Baton EVPOS-1TACA Operation manual

Owner's Operating Manual

EVPOS-1TACA Welding Positioner

Chapter 1: Introduction

A

W

B

Objective

Restriction of the work piece

1.1.1 The POS for MCA series positioner can be used welded, cut and grind, it has one table rotate and table angle move, the operator can be apt to

adjust the work piece position fast, enable him to finish the work and keep quality fast.

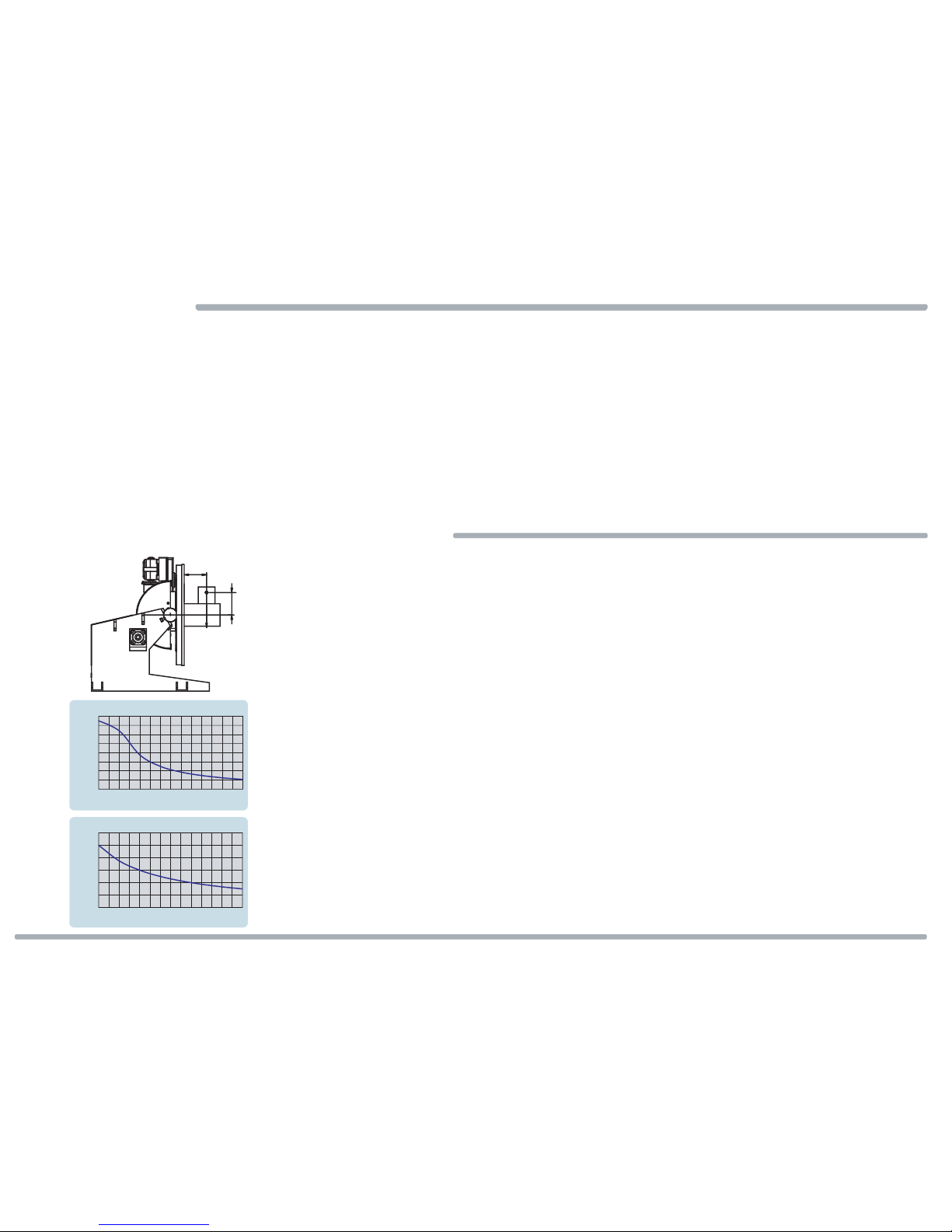

1.1.2.1 The weight or length of the work piece exceed designing limiting, please look at charts [Figure:1.2-1].

1.1.2 Forbid using the case:

1.1.2.2 The work piece does not have certain locking in table of EVPOS for MCA series positioner.

1.1.2.3 The scope of activities of the work piece has personnel or hinders things.

1.1.2.4 Have not imputed the machine to the ground or firm foundation.

Figure: 1.2-2

1.1

1.2

1.2.1 CAPABILITY

Page 1

0

200

400

600

800

1000

1200

1400

1600

020 40 60 80 100 120 140

0

200

400

600

800

1000

1200

30 40 50 60 70 80 90 100

EVPOS-1TACA Positioner Eccentric Load

A : Eccentric Center (cm.)

