_____________________________________________________________________________________

STI S.r.l. – Via Dei Caravaggi 15, 24040 Levate (BG) – ITALY www.imi-critical.com

Manual 9031, rev. 02 27/02/2018 – FTC

- 2

- The laptop used must be powered from battery or by a power supply unit in

compliance with IEC 60950-1 with Maximum Output Voltage (Um) ≤ 30V.

Warning

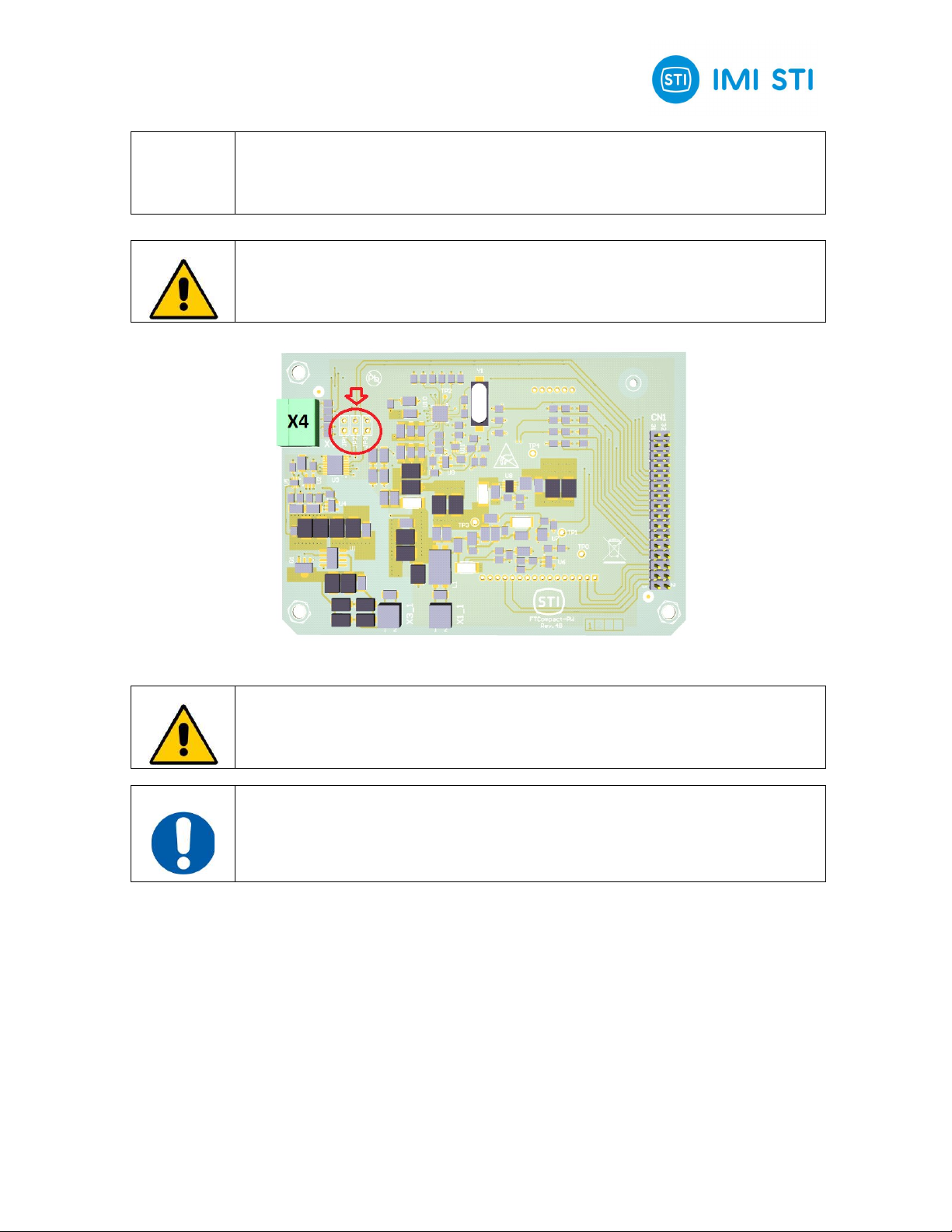

In case of “minimum ambient temperature” below -40°C, the optional FEEDBACK

cannot be connected and the jumpers on the PCB FTCompact-PW, for internal

circuit connection, must be removed by the User.

