Bathology Atmospheric 330 User manual

BATHOLOGY

rediscover bathing

Atmospheric 330

In-Shower Ventilation

Installation and Operation Manual

Atmospheric 330 by BATHOLOGY

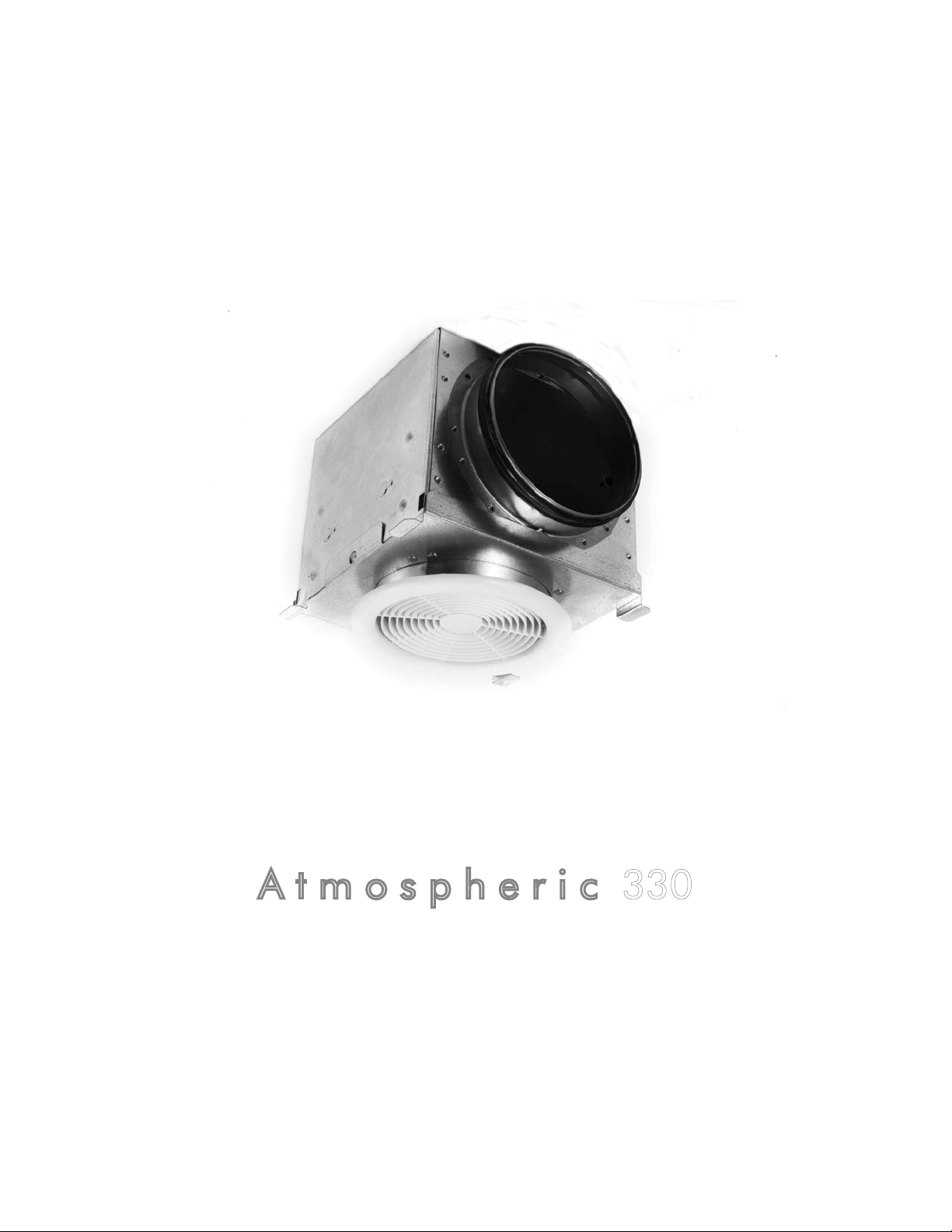

Components

2

1x Electronic Time

Control

1x Timer Face (White)

(Pre-installed)

Damper, 6”1x

Spec

Page

Install

Page

1x 66-8

11 11 - 13

14 14

190 CFM

Exhaust Fan, 6”

1x Mounting Bracket

4x 1” Screws

4x 7/16” Screws

A

C

E

Flex Duct,

6”x25’

1x

H16 16 - 17

Mastic Tube

Net Contents: 1/12 Gallon

1x 8x Flex Duct Tie, 18”

3x Damper Screws

2x Mounting Screws

1x Timer Face (Ivory)

1x Timer Face (Almond)

Fan

Electronic Time Control

Damper

Duct

I16 16 - 17

Mastic and Duct Ties

1x 99-10

Expansion Vent

Housing, 6” duct

1x Expansion Vent

Grille

4x Hanger Bars

4x 1” Screws

2x 3/8” Short Screws

B

Expansion Vent

Fan Kit

Atmospheric 330 by BATHOLOGY

Components Continued

3

1x Slide Speed

Control

2x Mounting Screws 11 11 - 13

D

3x Wire Nuts

Slide Speed Control

Wall Vent, 6”

1x

Roof Cap, 6”

