Bartell Global CONTEC CT250 User manual

Doc. # OIPB-C15009

Orig. Rel. –08/2020

Curr. Rev. - 00

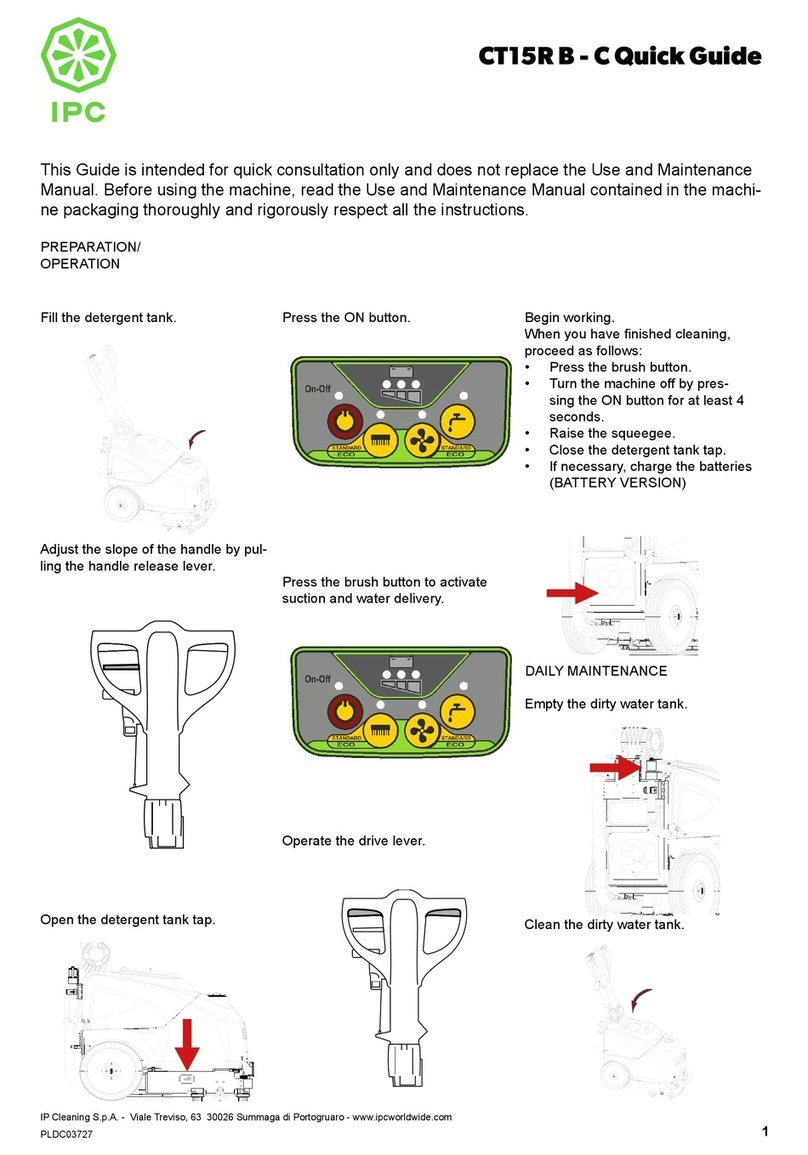

FLOOR PLANER/SCARIFIER

CT250

OWNER’S MANUAL AND PARTS BOOK

CT250 FLOOR PLANER/SCARIFIER

OWNER’S MANUAL AND PARTS BOOK

2

OIPB –C15009

Index

1. Machine applications ...3

2. Technical data ...3

2.1 Planer ...3

2.2 Tools ...3

3. Applications of the tools ...4

4. Safety rules ...4

5. Operating ...4

6. Changing the drum ...5

7. Adjusting the drum ...5

8. Maintenance and cleaning ...6

8.1 Bearings ...6

8.2 Height adjustment and joints ...6

8.3 Belt drive ...6

8.4 Cleaning ...6

9. Diagram ...7

10. Appendix ...7

CT250 FLOOR PLANER/SCARIFIER

OWNER’S MANUAL AND PARTS BOOK

3

OIPB –C15009

1. Machine applications

Planing of horizontal, dry floors such as concrete and steel surfaces with or without a coating and

asphalt using CONTEC®planing tools. The use of the machine outside is only possible in dry weather.