W : Load (kg.)

EVPOS-1TACA Center of Gravity

B : Center of Gravity (cm.)

W : Load (kg.)

Structure

1.3

1.3.1 Specification

1.3.2 Standard Accessories 1.3.3 POS for ACA series Structure

Figure: 1.3-1 Figure: 1.3-2

Part Name Quantity

Pedal Switch 1

Welder start wire 1

Table

Controller

Angle limit switch adjustment unit

Rotation gearbox of table

Angle labelling

Page 2

Specification

Power

Table rotate motor

Capacity

Eccentricity

Center of Gravity

Table Dia.

Spindle Thru Hole

Table speed

Table angle

Table angle speed

Table angle motor

Table angle lock

Table rotate control

OverLap timer(Fixing point)

Timer (Fixing point)

Lap well timer (Fixing point)

Start / Crater arc timer

Arc way of the welder

Welding current

Table rotate control

Remote control

EVPOS-1TACA

V1:AC 220V / 20A / 50;60Hz / 3Ø

V2:AC 380V / 18A / 50Hz / 3Ø

DC 180V / 400W

1000Kg.

300mm.

300mm.

900mm.

120mm.

0.05-0.5 RPM

0° - 135°

55!sec / 135°

AC 0.5HP

Motor brake

inch / Hold / Overlap / Timer

0 - 99.9sec(display unit : 0.1sec)

0 - 999sec(display unit :1sec)

0 - 99.9sec(display unit : 0.1sec)

0 - 99.9sec(display unit : 0.1sec)

Standard(2 cycle) / Cater(4 cycle)

1000A / 100%

Pedal switch(The wire is 4M Cable)

Control line(The wire is 4M Cable)

S

peci

f

ication

Chapter 2: Safety

Safty Information

2.1.1 This document provides general safety instructions. Some information requires special attention for either safety or procedural reasons. Label with an appropriate heading WARNING and

CAUTION will be used throughout this manual. For example:

2.1.1.1 Failure to follow WARNING instruction could result in severe injury or death to the operator, a bystander or a person inspecting or repairing the machine.

2.1.1.3 Failure to follow DANGER instruction could result in severe injury or death to the operator, a bystander or a person inspecting or repairing the machine.

2.1.1.2 Failure to follow CAUTION instruction may result in injury to the operator, a bystander or a person inspecting or repairing the machine, or damage to the machine’s part and/or controller.

2.1.1.4 Failure to follow ATTENTION instruction may result in injury to the operator, a bystander or a person inspecting or repairing the machine, or damage to the machine’s part and/or controller.

WARNING

ATTENTION

2.1 Page 3

Safety Labels

Figure:2.2-2

Figure:2.2-1

WARNING ATTENTION

Fix machinery on the ground or the strong foundation.

When the mechanical table angle is moved or static, forbid having operators below the work piece.

Forbid operators on the mechanical table.

2.2 Page 4

Figure:2.3-3

Figure:2.3-7

Electrical Hazards And High Temperature

-HIGH TEMPERATUR Don’t Touch

HIGH TEMPERATURE Don’t Touch

-Electrical Hazard Label.

2.3

Figure:2.3-1 Figure:2.3-2

Page 5

Figure:2.4-3 Figure:2.4-4

carbon Brush the

contact area, do not

use oil.

Figure:2.4-7

Rotaing And Other

-ROTATING keep hands away.

2.4

Figure:2.4-1 Figure:2.4-2

Page 6

carbon Brush the

contact area, do not

use oil.

-Carbon Brush the contact area, do not use oil.

