Bartell Global CONTEC ALPHA User manual

Doc. # OIPB-C

Orig. Rel. –11/2018

Curr. Rev. - 00

FLOOR GRINDER

ALPHA

OWNER’S MANUAL AND PARTS BOOK

www.BARTELLGLOBAL.com

ALPHA FLOOR GRINDER

OWNER’S MANUAL AND PARTS BOOK

1

OIPB –C15001

www.BARTELLGLOBAL.com

Bartell Morrison Inc.

170 Traders Blvd E

Mississauga, Ontario, Canada

L4Z 1W7

Tel: (647) 953-4100

Fax: (647) 953-4101

Bartell Morrison USA LLC

200 Commerce Drive, Unit A

Freehold, NJ, USA

07728

Tel: (848) 225-8100

Fax: (848) 225-8101

SPE International Ltd

Honeyholes Lane

Dunholme, Lincoln, England

LN2 3SU

Tel: 01673 860709

Fax: 01673 861119

Innovatech

4701 Allmond Ave

Louisville, Kentucky, USA

40209

Tel: (425) 405-9100

Fax: (425) 405-9101

ORIGINAL LANGUAGE OPERATING MANUAL FOR

CONTEC FLOOR GRINDER

© 2019 Bartell Morrison Inc.

No part of this work may be reproduced or transmitted in any form or by any means, electronic

or mechanical, including photocopying and recording, or by any information storage or retrieval

system without the prior written permission of Bartell Morrison Inc. unless such copying is

permitted by federal copyright laws.

Address inquiries or reference permissions care of:

Bartell Morrison Inc., 170 Traders Blvd E., Mississauga, Ontario, Canada, L4Z 1W7

REV.

DATE

DESCRIPTION

APPROVED BY:

00

11/2018

Initial Release

AN

ALPHA FLOOR GRINDER

OWNER’S MANUAL AND PARTS BOOK

2

OIPB –C15001

SAFETY PRECAUTIONS

DANGER

EXPLOSION HAZARD

Never operate the machine in an explosive

atmosphere, near combustible materials, or

where ventilation does not clear exhaust fumes.

WARNING

BURN HAZARD

Never come into contact with the engine or

muffler when engine is operating or shortly after it

is turned off. Serious burns may occur.

CAUTION

ROTATING HAZARD

Never place hands or feet inside safety guard

rings. Serious injury will result from contact with

rotating blades.

CAUTION

MOVING PARTS

Before starting the machine, ensure that all

guards and safety devices are in place and

functioning properly.

ATTENTION

READ OWNER’S MANUAL

Read and understand owner’s manual before

using this machine. Failure to follow operating

instructions could result in serious injury or death.

ALPHA FLOOR GRINDER

OWNER’S MANUAL AND PARTS BOOK

3

OIPB –C15001

TABLE OF CONTENTS

QUALITY ASSURANCE/ MACHINE BREAK IN 4

WARRANTY INFORMATION 4

SPECIFICATIONS 5

PREVENTATIVE MAINTENANCE AND ROUTINE SERVICE PLAN 6

oROUTINE SERVICE SCHEDULE 7

oROUTINE SERVICE INTERVALS 7

OPERATING SAFETY PRECAUTIONS 8

OPERATION INSTRUCTIONS 9

oSETTING UP YOUR ALPHA GRINDER 9

oPRIOR TO OPERATION 9

oCHANGING OR INSTALLING TOOLING 9

oOPERATION 10

PARTS LIST 1 –ALPHA GRINDER 11

oALPHA GRINDER –PARTS LIST 1 12

PARTS LIST 2 –ALPHA GRINDER *CANADA ONLY* 13

oALPHA GRINDER –PARTS LIST 2*CANADA ONLY* 13

ALPHA FLOOR GRINDER

OWNER’S MANUAL AND PARTS BOOK

4

OIPB –C15001

QUALITY ASSURANCE/ MACHINE BREAK IN

The Contec Floor Grinder is the product of extensive engineering development designed

to give long life and unmatched performance. The Floor Grinders are shipped completely

assembled.

