Bartell Global S151 User manual

Doc. # OI-M09205

Orig. Rel. –01/2022

Curr Rev. –00

POWER SPRAYER

S151, S201

OWNER’S MANUAL

S151, S201

OWNER'S MANUAL

1

OI-M09205

Page Intentionally Left Blank

S151, S201

OWNER'S MANUAL

2

OI-M09205

Bartell Morrison Inc.

170 Traders Blvd E

Mississauga, Ontario, Canada

L4Z 1W7

Tel: (647) 953-4100

Fax: (647) 953-4101

Bartell Morrison USA LLC

200 Commerce Drive, Unit A

Freehold, NJ, USA

07728

Tel: (848) 225-8100

Fax: (848) 225-8101

SPE International Ltd

Honeyholes Lane

Dunholme, Lincoln, England

LN2 3SU

Tel: 01673 860709

Fax: 01673 861119

Innovatech

4701 Allmond Ave

Louisville, Kentucky, USA

40209

Tel: (425) 405-9100

Fax: (425) 405-9101

ORIGINAL LANGUAGE

© 2022 Bartell Morrison Inc.

No part of this work may be reproduced or transmitted in any form or by any means, electronic

or mechanical, including photocopying and recording, or by any information storage or retrieval

system without the prior written permission of Bartell Morrison Inc. unless such copying is

permitted by federal copyright laws.

Address inquiries or reference permissions care of:

Bartell Morrison Inc., 170 Traders Blvd E., Mississauga, Ontario, Canada, L4Z 1W7

REV.

DATE

DESCRIPTION

APPROVED BY:

01

01/22

New Format

AN

S151, S201

OWNER'S MANUAL

3

OI-M09205

SAFETY PRECAUTIONS

DANGER

EXPLOSION HAZARD

Never operate the machine in an explosive

atmosphere, near combustible materials, or

where ventilation does not clear exhaust fumes.

WARNING

BURN HAZARD

Never come into contact with the engine or

muffler when engine is operating or shortly after it

is turned off. Serious burns may occur.

CAUTION

MOVING PARTS

Before starting the machine, ensure that all

guards and safety devices are in place and

functioning properly.

ATTENTION

READ OWNER’S MANUAL

Read and understand owner’s manual before

using this machine. Failure to follow operating

instructions could result in serious injury or death.

S151, S201

OWNER'S MANUAL

4

OI-M09205

TABLE OF CONTENTS

QUALITY ASSURANCE/ MACHINE BREAK IN 5

WARRANTY INFORMATION 5

SPECIFICATIONS 6

INTRODUCTION 6

o1. MORRISON POWER SPRAYER 6

o2. OPTIONS 7

o3. DIMENSIONS 7

o4. SPRAYER MAIN COMPONENTS 8

SAFETY INSTRUCTIONS 9

o1. READING OPERATING INSTRUCTIONS 9

o2. SAFETY RULES 9

SPRAYER ASSEMBLY 11

SPRAYER OPERATING INSTRUCTIONS 12

OPERATING TIPS AND REMINDERS 14

PREVENTATIVE MAINTENANCE AND ROUTINE SERVICE PLAN 15

oROUTINE SERVICE SCHEDULE 16

CLEANING 17

S151, S201

OWNER'S MANUAL

5

OI-M09205

QUALITY ASSURANCE/ MACHINE BREAK IN

The Power Sprayer is the product of extensive engineering development designed to

give long life and unmatched performance. You can help ensure that your Power Sprayer will

perform at top levels by observing a simple routing on first use. Consider that your new Power

Sprayer is like a new car. Just as you would break in a new car to the road or any new machine

to the job, you should start gradually and build up to full use. Learn what your machine can do

and how it will respond. Refer to the engine manufacturer’s manual for run-in times. Full throttle

and control may be used after this time period, as allowed by material. This will serve to further

break in the machine on your specific application, as well as provide you with additional

practice using the machine.