Power

2.5

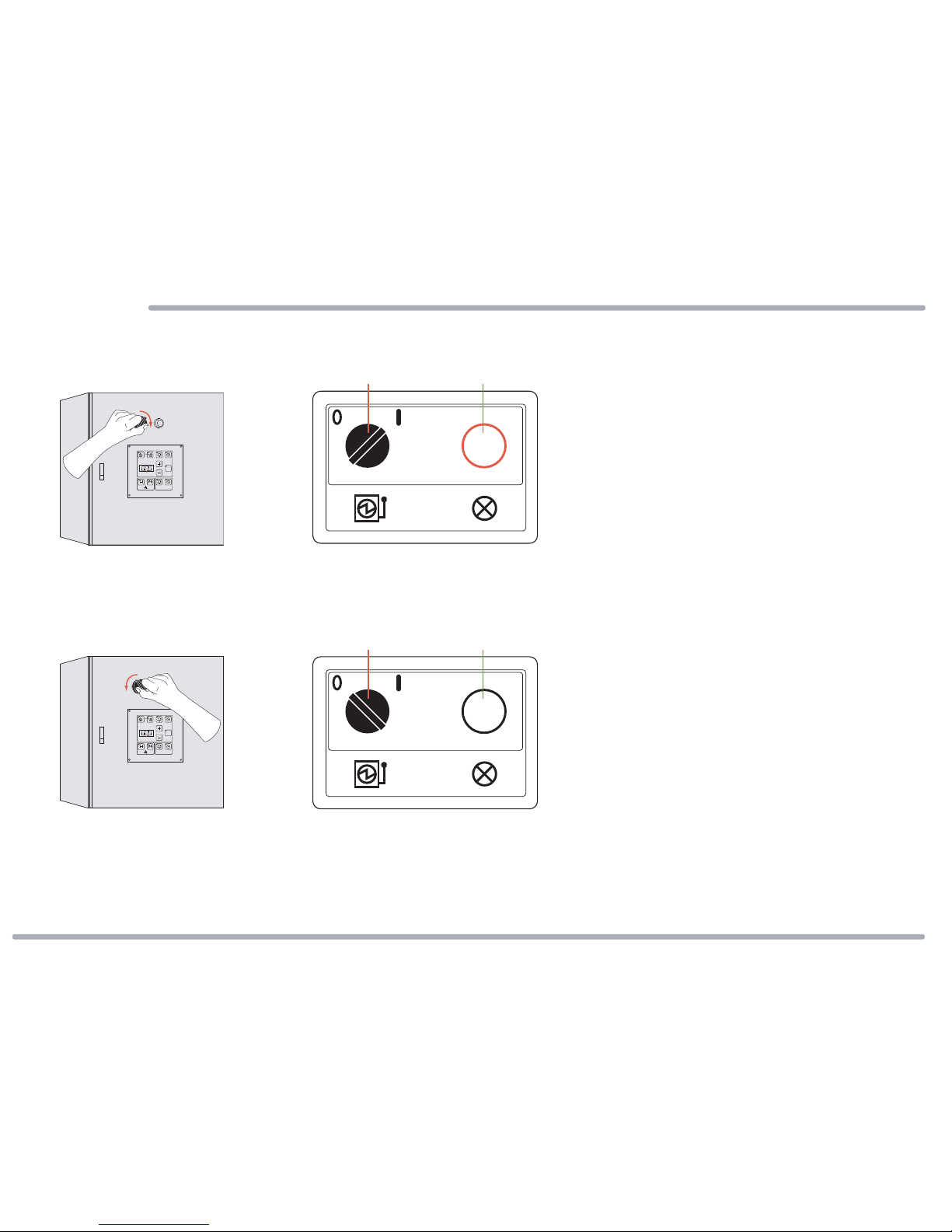

Power ON

2.5.1

Power OFF

2.5.2

Figure:2.5-1

Figure:2.5-2

Page 7

Standard

Set

AUTOMODE

EVPA01

Crater

UNIT:0.1 sec

00.0 ~ 99.9 sec

Standard

Set

AUTOMODE

EVPA01

Crater

UNIT:0.1 sec

00.0 ~ 99.9 sec

Power switch Power lamp

I-ON

Power switch Power lamp

O-OFF

The stop result with continues, Reference page 31,32,41,42.

