Bartell Global SPE DG250-II User manual

Table of contents

Other Bartell Global Floor Machine manuals

Popular Floor Machine manuals by other brands

Tennant

Tennant castex falcon 2800 WF2800 Operator and parts manual

Advance acoustic

Advance acoustic Advolution 20B Instructions for use and parts list

Bona

Bona FlexiSand AMO310000 Manual and safety instructions

Sprintus

Sprintus EM17 EVO Original user manual

Nilfisk-Advance

Nilfisk-Advance SW700B Operator's manual

Windsor

Windsor COMDU 1.008-612.0 operating instructions

Bissell

Bissell SPINWAVE 2859 Series Quick tips

GADLEE

GADLEE GT 55 Operator's manual

Kärcher

Kärcher KM 35/5 C Original instructions

NSS Enterprises

NSS Enterprises COMMANDER Operation manual

Minuteman

Minuteman M20130-00 Operation service parts care

SSS Siedle

SSS Siedle ACHIEVER 80 Operating & maintenance instructions

Tennant

Tennant sentinel Operator's manual

Kärcher

Kärcher BD 45/40 Service manual

Intelligent Cleaning Equipment

Intelligent Cleaning Equipment iP17 Operator's & parts manual

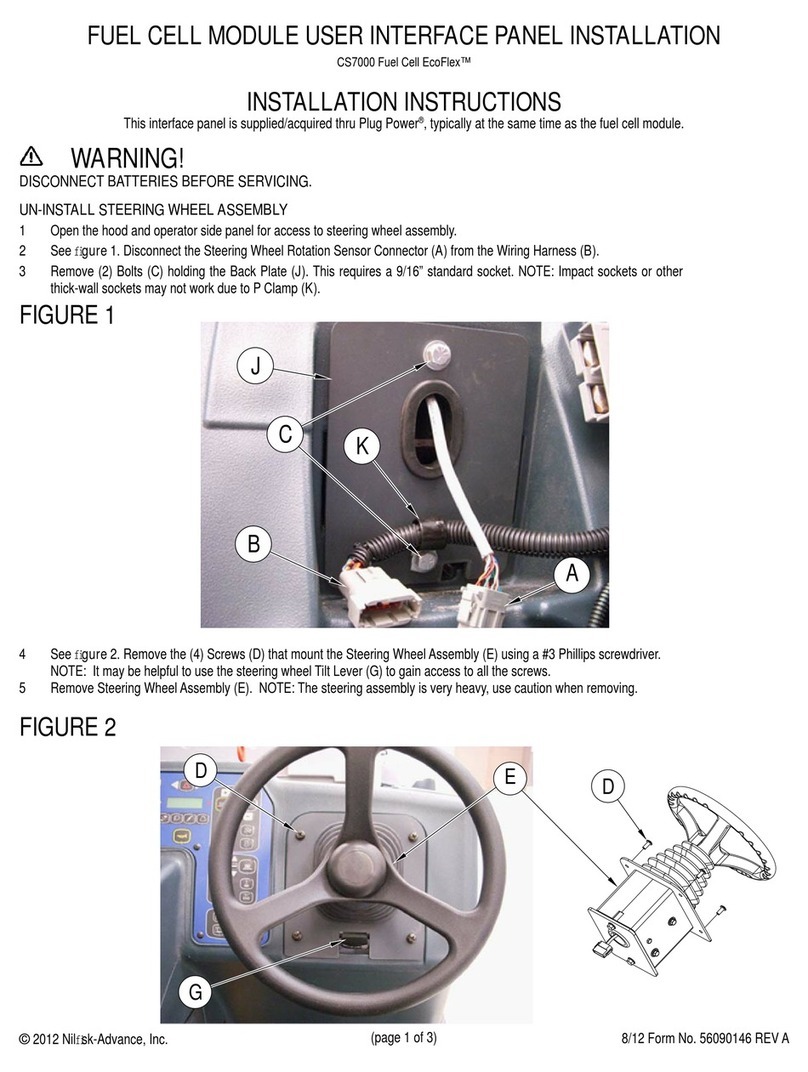

Nilfisk-Advance

Nilfisk-Advance CS7000 Fuel Cell EcoFlex installation instructions

Schwamborn

Schwamborn DSM 450 user manual

Nilfisk-Advance

Nilfisk-Advance PBU 21KACAT Service manual