We thank you for the confidence you have placed in us by purchasing a Power Sprayer

and wish you many years of satisfied use.

WARRANTY INFORMATION

Bartell Morrison Inc. agrees to furnish without charge, F.O.B. our plant, a

replacement for any part or portion thereof, comprising the sprayer part of the Bartell

Power Sprayer, consisting of the, pump, hose system, save and except for power units

and/or bearings which prove upon our examination, to be defective in either material or

workmanship within a period of twelve (12) months from date of purchase, provided that

notice of such defective part or portion thereof is given to Bartell Morrison Inc. within the

twelve month warranty period. No further or other guarantee or warranty expressed or

implied in connection with the sale of the Power Sprayer is given and our sole liability

consists in replacing defective parts or portions thereof. We shall not be responsible for

any special, indirect or consequential damages arising in any manner whatsoever.

This guarantee is for the sole benefit of the original purchaser as end user. Our

responsibility under this guarantee ends in the case the original purchaser transfers

ownership of the Power Sprayer, makes any changes, or adds any parts or devices not

of our manufacture to the Power Sprayer.

S151, S201

OWNER'S MANUAL

6

OI-M09205

SPECIFICATIONS

Introduction

TO THE OPERATOR:

DO NOT OPERATE THE BARTELL MORRISON POWER SPRAYER UNLESS

YOU HAVE READ AND STUDIED THIS MANUAL CAREFULLY.

REMEMBER THAT YOU ARE THE KEY TO SAFETY. GOOD SAFETY

PRACTICES NOT ONLY PROTECT YOU, BUT ALSO THOSE WORKING

AROUND YOU. MAKE THIS MANUAL A WORKING PART OF YOUR SAFETY

PROGRAM.

For safe operation of the power sprayer, you must be a qualified and authorized

operator. To be qualified, you must understand these written instructions, have

training, including actual operation of the power sprayer and know the safety rules

and regulations for your job site.

An operator should never use drugs, alcohol or any other substance which can

change his/ her alertness or coordination.

This manual is complied from information available and current at time of approval for

printing. Bartell Morrison Inc. reserves the right to improve its products without giving

prior notice or incurring any obligation.

1. Morrison Power Sprayer

The Morrison Power Sprayer is ideal for spraying all types of curing compound on

bridge decks, highways, floor slabs, drainage channels, etc, after finishing work is

completed. Easily handles form oils, pigmented curing compounds, bond

breakers, soaps and detergents, pest control liquids, and most liquid type

material.

It is powered by a dependable Honda engine and comes with 25’ (7.6m) of 3/8”

(0.95cm) hose with an adjustable spray nozzle.

S151

S201

Engine

Honda 3.2 HP (GX120) (2.4 kW)

B&S 3.5 HP (XR550) (2.6 kW)

Pressure

40-120psi

Hose Lengths

25’ (7.6m)

50’ (15.2m)

75’ (22.8m)

Flow Rate

8gal/minute (30L/min) OR

.03–.05 gal/min (3.8 –6.4 oz/min)

Weight

120lbs (55kg)

Max Solids

20%

40%

S151, S201

OWNER'S MANUAL

7

OI-M09205

2. Options

Hose Lengths: 50’ (15.2m), 75’ (22.7m), 100’ (30.5m)

Fan Spray Nozzle

Pistol Grip Handle

Hand Cart

Tow Cart

3. Dimensions

FIG. 1

S151, S201

OWNER'S MANUAL

8

OI-M09205

4. Sprayer Main Components

FIG. 2

S151, S201

OWNER'S MANUAL

9

OI-M09205

Safety Instructions

1. Reading Operating Instructions

Read and understand this entire manual before attempting to operate or service the equipment

described herein. Failure to follow these operating instructions could result in serious injury or death.

Store this manual with the machine and ensure it is apparent and available to any users.