You can help ensure that your Floor Grinder will perform at top levels by observing a

simple routing on first use. Consider that your new Grinder is like a new car. Just as you would

break in a new car to the road or any new machine to the job, you should start gradually and

build up to full use. Learn what your machine can do and how it will respond. Full throttle and

control may be used after this time period, as allowed by material. This will serve to further

break in the machine on your specific application, as well as provide you with additional

practice using the machine.

We thank you for the confidence you have placed in us by purchasing a Contec Floor

Grinder and wish you many years of satisfied use.

WARRANTY INFORMATION

Bartell agrees to furnish without charge, F.O.B. our plant, a replacement for any part or

portion thereof, comprising the main unit of the Contec Floor Grinder, consisting of the handle,

housing assembly, save and except tooling, and power units, prove upon our examination, to

be defective in either material or workmanship within a period of twelve (12) months from date

of purchase, provided that notice of such defective part or portion thereof is given to Bartell Ltd.

within the twelve month warranty period. No further or other guarantee or warranty expressed

or implied in connection with the sale of the Grinder is given and our sole liability consists in

replacing defective parts or portions thereof. We shall not be responsible for any special,

indirect or consequential damages arising in any manner whatsoever.

This guarantee is for the sole benefit of the original purchaser as end user. Our

responsibility under this guarantee ends in the case the original purchaser transfers ownership

of the Floor Grinder, makes any changes or adds any parts or devices not of our manufacture

to the Floor Grinder machine.

ALPHA FLOOR GRINDER

OWNER’S MANUAL AND PARTS BOOK

5

OIPB –C15001

SPECIFICATIONS

ALPHA

Dimensions

Grinding Width, mm (in)

230 (9)

Overall Width, mm (in)

30 (12)

Overall Length, mm (in)

60 (24)

Overall Height, mm (in)

51 (20)

Weight

Weight, kg (lb)

42 (93)

Performance

Speed of Grinding Head (RPM)

1680

Power Source

Power kw (HP)

1.1 (1.5)

Volts (V)

110

Frequency (Hz)

60

Amperage (A)

15

ALPHA FLOOR GRINDER

OWNER’S MANUAL AND PARTS BOOK

6

OIPB –C15001

PREVENTATIVE MAINTENANCE AND ROUTINE SERVICE PLAN

This Contec Floor Grinder has been assembled with care and will provide years of

service. Preventative maintenance and routine service are essential to the long life of your

Floor Grinder. Your dealer is interested in your new machine and has the desire to help you get

the most value from it. After reading through this manual thoroughly, you will find that you can

do some of the regular maintenance yourself. However, when in need of parts or major service

be sure to see your Bartell dealer. For your convenience, we have provided this space to record

relevant data about your Floor Grinder. When in need of parts or service be prepared to provide

your Floor Grinder serial number. Locate the serial number now and record in the space below.

Date Purchased:

Type of Machine:

Dealer Name:

Model:

Dealer Phone:

Serial Number:

Replacement Parts Used

Maintenance Log:

Part No.