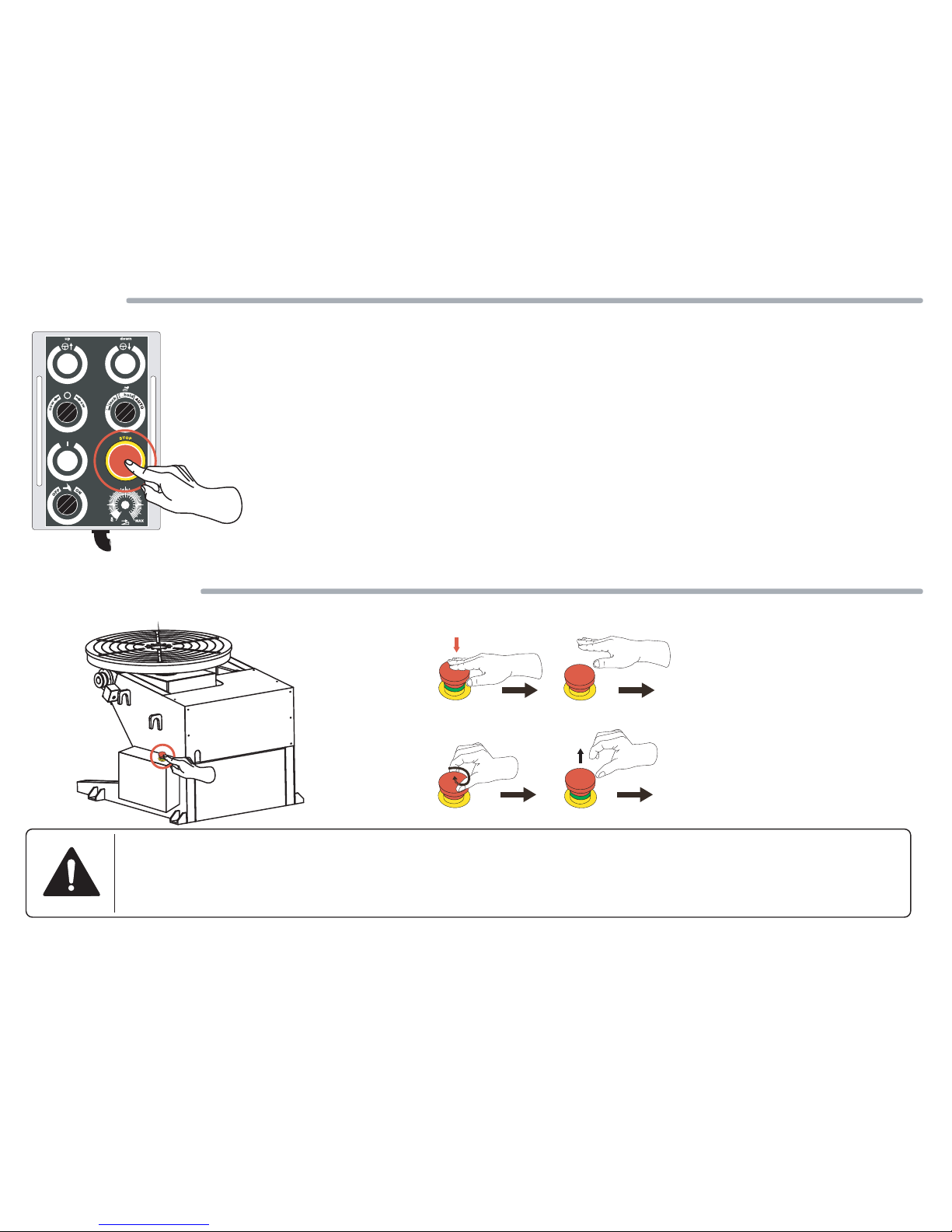

Stop

2.6

Emergency Stop

2.6-1

Page 8

1

0

2

0

3

0

4

0

5

0

6

0

7

0

8

0

9

0

E

M

E

R

G

E

N

C

E

M

E

R

G

E

N

C

E

M

E

R

G

E

N

C

E

M

E

R

G

E

N

C

E

M

E

R

G

E

N

C

The power and all control movements are closed at the same time.

The power and all control movements resume the function.