1x 15 15

F

15 15

G

Roof Cap

Wall Vent

Vent Options

Optional

by BATHOLOGY

Atmospheric 330

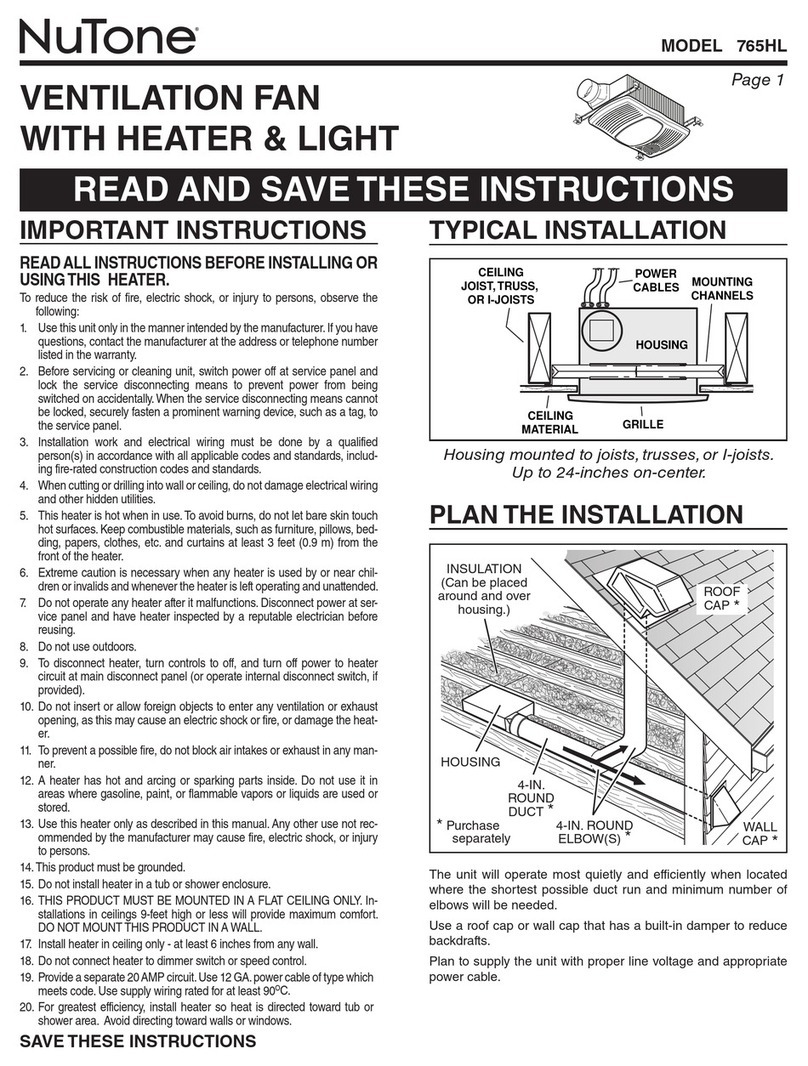

Typical Installation - Exterior Roof

A

B

C

D

E

F

H

I

Fan

Expansion Vent

Electronic Timer Control

Speed Slide Control

Damper

Roof Cap

Duct

Mastic and Ties

6 - 8

9 - 10

11 - 13

11 - 13

14

15

16 - 17

16 - 17

Page ID Product

Important: It is recommended that all electrical equipment be tested prior to installation.