Quantity

Cost

Date

Date

Operation

ALPHA FLOOR GRINDER

OWNER’S MANUAL AND PARTS BOOK

7

OIPB –C15001

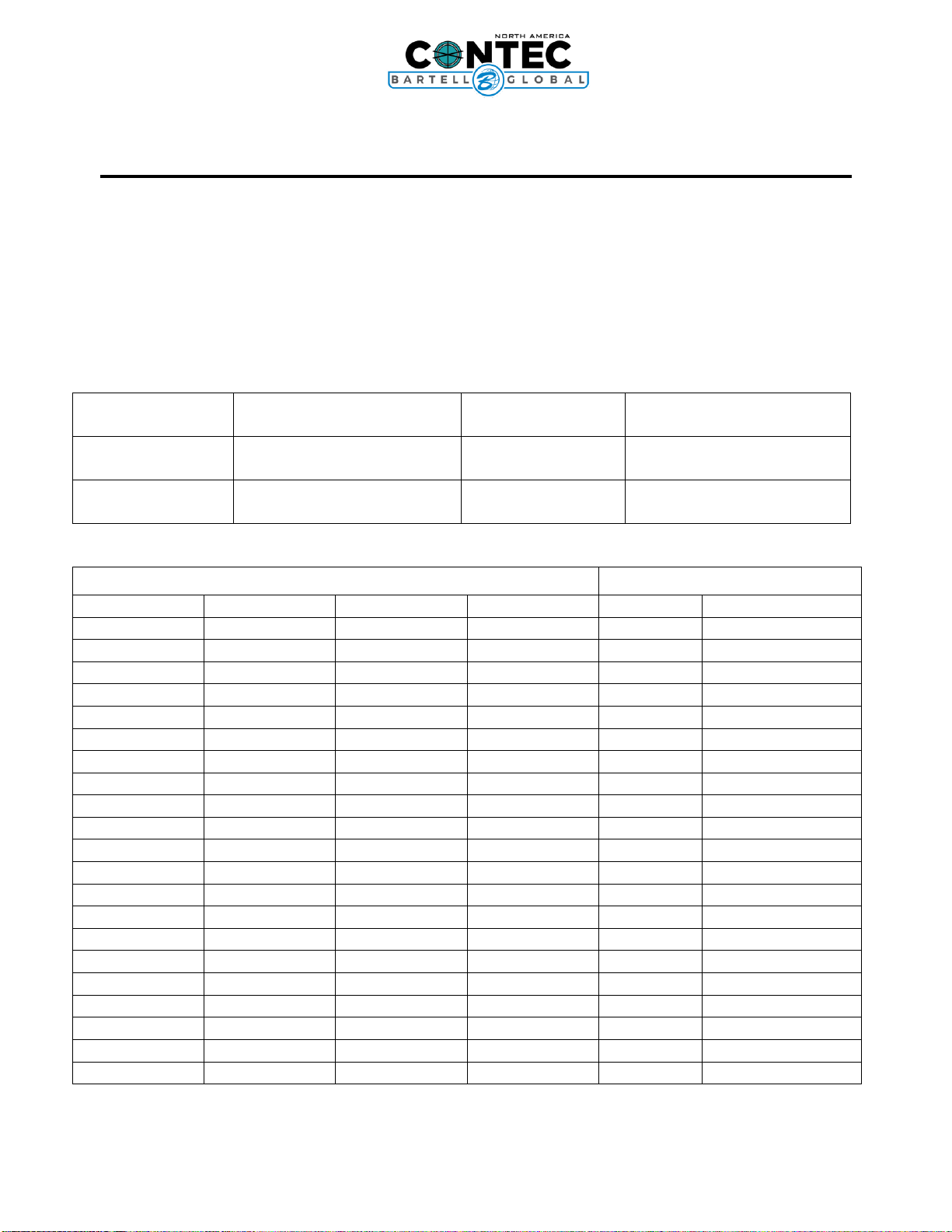

ROUTINE SERVICE SCHEDULE

Routine Service Intervals

Each

Use

After 1.5

months

or 50 hrs

Each 3

months

or 100

hrs

Each 6

months

or 200

hrs

Each 9

months

or 300

hrs

Each 12

months

or 400

hrs

General Inspection

Guards

Check

O

O

O

O

O

Warning Stickers

Check

O

O

O

O

O

Test Run

Check Operation

O

O

O

O

O

Fasteners

Check Tightness

O

Electrical

Cord

Check for

Damage

O

Plug

Check for

Damage

O

Switches/Buttons

Check

O

Grinding Components

Tooling

Check Life

O

Drive Coupling

Check for

Damage

O

Tooling Plate

Check

O

O

O

O

Motor

Fan

Check - Clean

O

O

O

O

O

ROUTINE SERVICE INTERVALS

Due to the nature and environment of use, Floor Grinders could be exposed to severe

operating conditions. Some general maintenance guidelines will extend the useful life of your

machine.

• The initial service for your grinder should be performed after 25 hours of use, at which time

your mechanic (or authorized repair shop) should complete all the recommended checks in the

schedule above. The maintenance log is handy for keeping a record of the maintenance

performed and the parts used for servicing your grinder.

• Regular service according to the schedule above will prolong the life of the floor grinder and

prevent expensive repairs.