2 Technical data

2.1 Planer

Width of cut

250 mm (10 in)

Width

44 cm (17 in)

Length

104 cm (41 in)

Height

99 cm (39 in)

Weight

135 kg (298 Ibs)

Dust port ¢

70 mm (2.86 in)

Height adjustment

Hand wheel and lever

Electric motor

USA

460 V, 9 kW (12 hp), 60 Hz

Honda petrol

9 hp

Other motors

On request

Average value of acceleration ahv *

8.6 m/s2

Noise level Lwa *

109 dB(A)

Noise level Leq *

96 dB(A)

2.2 Tools

Drum diameter

180 mm (7.3 in)

Cutter shaft diameter

16 mm (0.65 in)

Number of shafts

6

TCT Cutter

57/6

Milling cutter

57/20

Beam flails

57

Cutter diameter

57

Max. No. of cutters

132

Max. No. of milling cutters

36

All specifications are approximate and subject to confirmation. They should only be used as a guide.

CT250 FLOOR PLANER/SCARIFIER

OWNER’S MANUAL AND PARTS BOOK

4

OIPB –C15009

3. Applications of the tools

TCT

Cutters

Heavy duty, long life cutters for all concrete texturing, scabbling, planing

and grooving applications. Also used for removal of road markings, roof

chippings and brittle coatings

Milling

cutters

Primarily for the removal of thermoplastic road / runway markings.

Tipped with tungsten carbide they are cost effective and highly efficient.

A range of cutter dimensions are available.

Beam flails

Heat treated cutters for the removal of paint coatings and laitance from

new concrete. Also for removing grease, dirt and ice deposits.

4. Safety rules

Attention ! The CT 250 floor planers are constructed according to existing safety rules and

regulations. These technical precautions should not be removed or changed under any circumstances.

While operating the machines the following points should also be kept in mind:

1. The planers should always be operated with all safety covers and technical precautions.

2. The operator should never leave the machine during operation.

3. Before leaving the machine all rotary parts should be brought to a stand still. The electric models

must be disconnected from the mains. Make sure that the machine cannot roll or move by itself.

4. After maintenance and adjustment all safety covers must be reattached.

5. If the noise level exceeds 90 dB(A) ear protectors must be worn.

6. In the event of a large amount of dust during operation connect a dust collector to the planer.

5. Operating

After mounting the appropriate tools the operation of the planer can begin.

The lever of the height adjustment (Appendix diagram No. 97 and 99) has to be in the upper position

before the machine is switched on. The hand wheel of the height adjustment must also be turned anti-

clockwise as far as possible.

Switch the motor on. Make sure the motor is spinning in the correct direction. If not, two phases of

the power supply have to be swapped with each other. The correct direction is indicated by an arrow

on the motor fan.

Attention: Operating the machine with the motor spinning in the wrong direction can cause serious

injury to the operator. The machine will jump towards the operator.

Lower the planer with the lever to the operating position. Turn the hand wheel of the height

adjustment until the tools are lowered to the floor and until you achieve the required finish.

Attention: Lowering the tools too much decreases the performance of the machine. You will also

CT250 FLOOR PLANER/SCARIFIER

OWNER’S MANUAL AND PARTS BOOK

5

OIPB –C15009

destroy the shafts in the drum and the bearings of the machine.

Attention: Never switch the motor of the planer on while the tools still touch the floor. Always lift

the machine and the tools clear from the floor and then switch the motor on.

Heavy dust can be avoided by connecting a dust collector to the dust port.

The vibration damped handle bar ensures an easier operation.

6. Changing the drum

Attention: Before any maintenance, the machine must be brought to a complete stand still. Always

disconnect the machine if it is an electric model.

-Lift the machine with the lever so that the tools are well clear of the floor.

