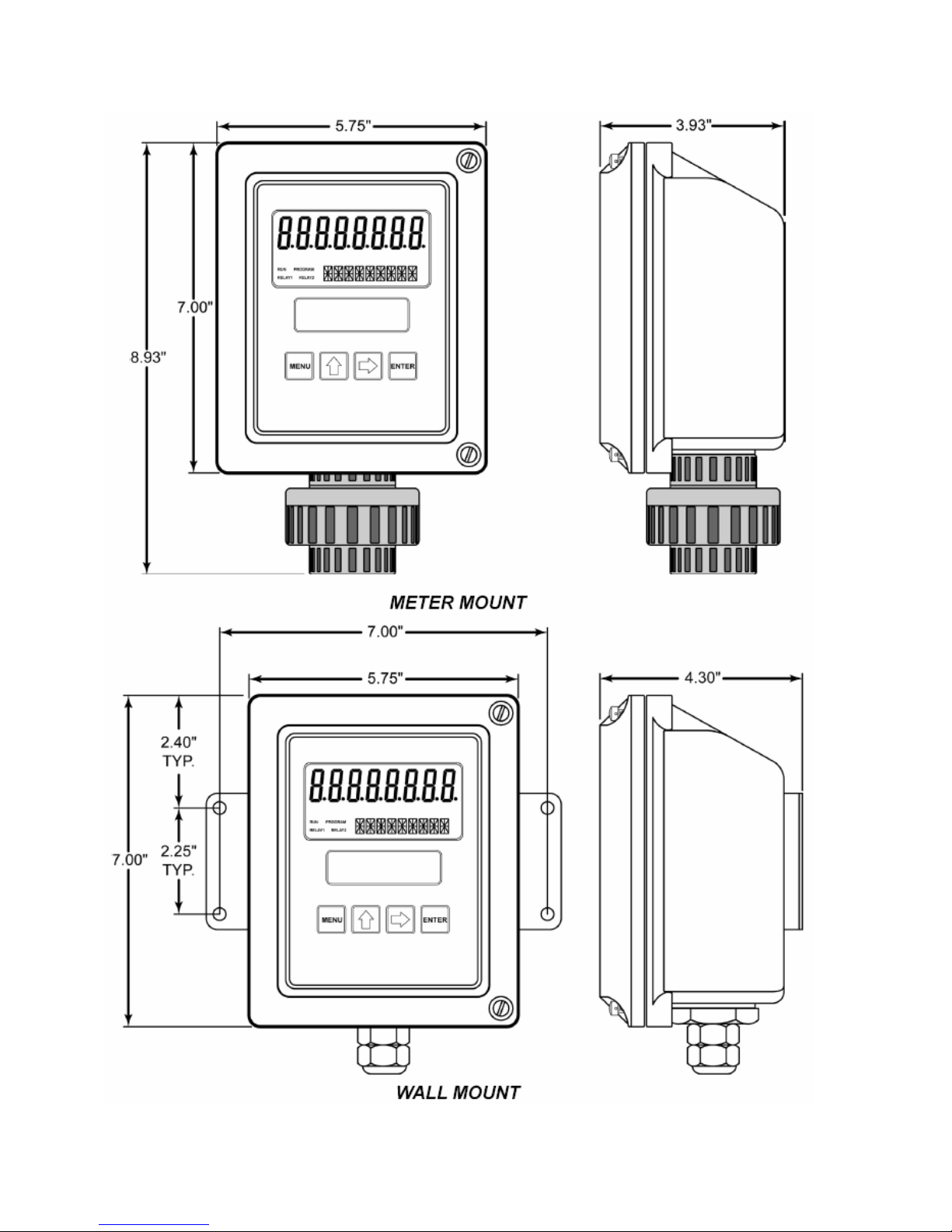

MOUNTING OPTIONS

20

Other manuals for B2800 Standard

5

Table of contents

Other Blancett Measuring Instrument manuals

Blancett

Blancett B1750 Service manual

Blancett

Blancett 1200 Service manual

Blancett

Blancett QuikSert B131-038 User manual

Blancett

Blancett 1100 Series Service manual

Blancett

Blancett B2800 Standard User manual

Blancett

Blancett B3000 User manual

Blancett

Blancett B253-102 User manual

Blancett

Blancett FloClean Service manual

Blancett

Blancett 1100 Series User manual

Blancett

Blancett 1100 Series Service manual