• Keeping your floor grinder clean and free from debris is the single most important regular

maintenance operation, over and above the checks in the service schedule above, that can be

performed. After each use your grinder should be cleaned to remove any dust and debris from

the undercarriage and surrounding components.

• In the Service Schedule above, items that should be checked, replaced or adjusted are

indicated by “o” in the appropriate column. For ease of recording place, a checkmark through

the “o” when the item is complete. If an item is not required or not completed place an “x”

through the “o” in the box.

• Failure to have your floor grinder regularly serviced and properly maintained in accordance

with the manufacturer’s instructions will lead to premature failure and void the warranty.

ALPHA FLOOR GRINDER

OWNER’S MANUAL AND PARTS BOOK

8

OIPB –C15001

OPERATING SAFETY PRECAUTIONS

The ALPHA floor grinders are constructed according to existing safety rules and

regulations. These technical precautions should not be removed or changed under any

circumstances. While operating the machines the following points should also be kept in mind:

The instructions provided in this manual are done so to ensure the operator’s safety as well

as that of others, the equipment, and the job site. Failure to follow these guidelines can lead to

serious personal injury and even death. The operator and any service personnel should read

and understand the entire manual before working with or servicing any Contec Floor Grinder.

•The grinders should always be operated with all safety covers and technical precautions.

•During transport, cleaning, repair or maintenance the grinder must be disconnected from

the power supply. That also applies to the changing of tools.

•The safety ring (Diagram No. 17) can only be removed while operating the machine

directly against the wall. While operating the machine without the safety ring dust can be

generated. In this case the operator must wear a mask. In all other cases the grinder

must be operated with the safety ring.

•The operator should never leave the machine unattended during operation.

•Before leaving the machine, all rotary parts should be brought to a standstill. Electric

models must be disconnected from the power supply. Make sure that the machine

cannot roll or move by itself.

•After any maintenance and adjustment all safety covers must be reattached.

•Ear protectors must be worn.

•Eye protectors must be worn.

•Safety shoes with steel caps must be worn.

•In the event of a large amount of dust during operation, connect a dust collector to the

grinder.

•Depending on the floor (floor coating) grinding can produce gases. The operator must be

held responsible if these generated gases are dangerous and if protection is necessary.

Grinding floors containing asbestos is especially dangerous and can cause health

problems. Special masks must be worn which keep the breathing air clean. A dust

collector must be used and should be equipped with filters suitable for asbestos dust.

•The floor must be brushed before grinding because loose material could get into the

tools and fly away. Anchor screws and bolts coming out of the floor can also be seen

better if the floor is clean. If the grinding head hits a anchor screw or bolt then serious

damage can be caused to the machine or grinding head.

ALPHA FLOOR GRINDER

OWNER’S MANUAL AND PARTS BOOK

9

OIPB –C15001

OPERATION INSTRUCTIONS

SETTING UP YOUR ALPHA GRINDER

Your Alpha Floor Grinder comes fully assembled with handle and motor fully installed.

The handle is folded to allow for easier transportation. The handle can be moved into operating

position by loosening the black knob and unfolding the handle into the up-right position. The

black knob can then be reinstalled to secure handle in place. Tooling can now be installed, and

your Floor Grinder is ready for use.

PRIOR TO OPERATION

•Make sure that all dust, debris etc., are thoroughly removed from the unit prior to

operation. Special effort should be given to the bottom of the machine where the tooling

plate is located.

•Check all bolts and screws for tightness and make sure all bolts and screws are securely

tightened. Loose bolts and screws may cause damage to the unit. Make sure tooling is

properly installed.

CHANGING OR INSTALLING TOOLING

•Tilt the machine onto the back wheels and rest it on the handlebar.

•All tool discs are fixed with three Allen screws to the tool bracket.

•Remove the screws with an 8mm Allen key.

•Check the grinding tool for wear and tear for the next application.

•Fix new tools

•Adjust the different heights of the tools by changing the position of the rear wheel swing.

The motor axis of the grinder must be 90° level to the floor.

ATTENTION: Before working on the grinder bring the motor to a total stand still and

disconnect from the power supply.

CAUTION: Tools can be hot after use.

