BASEWEST 700 Series Installation and operation manual

BASEWEST

Operating & Maintenance

Manual

Battery Power Units,

Escape Slide Lighting Systems

Model 725 thru 785

Reissued

10 March 2014

BASEWEST INC.

4240 116th Terrace N • Clearwater FL 33762

Tel: 727/573-2700 • Fax: 727/573-4307

E-mail: [email protected]

www.basewest.com

25-60-51

BASEWEST

Operating & Maintenance Manual

Escape Slide Lighting Batteries - Model 725 thru 785

Page 2 of 7 25-60-51

10 March 2014

1.0 INTRODUCTION

1.1 This manual covers the general configuration, installation, operation, test, and mainten-

ance of Model 700-Series escape slide lighting battery power units (Models 725 through

785) manufactured by BaseWest Inc. These batteries are the basic, non-rechargeable,

non-regulated versions designed to power incandescent lighting harnesses on aircraft

inflatable evacuation slides and slide/rafts. BaseWest Operating & Maintenance Manual

25-60-53 covers the Model 790-Series IC-regulated “smart” batteries which are used on

LED-based escape slide lighting systems. For specific instructions relative to operation

and installation on a specific escape slide, please refer to the corresponding OEM es-

cape slide or slide/raft manual.

1.2 BaseWest's Model 700-Series batteries are FAA/PMA and/or OEM-approved for use

with original equipment escape slide lighting system, and are fully interchangeable with

original equipment batteries. These units are fully compatible with the DME/Astronics

TU-14 test set, as well as BaseWest’s OEM-approved TS-420 test set. Test instructions

provided in OEM manuals are applicable to all BaseWest Model 700-Series batteries.