Emergency Stop

Release

2.7 Page 9

Figure:2.7-1

Figure:2.7-2

Figure:2.7-3

Figure:2.7-4

Figure:2.7-5

1

0

2

0

3

0

4

0

5

0

6

0

7

0

8

0

9

0

1

0

2

0

3

0

4

0

5

0

6

0

7

0

8

0

9

0

Table Angle Sensor

-10mm Nut spanner

-5mm Hexagon spanner

Up limit switch

Down limit switch

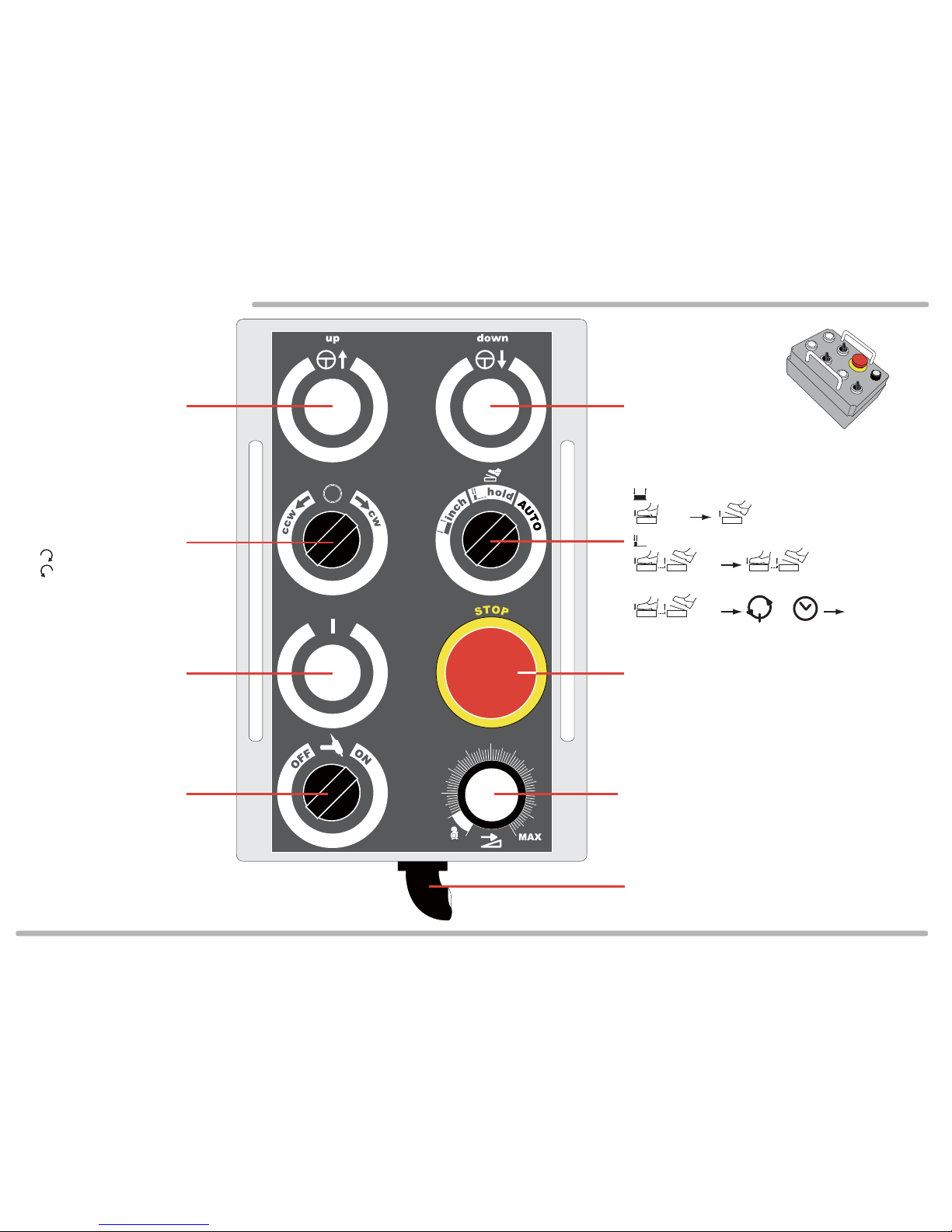

Contril Panel

2.8 Page 10

Standard

Set

AUTO MODE

EVPA01

Crater

Overlap2 Cycle

Time4 Cycle

Power switch Power lamp

Welder start socket

Pedel switch socket

Rrmote contril line

Power line.