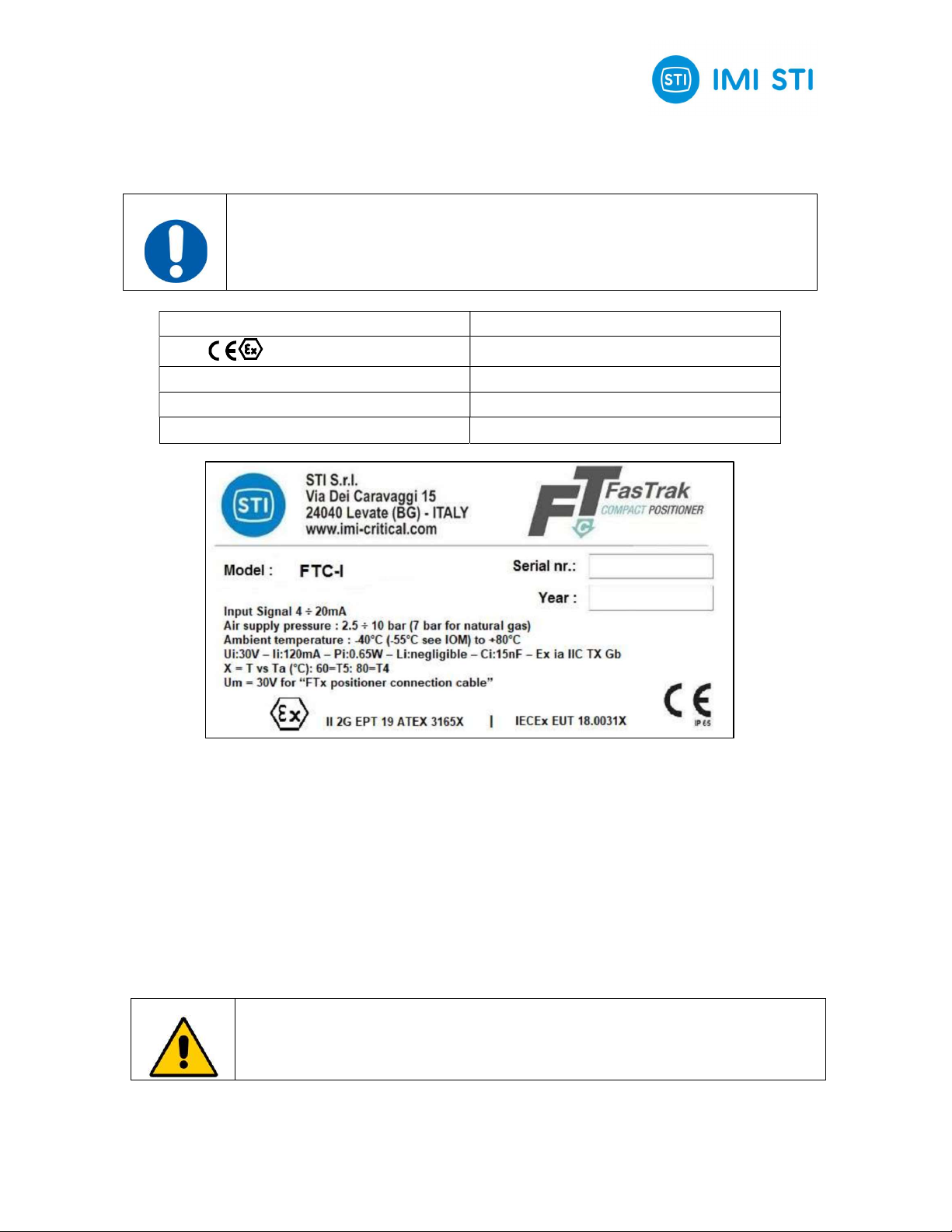

Figure 2 – FTC-I electric circuit

Warning

Highlighted in the red circle are the jumpers (JP1, JP2 and JP3) that must be

removed to exclude the feedback circuit when the minimum temperature can be

below -40°C.

Important

Positioners series FTC-Ixxxxxx are designed and certified in conformity to the

European Directive 2014/34/EU, and according to the International IECEx Scheme.

The Positioners shall be connected to 1 or 2 [Ex ia] or [Ex ib] Associated Apparatus (Diode Safety Barrier or

Galvanic Isolator), in compliance with the maximum voltage (Ui), current (Ii) and power (Pi) values stated in

the label (see "Rated characteristics"). In both cases the Positioner can be installed in Zone 1 (or Zone 2),

but when the whole system has "ib" protection level, the Positioner shall not be used to modulate natural gas

(CH4). In case the system has "ic" protection level, the Positioner may be installed only in Zone 2 and, of

course, it cannot be used to modulate natural gas (CH4).

The Positioner shall be installed in compliance with EN IEC 60079-14 Standard (current Issue) and any

inspection maintenance shall be carried out following the provisions of EN IEC 60079-17 Standard (current

Issue); all Intrinsically Safe circuits shall be included in Descriptive System Documents (EN IEC 60079-14,

art. 4.2 and EN IEC 60079-25, art. 4).