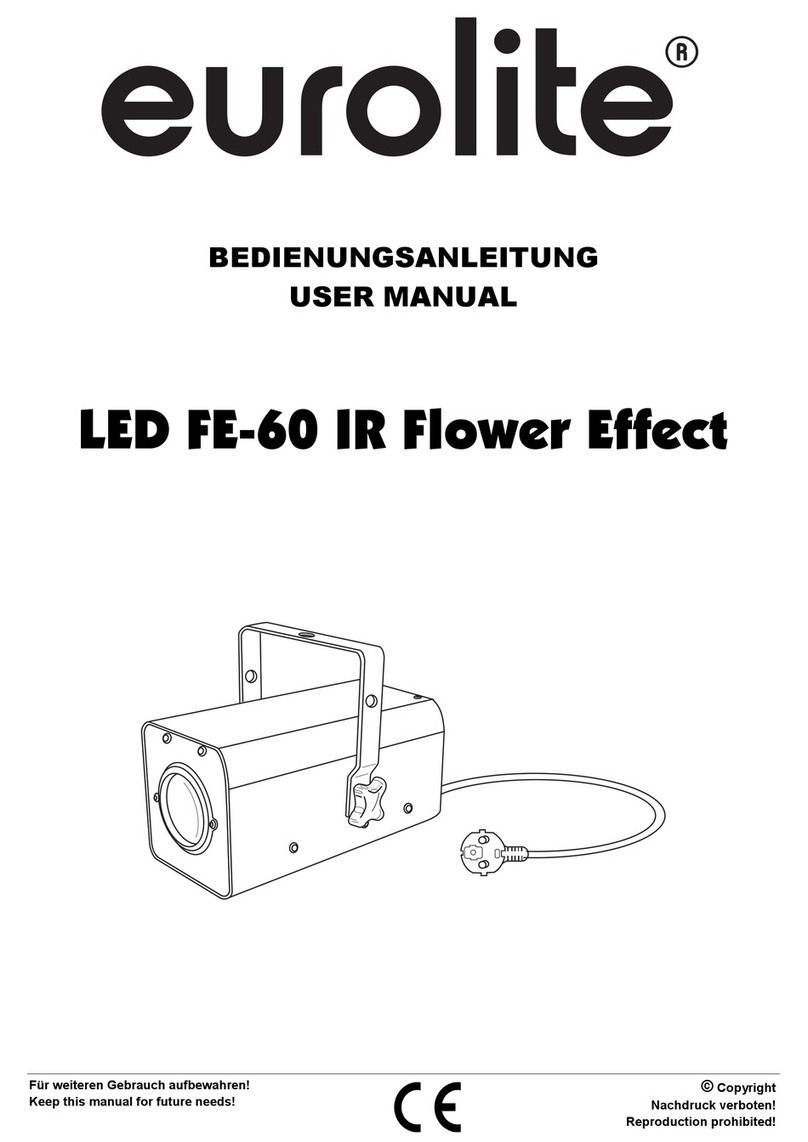

Figure 1 - Typical Model 700-Series Batteries

2.0 DESCRIPTION

2.1 General Configuration

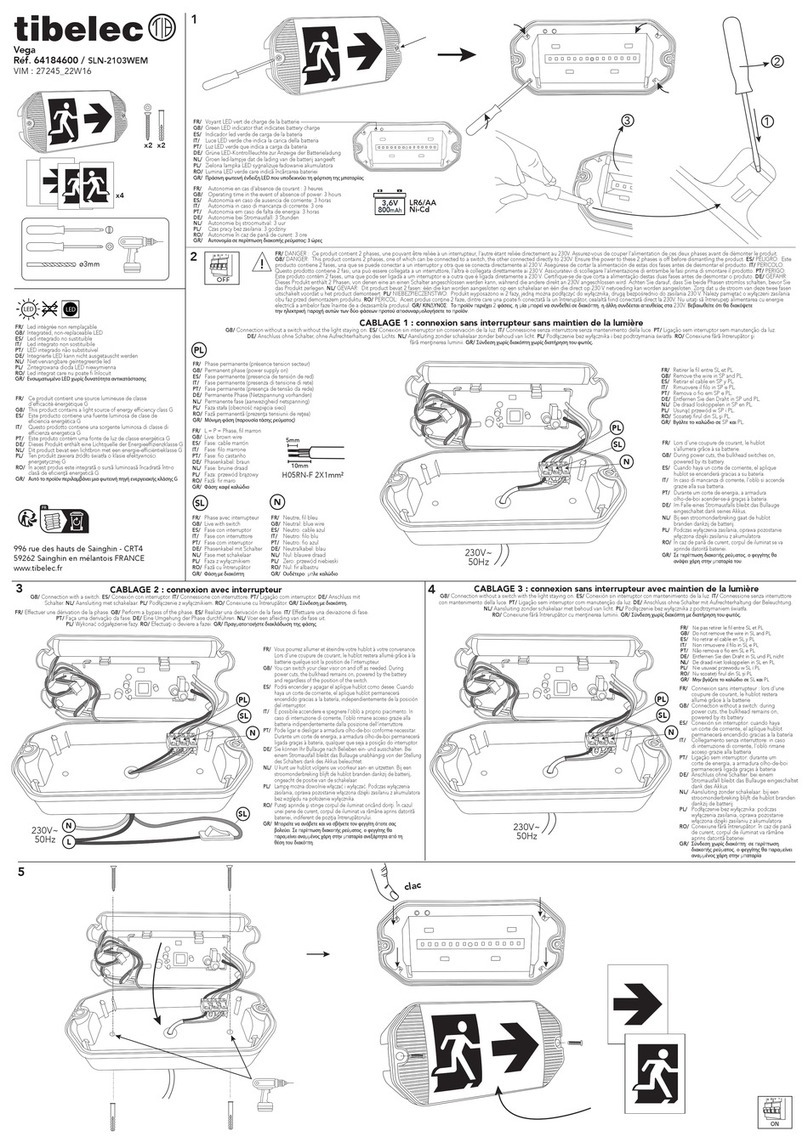

BaseWest's Model 700-Series batteries are non-rechargeable, non-regulated DC battery

packs configured in a cylindrical package of polycarbonate material. Power and test

leads are provided at one end of the battery pack and the activation switching means at

the other. Switching is accomplished with a miniature snap-acting microswitch. The

internal and external wiring conforms to mil-standard M16878/E (multi-stranded, TFE in-

sulated).The size, weight, and configuration of power and test leads vary with the model

number. A representative configuration of the basic Model 700-Series batteries is

shown in Figure 2 below.

BASEWEST

Operating & Maintenance Manual

Escape Slide Lighting Batteries - Model 725 thru 785

Page 3 of 7 25-60-51

10 March 2014

BLK

WHT

BLU

WHT (-)

BLU (+)

BLU (+)

WHT (-)

BLK (-)

BLU (+)

(+)

(-)

4

3

2

1

WIRING SCHEMATIC

BATT

SWITCH

BLK

(BLK) 2

(WHT) 4 3 (BLU)

1 (BLU)

(TEST CONN.

LOOKING IN)

POWER

LEADS

SWITCH END

CAP ASSEMBLY

DIODE PC BOARD

(SERIES-PARALLEL

BATTERIES ONLY)

CELL STACK ASSEMBLY SECURITY TIE-CORD

POWER LEADS

(ONE SET ORTWO)