4

F

A

H

E

D

C

B

Power Source

Accessible Area

Bath Area

Exterior Roof

H

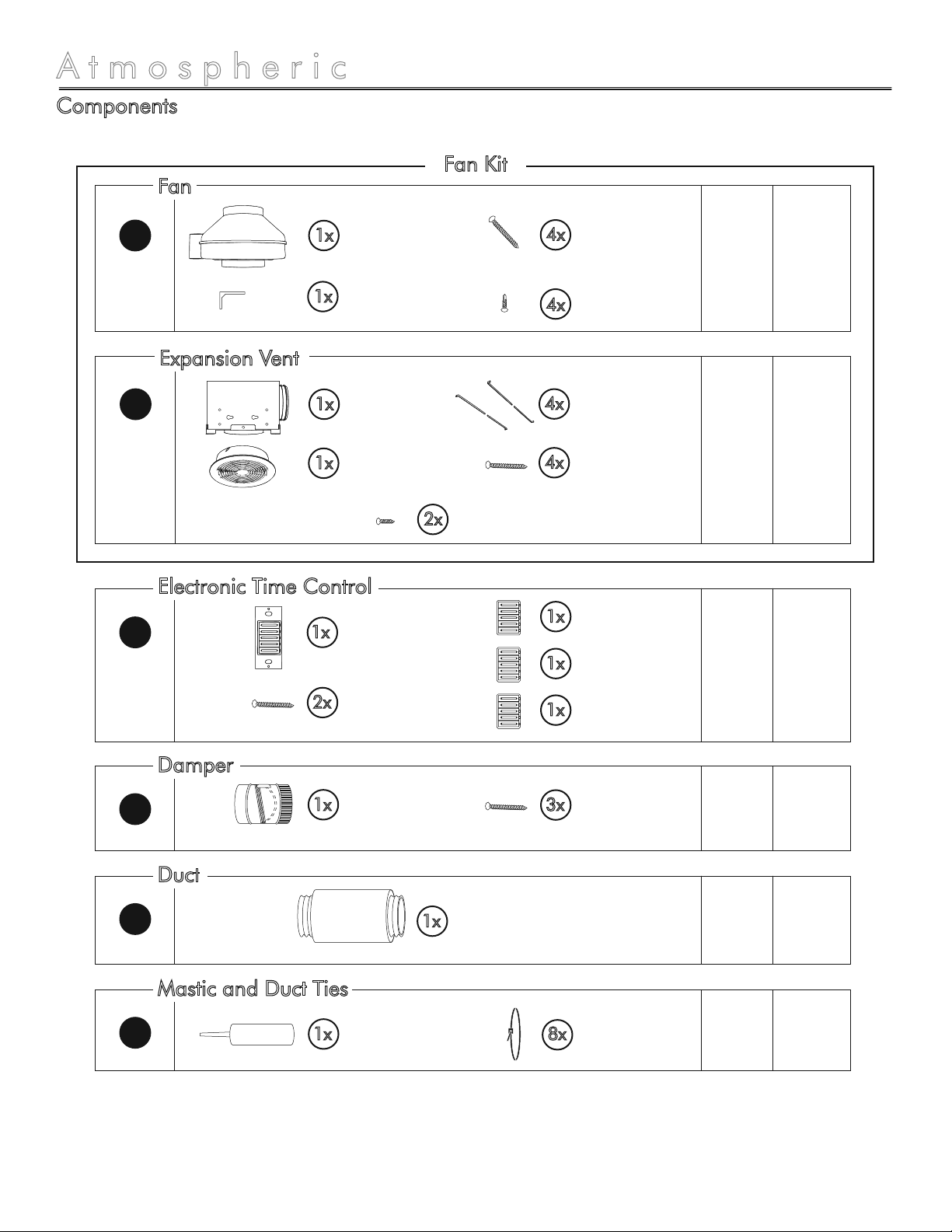

by BATHOLOGY

Atmospheric 330

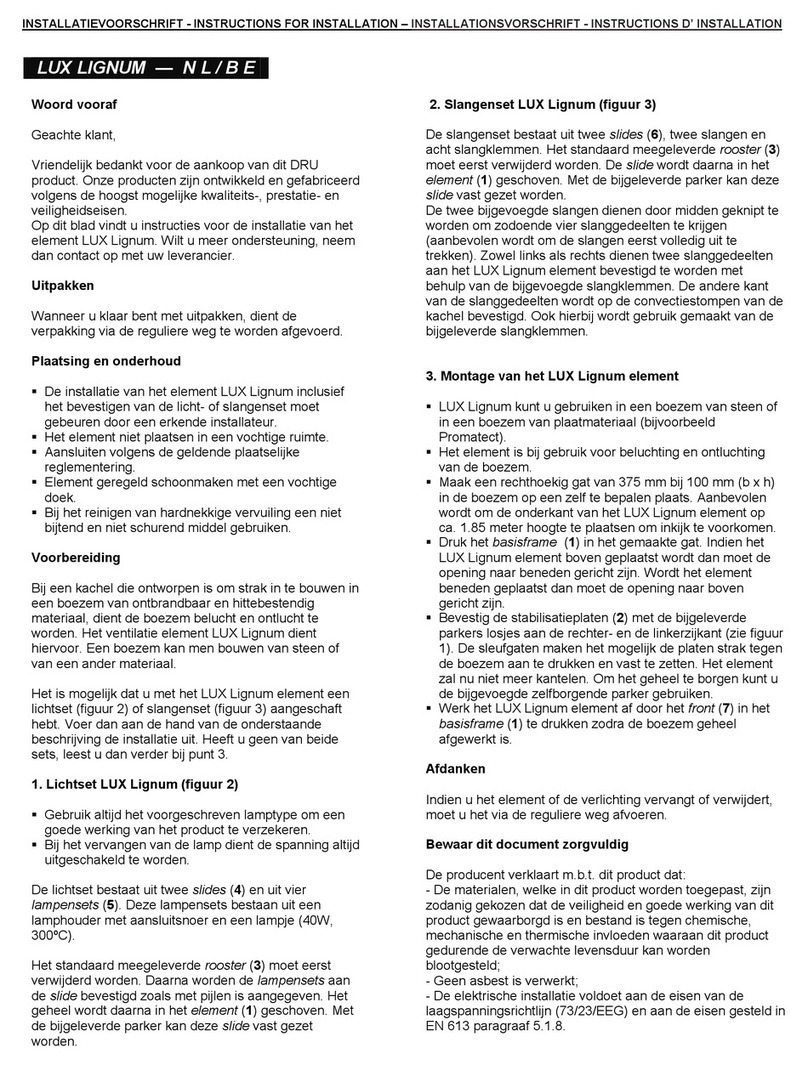

Typical Installation - Exterior Wall

Important: It is recommended that all electrical equipment be tested prior to installation.

5

H

G

A

E

D

C

B

Power Source

Accessible Area

Exterior Wall

Bath Area

A

B

C

D

E

G

H

I

Fan

Expansion Vent

Electronic Timer Control

Speed Slide Control

Damper

Wall Vent

Duct

Mastic and Ties

6 - 8

9 - 10

11 - 13

11 - 13

14

15

16 - 17

16 - 17

Page ID Product

by BATHOLOGY

6

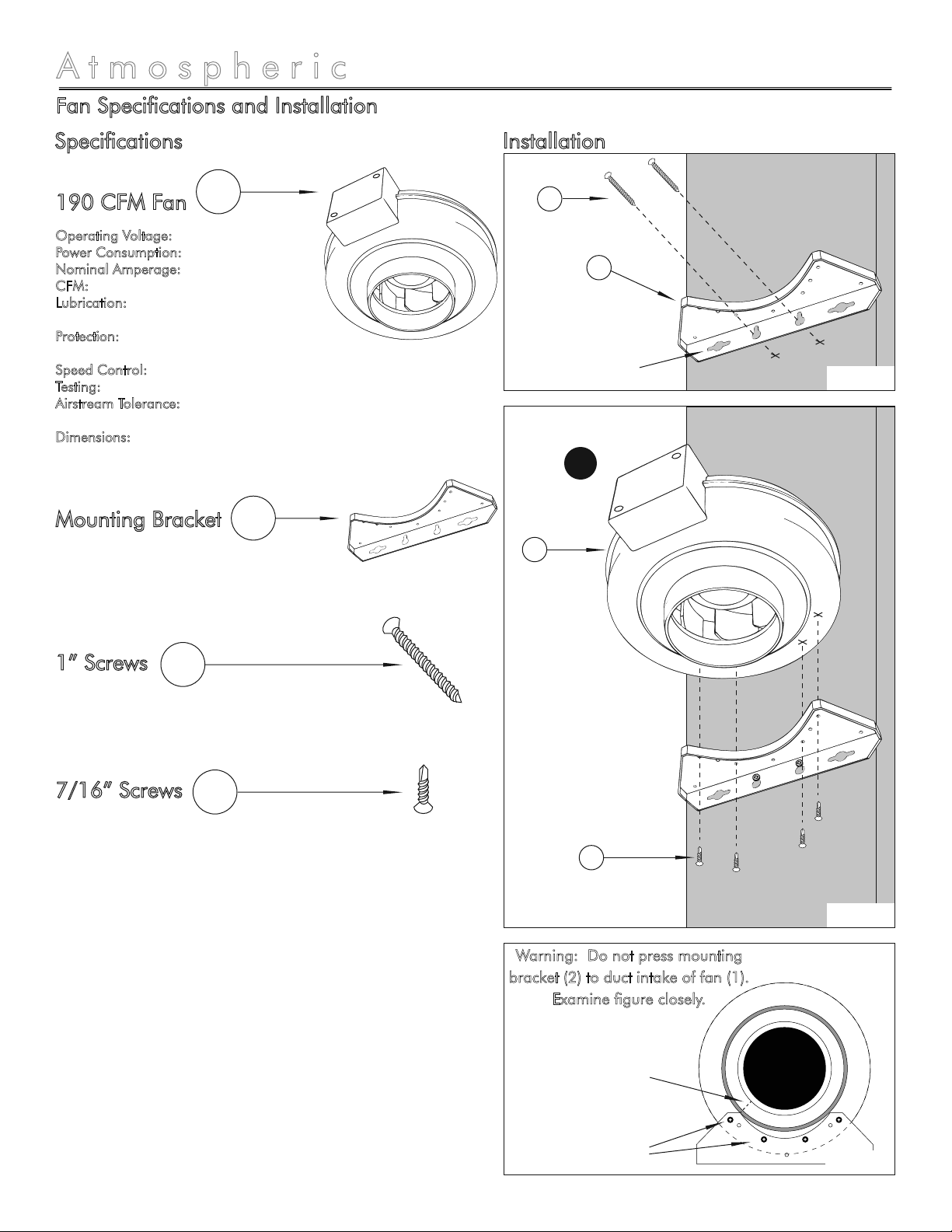

Fan Specifications and Installation

Atmospheric 330

190 CFM Fan

Operating Voltage: 120VAC

Power Consumption: 60W

Nominal Amperage: 0.52 Amps

CFM: 190 @ .20” W.G.

Lubrication: Permanently Lubricated

Sealed Ball Bearings

Protection: Automatic Reset Thermal

Overload Protection

Speed Control: 100% Speed Controllable

Testing: U.L. Listed; CSA Certified

Airstream Tolerance: Suitable for Airstream

Temperatures up to 140°F

Dimensions: 11-3/8” Diameter x 8” Length

1

Mounting Bracket 2

1” Screws 3

7/16” Screws 4

Stud /

Ceiling Joist

Stud /

Ceiling Joist

1” Screw

3

Mounting

Bracket

2

190 CFM

Fan

1

7/16” Screw

4

A

Figure 1

Figure 2

Specifications

Warning: Do not press mounting

bracket (2) to duct intake of fan (1).

Examine figure closely.

Installation

II

III III

Mount fan to mounting

bracket through slots

“I” and “III” of each side

Mounting Bracket spaced

correctly from duct intake

Figure 3

Use exterior slots for

horizontal installation

by BATHOLOGY

7

Fan Installation

Atmospheric 330

Installation Considerations

Warning: For your safety, read and understand

instructions completely before starting. Before

wiring to power supply, turn off electricity at the

fuse or circuit breaker box. Make sure electrical

service to fan is locked in “OFF” position.

Note: Prior to installation, consider the placement

of the 190 CFM Fan carefully, taking into account

the location of electrical, plumbing, and other

fixtures.