-Unscrew the screws on the right side plate (M10, Key width 17 mm)

-Carefully remove the side plate.

-Take out the drum. Remove worn out tools. Check shafts and drums for wear and tear. If

necessary replace new tools on the drum.

-Push drum on freshly greased shaft.

-Reconnect side plate.

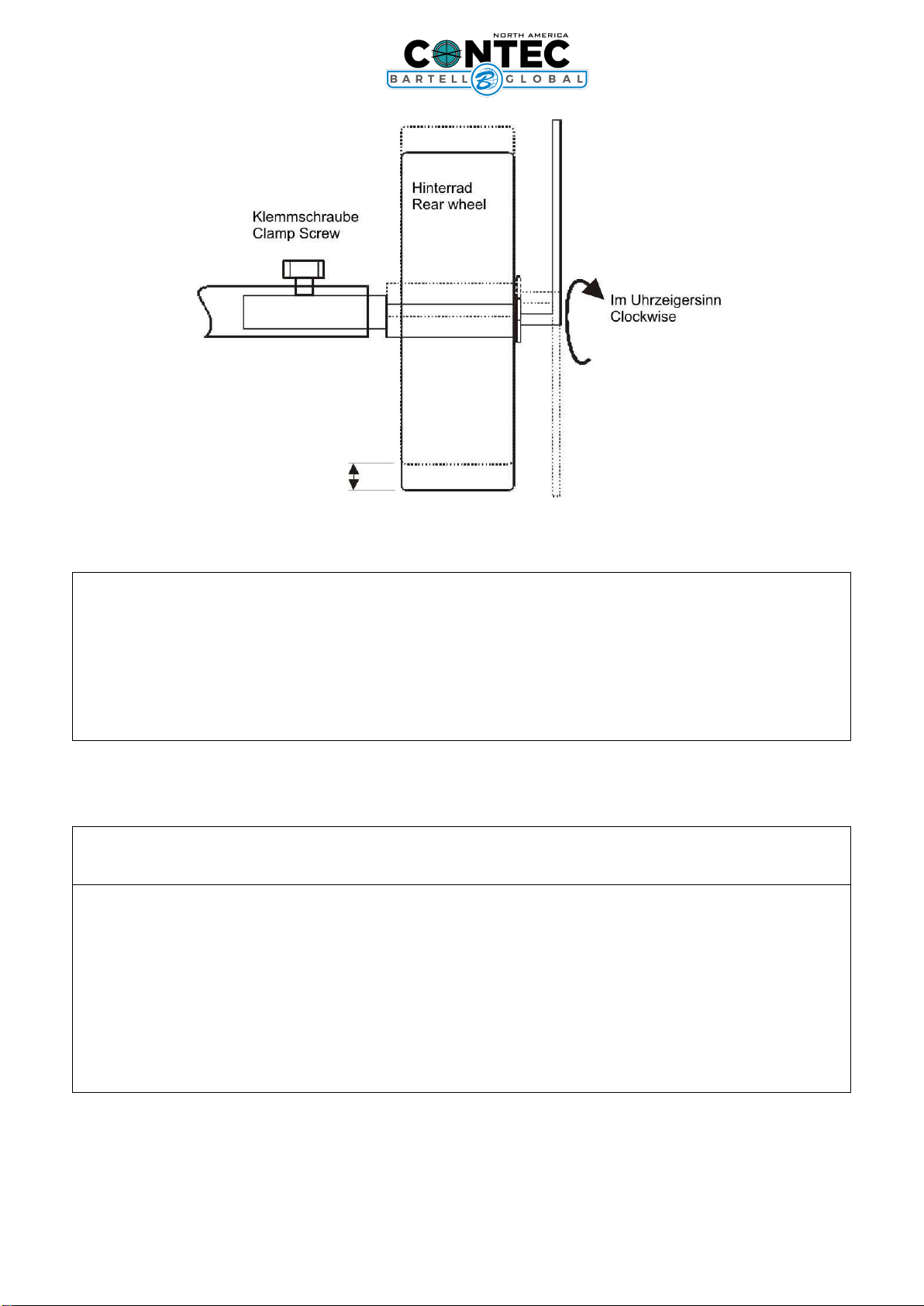

7. Adjusting the drum

During the operation of the CT 250 floor planer or after a drum has been changed or replaced, the

drum shaft and the rear wheel axis can fall out of alignment. This results in an uneven track on the

floor. On one side the drum touches the floor before the other and therefore removes more surface

material on this side.