TEST LEAD

END CAP &

STRAIN RELIEF

ASSEMBLY

ACTIVATION

LANYARD

Model Cell Type ( Number &

Configuration) Power Lead

Sets Nominal Length &

Diameter

725 AAA (35, series-parallel) 1 10.75 x 1.65 Dia

730 C (6 in series) 2 13.75 x 1.28 Dia

735 C (6 in series) 2 13.75 x 1.28 Dia

740 C (6 in series) 2 13.75 x 1.28 Dia

745 AAA (20, series-parallel) 1 9.00 x 1.28 Dia

750 AAA (14, series-parallel) 1 7.70 x 1.28 Dia

755 C (6 in series) 1 13.75 x 1.28 Dia

760 C (6 in series) 1 13.75 x 1.28 Dia

765 C (7 in series) 2 15.57 x 1.28 Dia

770 AA (28, series-parallel) 1 10.56 x 2.0 Dia

771 AA (28, series-parallel) 2 10.56 x 2.0 Dia

775 C (5 in series) 2 11.5 x 1.28 Dia

780 C (7 in series) 2 15.5 x 1.28 Dia

785 C (6 in series) 2 13.75 x 1.28 Dia

Figure 2 – General Configuration - Model 725 through 785

BASEWEST

Operating & Maintenance Manual

Escape Slide Lighting Batteries - Model 725 thru 785

Page 4 of 7 25-60-51

10 March 2014

2.2 Battery Cell Type

BaseWest's Model 700-Series batteries are based on standard “AAA”, “AA”, or “C” size

non-rechargeable Energizer® alkaline-manganese dioxide cells. The number of cells,

size, and series and/or series-parallel arrangements vary with the model number accord-

ing to the chart in Figure 2. These types of cells are not considered hazardous materials

for transport or disposal and contain no mercury. Energizer technical information re-

garding these cells including the Product Safety Data Sheets, and the “Alkaline Manga-

nese Dioxide Battery Handbook and Application Manual” which includes transport and

disposal guidelines can be found the following link.

•https://data.energizer.com/pdfs/alkaline_appman.pdf

2.3 Theory of Operation

Battery activation and illumination of the escape slide lighting system is accomplished

automatically upon inflation of the host device. An activation lanyard with a switch plug

snaps into a retention clip which is part of the battery’s switch end assembly. The switch

plug, when properly seated in the retention clip, depresses the plunger of the snap-

action microswitch, rendering the battery power circuit open, and the system off. The

lanyard is short-rigged and tied-off, so that inflation and extension of the escape slide

causes the switch plug to be pulled from its retention clip, allowing the microswitch to

snap to the closed circuit condition, providing power to the slide light assembly.