Note: All units are suitable for use with solid-state

speed controls

Note: This unit has rotating parts and safety

precautions should be exercised during

installation, operation and maintenance.

Caution: For general ventilation use only. Do not

use to exhaust hazardous or explosive materials

and vapors.

Note: All wiring must be done in accordance with

National Electrical Code and local building code.

Note: The combustion air-flow needed for safe

operation of fuel burning equipment may be

affected by this unit’s operation. Follow the

heating equipment manufacturer’s guidelines and

safety standards such as those published by the

National Fire Protection Association (NFPA), the

American Society of Heating, Refrigeration, and

Air Conditioning Engineers (ASHRAE).

Note: Exhaust fans must always be vented to the

outdoors.

Note: Acceptable for use over a bathtub or

shower.

Warning: NEVER place a switch where it can be

reached from a tub or shower.

Warning: For installation over a tub or shower,

power source must be externally switched GFCI

circuit and must be installed in accordance with

local and building codes.

-

-

-

-

-

-

-

-

-

-

-

When selecting fan (1) mounting location, the

following criteria should be considered: a)

mounting to minimize noise generated by fan

operation; b) service accessibility.

Mounting to minimize noise generated by fan

operation: Mounting the fan (1) as far as

possible from the intake point will minimize fan

operating noise from being transmitted back

through the duct work. Insulated flexible type

duct work (recommended for all bathroom

exhaust applications) will result in much quieter

operation. It is recommended that a minimum

8’ of insulated flexible ducting be used between

any expansion vent and fan (1) for low noise

level.

Service accessibility: Fan (1) location should

allow sufficient access for service.

1.

a)

b)

Installation

-

-

Warning: Check voltage at the fan to see if it

corresponds to the motor nameplate.

Warning: Guards must be installed when fan is

within reach of personnel or within seven (7) feet

of working level or when deemed advisable for

safety.

For safety purposes, use safety goggles

at all times.

Check for piping/electrical before

cutting or drilling.

If there is any risk of uninsulated

electrical connections in your wall/ceiling area, use

insulating gloves.

Before wiring to power supply, turn off

electricity at the fuse or circuit breaker box.

Important: It is recommended that all electrical

equipment be tested prior to installation.

by BATHOLOGY

8

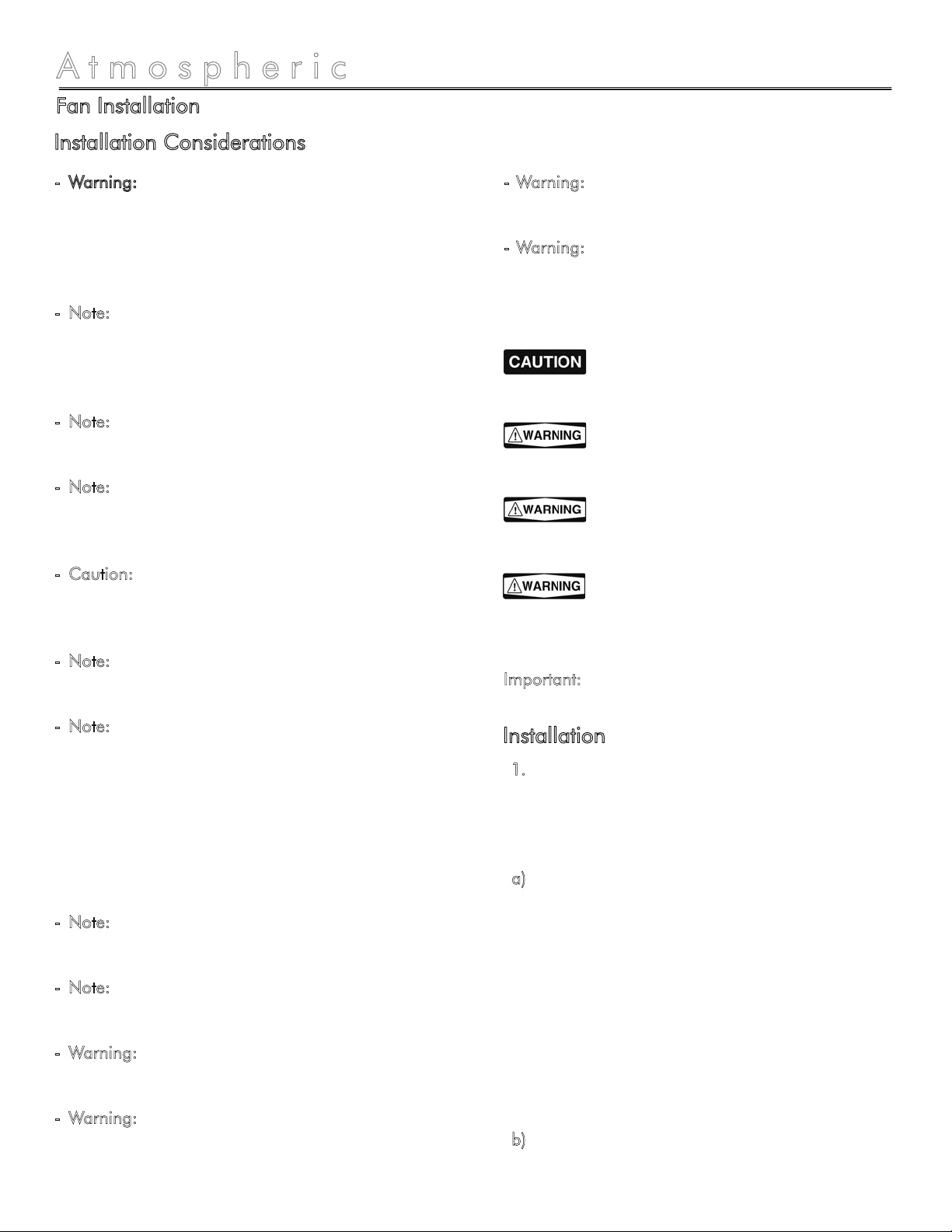

Fan Installation

Atmospheric 330

Remove the screws securing the terminal box

cover plate located on the side of the fan (1)

(see figure 3). All fan motor connections are

pre-wired to an electrical terminal strip. A 3/8”

romex type cable restraint connector will be

needed to secure the wiring through the

knockout provided on the side of the terminal

box.

Bring incoming electrical service through the

romex connector and the fan knockout. Be

sure to place the connector nut over the wiring

coming into the terminal box. There are two

open ports on the terminal strip. Using a small

regular screwdriver, tighten the neutral (white)

wire of the incoming supply under the open

terminal strip port labeled “N”. Tighten the line

(black) wire of the incoming supply under the

open terminal strip port labeled “L”. Since the

fan motor is isolated within a plastic housing,

grounding is not necessary (see figure 4).

4.

5.

Secure the romex connector. Secure the

incoming supply with the romex connector.

Replace the fan terminal box cover. All fan

motor and capacitor connections have been

pre-wired from the factory. No additional fan

wiring is necessary.

6.