The two rear wheels are mounted on an eccentric shaft (see diagram).

CT250 FLOOR PLANER/SCARIFIER

OWNER’S MANUAL AND PARTS BOOK

6

OIPB –C15009

If the drum has to be adjusted proceed as follows: Place the planer on an even floor. Lift the machine

with the height adjustment hand wheel, until all the tools are well clear of the floor. Loosen the

clamping screw of the eccentric shaft. On the other side of the rear wheel is a screw which keeps the

wheel on the shaft. Turning the screw will also turn the eccentric shaft. The floor planer moves up

and down on one side. Always turn the screw clockwise. Anti clockwise would loosens the screw.

Keep turning until all the tools on the drum are the same distance to the floor. Tighten the clamping

screw again.

8. Maintenance and cleaning

8.1 Bearings

All bearings are greased for their life time.

8.2 Height adjustment and joints

All joints have to be greased periodically with a standard machine grease.

8.3 Belt drive

Check the belt after approximately every 30 hours of operation. For tensioning the belt you need to

change the position of the belt tensioner wheel underneath the belt cover.

8.4 Cleaning

Regular cleaning of the machine increases the life of all components and tools of the planer.

CT250 FLOOR PLANER/SCARIFIER

OWNER’S MANUAL AND PARTS BOOK

7

OIPB –C15009

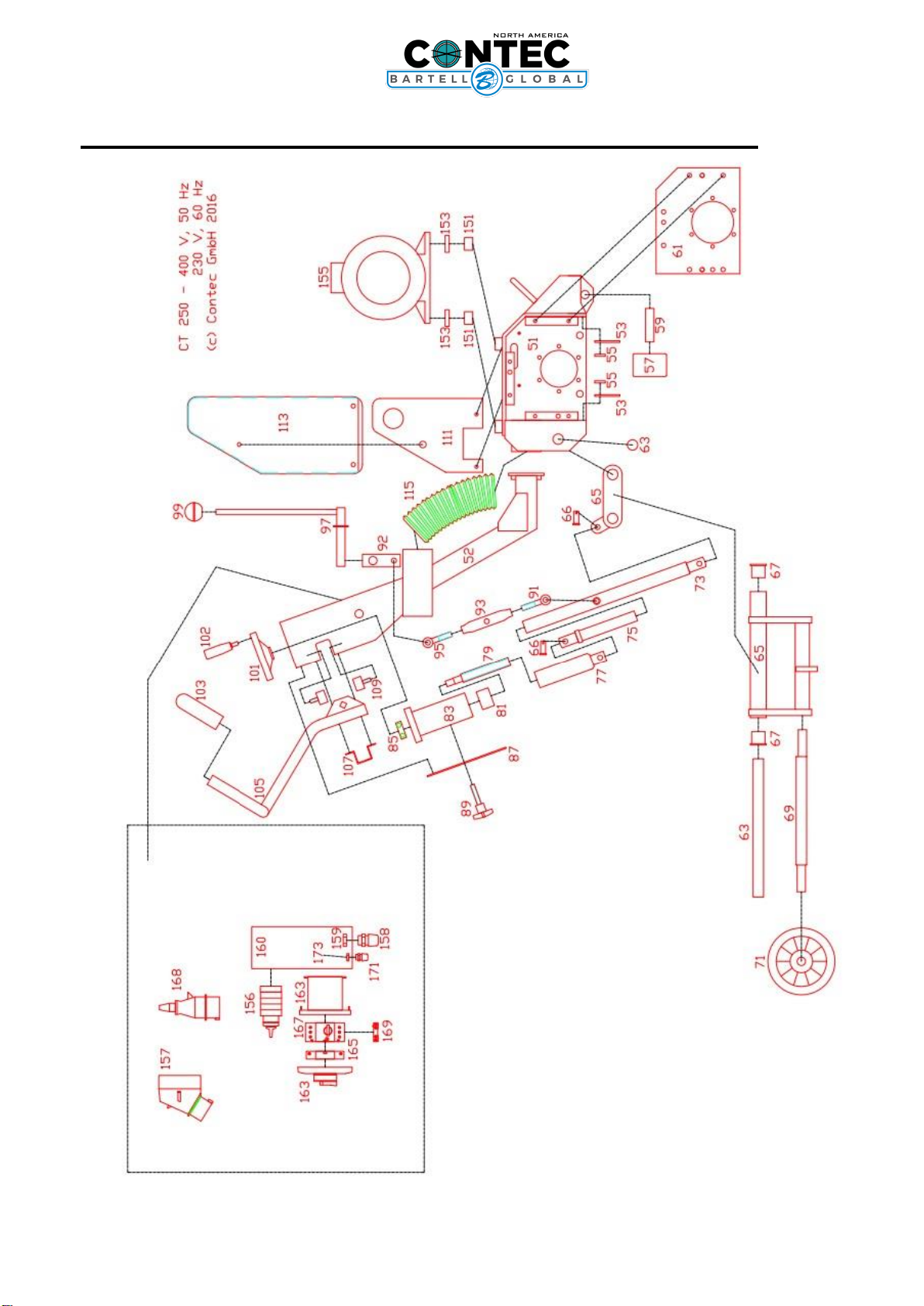

9. Diagram

Handle bar

Height adjustment hand wheel

On- Off switch for electric models

Motor