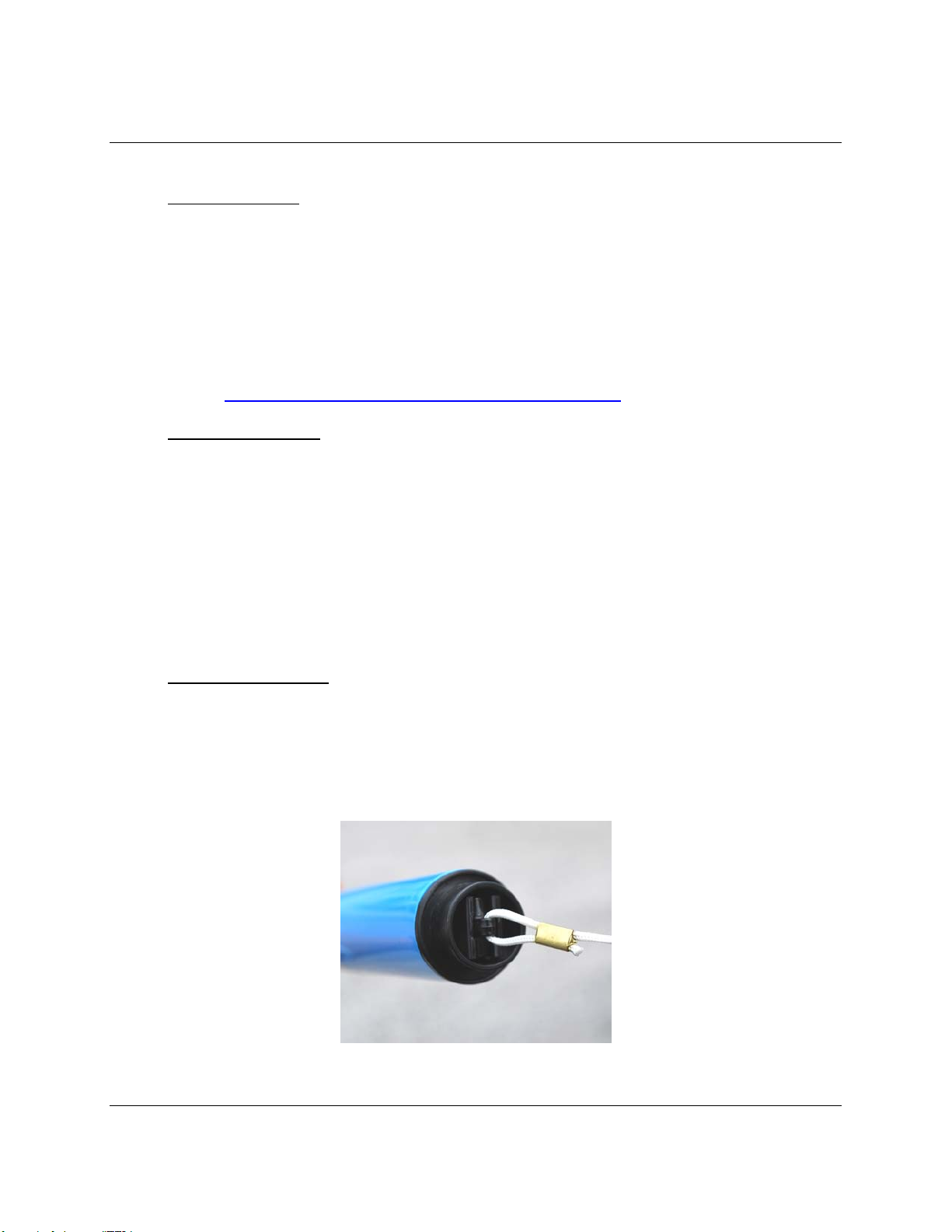

3.0 INSTALLATION, RIGGING and OPERATION

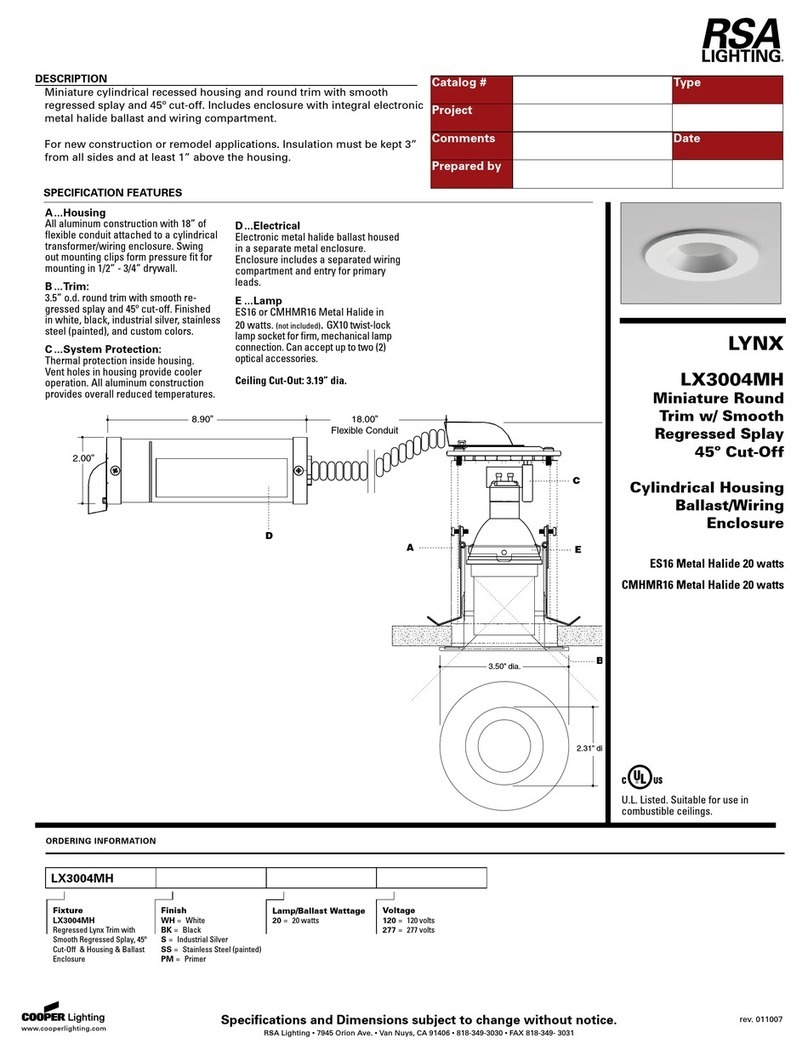

3.1 Installation & Rigging

Install the Model 700-series battery pack in accordance with escape slide manufacturer's

component maintenance manual procedures. Secure the end of the activation lanyard

to the escape slide structure and route it to the battery pack in accordance with the es-

cape slide manufacturer's CMM. Fully install the switch plug (located on the end of the

activation lanyard) into the clip in the switch end of the battery pack per Figure 3. Do not

safety-tie or otherwise obstruct free release of the switch plug from its retention clip.

Figure 3 - Installation of Activation Switch Plug

BASEWEST

Operating & Maintenance Manual

Escape Slide Lighting Batteries - Model 725 thru 785

Page 5 of 7 25-60-51

10 March 2014

3.2 Packing

Care must be taken during the packing process to ensure that sufficient slack is availa-

ble in the activation lanyard to ensure that folding, packing, and compression will not in-

advertently place sufficient tension on the activation lanyard to cause it to pull from the

retaining clip in the end of the battery; such a condition will result in inadvertent activa-

tion of the lighting system and premature depletion of the battery pack.

Further care must be taken to avoid placing the battery in a location that will result in

bending stresses, or point load compression against hard surfaces (e.g., bottles or regu-

lators) within the pack that could compromise the battery pack.