Using the 1” wood screws (3) provided, attach

the fan mounting bracket (2) to a support beam

at the selected location (see figure 1 on page

6). Note: Fan (1) mounting can be at any

point along the duct and in any angle;

however, vertical mounting is recommended to

reduce condensation buildup in the fan (1). If a

horizontal installation is necessary and

condensation buildup may pose a problem,

wrap insulation around the fan (1).

Attach fan (1) to the mounting bracket (2) with

the four 7/16" sheet metal screws (4) provided,

making sure the wiring box is positioned for

easy access (see figure 2 and 3 on page 6).

Note: Screws are self tapping and do not

require pilot holes. Warning: Do not press

mounting bracket (2) to duct intake of fan (1).

Examine figure closely.

2.

3.

Wiring the Fan

Screws

Figure 3

Figure 4

Ground Green/Yellow

Blue

Black

Brown

Capacitor

White (N)

Black (L)

Supply Voltage

(Electronic Time

Control / Slide

Speed Control)

by BATHOLOGY

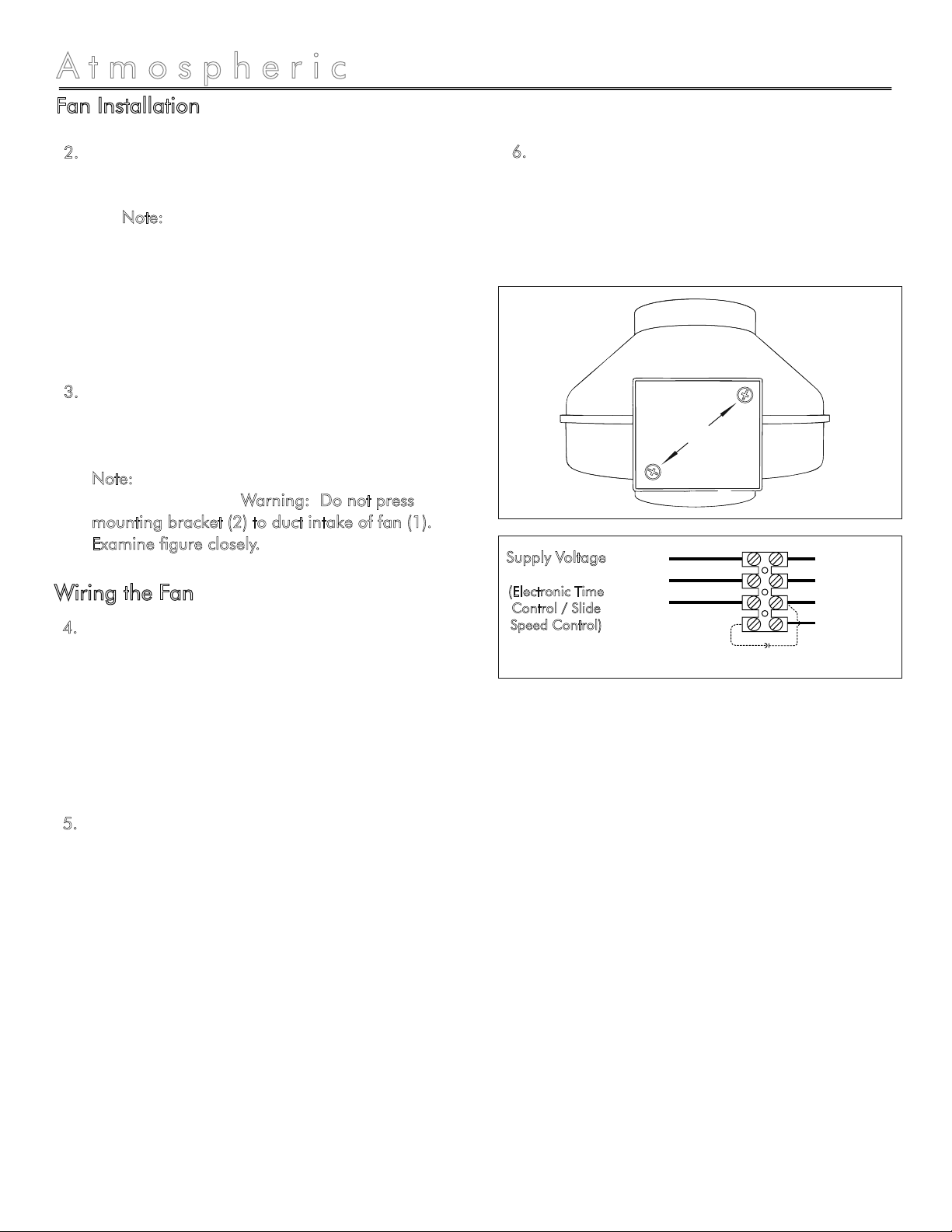

Housing Specifications and Installation

Atmospheric 330

Installation Considerations

9

Specifications Installation

Expansion Vent

Housing

Expansion Vent

Grille

Expansion Vent

Hanger Bars

Duct Connection: 6”

Rough-in Cutout: 6”

1

2

3

For safety purposes, use safety goggles

at all times.

Check for piping/electrical before

cutting or drilling.

If there is any risk of uninsulated

electrical connections in your wall/ceiling area, use

insulating gloves.

Warning: For your safety, read and understand

instructions completely before starting.

Note: Prior to installation, consider the placement of

the Expansion Vent carefully, taking into account the

location of electrical, plumbing, and other fixtures.

Note: The combustion air-flow needed for safe

operation of fuel burning equipment may be affected by

this unit’s operation. Follow the heating equipment

manufacturer’s guidelines and safety standards such as

those published by the National Fire Protection

Association (NFPA), the American Society of Heating,

Refrigeration, and Air Conditioning Engineers

(ASHRAE).

Note: Exhaust fans must always be vented to the

outdoors.

-

-

-

-

6” Cutout

Ceiling

Material

2

Expansion

Vent

Grille

B

1

Expansion

Vent

Housing

Mounting Directly to Joist

Mounting Brackets to Joist

15/32” from

bottom edge

of joist.

Secure front and

back hangar bars

with 3/8” screws

Position Locator Tabs

flush with bottom

edge of joist

Screws

B

B

Figure 1

Figure 2

Figure 3

1

Expansion Vent

Housing

1

Expansion Vent

Housing

3

Expansion Vent

Hanger Bars

by BATHOLOGY

10

Expansion Ventilation Installation

Atmospheric 330

1.

2.

3.

4.

Based on the bathroom layout and fixtures,

plan the location of the expansion vent grilles

(2) for the most effective ventilation.

Mount expansion vent housing (1) directly to

the ceiling joist using screws and keyhole slots.

Locator tabs on housing should be flush with

the bottom edge of the ceiling joist for correct

positioning of the unit once ceiling material is

installed (see figure 1 on page 9).

OR

Use the expansion vent hanger bars (3) to

suspend the expansion vent housing (1)

between ceiling joists. For correct positioning,

hanger bars (3) should be positioned 15/32"

up from the bottom edge of the ceiling joist.

Secure hanger bars with 3/8” screws (see figure

2 on page 9).

Note: Expansion vent hanger bars (3) can be

used on ceiling joists up to 16" on center.