Rear wheel

Front wheel

Left side plate

10. Appendix

Diagrams

Wire diagram

Tools

Part list

CT250 FLOOR PLANER/SCARIFIER

OWNER’S MANUAL AND PARTS BOOK

8

OIPB –C15009

PARTS LIST 1 –CT250 MAIN ASSEMBLY Electric Version

CT250 FLOOR PLANER/SCARIFIER

OWNER’S MANUAL AND PARTS BOOK

9

OIPB –C15009

PARTS LIST 2 –CT250 MAIN ASSEMBLY Gas Version

CT250 FLOOR PLANER/SCARIFIER

OWNER’S MANUAL AND PARTS BOOK

10

OIPB –C15009

PARTS LIST 3 - CT250 BELT DRIVE AND SHAFT

CT250 FLOOR PLANER/SCARIFIER

OWNER’S MANUAL AND PARTS BOOK

11

OIPB –C15009

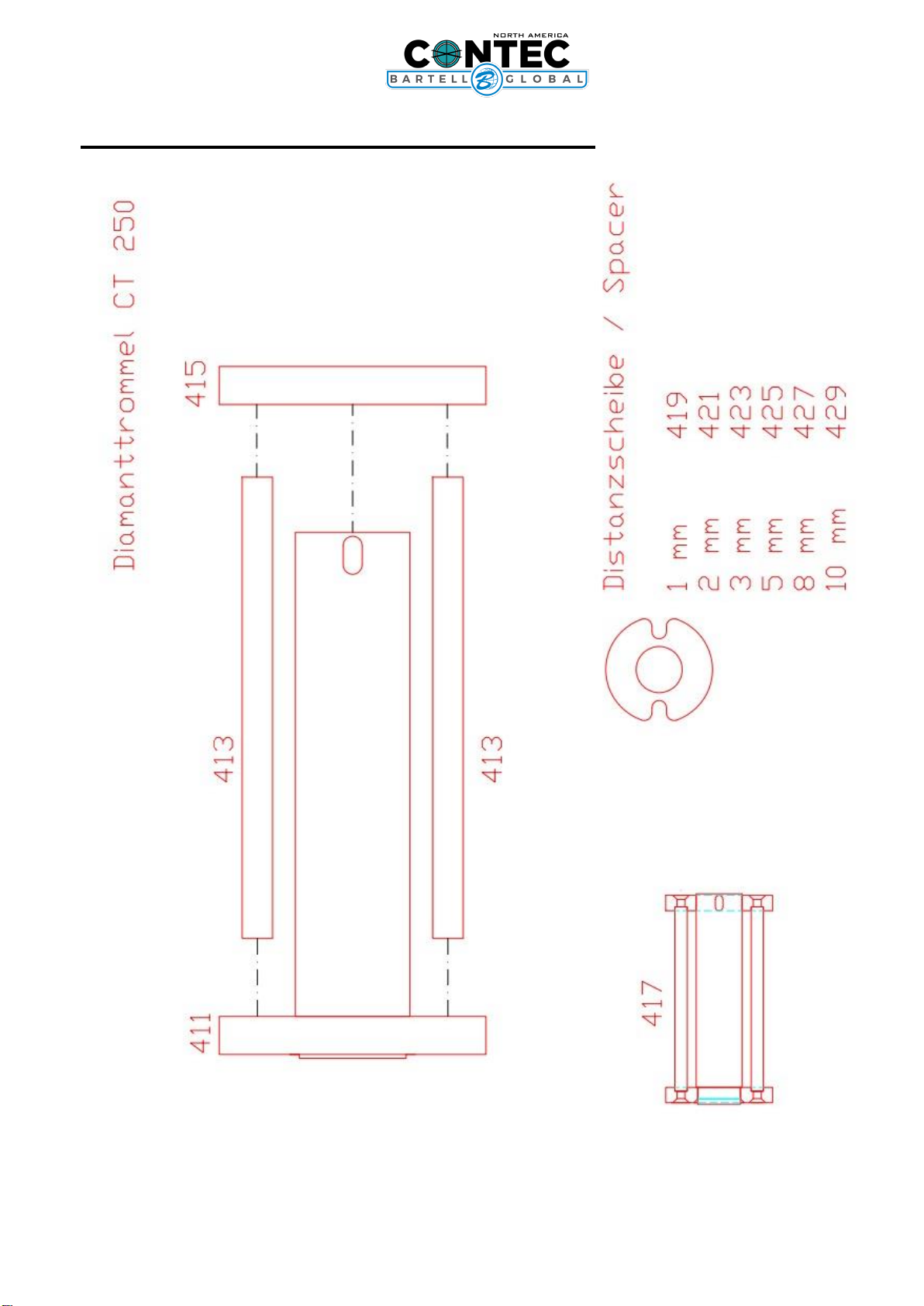

PARTS LIST 4 –CT250 DRUM ASSEMBLY

CT250 FLOOR PLANER/SCARIFIER

OWNER’S MANUAL AND PARTS BOOK

12

OIPB –C15009

PARTS LIST 5 –CT250 DRUM ASSEMBLY 2

CT250 FLOOR PLANER/SCARIFIER

OWNER’S MANUAL AND PARTS BOOK

13

OIPB –C15009

PARTS LIST 6 –CT250 ELECTRIC DIAGRAM

CT250 FLOOR PLANER/SCARIFIER

OWNER’S MANUAL AND PARTS BOOK

14

OIPB –C15009

PARTS LIST –CT250 MAIN ASSEMBLY

Item #

Part #

Description

QTY

3

19-10-07-03

Bearing Lid right Side

1

5

61-30-00-47

Circlip

1

7

61-20-62-10

Bearing right Side

1

9

19-21-07-06

Hexagon Ring

1

11

19-10-07-04

Bearing Housing right Side

1

13

19-21-07-05

Drive Shaft

1

17

68-85-30-8-7

Key

1

19

19-10-07-01

Spacer

1

21

61-30-01-70

Circlip

1

23

61-20-32-07

Bearing left Side

1

25

19-10-07-02

Bearing Housing left Side

1

27

19-21-07-07

Nut on Drive Shaft

1

29

70-44-8M-50

Pulley Drum

1

30