3.3 Operation

The battery pack, when properly installed, secured and rigged in accordance with the

escape slide manufacturer’s instructions, will operate automatically upon inflation of the

escape slide. The activation lanyard is “short-rigged” to the escape slide such that the

activation switch plug will be pulled from the battery when the escape slide is inflated.

3.4 Special Activation Lanyards

Some OEM battery installations call out special activation lanyards - including those with

integral attachment loops, dual activation devices, and DOT fasteners. BaseWest main-

tains TSO C69b authority to allow use of corresponding replacement BaseWest special

lanyards designed to interface with BaseWest's unique battery activation design. Please

contact BaseWest for any special activation lanyard requirements.

4.0 TESTING

4.1 General

4.1.1 BaseWest escape slide light systems are designed to be tested with BaseWest's Model

TS-420 test set or functionally equivalent test units such DME/Astronics Model TU-12

and TU-14. OEM test instructions which call out instructions for testing OEM batteries

with the Models TU-12 or TU-14 are directly applicable to BaseWest Model 700-Series

batteries and the BaseWest Model TS-420 test set. Published GO-NO GO test values

are also directly applicable.

BASEWEST

Operating & Maintenance Manual

Escape Slide Lighting Batteries - Model 725 thru 785

Page 6 of 7 25-60-51

10 March 2014

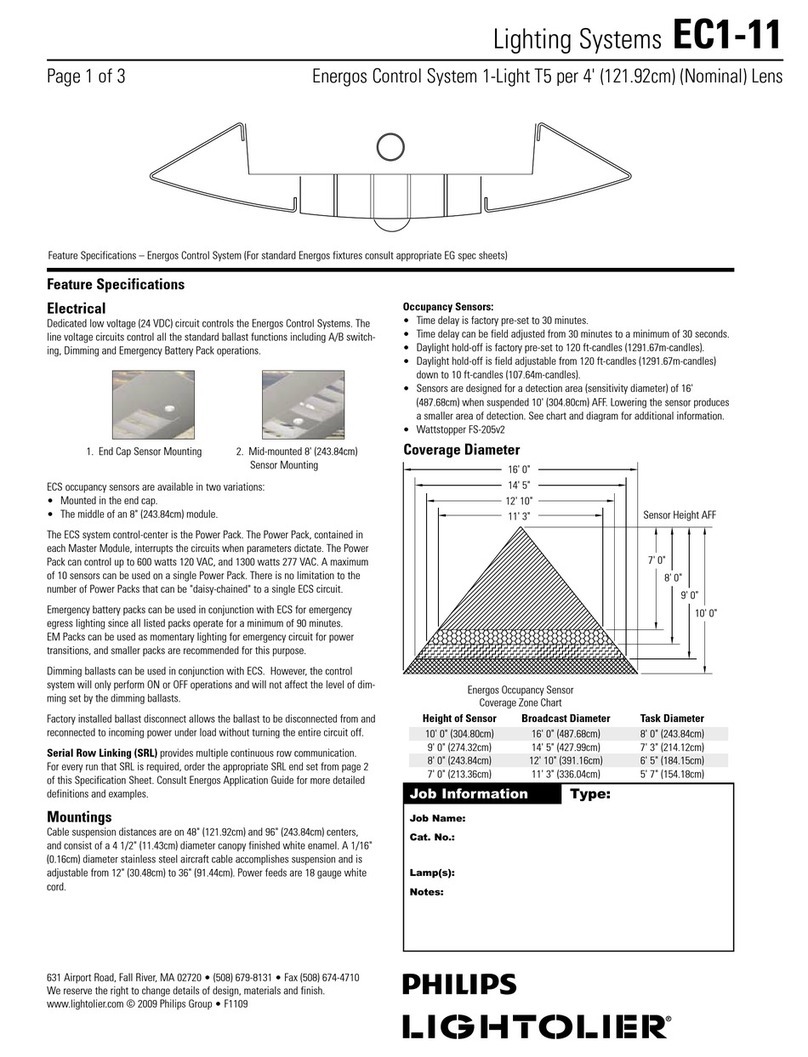

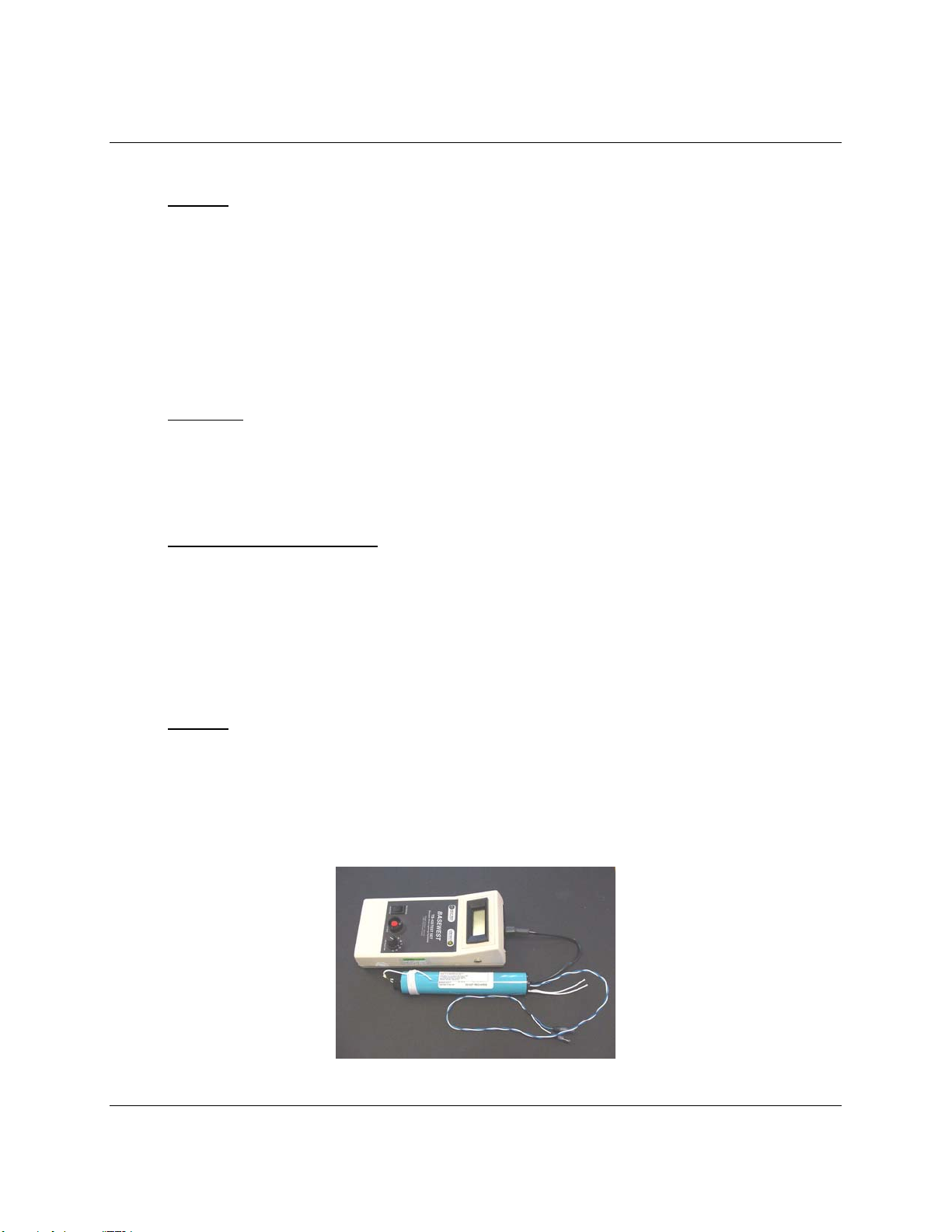

Figure 4 – Battery Testing with TS-420 Test Set

4.1.2 This section applies, generally, to an individual battery, either installed on a slide or

uninstalled. The procedures in this section assume that the battery is testing indepen-