Note: If ceiling material is thicker than 5/8" the

locator tabs may be removed to allow the grille

collar to be flush with the finished ceiling

material.

Note: Designed for 1-1/8” ceiling material

maximum.

Cut a 6" round hole for the expansion vent

grille (2).

Install the expansion vent grille (2) by pushing it

firmly into the steel collar until it is shouldered

by the ceiling material (see figure 3 on page 9).

Installation

by BATHOLOGY

11

Control Specifications and Installation

Atmospheric 330

Electronic Time Control

Operating Voltage: 120VAC, 60Hz

Nominal Amperage: 20 Amps

Motorload: 1HP

1Warning: For your safety, read and understand

instructions completely before starting. Before wiring to

power supply, turn off electricity at the fuse or circuit

breaker box.

Note: All wiring must be done in accordance with

National Electrical Code and local building code.

Note: NEVER place a switch where it can be reached

from a tub or shower.

Note: Recommended minimum wall box depth is

2-1/2”.

Note: Maximum wire length from electronic time

control to all installed remote switches cannot exceed

300 ft (90m).

Note: Use these devices with copper or copper clad

wire only.

Note: When combinations of electronic time control /

slide speed control are installed in a ganged wall or

outlet box, derating is required. When two devices are

mounted in a ganged box, the maxminum load per

device shall not exceed 4A or 500 watts. When three or

more devices are mounted in a ganged box, the

maximum load shall not exceed 3A or 400 watts.

Note: The electronic time control and the slide speed

control should be installed 48” above the floor, on a

vertical wall, convenient for user operation.

-

-

-

-

-

-

-

-

For safety purposes, use safety goggles

at all times.

Check for piping/electrical before

cutting or drilling.

Electrical components are not

waterproof.

If there is any risk of uninsulated

electrical connections in your wall/ceiling area, use

insulating gloves.

Before wiring to power supply, turn off

electricity at the fuse or circuit breaker box.

Installation Considerations

Slide Speed Control

Operating Voltage: 120VAC, 60Hz

Nominal Amperage: 5 Amps

2

Optional

Specifications

by BATHOLOGY

12

Atmospheric 330

Control Installation

Hot (Black)

Line 120VAC

60Hz

Line 120VAC

60Hz

Line 120VAC

60Hz

Line 120VAC

60Hz

Neutral (White)

Black

Green

Ground Black

White

White

Red

Fan

Timer / Fan Wiring

Timer / Light / Fan Wiring

Hot (Black)

Neutral (White)

Black

Black

White

White

Black

White

Red Black

Fan

Vent

Lights

Timer / Slider / Fan Wiring

Hot (Black)

Neutral (White)

Black

Black

White

White

Red Black Black

Fan

Timer / Lights / Slider / Fan Wiring

Hot (Black)

Neutral (White)

Black

Black

White

White

Black

White

Red Black Black

Fan

Vent

Lights

Green

Ground

Green

Ground

Green

Ground

Green

Ground

Green

Ground

C

C

C

CD

D

B

B

A

A

A

A

by BATHOLOGY

13

Control Installation

Atmospheric 330

Press timer button based on desired operation time.

This will enable use of the slide speed control (B), as

well as illuminate expansion vent lighting if present.

Slide bar control up or down for desired fan rotation

speed. ON/OFF rocker switch will turn fan ON at

speed set by slide bar.

To change faceplate of electronic time control

(1), push in the side of the faceplate at the tabs

to release. With desired faceplate, line up tabs

and press in sides one at a time to attach.

Remove pre-cut 3/8” of insulation from each

circuit conductor. Make sure the ends of wires

are straight.

Install electronic time control (1) and slide

speed control (2) into double gang box, two

single gang boxes, or single gang box as

installation permits.

Connect wires per applicable wiring diagram

on previous page: Twist strands of each lead

tightly together and, with circuit conductors,

push firmly into appropriate wire connector.

Screw connectors on clockwise making sure no

bare conductors show below the wire

connectors. Secure each connector with

electrical tape.

Restore power at circuit breaker or fuse.

1.

2.

3.

4.

5.

Installation

Operation

Important: It is recommended that all electrical

equipment be tested prior to installation.