O-OFF

I-ON

Add time

+0.1 sec

UNIT:0.1 sec

00.0 ~ 99.9 sec

Minus time

-0.1 sec

Overlap set

Timer set

Overlap set

Timer set

Arc way of the welder

Start welding arc time set

Start welding arc time set

Crater welding arc time set

Crater welding arc time set

Select set

Figure:2.8-1

Timer set UNIT:1 sec

Contril Panel

2.9 Page 11

Table Rotation Speed

1

0

2

0

3

0

4

0

5

0

6

0

7

0

8

0

9

0

Weld in step switch

O-OFF

I-ON

Table Rotation Start Button Stop button

Table Roation Direction Switch

-cw:Clockwise

-ccw:counterclockwise

-inch

-Start -Stop

-hold

-Start

-Start

-Stop

-Stop

AUTO

Overlap Time

or

Table Roation Start Method

Remote Contril Line

Figure:2.9-1

Table Angle Down ButtonTable Angle Up Button

Chapter 3: Machine Installation

General

3.1

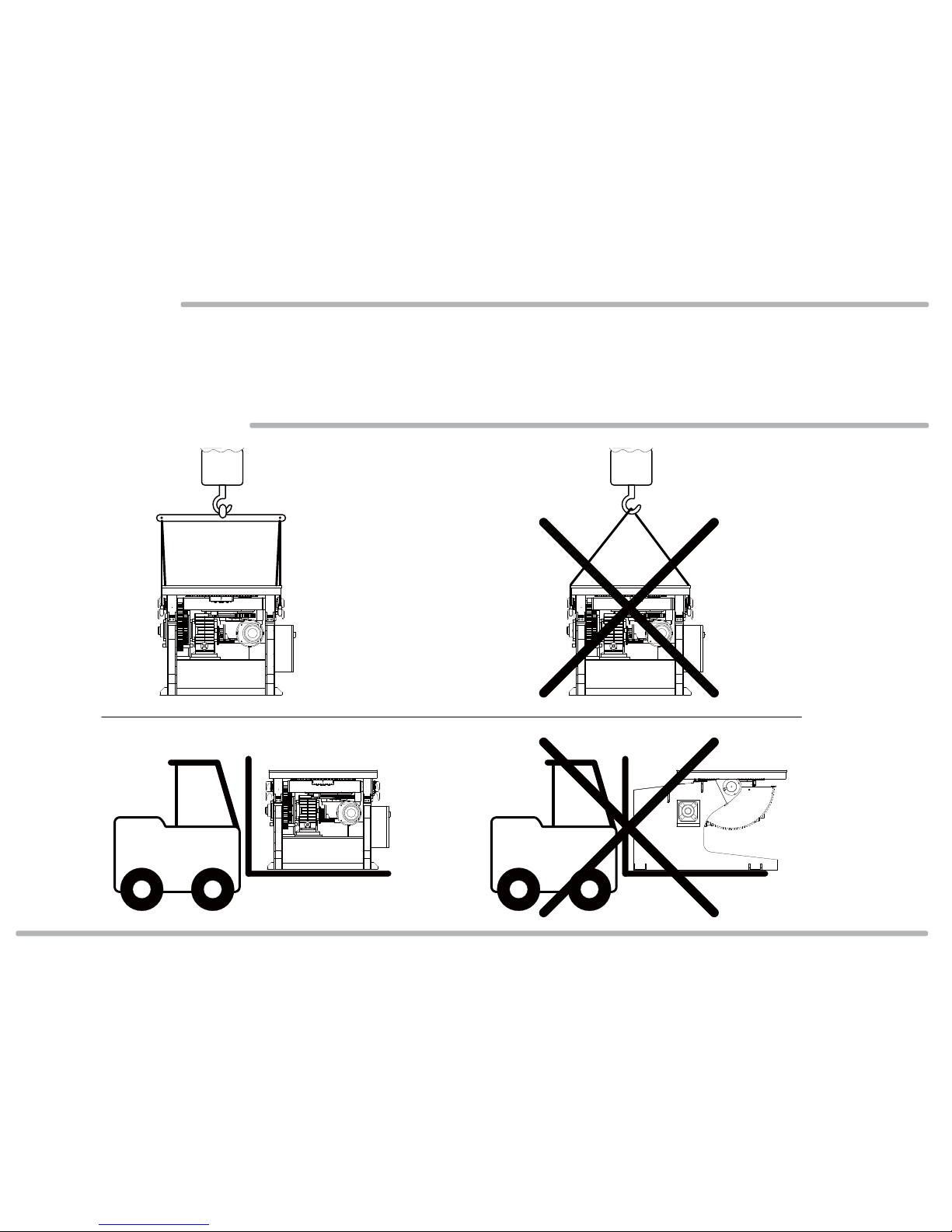

Transporting

3.2

3.1.1 In order to guarantee the security that the work piece moves, so need really installation POS for MC18 series positioner, can operate after confirming installing finishing, please scrutinize the

explanation of this chapter and do it.