dently, and that it is not attached to slide light harness. This test is suitable for receiving

inspection, pre-installation or pre-packing test.

4.2 Battery Condition Test

This test is designed to verify the condition of the internal battery cells under test load,

only. A functional test of the battery is provided in the next section.

(a) Identify the part number of the battery to be tested (and its OEM cross-reference, if

applicable). Determine the applicable test load settings and GO-NO GO criteria as

published in the applicable OEM maintenance manual.

(b) Gain access to the battery's 4-contact test connector, as shown in Figure 4, and

plug it into the corresponding receptacle on the TS-420 test set (or equivalent).

(c) With switch plug INSTALLED, place the test set in the "VOLTMETER" or battery

test mode. Set the LOAD SELECTOR rotary switch to the proper position ("A"

through "F" or "NO LOAD"), as called out in the OEM maintenance manual.

(d) Press the test set switch and record voltage within 2-3 seconds. Release test

switch.

4.3 Battery Functional Test

This section covers functional testing of the Model 700-Series battery connected to a

slide lighting harness before repacking of the slide. DO NOT PERFORM THIS

PROCEDURE WITH TEST SET CONNECTED TO THE BATTERY.

a) Install the battery, rig the activation lanyard, and connect it to the slide light har-

ness in accordance with slide manufacturer instructions and Section 2.0 of this

manual.

b) With the escape slide laid out fully and all slide light luminaires visible (inflated or

non-inflated), pull the activation switch plug from the battery. Observe that the

slide lights function properly. IMMEDIATELY reinstall the switch plug to de-

activate the battery.

CAUTION: OPERATION OF THE LIGHTING HARNESS WITH THE INSTALLED BATTERY WILL

DEPLETE THE BATTERY.