by BATHOLOGY

14

Damper Specifications / Installation

Atmospheric 330

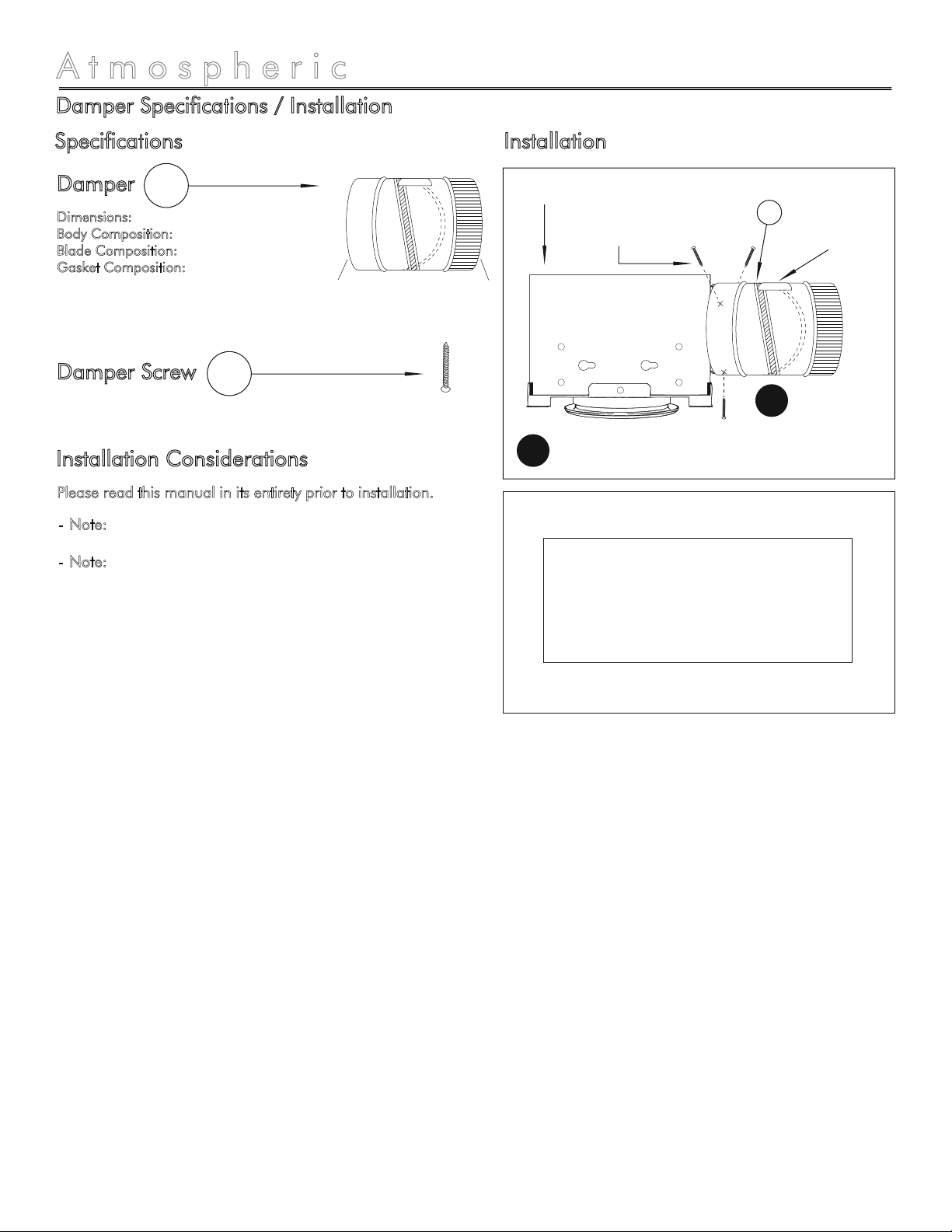

Damper

Dimensions: 6” Diameter x 6” Length

Body Composition: 28 guage galvanized steel

Blade Composition: Aluminum blades

Gasket Composition: Foam

1

InstallationSpecifications

Damper Screw 2

Note: Output end should never be lower than input.

Note: Follow all applicable codes and standards.

-

-

Installation Considerations

Please read this manual in its entirety prior to installation.

Label must

be upright

Screw Damper Input to

Expansion Vent Housing

Figure 1

Damper

Expansion Vent

1

Figure 2

B

E

Input Output

Install with this label up. Output end

should never be lower than input.

>>>>> AIR FLOW >>>>>

>>>>> AIR FLOW >>>>>

by BATHOLOGY

15

Roof Cap / Wall Vent Specifications and Installation

Atmospheric 330

Roof Cap, 6” 1

Wall Vent, 6” 2

Specifications Installation

Note: Do not install the roof cap on a flat roof!

Note: Follow all applicable codes and standards.

-

-

Installation Considerations

Please read this manual in its entirety prior to installation.

F

G

A

A

H

H

Roof Cap

1

Composition: Galvanized Steel

Rough-in Cutout: 6-1/8”

Duct Connection: 6”

Cap Dimensions: 10-3/4”L x 8-1/4”W x 5-1/4”H

Grille Composition: Plastic

Extension Composition: Galvanized Steel

Rough-in Cutout: 6-1/8”

Duct Connection: 6”