2. Safety Rules

•The instructions provided in this manual are done so to

ensure the operator’s safety as well as that of other

workers, the equipment, and the job site. Failure to abide

by these guidelines can lead to serious personal injury and

even death. The operator and any service personnel

should read and understand the entire manual before

working with or servicing the power sprayer.

•The operator’s manual should be kept at all times in a place that is accessible

to any persons working with the machine. Replacement manuals can be

purchased from the equipment manufacturer or from your local dealer.

•Only use parts and attachments supplied or approved by your Bartell Morrison

equipment dealer. The consequences of modifying the design of this

equipment can include personal injury, equipment failure, and voiding your

warranty. If you are unsure about a repair or an apparent malfunction, contact

your Bartell Morrison dealer or the technical support line at the bottom of each

page of this manual.

•NEVER use the power sprayer in an enclosed space with

poor air flow, such as a basement or small room. The

gasoline engine produces, among other things, toxic carbon

monoxide gas. Without proper ventilation, this gas will build

up and cause health effects such as organ damage and

death to anyone in the vicinity.

•The operator should always be lucid and aware of his/her surroundings.

NEVER operate the power sprayer while under the influence of drugs, alcohol,

fatigue, sickness, hangover, extreme depression, anti-depressants, or

emotional distraction.

•ALWAYS wear appropriate personal protective equipment while operating the

Power Sprayer. This includes (but is not limited to) safety glasses, hearing

protection, protective footwear, and heavy or padded gloves. Other safety gear

may be job-site appropriate.

•NEVER leave the power sprayer unattended while running.

•Children and small animals should NEVER be present in the work area during

operation of the power sprayer.

•ALWAYS check your power sprayer for loose or missing nuts

and bolts before starting. Tighten any loose fasteners and replace

missing or broken parts.

•Perform all routine maintenance as described within this manual. Failure to do

so will void your warranty and will eventually result in premature equipment

S151, S201

OWNER'S MANUAL

10

OI-M09205

failure.

•NEVER perform maintenance on a running piece of equipment. Shut down the

engine and allow it to cool before servicing the power sprayer, including

mechanical work or lubrication.

•ALWAYS replace missing, damaged, or unclear safety

labels to ensure operator awareness and safety.

•NEVER operate the power sprayer with missing or

damaged safety guards. Replace immediately with

appropriate Morrison parts.

•NEVER put hands, feet, or other appendages inside the

belt guard while the engine is running, even at idle or

with protective clothing, as serious injury may result.

•NEVER wear loose fitting clothing or jewelry around rotating equipment such

as the power sprayer as it may become entangled in the machinery, resulting

in serious injury.

•ALWAYS refuel the power sprayer in a well-ventilated area,

away from ignition sources such as sparks, flames, and lit

cigarettes. Smoking while fuelling the equipment may result in

explosion.

•Ensure the engine has cooled sufficiently before refueling to

avoid igniting gasoline fumes.

•NEVER operate the power sprayer in explosive environments

such as paint fumes, methane, natural gas, fine particulate,

aerosol propellant, or solvent fumes.

•NEVER smoke near the power sprayer as stray gasoline fumes

may ignite. Operating the power sprayer around an open flame

may also result in explosion.

•ALWAYS shut down the engine and allow it to cool off before lifting or

transporting the power sprayer.

•ALWAYS tie down the power sprayer when being transported in a truck or on

a flatbed. Empty the fuel tank if transporting it over long distances.

S151, S201

OWNER'S MANUAL

11

OI-M09205

Sprayer Assembly

Your new Power Sprayer will arrive with everything you

need in one shipping carton. Be sure to examine the

content to be certain that the following items were

included:

Return Hose: ½” hose/pipe

Suction Hose: ¾” hose/pipe

Sprayer Wand Assembly: 25 ft. of 3/8” hose and (2) 3/8”

pipes with a coupler

1. Remove the sprayer from the carton and place it on the

curing drum you will be using. The sprayer should be

mounted so that the openings on the drum are accessible

on either side of the sprayer. Tighten the hold down tabs

on the sprayer to the drum.