CAUTION: DO NOT REMOVE CONNECTOR HOUSINGS OR CONTACT INSULATORS FROM

THE POWER LEADS EXCEPT AS NECESSARY TO CONNECT THE BATTERY TO THE

LIGHTING HARNESS. DO NOT ALLOW THE BARE CONNECTOR CONTACTS TO TOUCH; THIS

WILL CAUSE A MOMENTARY SHORT CIRCUIT AND CAN REDUCE BATTERY CAPACITY

SIGNIFICANTLY.

BASEWEST

Operating & Maintenance Manual

Escape Slide Lighting Batteries - Model 725 thru 785

Page 7 of 7 25-60-51

10 March 2014

5.0 MAINTENANCE

5.1 General

BaseWest's Model 700-Series batteries are non-repairable, non-rotable items that have

a limited service life of five (5) years from date of manufacture. Repairs are not autho-

rized. Do not recharge.

5.2 Storage

The Model 700-Series batteries should be stored in a dry, temperature-controlled area at

nominal room temperature or cooler. They should remain in their primary unit packing

until pulled from stock for use. Do not expose the power lead contacts to contact with

conductive materials, or to contact with each other. Maintain the switch plug fully seated

and connector housings and/or insulation sleeves on power lead contacts at all times.

5.3 Service Life

The Model 700-Series batteries are FAA-approved for a five (5) year service life; both

the manufacture date and replace-by date are marked on the battery nameplate.

5.4 Transportation & Disposal

For information relating to transportation and disposal, please refer to the Energizer do-

cumentation provided in the internet links in Section 2.2.