Cap Dimensions: 8-1/8”L x 8-1/8”W x 7/16”H

Duct Extension: 6” Diameter x 12” Length

Wall Vent

2

by BATHOLOGY

16

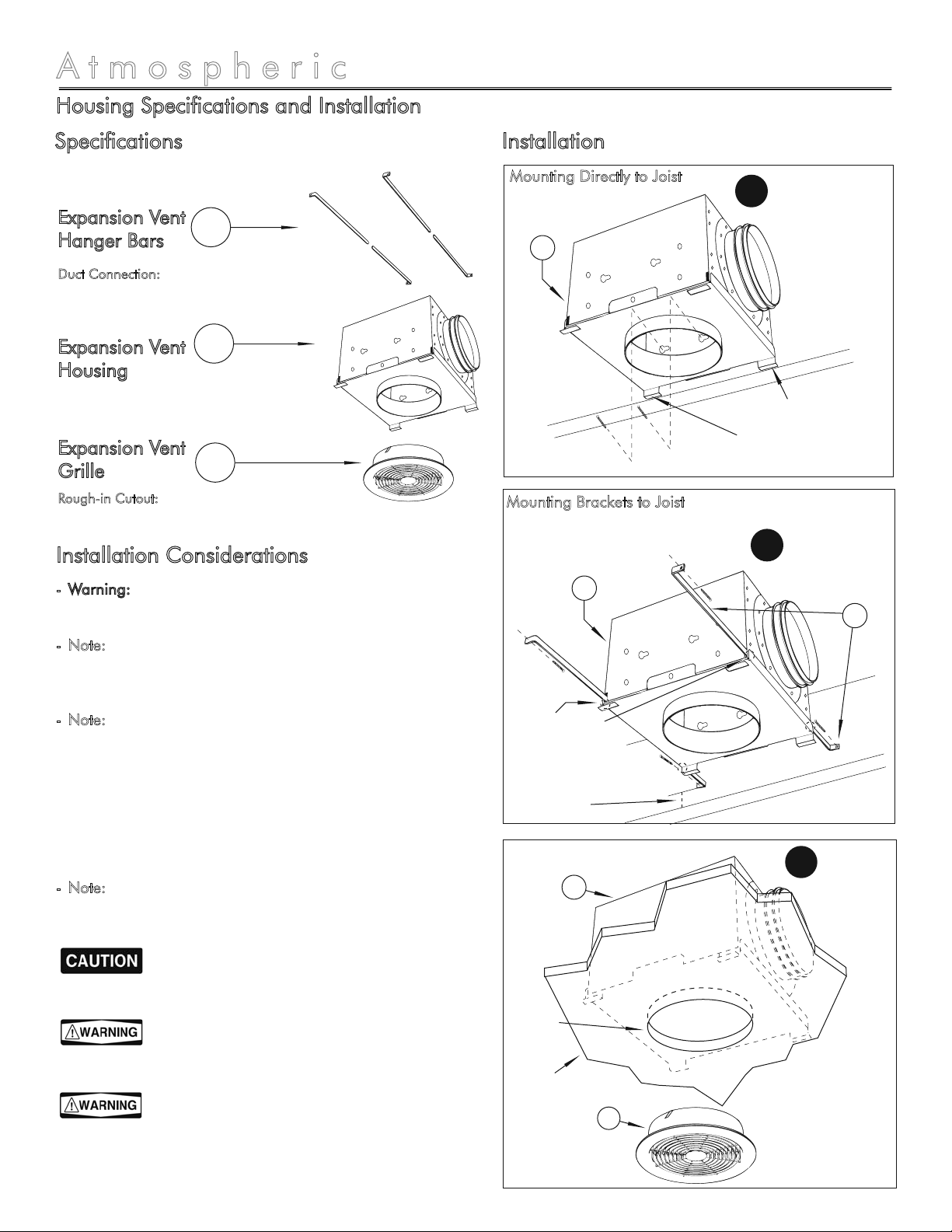

Duct Specifications and Installation

Atmospheric 330

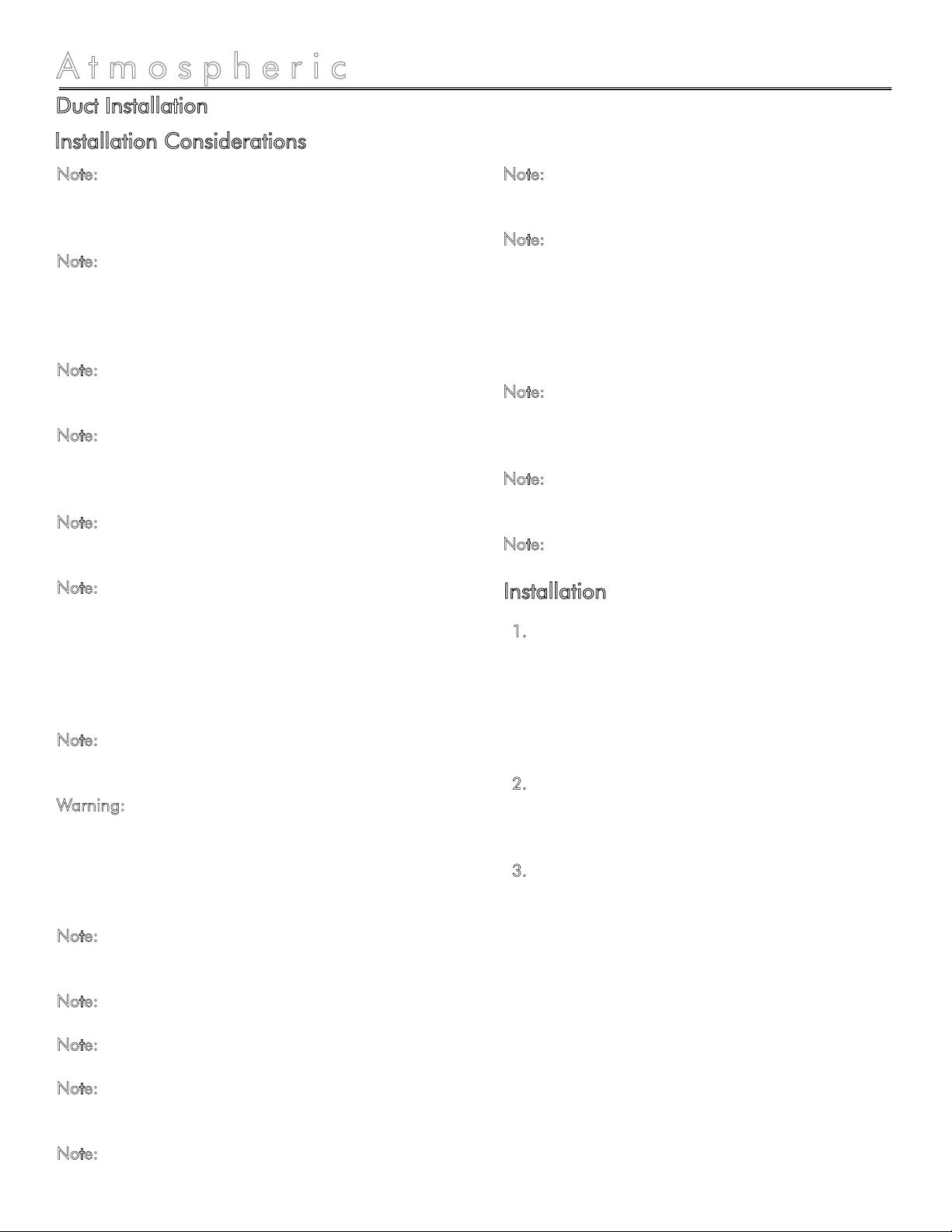

Flex Duct, 6”

Dimensions: 6” Diameter x 25’ Length

Insulation: Fiberglass

Outer Cover: Tri-directional, scrim reinforced grey polyester

Testing: U.L. Listed, Suitable for Wet Locations

R-Value: 4.2

Rated Positive Pressure: 10“ w.g. per UL-181

Maximum Positive: 6” w.g.

Maximum Negative: 3/4” w.g.

Maximum Velocity: 5000 FPM

Maximum Operating Temperatures: -20°F to 140°F

Continuous (@ maximum pressure)

1

Compliance: UL-181-B

Flex Duct Tie, 36” 2

Compliance: UL-181-B

Net Contents: 1/12 Gallon

Mastic Tube 3

100 CFM Fan

Exhaust to Roof

Cap or Wall Vent

Damper, 4”

Expansion Vent

Flex Duct

Tie, 36”

2

Flex Duct,

6” x 25’

1

Figure 1

Figure 2

Figure 3

Fold back outer

cover and insulation

Pull outer cover and insulation

to completely cover the fitting.

Apply Mastic (3)

over fitting and / or

inside the inner liner

Slide inner liner

at least 1” over fitting

Secure inner liner

to fitting with 36” tie (2)

Secure outer cover and

insulation to fitting

with 36” tie (2)

Apply additional mastic (3)

over the connection

Specifications Installation

Minimum radius =

the diameter of

flexible ducting used

Install duct fully extended. Do not install

in a compressed state or use excess lengths.

by BATHOLOGY

17

Duct Installation

Atmospheric 330

After desired length is determined, cut

completely around the through duct with

multipurpose tool. Fold back outer cover and

insulation. Apply mastic over fitting and / or

inside the inner liner (see figure 2 and 3 on

page 16).

Slide at least 1” of inner liner over fitting. Seal

inner lining to collar. Secure connection with tie

placed over the inner lining.

Pull outer cover and insulation back over inner

lining. Secure connection with tie placed over

the outer cover and insulation.

1.

2.

3.

Note: Do not use “outdoors” or install where duct

can be exposed to direct sunlight. Prolonged

exposure may cause degradation of vapor barrier.

Note: Do not install where duct can be exposed to

UV radiation from bio-treatment lamps within the

HVAC system. Exposure may cause degradation of

the inner core.

Note: Not not exceed published pressure or

temperature limits.

Note: Do not use duct to hang or support any

diffuser, register, or other equipment during

installation.

Note: Do not use screws or barbed fitting to make

connections on ducts with plain ends.

Note: Duct should be supported at 5’ maximum

intervals unless resting on ceiling joists or truss

supports. 1/2” sag per foot of support spacing is

permissible. Vertically installed duct shall be

stablized by support straps at a maximum of 6’ on

center.

Note: Do not use on oval collars for medium or

high pressure.

Warning: Insulated flexible duct contains fiber glass

wool which has been classified as a possible cancer

hazard by inhalation. Fiber glass wool may cause

temporary irritation to skin, eyes, and respiratory

tract.

Note: Use a poperly fitted NIOSH or MSHA

approved dust/mist respirator.

Note: Avoid breathing fiber glass duct.

Note: Avoid contact with skin and eyes.

Note: Wear long-sleeved, loose fitting clothing,

gloves and eye protection.

Note: Wash with soap and warm water after

handling.

Note: Wash work clothes separately and rinse

washer thoroughly.

Note: All tapes, mastics, and non-metallic fasteners

used for field installation of flexible ducts shall be

listed and labeled to Standard UL-181-B - Closure

Systems for use with Flexible Air Ducts and Air

Connectors. Non-metallic fasteners are limited to

6” w.g. maximum positive pressure.

Note: It is recommended a minimum 8’ of

insulated flexible ducting be used between any

expansion vent and fan for low noise level.

Note: A multipurpose tool is recommended for duct

installation.

Note: Follow all applicable codes and standards.

Installation Considerations

Installation

900-0514-0713

BATHOLOGY

rediscover bathing

A division of Bathing Brands, Inc.

www.Bathology.com 847-465-1070

Table of contents

Other Bathology Fan manuals