19-10-70-15

Lock for Pulley

1

31

70-24-08-80

Belt

1

33

70-24-8M-50

Motor Pulley

1

35

70-26-27-00

Belt Tensioner

1

37

19-10-12-04

Bracket for Tensioner

1

39

19-10-12-03

Bracket for Tensioner

1

51

19-10-01-00

Chassis

1

53

70-24-16-60

Rubber Sealing front/rear

2

55

19-10-13-01

Bracket for Rupper Sealing

2

57

80-20-80-60

Front Wheel

1

59

19-10-01-07

Front Wheel Axis

1

61

19-10-01-01

Side Plate

1

63

19-10-04-05

Axle for Wingarm

1

65

19-10-04-00

Wing Arm for rear Axis

1

66

60-33-12-25

Pin for lifting Rod

2

67

61-24-50-30

Bronze Bearing

1

69

19-10-04-06

Rear Axis with Excenter

1

71

80-20-31-60

Wheel

2

73

19-10-05-05

Lifting Rod lower Part

1

75

19-10-05-06

Lifting Rod upper Part

1

77

19-10-05-03

Height Control Piston

1

79

19-10-05-02-C

Spindle

1

81

61-24-40-46

Bronze Bearing

1

83

19-10-05-01

Housing Height Adjustment

1

85

61-20-63-02

Lager Bearing

1

87

19-10-02-07

Cover

1

89

60-30-10-50

Cross Handle Screw

1

91

61-50-12-60

Eye Screw

2

CT250 FLOOR PLANER/SCARIFIER

OWNER’S MANUAL AND PARTS BOOK

15

OIPB –C15009

92

19-10-10-01

Lever

1

93

19-10-05-07

Spanner Nut

2

95

61-50-12-60-L

Eye Screw left Threat

1

97

19-10-05-08

Lever

1

99

90-21-45-12

Ball Head

1

101

90-21-95-50

Level Adjustment Wheel

1

102

90-21-95-51

Knob for Handwheel

1

103

70-21-26-10

Rubber Grip

1

105

19-10-03-01

Handle

1

107

70-26-18-00

Bracket for Rubber Block