This manual suits for next models

14

Table of contents

Popular Lighting Equipment manuals by other brands

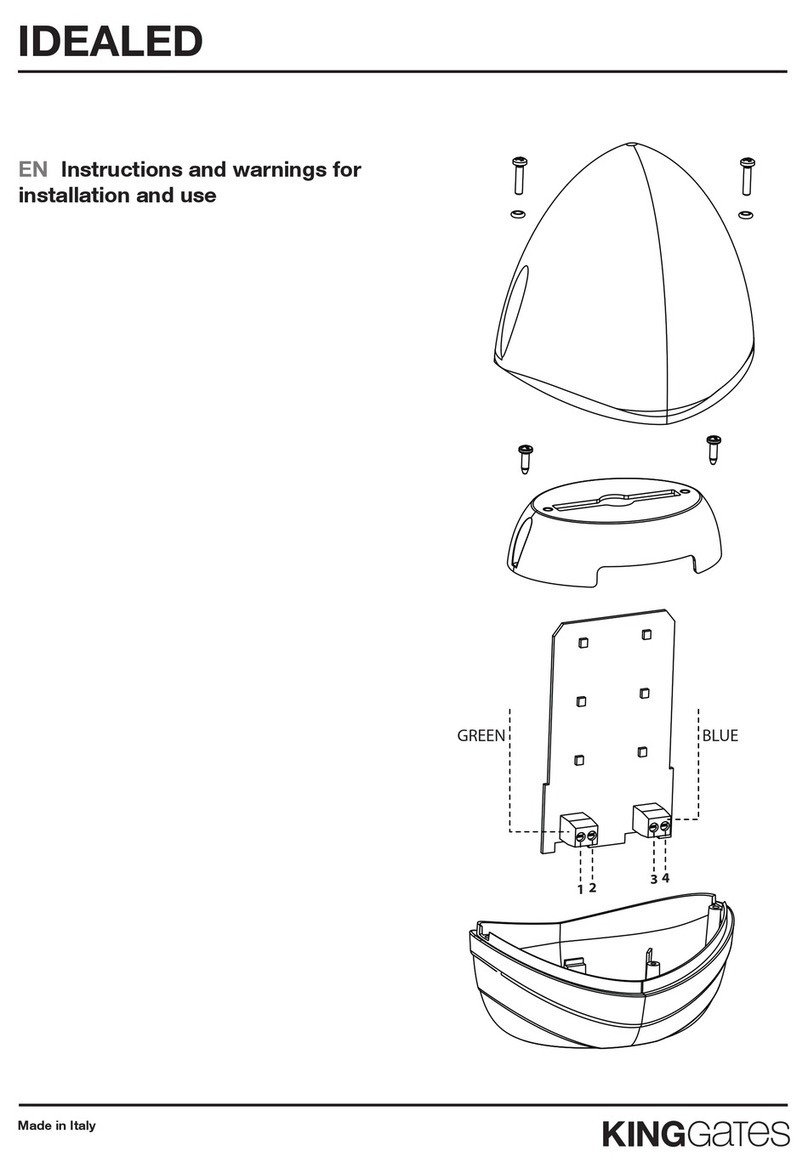

King gates

King gates IDEALED Instructions and warnings for installation and use

Anslut

Anslut 019920 operating instructions

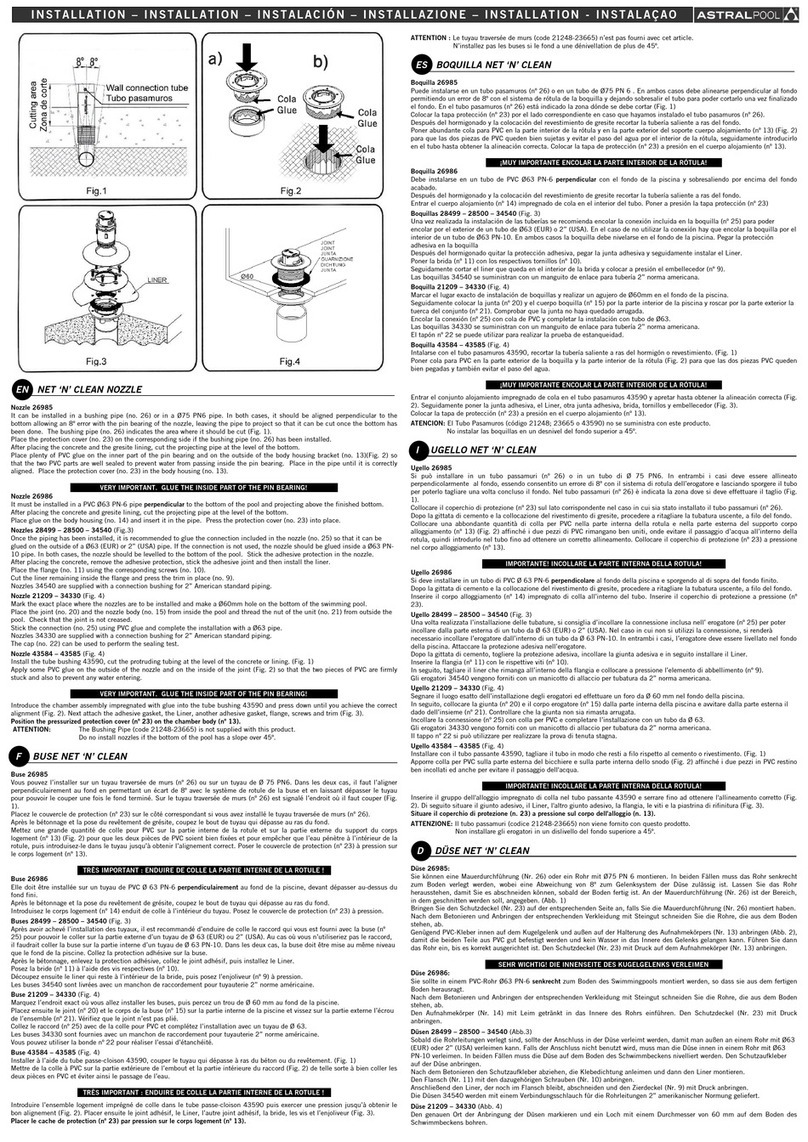

Astrapool

Astrapool NET ‘N’ CLEAN 26985 Installation

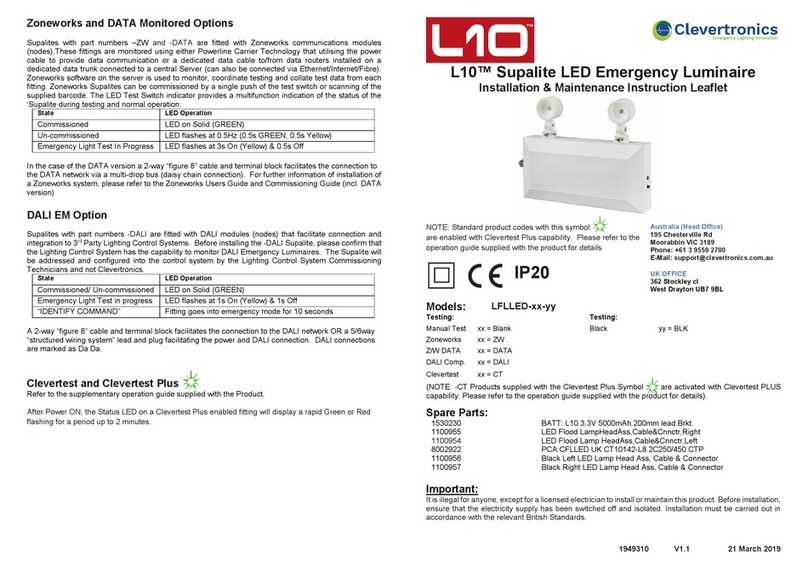

Clevertronics

Clevertronics L10 Supalite LFLLED Series ASSEMBLY, INSTALLATION & MAINTENANCE INSTRUCTIONS

Current

Current Lumination Tetra AL10 Series installation guide

Toast

Toast YC ONION LED Light user manual