2. Attach the suction hose/pipe to the sprayer using the

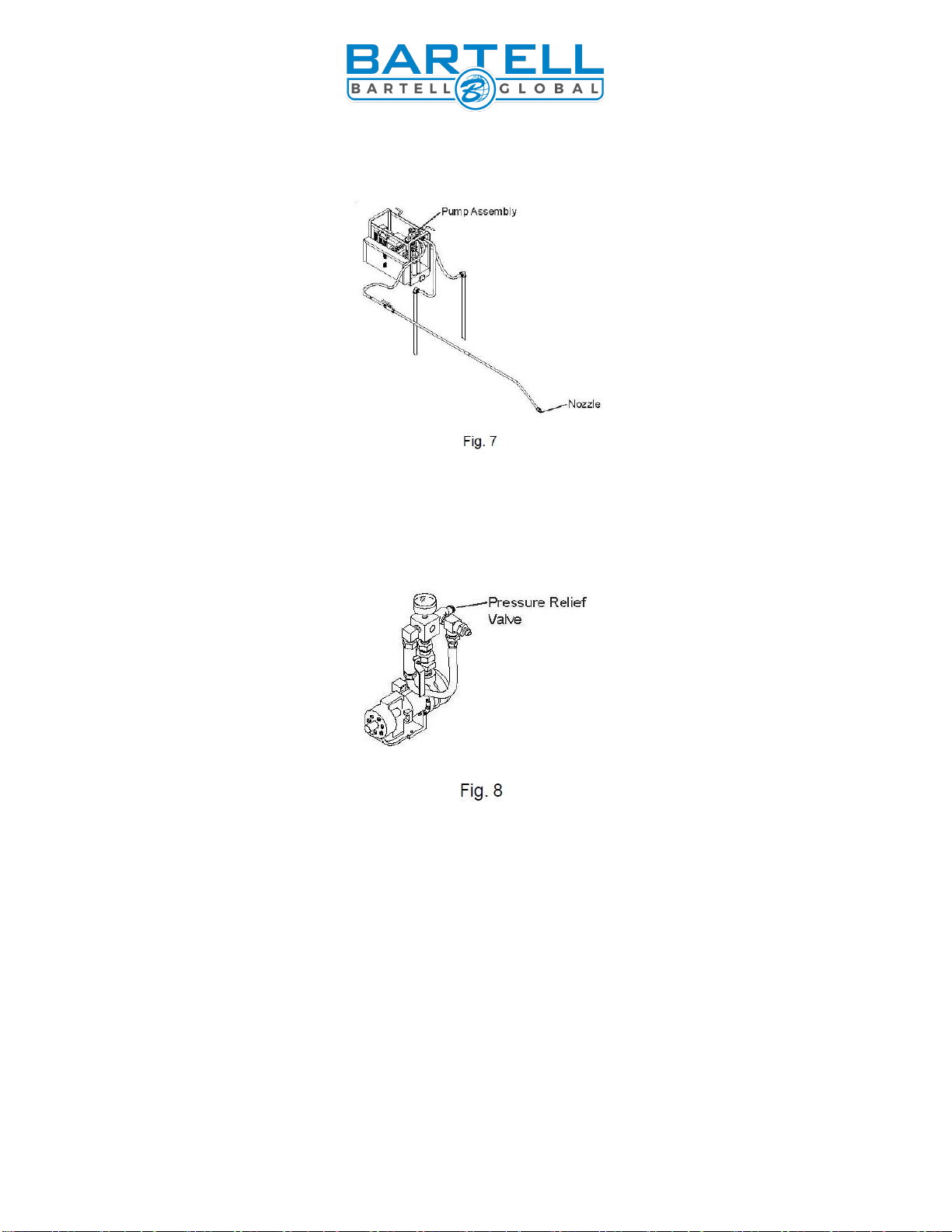

fitting mounted directly to the pump. (See Fig. 4)

3. Attach the fitting end of the return hose/pipe to the

sprayer using the ½” connection on the spray block

assembly. (See Fig. 5)

4. Join the two sections of the sprayer wand together

using the pipe coupling provided. (See Fig. 6)

5. Attach the spray hose to the last fitting on the sprayer

block assembly. (See Fig. 6) You are now ready to begin

operation of the sprayer.