5 Ton 5 Ton

Figure:3.2-3 Figure:3.2-4

5 Ton 5 Ton

Figure:3.2-1 Figure:3.2-2

Page 12

Page 13

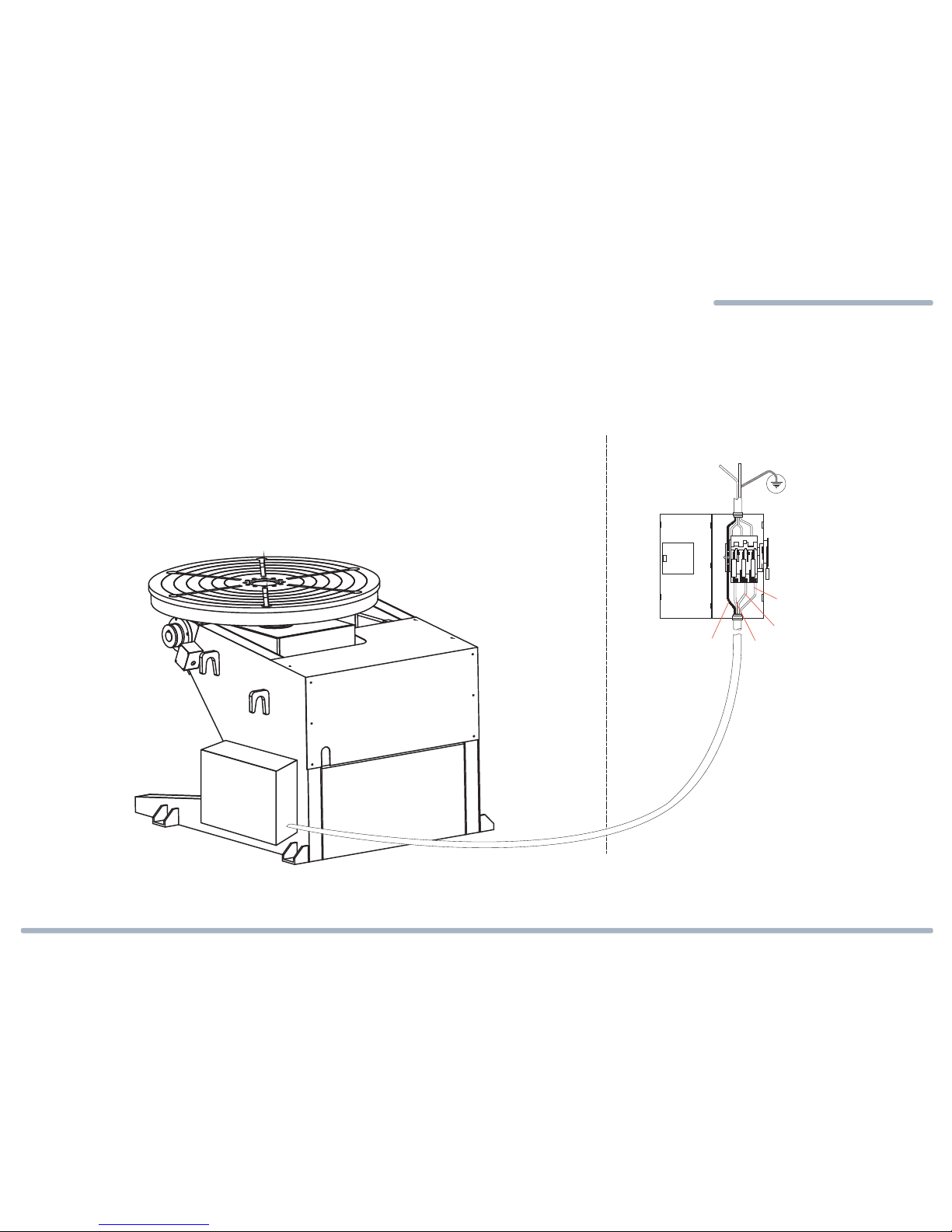

Electrical Supply Requirements and Connection

V1:AC 220V / 20A / 50;60Hz / 3Ø

V2:AC 380V / 18A / 50Hz / 3Ø

V1:AC 220V / 20A / 50;60Hz / 3Ø

V2:AC 380V / 18A / 50Hz / 3Ø

3.2

3.2.1 The power is and has earth circuit.

3.2.2 Use the power broken circuit switch ( Electric current 5A ).

3.2.3 Use the proper tool and really lock the power cable and power broken circuit switch.

3.2.4 There can't be damage on the power cable surface or join after the electric wire ruptures.

3.2.5 Do not propose joining the power switch with welde machine.

USER SIDE

L1

L2

L3

PE

Figure:3.2-1

1 2