ALPHA FLOOR GRINDER

OWNER’S MANUAL AND PARTS BOOK

10

OIPB –C15001

OPERATION

Operating

After mounting the appropriate tools, the operation of the grinder can begin.

Adjust the grinder by loosening the screws of the rear wheel swing (Appendix diagram No. 3)

and changing its position in the slots so that the motor axis is 90° level to the floor. Tighten the

screws again. Connect the grinder to the mains. Lift the tool from the floor by tilting the machine

onto its back wheels. Switch the motor on.

After the motor has reached full speed, place the grinding head carefully on the floor. If the

machine is correctly adjusted (see above) it is easy to move across the floor. If the machine

pulls to the left or right, the machine must be re-adjusted by changing the position of the rear

wheel swing (see above).

Dust emission should be prevented by connecting a dust collector.

Stopping Procedure

Before finishing the grinding process the machine must be switched off and the tools must be

brought to a standstill by letting them touch the floor. Disconnect from the power supply.

ATTENTION: When switching on the motor, the machine may jump slightly due to

rotating tooling.

ATTENTION: Never switch on machine while the grinding head is on the floor.

ALPHA FLOOR GRINDER

OWNER’S MANUAL AND PARTS BOOK

11

OIPB –C15001

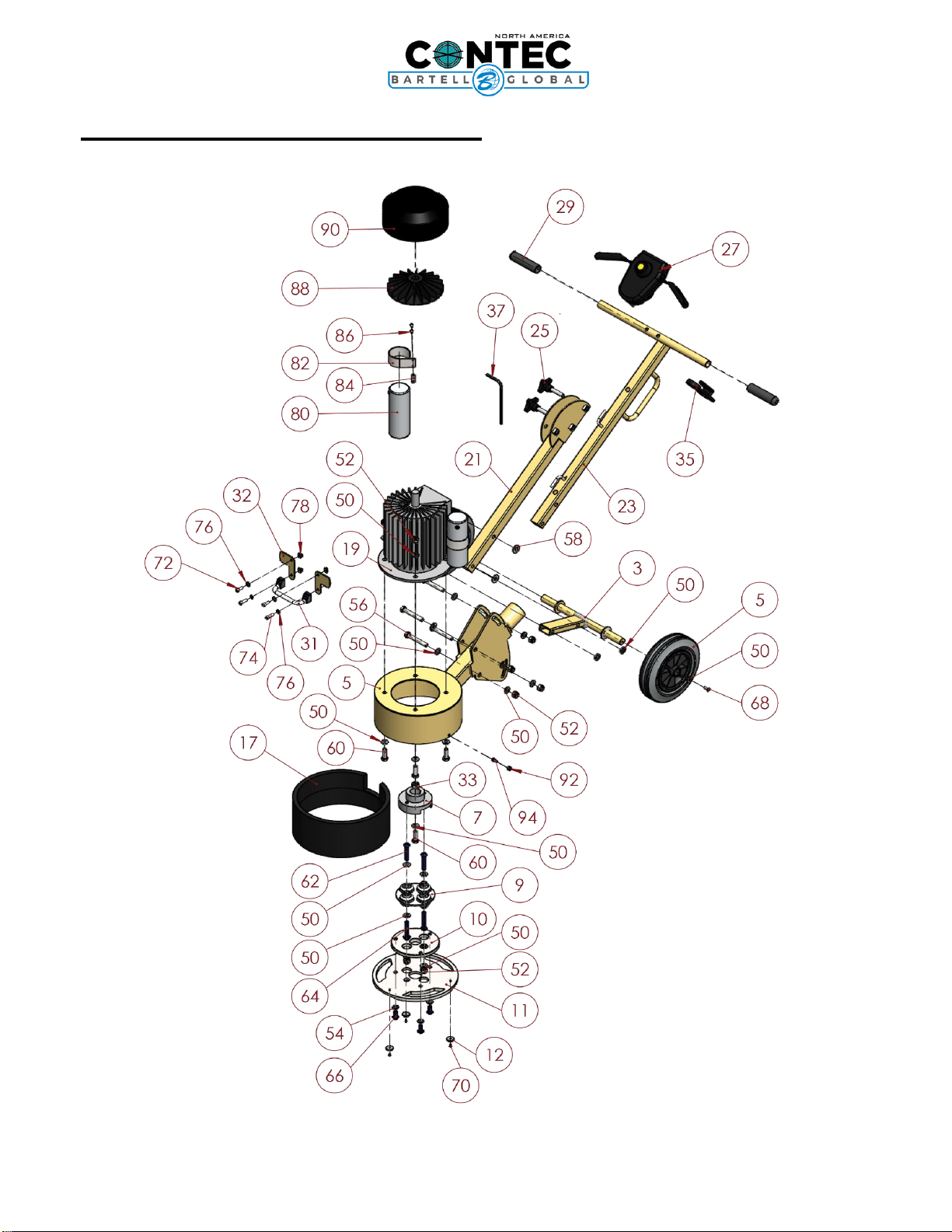

PARTS LIST 1 –ALPHA GRINDER

ALPHA FLOOR GRINDER

OWNER’S MANUAL AND PARTS BOOK

12

OIPB –C15001

ALPHA GRINDER –PARTS LIST 1

Item #

Part #

Description

QTY

Remarks

1

8704100100

FRAME

1

3

8704100401

REAR SWING ARM

1

5

8780205222

REAR WHEEL

2

7

8704170601

BRACKET FOR COUPLING

1

9

8790251001

RUBBER COUPLING

1

10

8714171005N

TOOL BRACKET

1

11

8704100302

MAGNETIC BRACKET

1

12

8704100305

MAGNET

3

17

8770238100

DUST RING BARTELL

1

19

8755031111US

MOTOR

1

21

8704100201N

HANDLE LOWER PART

1

23

8704100300N

TOP HANDLE

1

25

8760301050

CROSS HANDLE SCREW

2

27

875020203742

SWITCH

1

29

87702112090

RUBBER GRIP

2

31

8790214513

HANDLE

1

32

8704100600

FAN COVER PROTECTION

2

33

8704100800

SPACER

1

35

8790200024

STRAIN-RELIEF

1

37

879009SW6

ALLEN KEY 6 MM

1

50

8761330000

WASHER M10

23

52

8761320003

NUT, NYLON M10

8

54

8761330033

WASHER, SERRATED M10

3

56

8761310002

HHCS, M10X70

4

58

8761330026

WASHER, WIDE M10X25X3

4

60

8761310037

FHSCS, M10X30

5

62

8761310024

BHSCS, M10X50

2

64

8761310058

BHSCS, M10X55

2

66

8761310059

SCREW ALLEN M10X20

3

68

8761310018

FHSCS, M6X16

2

70

8761310000

FHSCS, M4X12

3

72

8761310023

SHCS, M6X16

2

74

8761310010

SHCS, M6X20

2