S151, S201

OWNER'S MANUAL

12

OI-M09205

Sprayer Operating Instructions

Before starting engine, refer to the engine owner’s manual, follow the engine manufacturer’s

instructions for proper starting procedures, and follow the steps below.

CAUTION: If the material you are working with has solids in it, these will settle to the bottom of

the drum. You must agitate it thoroughly before attempting to spray the material. If you do not

do this, the sprayer will become clogged and possibly damage the pump.

1. Insert the suction hose into the drum using the larger of the two access holes. We

recommend using a support under the hose so that it will not reach the bottom of

the drum where sediment can clog the suction hose.

2. Insert the return hose into the drum using the smaller of the two openings.

3. The sprayer has a bypass valve that allows the engine to be started without pressure

building in the pump. Turn out counterclockwise the pressure relief to lowest setting and rotate

the bypass valve handle to the downward position before starting the engine. This valve allows

you to stir the curing material by circulating it directly through the pump.

4. Read the engine manufacturer’s instructions carefully before starting the engine. CHECK

OIL!!

5. Check the end of the suction hose to be certain it is immersed in the liquid but not in the

sediment in the bottom of the drum.

6. With the bypass valve in the on, downward position, start the engine and allow it to run for 2-

10 minutes. This aids in the mixing of the spray compound and assures greater pump efficiency

and life. (See Fig. 6)

NOTICE: Some compounds have a tendency to foam when air is introduced. This foaming can

cause erratic pump performance. Please do not insert spray nozzle into the drum in n attempt

to stir the material! This will only cause more foam in the compound.

7. Be certain the spray wand is off before turning the bypass valve to the off position

to pressurize the system.

8. Turn the bypass valve to the off position. You are now ready to spray.

S151, S201

OWNER'S MANUAL

13

OI-M09205

9. Adjustments to the spray pattern can be made with the nozzle at the end of the

spray wand. Turn the nozzle counterclockwise to narrow the spray pattern, and

clockwise to broaden the spray pattern.

10. The sprayer has an adjustable pressure relief valve (See Fig. 8) on the block assembly.

You may need to vary the pressure according to the viscosity of the material you are using.

Thinner liquids tend to need more pressure to assure a good coverage pattern. It is

recommended to use a lower pressure setting for certain liquids, especially with higher solids,

as high pressures can be problematic.

CAUTION: NEVER EXCEED 100 PSI (S151) or 150 PSI (S201)

11. While not spraying, turn the bypass valve on to remove unnecessary pressure from the

pump. Turning off the engine when not spraying will prolong the life of the pump.

12. The return hose may be used to check for any sediment remaining lodged at the bottom of

the drum. If none is detected, the suction hose can be lowered completely into the drum. If

sediment remains after several minutes of spraying, it may be necessary to remove the sprayer

and stir the material manually.

S151, S201

OWNER'S MANUAL

14

OI-M09205

Operating Tips and Reminders

1. Always start the engine with the bypass valve in the on position to reduce system pressure

and the pressure relief set to low.

2. Always stir the compound before attempting to operate the sprayer.

3. When not spraying, turn the bypass valve to the on position, or stop the engine. This will add

several hours of life to your sprayer.

4. Follow manufacturer’s directions and safety procedures in the use of materials used to clean

the sprayer.

5. Periodically clean the spray nozzle, as materials tend to clog, causing poor spray

performance.