2

109

70-26-30-00

Rubber Block

4

111

19-10-06-01

Bracket for Belt Cover

1

113

19-10-06-03

Belt Cover

1

115

70-25-02-70

Dusthose

1

151

19-10-12-08

Motor Spacer

4

153

19-10-12-05

Bracket for Electric Motor

2

155

55-03-46-75

Motor

1

156

50-20-20-04

Star-Delta-Switch

1

157

50-20-16-01

Wall Plug

1

158

50-20-23-M-25

Cable Gland

1

159

50-20-23-GM-M-25

Nut

1

160

50-10-10-41

Switch Box

1

163

51-10-10-01

Motor Protective Switch Box

1

165

51-20-30-03

Low Voltage Protective

1

167

51-20-30-01

Motor Protective

1

169

50-20-10-07

Auxiliary Switch

1

171

50-20-23-M-16

Cable Gland

1

173

50-20-23-GM-M-16

Nut

1

300

95-10-250-T

Drum

1

301

95-16-57-06

TC Cutters 57/6

1

303

95-16-57-20

Milling Flails 57 / 20

1

307

95-16-30-17

Spacer

1

309

95-10-250-A

Axis for Drum

6

311

95-10-250-S

Drum Side Disc

2

411

19-10-55-24

Drum Shaft with Flange

1

413

19-10-55-13

Shaft for Diamond Drum

2

415

19-10-55-03

Flange for Diamond Drum

1

417

19-10-55-11

Drum for Diamond Blades

1

419

19-10-55-17

Spacer 1mm for Diamond Drum

1

421

19-10-55-14

Spacer 2mm for Diamond Drum

1

423

19-10-55-15

Spacer 3mm for Diamond Drum

1

425

19-10-55-16

Spacer 5mm for Diamond Drum

1

427

19-10-55-18

Spacer 8mm for Diamond Drum

1

429

19-10-55-19

Spacer 10mm for Diamond Drum

1

Doc. # OIPB-C15009

Orig. Rel. –08/2020

Curr. Rev. - 00

Table of contents

Other Bartell Global Floor Machine manuals