76

8761330032

WASHER, SERRATED 6MM

4

78

8790214515

NUT, GROOVE M6

4

80

8755031112US

CAPACITOR

1

82

8755030221US

CLAMP

1

84

8761320026

NUT, GROOVE M4

1

86

8761310074

LENS HEAD SCREW M4X16

2

88

8755030021LF

FAN

1

90

8750031112

FAN COVER

1

92

8761320020

NUT M6

2

94

8761310073

SCREW, HEXAGON M6X10

2

ALPHA FLOOR GRINDER

OWNER’S MANUAL AND PARTS BOOK

13

OIPB –C15001

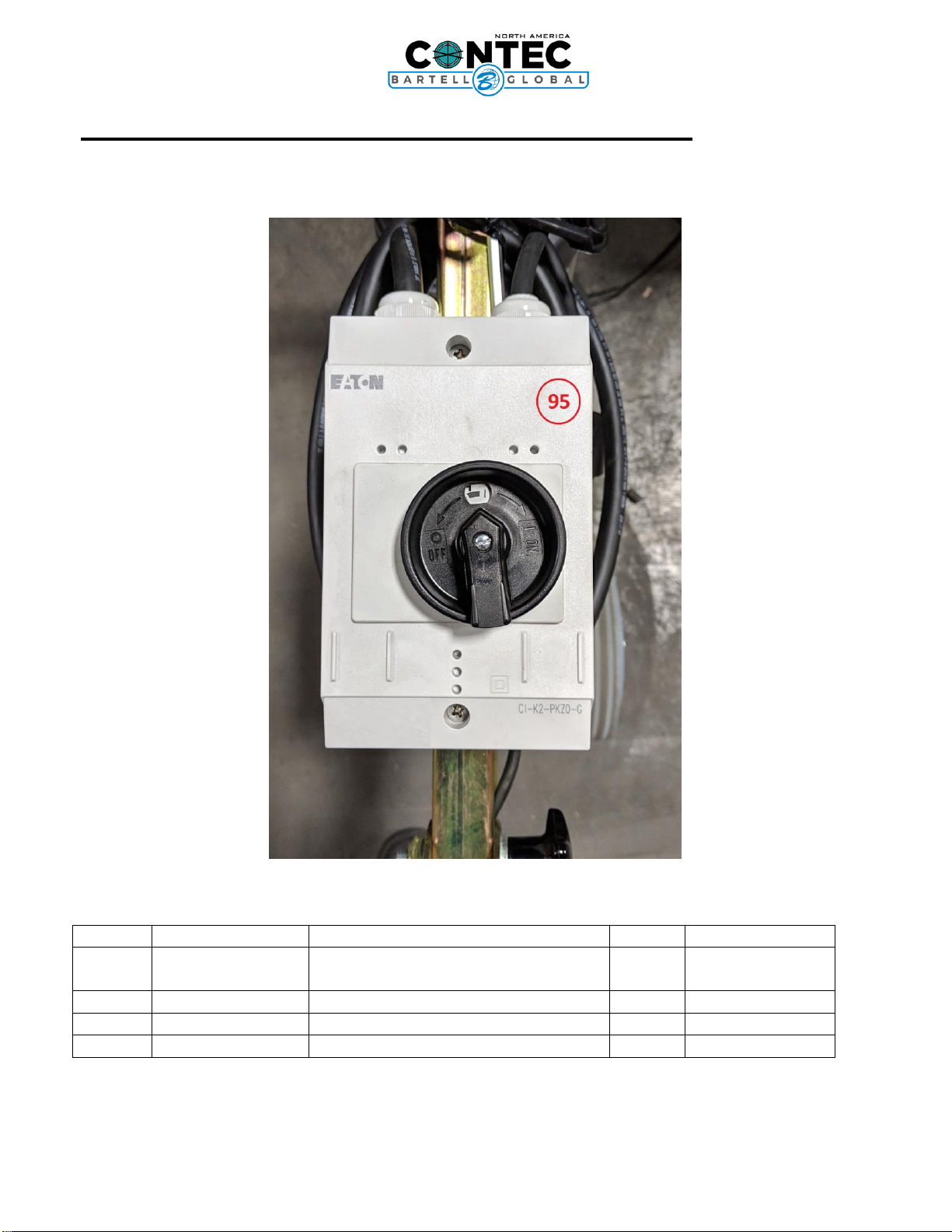

PARTS LIST 2 –ALPHA GRINDER *CANADA ONLY*

ALPHA GRINDER –PARTS LIST 2 *CANADA ONLY*

ALPHA GRINDER –PARTS LIST 2

Item #

Part #

Description

QTY

Remarks

95

8750201008

CSA PROTECTION KIT

(CANADA ONLY)

1

Includes Item

96 + 97

96

8751203001

MOTOR PROTECTOR

1

97

ENCLOSURE

1

98

12128

M25 NYLON STRAIN RELIEF

2

ALPHA FLOOR GRINDER

OWNER’S MANUAL AND PARTS BOOK

14

OIPB –C15001

This Page Left Intentionally Blank

Table of contents

Other Bartell Global Floor Machine manuals

Popular Floor Machine manuals by other brands

SCANMASKIN

SCANMASKIN BURNISHER SX manual

Taski

Taski swingo 750E Instructions of use

Clarke

Clarke BOS-18 Operator's manual

Mercury Floor Machines

Mercury Floor Machines BOSS-II Safety, operation and maintenance manual

Windsor

Windsor Cadet 7 operating instructions

Tornado

Tornado DS Series of 175 RPM Operation & maintenance manual