6. Clean the sprayer after every use.

7. Flush after cleaning completely so that no solvents remain in the system.

8. Use care to avoid crimping or damaging hoses. Do not allow accumulations of compounds to

build up on hoses.

9. NEVER directly spray nozzle in the direction of eyes or face.

S151, S201

OWNER'S MANUAL

15

OI-M09205

PREVENTATIVE MAINTENANCE AND ROUTINE SERVICE PLAN

This Bartell Power Sprayer has been assembled with care and will provide years of

service. Preventative maintenance and routine service are essential to the long life of your

Power Sprayer. Your dealer is interested in your new machine and has the desire to help you

get the most value from it. After reading through this manual thoroughly, you will find that you

can do some of the regular maintenance yourself. However, when in need of parts or major

service be sure to see your Bartell dealer. For your convenience we have provided this space

to record relevant data about your Power Sprayer. When in need of parts or service be

prepared to provide your Power Sprayer serial number. Locate the serial number now and

record in the space below.

Date Purchased:

Type of Machine:

Dealer Name:

Model:

Dealer Phone:

Serial Number:

Replacement Parts Used

Maintenance Log:

Part No.

Quantity

Cost

Date

Date

Operation

S151, S201

OWNER'S MANUAL

16

OI-M09205

Routine Service Schedule

Routine Service Intervals

Each

Use

After 1.5

months

or 50 hrs

Each 3

months

or 100

hrs

Each 6

months

or 200

hrs

Each 9

months

or 300

hrs

Each 12

months

or 400

hrs

General Inspection

Guards

Check

O

O

O

O

O

O

Warning Stickers

Check

O

O

O

O

O

Test Run

Check -

Operation

O

O

O

O

O

Engine

Engine Oil

Check level

O

O

O

O

O

O

Change

O

O

O

Air Cleaner

Check - Clean

O

O

Replace

O

Sediment Cup

Clean

O

O

O

O

Spark Plug

Check - adjust

O

O

O

Replace

O

Idle Speed

Check - adjust

O

O

Valve Clearance

Check - adjust

O

Combustion

Chamber

Clean

After every 500 Hrs.

Fuel Tank + Filter

Clean

Every 6 months or 100 Hrs.

Fuel Tube

Check

Every 2 years (Replace if necessary)

Spray System

Pump and Hoses

Clean

O

O

O

O

O

O

Hoses

Check for

punctures

O

O

O

O

O

Replace if

damaged

S151, S201

OWNER'S MANUAL

17

OI-M09205

Cleaning

It is essential that the sprayer be cleaned after each use. Parts that fail due to improper

cleaning will not be warranted. Use the following steps as a guide to proper cleaning and

maintenance.

1. Place the suction hose into a container that has been filled with a solvent recommended by

the compound manufacturer to clean spraying equipment after use.

2. Place the return hose in an empty container the same size, or larger than the one with the

cleaning agent.

3. Turn the bypass valve to the on position and start the engine. Allow the cleaning agent to run

through the pump for 2-3 minutes.

4. Turn the bypass valve to the off position and spray wand to the on position. Allow the want to

spray into the empty container for about 20 seconds. This procedure may need to be repeated

several times to ensure that the pump and spray wand are clean.

5. Check the procedures for cleaning provided by the solvent manufacturer. Some cleaning

solvents require that they be flushed out with water after they are used. If this is the case, we

recommend that a small amount of form oil or diesel fuel be used AFTER using water. This will

prevent the internal components of the pump from seizing, due to the formation of rust on the

pump internals.

6. Disconnect all the hoses and allow all the liquid to drain from the lines.

7. As you begin your next spraying operation, spray a small amount of compound through the

lines and into an empty container. This will clear any remaining water or solvent before it is

mixed with the regular spraying compound.

S151, S201

OWNER'S MANUAL

18

OI-M09205

Page Intentionally Left Blank

This manual suits for next models

1

Table of contents