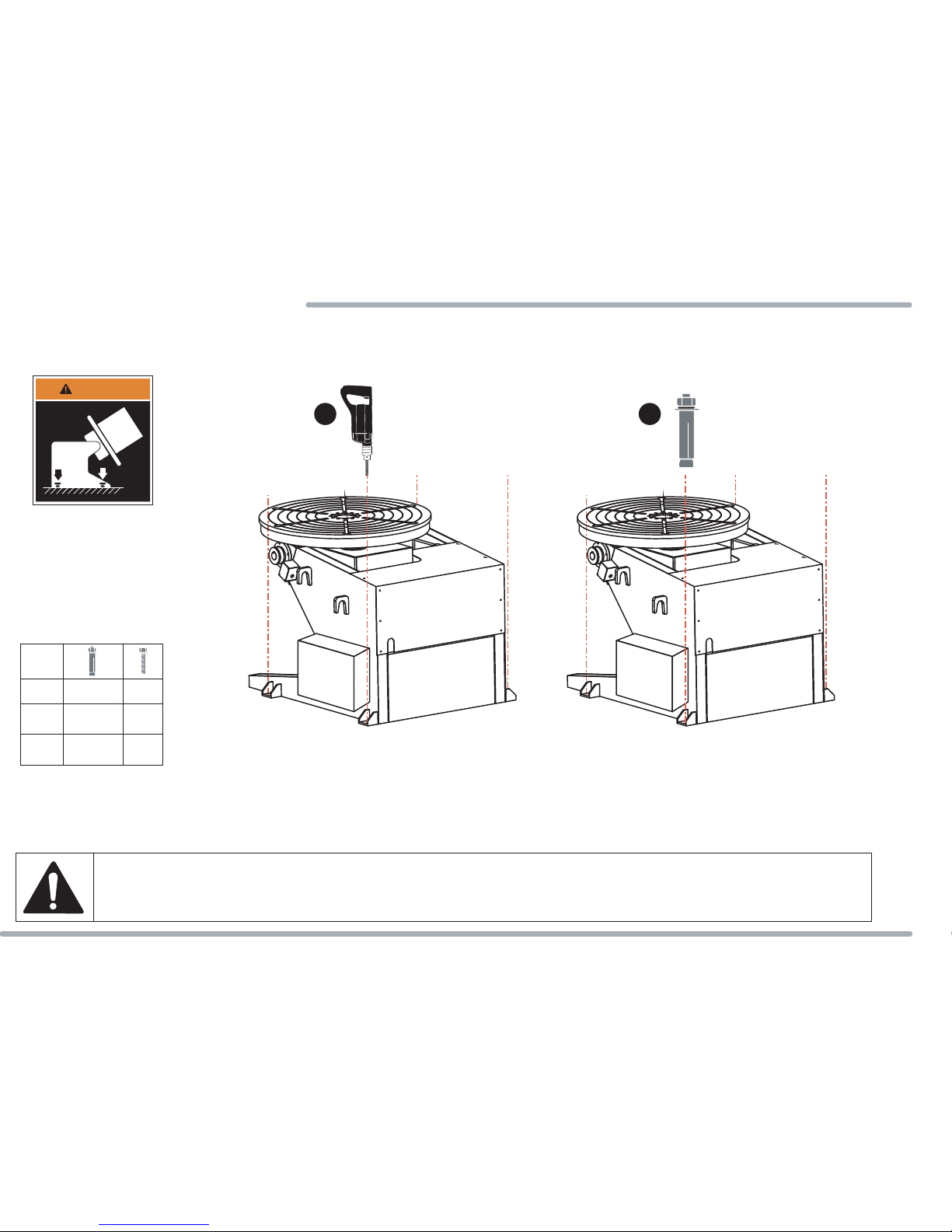

Figure:3.3-3 Figure:3.3-4

Regular Machinery

ATTENTION

3.3

3.3.1 If machinery was fixed and installation in the ground , use the ground bolt [Figure:3.3-2] to lock machinery on the ground.

Figure:3.3-1

Figure:3.3-2

If machinery was fixed and installation in the strong steel foundation, please drilling four screw holes on the strong steel foundation and use the screw [Figure:3.3-2]

to lockmachinery on the strong steel foundation.

Page 14

300MCA

500MCA

750MCA

M12x40mm

M12x40mm

M12x40mm

M14

M14

M14

TO

Welding machine

Figure:3.4-1

Page 15

Welder Cooperates

3.4.1 Please lock the cable ,welder contact and carbon brush firmly.

Chapter 4: Machine's Operation

Table of contents